5s Prinzip

Ppt 3m 5s Powerpoint Presentation Free Download Id

Weg Zur Einfuhrung Der 5s Methode Advance Tapes

Das Lean Prinzip Posts Facebook

5s Wikipedia

5s Methode Kostenloses E Book

5s Methode Lean Production Exp

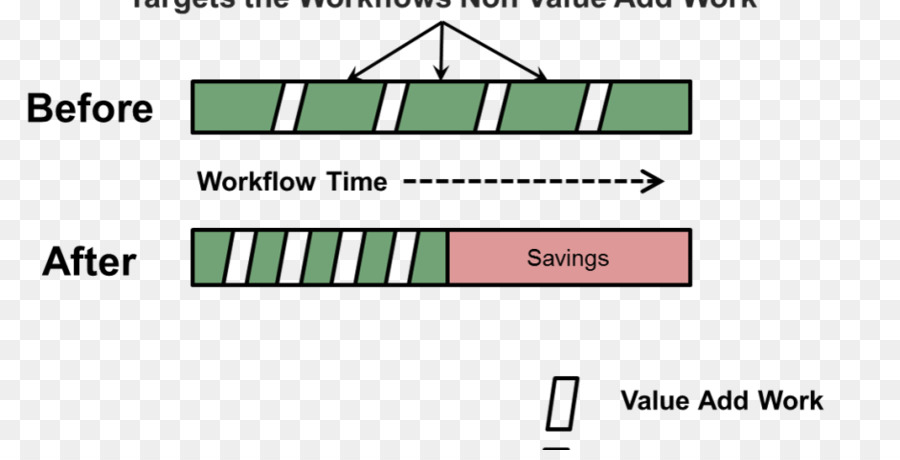

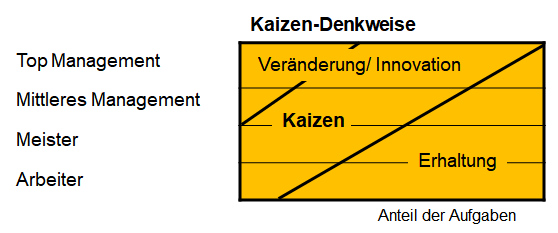

5S Productivity Improvemetnt Process Focus Discipline In the Workplace Teams Improvement The Kaizen Philosophy Figure2 The kaizen constituents The essence of Kaizen is that the people that perform a certain task are the most knowledgeable about that task;.

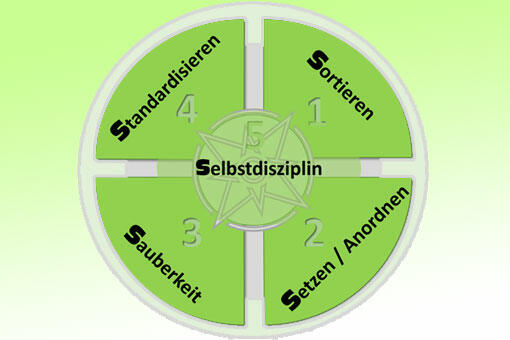

5s prinzip. Um diese Prinzipien zu erreichen, hat man im Laufe der Zeit zahlreiche Methoden und Tools beschrieben, die zur Unterstützung der Umsetzung dienen Kanban oder 5S sind einige davon – es gibt aber unzählige Begriffe, die im Zusammenhang mit Lean Management genannt werden Heute beschäftigen wir uns mit der Definition der zehn Prinzipien des Lean Managements Ausrichtung. “Originally developed as a methodology to make production processes highly efficient, lean techniques have been adopted by more than 72 percent of machine shops across the country For many of these, the techniques have helped them to dramatically increase their competitive edge, while continuing to remove wasteful practices and contribute to the bottom line”. The process capability is a measurable property of a process to the specification, expressed as a process capability index (eg, C pk or C pm)The output of this measurement is usually illustrated by a chronological control sample, histogram and calculations that predict how many parts will be produced out of specification (OOS).

