Hygienic Design Guidelines

Hygienic Design And Safe Use Of Double Seat Mixproof Valves Ehedg

Sanitary And Hygienic Design Guide For Food Equipment Mpc

Ehedg Connects Edition 2 By Ehedg Issuu

Hygienic Design Is Important In New Production Equipment

Hygienic Design Requirements For Components In Hygienic And Sterile Processes New Food Magazine

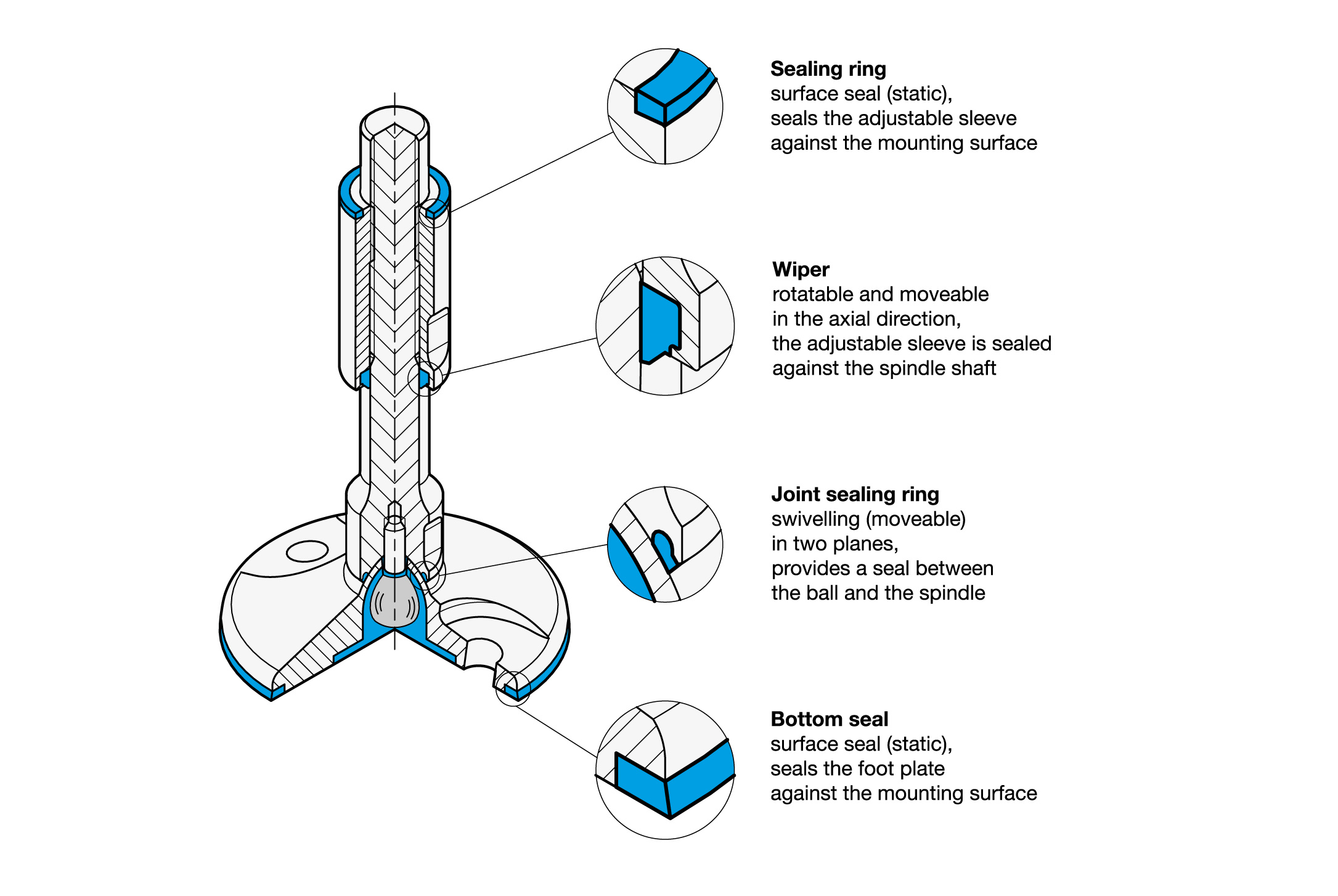

Gn Stainless Steel Leveling Feet Hygienic Design With Mounting Holes Jw Winco Standard Parts

Guidelines for dairy food manufacturing premises 7 Contaminants Std 323 Div 2 Clause 3 The design and construction must, to the extent that is practicable, exclude dirt, dust, fumes, smoke and other contaminants The exclusion of contaminants such as microorganisms, chemicals and foreign matter from the food processing.