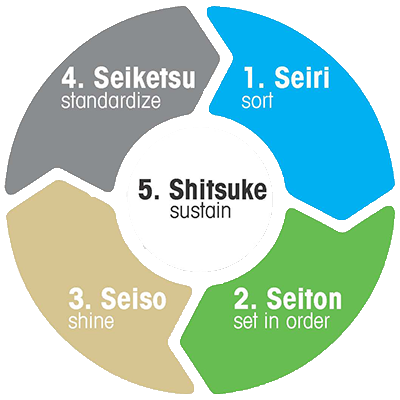

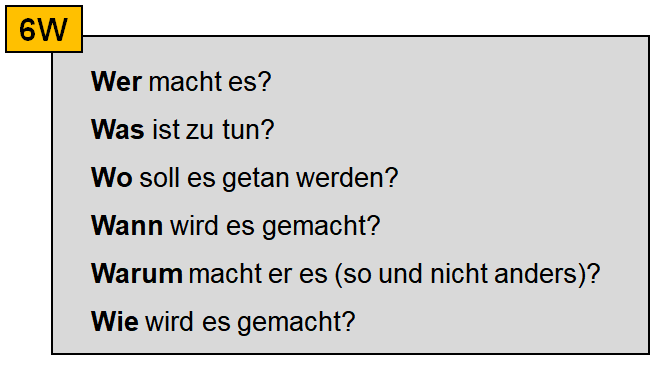

VierAugenPrinzip {n} 4AugenPrinzip Beteiligung od Kontrolle durch zwei Instanzen (Personen, Prüfeinrichtungen) and everything in its place old principle of order;. 5S implementation responsibilities are to be distributed throughout the organisation Every member must know their own 5S responsibilities and perform accordingly It is the duty of the Chairman to administer accountability for each of the responsibilities, as outlined below 5S Council (See page & 21) comprises the following 5S Training. One Lean tool that can help you eliminate these forms of waste is the 5S system 5S helps to declutter, clean, and organize the workplace using the five “S” principles sort, set in order, shine, standardize, and sustain Sort is the first step in 5S During this phase, you remove tools, supplies, and equipment that are not part of the work.

Sustain 5S is a habit and is continually improved 5S is a simple concept with powerful results You will get additional information on 5S so that you will be well equipped Our experience is that the more we do 5S the better the work environment becomes cleaner, safer, more organized, the work is easier, less confusion and less stress. 5S for your Warehouse Lean warehousing is the way of the future In its April 14 report, the Council of Supply Management Professionals identified Lean as a projected characteristic of the 25 India supply chainAccording to the report “The pressure to do more with less will not subside. Without a structured, continuous approach to process improvement, it’s difficult to keep momentum moving It’s also far too easy for busy, overworked teams to become desensitized to process inefficiencies and allow bad habits to fester and affect the quality of their work and speed of their delivery.

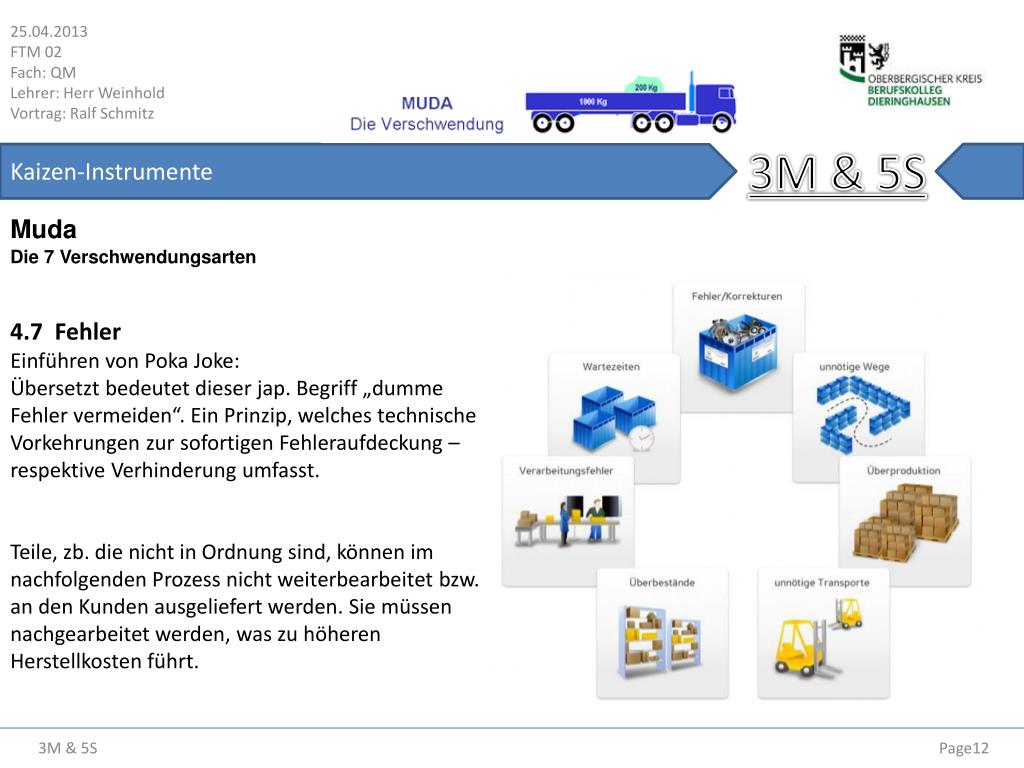

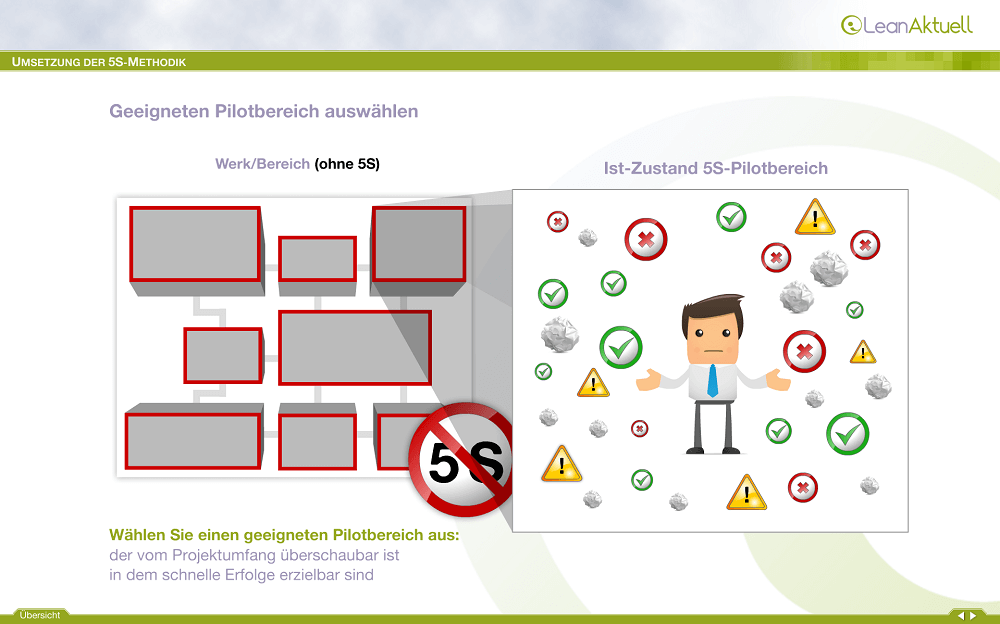

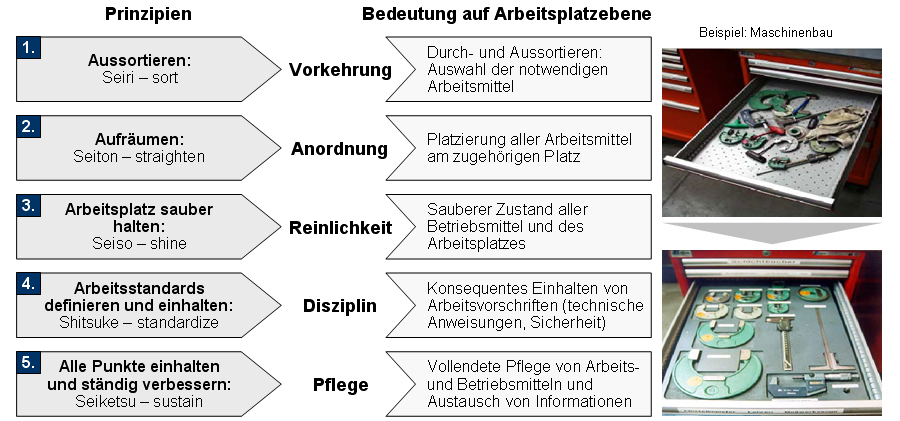

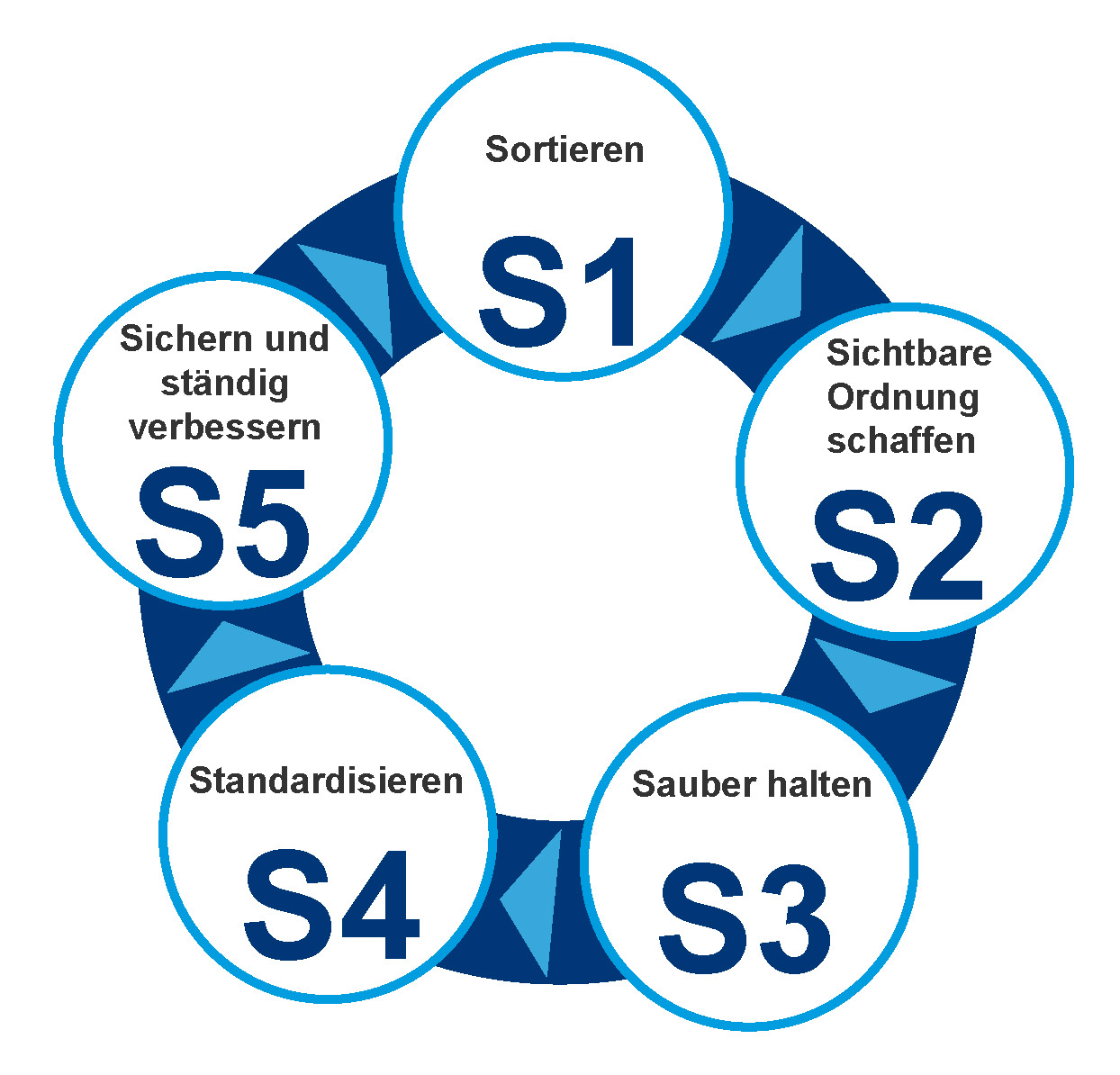

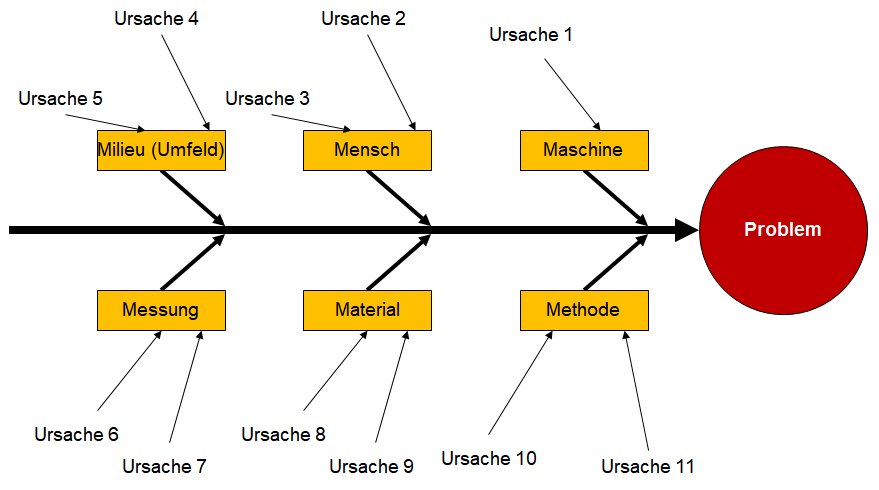

Ishikaw a diagram also referred as fishbone diagram and causeandeffect diagram is often used to identify possible causes of a problem This quality tool is often used during Analyze phase of lean six sigma DMAIC methodology application. A 5S map is a diagram or floor plan that provides an overview of a work area, process, or station It provides a visual reference to show where the tools, supplies, workers, and travel paths are, and how they relate to each other A good map may also include a description of the work that happens in the area shown. Definition Die 5SMethode ist eine systematische Vorgehensweise zur Gestaltung der eigenen Arbeitsumgebung Ziel ist, durch eine strukturierte Organisation des Arbeitsplatzes nicht wertschöpfende Tätigkeiten, also Verschwendung (7 Verschwendungsarten) zu minimierenDie 5SMethode ist damit die Basis für weitere Prozessoptimierungen wie das Toyota Produktionssystem (TPS), in dessen Rahmen.