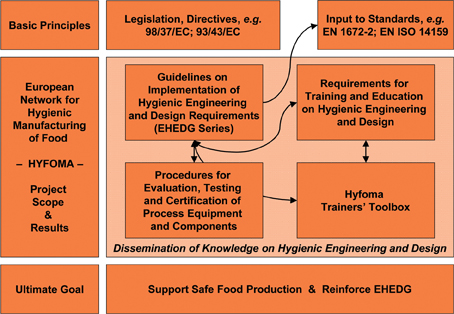

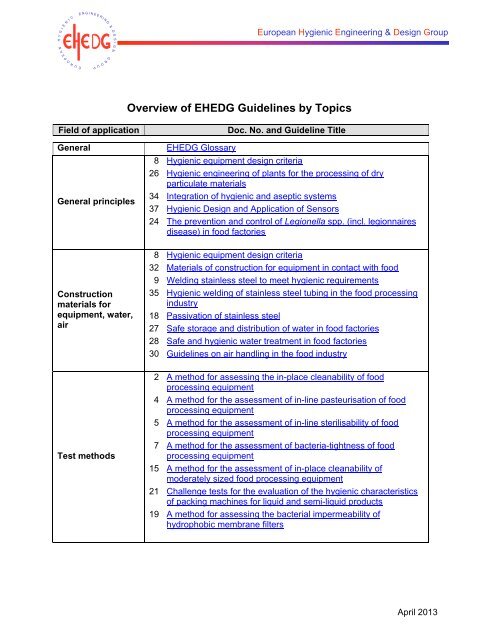

Hygienic design guidelines. To assist in the design of safe and hygienic machinery, EHEDG has published a number of guidelines In cooperation with FoodInfonet and Elsevier Scientific Publishers, the summaries of the guidelines are published here The full documents are available on the EHEDG website The published guidelines are shown in the table below. 11 All internal angles of less than 135 degrees on product contact surfaces shall have at least a 1/4 inch (6mm) radius except a Fillets of welds where one or both of the pieces being joined are 3/16 of an inch (5mm) thick or less, in which case the radius shall be not less than 1/8 inch (3mm) June 01 E 8 b. 17 Hygienic design of pumps, homogenizers and dampening devices (13) 18 Chemical Treatment of Stainless Steel Surfaces (14) 19 A method for assessing the bacterial impermeability of hydrophobi c membrane filters (12) Hygienic design and safe use of doubleseat mixproof valves ( 00).

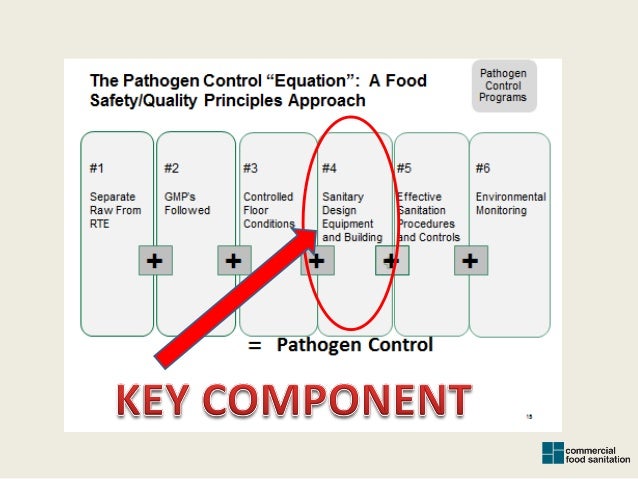

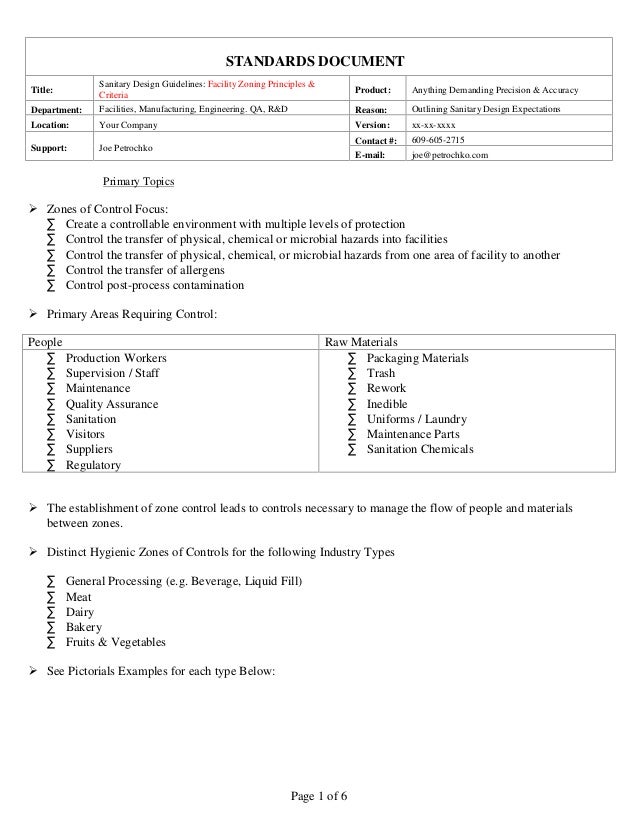

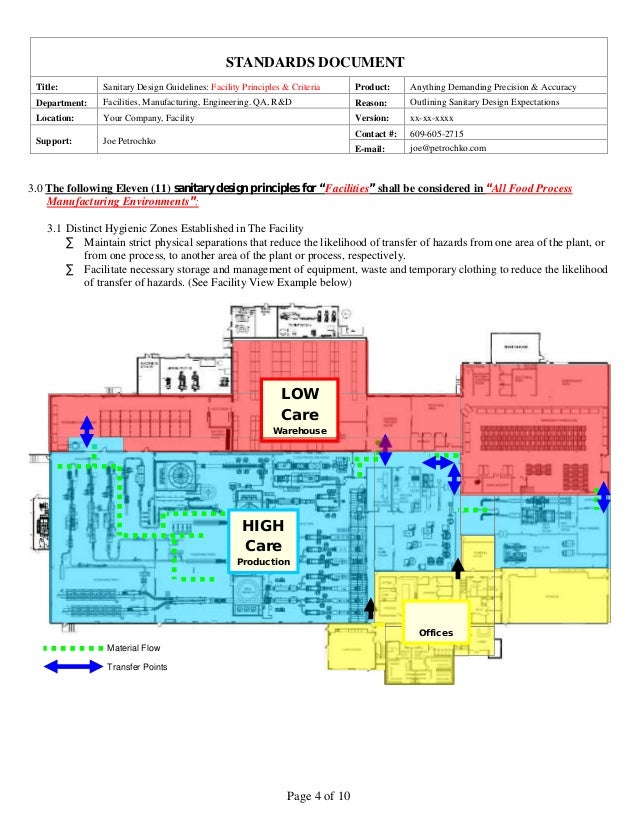

Hygienic design standards generally specify the welding materials allowed and that welds be of butt type (not overlapping) and ground to a smooth finish (Ra of 08 µm or less) Bolts and threads, if necessary, in the food contact zone must be of the acceptable hygienic type. Training Topics Training includes existing hygienic design standards (guidance, checklists, regulations), equipment hygienic design principles, hygienic principles for facility design, traffic patterns, zoning, material selection and compatibility, importance of managing utilities, and project management basics. Hygienic Design of Food Manufacturing Premises Dr John Holah Technical Director IFTS Hygienic Design Conference 25 th February 16 Guideline No 44 2 9608 British Standards G Goods in Goods out Wet store Dry store Despatch store Administration and amenities Site.

Internal corners and angles shall have a smooth and continuous radius of at least 1/8 inch (angles of less than 135°) For effectiveness and efficiency of cleaning food processing equipment, all areas must be accessible and subject to the application of mechanical action, detergent and sanitizer penetration. Read and download Graintec’s new publication Hygienic Design and Sanitary Guidelines The sanitary design of production facilities is important in order to ensure safety Especially in pet food production, demands are high with regard to strict hygiene regulations and food processing standards. Download Hygienic Design Guidelines Comments Report "Hygienic Design Guidelines" Please fill this form, we will try to respond as soon as possible Your name Email Reason Description Submit Close Share & Embed "Hygienic Design Guidelines" Please copy and paste this embed script to where you want to embed.

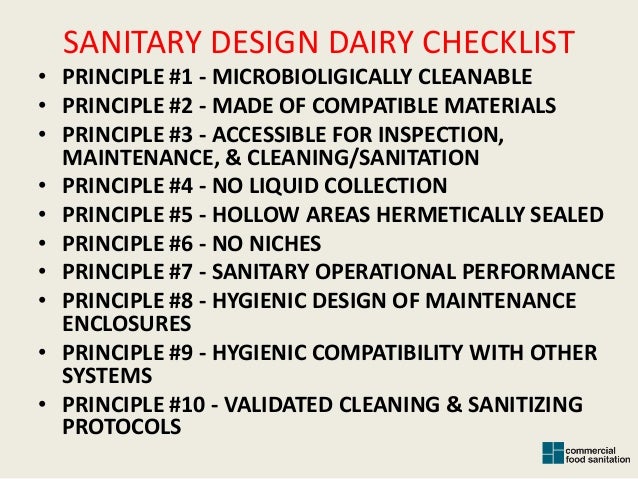

Physical design of the enclosures should be sloped or pitched to avoid use as storage area 9 Hygienic compatibility with other plant systems Equipment design must ensure hygienic compatibility with other equipment and systems, such as electrical, hydraulics, steam, air and water 10 Validated cleaning and sanitizing protocols. Hygienic design principles are Product contact surfaces (direct or indirect) All surfaces that intentionally (direct) or unintentionally (indirect, eg due to splashing) comeinto contact with the product, or from which product, condensate or soil may drain, drop or be drawn back into the main. After all, you do want to keep your food safe and germs and illnesses at bay Here’s a look at some easytofollow rules for kitchen hygiene and safety Good Hygiene Practices For The Kitchen 1 Wash Your Hands This one sounds obvious and simple but is probably the most effective thing you can do to maintain good kitchen hygiene.