5S is a system and way of organizing and managing workspaces to improve efficiency by eliminating waste, improving flow and reducing the number of processes where possible 5S systems are common in manufacturing, warehouses, offices and hospitals but 5S principles can be applied to any workplace. 23Nis18 'te Ertugrul adlı kullanıcının "5S" panosunu inceleyin iş yönetimi, araç deposu, garaj düzenleme hakkında daha fazla fikir görün. This 5S Lean Workplace List Poster is a full color high quality poster will help with the daily 5S reminder Follow Us • • Contact Us Register / Sign In • Track Order.

5S Ordnung, Struktur , Visuelle Anleitungen einfache Informationen die zum richtigen Handeln anleiten Auto. 5S is a fundamental first step for any manufacturing company, wishing to call itself world class We will understand this with step by step approach of its deployment The 5S program mandates that resources be provided at the required location and be available to support work activities. One of the most difficult tasks of an organisation´s leadership is to execute the vision, mission and strategy It´s pretty easy to describe the ambitions, but difficult to execute and more difficult to sustain the strategic intent The IPMA Organisational Competence Baseline (IPMA OCB®) describes in Chapter 33 what needs to be done in order.

Consequently, by involving them and showing confidence in their capabilities,. 5m 5s Iterator Umsetzung und Diskussion 6m 47s 3 Zusammenhänge Muster im Zusammenspiel 2m 31s Viele Muster, viele Ähnlichkeiten Abgrenzungen Prinzip 5 Offen und geschlossen 4m 9s Prinzip 6 HollywoodPrinzip 4m 22s Prinzip 7 Ein und nur ein Grund für Veränderung. Process capability excel template png If you want to to have a more scientific look on process control you can check this discussion in the minitab blogAnother way is to look on the homepage of ASQ Please feel free to contact me, if you have some suggestions to improve this page (rolandschnurr@sixsigmablackbeltde).

Who We Are/What We Do We are a family of motorcycle and power sport enthusiasts who design and manufacture Distinctive Performance Exhausts and RideEnhancing Products. Die logistische Wertschöpfungskette ist komplex und betrifft ua Kunden, Produktion und Logistik Für die ganzheitliche Optimierung aller involvierten Prozesse wurde das Konzept „Lean Logistics“ entwickelt, um die Effizienz von Logistikprozessen zu steigern und Ressourcenverschwendung zu vermeiden In unserem Seminar lernen Sie, wie Sie Lean Management für sich und Ihr Unternehmen. The 5S methodology is a very appropriate way to initiate and achieve the process of continuous improvement This paper studies management practices in successful Japanese companies in order to determine what 5S principles are behind them After visiting and conducting interviews at five different plants, a multicase study analysis was.