Physical design of the enclosures should be sloped or pitched to avoid use as storage area 9 Hygienic compatibility with other plant systems Equipment design must ensure hygienic compatibility with other equipment and systems, such as electrical, hydraulics, steam, air and water 10 Validated cleaning and sanitizing protocols. Metaltometal joints should be eliminated by hygienic application of Orings;. EHEDG, the (European Hygienic Engineering and Design Group) is a Europeanbased nongovernmental organization devoted to the advancement of hygienic design and food engineeringEHEDG is a consortium of equipment manufacturers, food industries, research institutes and public health authorities, founded in 19 with the aim to promote hygiene during the processing and packing of food products.

Read "Guidelines for the hygienic design, construction and layout of food processing factories" by Dr John Holah available from Rakuten Kobo Get factory layout right first time with the help of practical guidance form food and construction industry specialists. ACO is committed to ultimate hygienic performance We design solutions with cost efficiency in mind but with absolutely no compromise in terms of food safety. However, hygienic design goes beyond compliance with standards and guidelines A good design avoids many problems later on Emsens machines have been fully designed in accordance with the guidelines of regulatory agencies to meet the highest requirements for food hygiene Emsens machines are distinguished by a completely new design.

The following criteria, guidelines and principles set forth the sanitary design and fabrication features required by USDA, Dairy Grading Branch for the acceptance of equipment intended for use in dairy plants surveyed and approved for USDA grading service. Flocks of agencies have put stringent standards into place to ensure that the foodgrade goods that you are manufacturing are consistently safe But when it comes to food equipment hygienic design, specifically, the program that must be strictly followed is the FDA’s FSMA or Food Safety Modernization Act. Guidelines for the Hygienic Design, Selection and Use of Dry Cleaning Equipment, Guideline No 44 Food Composition Data Second Edition 4th Edition of CFA best practice guidelines published A baseline assessment of US naval food facilities using the Food Code's new riskbased inspection program and the personal and general hygiene.

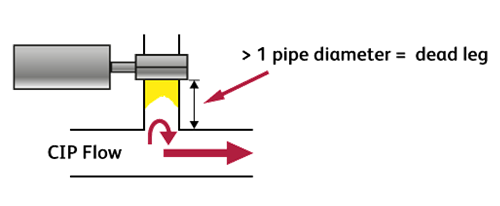

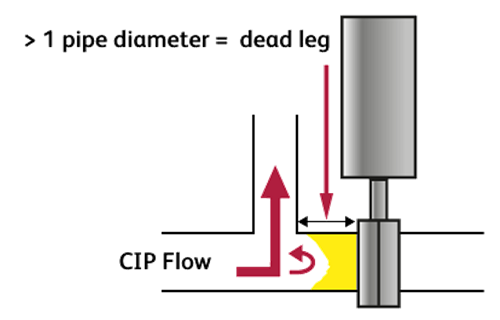

Hygienic design is bad, complicated engineering This is false Hygienic design when applied from the very first steps of the design process is very good engineering Hygienic features such as the removal of cracks and crevices to eliminate microbiological contamination also reduce such engineering problems as stress and crevice corrosion. Creating Hygienic Standards The basic principles of hygienic design have been codified, thanks to the European Hygienic Engineering and Design (EHEDG) and 3A Sanitary Standards Inc (3A SSI) groups EHEDG and 3A SSI both created standards that are often used to produce hygienically designed food manufacturing equipment. Details in Hygienic Design National Food Institute, Technical University of Denmark Details in Hygienic Design Fastners with eg nuts, bolts, screws and rivets shall be avoided in product contact areas Alternative fastening methods should be used Pipes and equipment should be self draining Dead spacesshould be avoided.

Hygienic sealing design There are two documents issued by the European Hygienic Engineering & Design Group (EHEDG) which deal with the hygienic design of valves for food processing5,6 Another document addresses the hygienic design of pumps7 These guidelines show how hygienic design requirements are to be implemented in detail. Welcome to EHEDG The European Hygienic Engineering & Design Group (EHEDG) was founded in 19 as a nonprofit consortium of equipment manufacturers, food producers, suppliers to the food industry, research institutes and universities, public health authorities and governmental organisations. Read "Guidelines for the hygienic design, construction and layout of food processing factories" by Dr John Holah available from Rakuten Kobo Get factory layout right first time with the help of practical guidance form food and construction industry specialists.