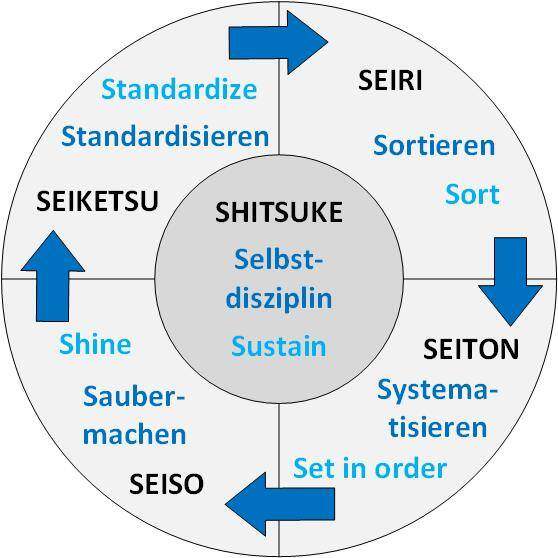

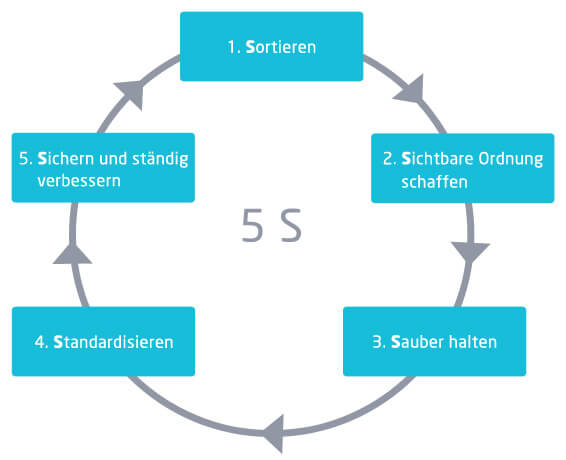

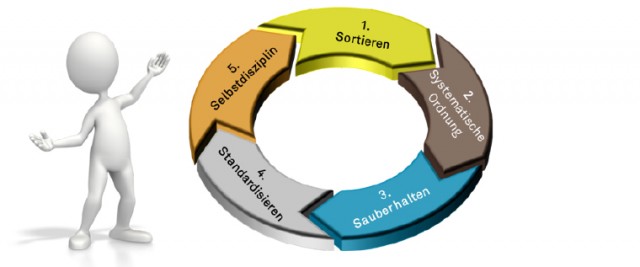

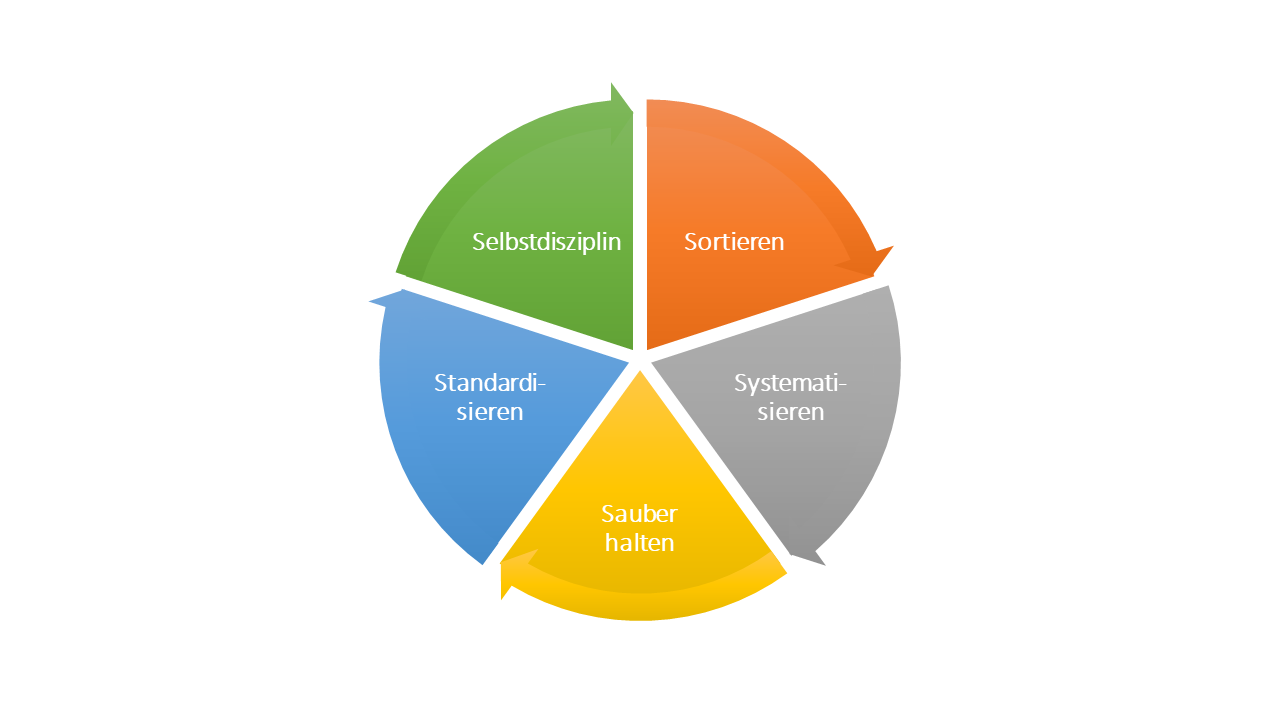

Die 5SArbeitsgestaltung, im deutschen Sprachraum auch 5A genannt, ist eine hauptsächlich in der Produktionsindustrie und zunehmend bei Dienstleistungen angewandte Methodik, wobei der Begriff für exakt definierte Maßnahmen steht Es ist eine Idee aus dem japanischen ToyotaProduktionssystem 5S dient als Instrument, um Arbeitsplätze und ihr Umfeld sicher, sauber und übersichtlich zu. Consequently, by involving them and showing confidence in their capabilities,. One Lean tool that can help you eliminate these forms of waste is the 5S system 5S helps to declutter, clean, and organize the workplace using the five “S” principles sort, set in order, shine, standardize, and sustain Sort is the first step in 5S During this phase, you remove tools, supplies, and equipment that are not part of the work.

The Hoshin Kanri method is among the most powerful tools in the Lean arsenal for effective strategic management When implemented properly, it bridges the gap between strategy and execution by creating alignment and focus The most popular way of implementing Hoshin Kanri is by applying the X matrix. The Origins of 5S – 5S & Lean Manufacturing 5S began as part of the Toyota Production System (TPS), the manufacturing method begun by leaders at the Toyota Motor Company in the early and midth centuryThis system, often referred to as Lean manufacturing in the West, aims to increase the value of products or services for customers. The Kaizen principle is a Japanese management philosophy which literally translates to continuous improvement This article describes in detail the Kaizen principle and how continuous improvement helps organizations increase productivity Key differences between Kaizen and Total Quality Management (TQM) are also outlined.