Internal corners and angles shall have a smooth and continuous radius of at least 1/8 inch (angles of less than 135°) For effectiveness and efficiency of cleaning food processing equipment, all areas must be accessible and subject to the application of mechanical action, detergent and sanitizer penetration. Hygienic Design Standards and Guidelines Larry Hanson Key Cleanability Design Considerations •Material of Constructions •Surface Finishes •Joint Design •No Cracks or Crevices •Free Draining •No Dead Legs –Blind Spots Hollows •Accessibility to Clean •Accessibility to Inspect. The European Hygienic Design Group (EHEDG) is the primary organization for food equipment approval in Europe While EHEDG has published a series of guidelines for the construction and design of food processing equipment, they have chosen not to issue standards Acceptance for food processing equipment used in some European.

Any surfaces intended to come into direct contact with any food should meet these requirements Be smooth and impervious Contain no crack or crevice of any type Made of nonporous and nonabsorbent material Not be conducive to contamination Not react to any food product Resist corrosion Require no. For the food and beverage industry, identifying seals that meet Hygienic Design standards is one of the most important challenges In food and beverage applications where seals are in direct contact with the end product, Hygienic Design is the key way to make sure that foods and beverages are produced, processed, and handled securely and. • Hygienic Equipment Design Criteria These were developed by the European Hygienic Engineering and Design Group (EHEDG) and detail the principle hygienicdesign criteria to be met by equipment for food processing They give guidelines on how to design, construct, and install equipment;.

Decided that for food production, hygiene is a “must”, resulting in several directives that made hygienic handling of food at all stages compulsory While the EC specified the requirements, EHEDG started to publish guidelines on how these requirements can be met Hygienic design of equipment. Download Hygienic Design Guidelines Comments Report "Hygienic Design Guidelines" Please fill this form, we will try to respond as soon as possible Your name Email Reason Description Submit Close Share & Embed "Hygienic Design Guidelines" Please copy and paste this embed script to where you want to embed. Decided that for food production, hygiene is a “must”, resulting in several directives that made hygienic handling of food at all stages compulsory While the EC specified the requirements, EHEDG started to publish guidelines on how these requirements can be met Hygienic design of equipment.

Hygienic Design Standards and Guidelines Larry Hanson Key Cleanability Design Considerations •Material of Constructions •Surface Finishes •Joint Design •No Cracks or Crevices •Free Draining •No Dead Legs –Blind Spots Hollows •Accessibility to Clean •Accessibility to Inspect. Integrate sanitation into facility design This final, but key, principle should guide the overall design process of your food processing facility Consider where sanitation systems, clean rooms, hygienic zones, and hand washing stations should exist and integrate cleaning and sanitation systems into the plant. Created Date 2/22/13 AM.

Hygienic design is bad, complicated engineering This is false Hygienic design when applied from the very first steps of the design process is very good engineering Hygienic features such as the removal of cracks and crevices to eliminate microbiological contamination also reduce such engineering problems as stress and crevice corrosion. The European Hygienic Engineering & Design Group (EHEDG) was founded in 19 as a nonprofit consortium of equipment manufacturers, food producers, suppliers to the food industry, research institutes and universities, public health authorities and governmental organisations. Hygienic design guidelines for dairy food manufacturing premises DESIGN AND CONSTRUCTION 5 Design and construction The decisions made at this stage of development can be critical for a business, as any changes needed to rectify poor choices following construction can be both disruptive and expensive Site location is important.