Nowadays also seen as a paraphrase of the Japanese concept of "5S" Alles hat seinen Platz und alles ist an seinem Platz. One of the most difficult tasks of an organisation´s leadership is to execute the vision, mission and strategy It´s pretty easy to describe the ambitions, but difficult to execute and more difficult to sustain the strategic intent The IPMA Organisational Competence Baseline (IPMA OCB®) describes in Chapter 33 what needs to be done in order. Naming trivialities aside, though, the purpose of 5S is straightforward 5S principles reduce waste and increase efficiency They’re meant to be followed chronologically and cyclically, as each stage of the practice enables the next and the process as a whole is designed to continually optimize the use of the workspace.

5S Productivity Improvemetnt Process Focus Discipline In the Workplace Teams Improvement The Kaizen Philosophy Figure2 The kaizen constituents The essence of Kaizen is that the people that perform a certain task are the most knowledgeable about that task;. VierAugenPrinzip {n} 4AugenPrinzip Beteiligung od Kontrolle durch zwei Instanzen (Personen, Prüfeinrichtungen) and everything in its place old principle of order;. In this interactive presentationone in a series of multimedia frameworksLowell Bryan, a director in McKinsey's New York office, examines 7S, a framework introduced to address the critical role of coordination, rather than structure, in organizational effectiveness.

A pull system is a Lean manufacturing principle created to reduce waste in the production process This kind of system offers many advantages, such as optimizing resources, increasing flow efficiency, and more. While some Lean Six Sigma (LSS) practitioners consider 5S a tool, it is more than that 5S, abbreviated from the Japanese words seiri, seito, seiso, seiketsu, shitsuke, is not just a methodology, it is a culture that has to be built in to any organization which aims for spontaneous and continuous improvement of working environment and working conditions. Commonly, 5S events run for three to five days Reserve a facilitator for an upcoming event Preparation for Your 5S Event Running this event is fairly simple and, with a bit of preparation, a 5S event can offer some pretty impressive results What’s more, it is also great for team building and morale.

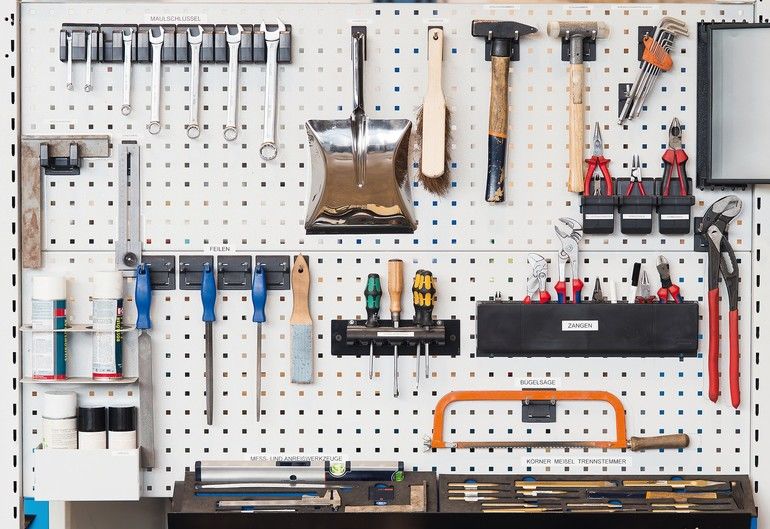

A pull system is a Lean manufacturing principle created to reduce waste in the production process This kind of system offers many advantages, such as optimizing resources, increasing flow efficiency, and more. Das Prinzip ist das gleiche nur die Dimensionen sind grösser Da wir meine Werkstatt auch noch für andere Aktivitäten brauchen (Kino, Disco etc) musste ich meine Werkstatt so einrichten, dass ich diese mit wenigen Handgriffen in einen Partyraum oder in ein Heimkino umfunktionieren kann We have vast experience in implementing 5s shadow. The term "lowhanging fruit" is a commonly used metaphor for doing the simplest or easiest work first, or for a quick fix that produces ripe, delectable results.

Wwwmlplusorg Veränderung durch Begeisterung!. “Originally developed as a methodology to make production processes highly efficient, lean techniques have been adopted by more than 72 percent of machine shops across the country For many of these, the techniques have helped them to dramatically increase their competitive edge, while continuing to remove wasteful practices and contribute to the bottom line”. Ich benutze als BT"Nachbrenner" ein altes Jabra 10 Das ist bzw war eigentlich für Handys ohne BT gedacht, arbeitet zwar mono aber bidirektional und ist sogar in der Lage, einen Tastendruck ans Handy zu übermitteln, also im Prinzip PTTfähig.