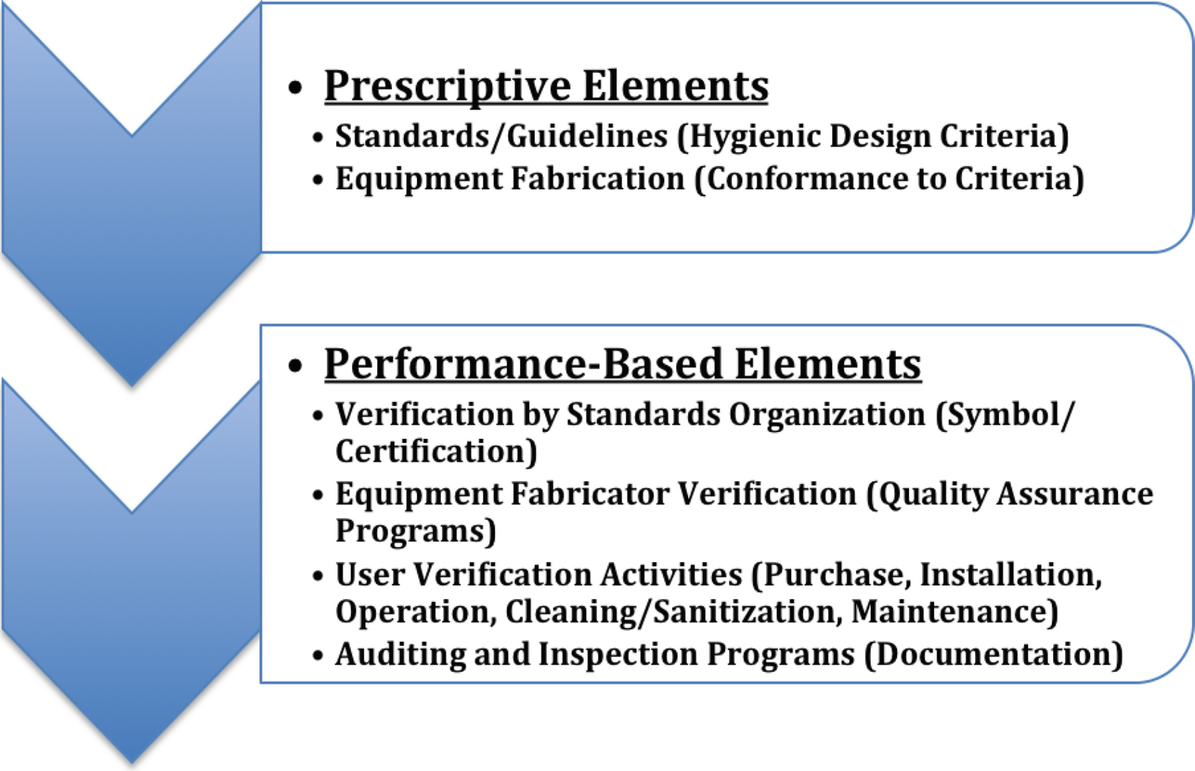

Overview of Principles of Hygienic Design & Foundation Elements This module begins with a brief introduction to 3A SSI and the important role it plays in hygienic design This module emphasizes the holistic approach to hygienic design and the link between hygienic equipment design, facility design, cleaning and sanitation, operational design. Guidelines Assurance of quality and safety is an essential need for the continued good reputation of foodstuffs The correct hygienic design and maintenance of food production systems is considered as a prerequisite to fulfill these requirements. Hygienic design is one of the most important aspects of good product inspection equipment, particularly when that equipment is designed for the food production industry It is important to understand the fundamental philosophies and requirements that go into this design in order to know what questions to ask, and what to look for, when choosing.

PRINCIPLES OF SANITARY DESIGN 9 Hygienic Compatibility with Other Plant Systems Design of equipment must ensure hygienic compatibility with other equipment and systems, eg, electrical, hydraulics, steam, air, water. Guidelines and standards for sanitary design of equipment and facilities have been proposed and developed by multiple organizations, including the 3A Sanitary Standards, Inc (3A SSI) 1 , the North American Meat Institute (NAMI) 2 , the European Hygienic Engineering and Design. Handbook of Hygiene Control in the Food Industry (1st Edition) This book is a standard reference on high hygiene standards for the food industry providing a comprehensive summary of the key trends in food hygiene research and reviewing the current best practice in hygienic design and operation.

A general 3A standard, which embodies the general principles of hygienic design, is also being developed that equipment fabricators and food industry personnel may use as a guideline 3A SSI has been very active in outreach training and knowledge transfer through its website and hygienic design workshops held at the company’s annual meeting and at other venues. The European Hygienic Design Group (EHEDG) is the primary organization for food equipment approval in Europe While EHEDG has published a series of guidelines for the construction and design of food processing equipment, they have chosen not to issue standards Acceptance for food processing equipment used in some European. Processing and producing food products requires particular sensitivity Extreme care is necessary, especially concerning the hygiene of work processes Accordingly, the laws, directives and standards governing the requirements are very strict with the aim of maximum food safety AVENTICS has expertise in designing hygienic devices that ensure that the foodstuffs currently produced are not contaminated, even with adhering food residue or microorganisms.

Design of equipment must ensure hygienic compatibility with other equipment and systems (eg, electrical, hydraulics, steam, air, water) Ensuring the hygienic compatibility of the equipment with other systems is both a processor responsibility to the equipment manufacturer as well as an equipment manufacturer responsibility to the processor. They apply to durable equipment used for batch. Overview of Principles of Hygienic Design & Foundation Elements This module begins with a brief introduction to 3A SSI and the important role it plays in hygienic design This module emphasizes the holistic approach to hygienic design and the link between hygienic equipment design, facility design, cleaning and sanitation, operational design.

Oring groove design should be improved and Orings should be positioned more appropriately, or alternatively gaskets having controlled compression should be used;. Basics of Hygienic Equipment Design The purpose of this training module is to provide basic principles of hygienic equipment design for equipment that will be used to produce or process a wide variety of products for human consumption, as well as pet foods. The hygienic design of equipment plays an important role in controlling the microbiological safety and quality of the products made A hygienic factory should prevent products from having high microbial counts, from containing toxins of microbial origin, and from containing residues of chemicals used for cleaning and disinfection.

In Europe, food safety is mostly governed by regulations, directives and laws capped by the EC Frame Regulation 1935/04, whereas the hygienic design and criteria of a pump are generally covered by standards such as EN and EN ISO maintained and published by the CEN (European Committee for Standardisation). Sanitary Design Chilled Food Association HYGIENIC DESIGN GUIDELINES First Edition 02 122 Temperature and moisture control • Humidity sensors can be used to monitor and control humidity levels within the proper ranges Typical dehumidification is performed by mechanical dehumidifiers, which overcool incoming air below the point where the. The European Hygienic Engineering and Design Group (EHEDG) has developed similar design criteria and guidelines on the hygienic design of equipment and hygienic processing The EHEDG has links with the Comité Européen de Normalisation (CEN), 3A Sanitary Standards, NSF International and ISO As these international standardsetting organizations continue efforts to specify hygienic design requirements, food processors will be able to more effectively select and introduce such equipment into.

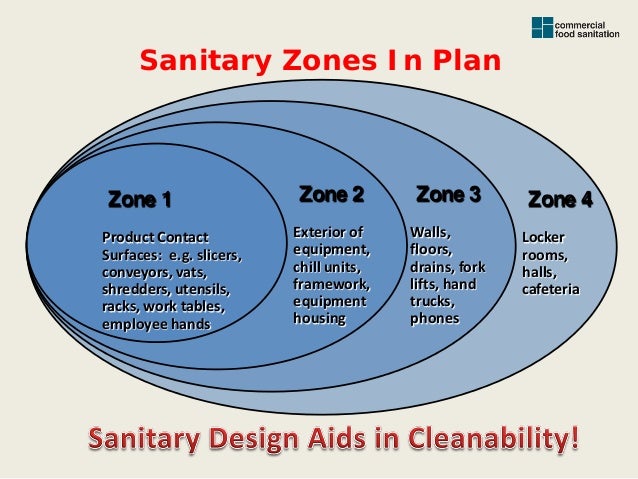

8 Hygienic Design of Maintenance Enclosures 9 Hygienic compatibility with other systems 10 Validated cleaning and sanitizing protocols Facility Design Guiding Principles 1 Defined Hygienic zones based on a Low Risk to High Risk definition 2 Controlled personnel, equipment, and process material flows in all zones 3. The length of the annular space within the mechanical seals should be reduced by changing the design of these mechanical seals (eg the elements of the mechanical seal should be reversed and. 3A Sanitary Standards, Inc Who We Are 3A Sanitary Standards, Inc maintains a large inventory of design criteria for equipment and processing systems developed using a modern consensus process based on ANSI requirements to promote acceptance by USDA, FDA and state regulatory authorities.

Ten Principles Of Hygienic And Sanitary Design Diversey

Hygienic Design Is Mandatory Hbm

Bulletin Of The Idf No 324 1997 Idf Guidelines For Hygienic Design And Maintenance Of Dairy Buildings And Services Idf Publications Catalogue

Hygienic Design Of Food Processing Equipment Sciencedirect

Ehedg Perspective Equipment Design Guidelines09 1 Pdf Pdf Hygiene Pipe Fluid Conveyance

Sanitary Design An Introduction To Standards Of Design Excellence Nov

Province Of Manitoba Agriculture Sanitary Design Of Equipment

European Hygienic Engineering Design Group Ehedg Linkedin

Ten Principles Of Hygienic And Sanitary Design Diversey

Sanitary And Hygienic Design Guide For Food Equipment Mpc

A Systems Approach To Hygiene In Food Processing Environments

New Era For Hygienic Food Manufacturing New Food Magazine

Hygienic Design And Maintenance Of Equipment Sciencedirect

Sanitary Equipment Design Guidelines Part 1 Of 2

Sanitary Design An Introduction To Standards Of Design Excellence Nov

The Hygienic Sanitary Design Of Food And Beverage Processing Equipment Springerlink

Hygienic Design And Sanitary Guidelines Graintec

Hygienic Equipment Design Is Essential For Low Moisture Food Manufacturing Profood World

Standards Aco Gully

Sanitary Facility Zoning Design Guidelines

Hygienic Design Syntegon

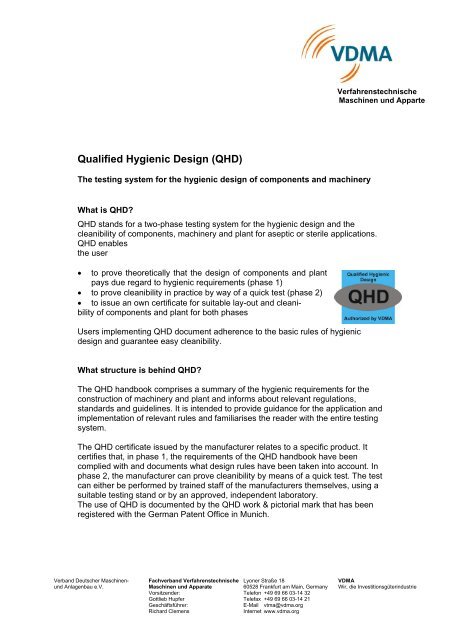

Qualified Hygienic Design Qhd

Ehedg Connects By Ehedg Issuu

Sanitary Design An Introduction To Standards Of Design Excellence Nov

Hygienic Design Of Conveyor Systems New Ehedg Guideline

Overview Of Ehedg Guidelines By Topics

Hygienic Design For Processing Equipment Food Quality Safety

Ten Principles Of Hygienic And Sanitary Design Diversey

Assessment And Management Of Seafood Safety And Quality

Designing Motors With Safety In Mind

Unique Hygienic Design Solutions From Laska

Standard Parts In Hygienic Design Jw Winco Standard Parts

Sanitary And Hygienic Design Guide For Food Equipment Mpc

Sanitary And Hygienic Design Guide For Food Equipment Mpc

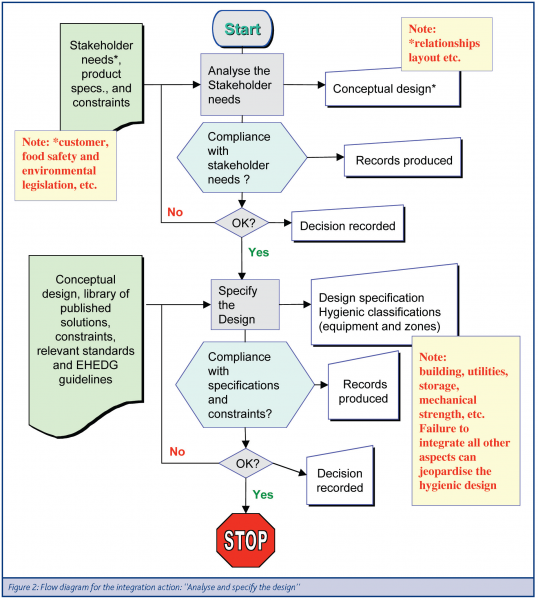

New Ways Of Hygienic Design A Methodical Approach Semantic Scholar

Guidelines For The Hygienic Design Construction And Layout Of Food Processing Factories Holah Dr John Amazon Com

Sign Up For Our Newsletter And Receive Our Newest Leaflet On Hygienic Design And Sanitary Guidelines Graintec

3 A Ssi And Ehedg Yin Yang 15 10 13 Food Engineering

Standard Parts In Hygienic Design Jw Winco Standard Parts

Iffa Exhibitors Products Igus Gmbh Hygienic Design Igus Reg Th3

Sanitary Design A Competitive Advantage Food Safety Magazine

When To Use Hygienic Design Vs Washdown Automation Insights

New Ways Of Hygienic Design A Methodical Approach Semantic Scholar

Hygienic Design Minebea Intec

Wanted Hygienic Systems Integration New Food Magazine

Guidelines For The Hygienic Design Construction And Layout Of Food Processing Factories Holah Dr John Amazon Com

3 A Ssi And Ehedg Yin Yang 15 10 13 Food Engineering

Gn 1580 Hexagon Head Screws Stainless Steel Hygienic Design Gn 1580 Hexagon Head Screws Are Certified According To Ehedg Guidelines An Hexagon Surface Screws

Home Ehedg

Hygienic Design And Maintenance Of Equipment Sciencedirect

When To Use Hygienic Design Vs Washdown Automation Insights

Migsa New Solids Dosing Screw In Hygienic Design According To Ehedg Guidelines Able To Cip

Hygienic Plant Design Sciencedirect

Hygienic Design Of Food Processing Equipment Sciencedirect

Hygienic Design Of Food Processing Equipment Sciencedirect

Hygienic Design Guidelines Doc Document

Gn Stainless Steel Leveling Feet Hygienic Design Without Mounting Holes Jw Winco Standard Parts

Hygienic Design Is Mandatory Hbm

Hygienic Design Food Safety Buhler Group

Standard Parts In Hygienic Design Ganter Norm

Sanitary Facility Design Guidelines Part 2 Of 2

The Growing Importance Of Hygienic Design Your Partners In Hygiene

Best Practice This High Precision Weighing Solution With Hygienic Design Is Winning Over The Pharmaceutical Industry Minebea Intec Pdf Catalogs Technical Documentation Brochure

World S First Plastic Energy Chain According To Hygienic Design Guidelines Beverage Manufacturing Ingredients Amp Additives Packaging Amp Filling

Hygienic Design Affi Food Safety Zone

Sanitary Design A Competitive Advantage Food Safety Magazine

Pdf Risk Management By Hygienic Design And Efficient Sanitation Programs

Hygienic Design Of Food Factories 1st Edition

Hygienically Optimised Design Is Top Priority By Minebea Intec

3 A Ssi And Ehedg Yin Yang 15 10 13 Food Engineering

Hygienic Design Affi Food Safety Zone

Cmp Equipment Hygienic Design Specialists Hygienic Design

Hygienic Spray Dryer Design For Processing Food Ingredients Processing Magazine