5M Method or 5Factor Method is a simple method of analyzing the causes and consequences (problems) based on five causes Manpower causes are in humans, people;. 5S is a system and methodology that serves as the foundation for all other Lean Manufacturing endeavours It creates a visual logic in the workplace and puts things in order so waste can easily be identified and removed. 5S methodology has expanded from manufacturing and is now being applied to a wide variety of industries including health care, education, and government Visual management and 5S can be particularly beneficial in health care because a frantic search for supplies to treat an introuble patient (a chronic problem in health care) can have dire.

5S Guide Improve efficiency with effective organization When the workplace is a mess, processes slow down 5S, a systematic method for workplace organization, keeps spaces clean and clear of clutter processes This 5S Guide explains the steps of a 5S program, how to start a program, and what tools you'll need to make 5S a success Get Free 5S. In some quarters, 5S has become 6S, the sixth element being safety (safe) Other than a specific standalone methodology, 5S is frequently viewed as an element of a broader construct known as visual control, visual workplace, or visual factory Under those (and similar) terminologies, Western companies were applying underlying concepts of 5S before publication, in English, of the formal 5S. The aufbau principle, from the German Aufbauprinzip (buildingup principle), also called the aufbau rule, states that in the ground state of an atom or ion, electrons fill atomic orbitals of the lowest available energy levels before occupying higher levels For example, the 1s subshell is filled before the 2s subshell is occupied In this way, the electrons of an atom or ion form the most.

The 5S methodology was born at Toyota in the 60s under an industrial environment to achieve better organized, tidier, and cleaner workplaces to increase productivity and to obtain a better working environment The 5S methodology has been widely spread, and many companies and organizations are implementing it worldwide Although it is conceptually simple and does not require a complex training. • 5S is a philosophy and a way of organizing and managing the workspace and work flow with the intent to improve efficiency by eliminating waste, improving flow and reducing process unreasonableness It is for improvement of working environment 8 What is 5S ?. Die logistische Wertschöpfungskette ist komplex und betrifft ua Kunden, Produktion und Logistik Für die ganzheitliche Optimierung aller involvierten Prozesse wurde das Konzept „Lean Logistics“ entwickelt, um die Effizienz von Logistikprozessen zu steigern und Ressourcenverschwendung zu vermeiden In unserem Seminar lernen Sie, wie Sie Lean Management für sich und Ihr Unternehmen.

The principles of 5S are also commonly known as ‘lean management’ and were instigated by Toyota in the 1950s The main purpose of 5S, also known as lean management, is to reduce waste and increase efficiency, thereby reducing production costs while increasing productivity, safety, and employee satisfaction To achieve lean management in your company, follow. What we call "6S" derives from "5S" the method of workplace organization and visual controls popularized by Hiroyuki Hirano (1990) The five "Ss" refer to five Japanese words—seiri, seiton, seiso, seiketsu, and shitsuke Seiri means to separate needed and unneeded materials and to remove the latter. The 5S methodology is a very appropriate way to initiate and achieve the process of continuous improvement This paper studies management practices in successful Japanese companies in order to determine what 5S principles are behind them After visiting and conducting interviews at five different plants, a multicase study analysis was developed to identify the key aspects of the success of.

The Pareto principle states that for many outcomes roughly 80% of consequences come from % of the causes (the “vital few”) Other names for this principle are the 80/ rule, the law of the vital few, or the principle of factor sparsity Management consultant Joseph M Juran developed the concept in the context of quality control, and improvement, naming it after Italian economist. BDSM is a variety of often erotic practices or roleplaying involving bondage, discipline, dominance and submission, sadomasochism, and other related interpersonal dynamicsGiven the wide range of practices, some of which may be engaged in by people who do not consider themselves to be practising BDSM, inclusion in the BDSM community or subculture often is said to depend on selfidentification. What are the Five S's (5S) of Lean Quality Glossary Definition Five S’s (5S) 5S is defined as a methodology that results in a workplace that is clean, uncluttered, safe, and well organized to help reduce waste and optimize productivity It's designed to help build a quality work environment, both physically and mentally.

Ich benutze als BT"Nachbrenner" ein altes Jabra 10 Das ist bzw war eigentlich für Handys ohne BT gedacht, arbeitet zwar mono aber bidirektional und ist sogar in der Lage, einen Tastendruck ans Handy zu übermitteln, also im Prinzip PTTfähig. The process of 5S was coined and made popular by Toyota It is based on 5 principles starting with the letter “S” In Japanese, Seiri (Sort), Seiton (Systematize), Seiso (Shine), Seiketsu (Standardize), and Shitsuke (Sustain) The implementation of 5S is one reason that Toyota Industrial Equipment continues to be one of North America’s. 5S is a method to improve and sustain workplace organisation 5S represents 5 disciplines for maintaining a visual workplace (visual controls and information systems)These are foundational to continual improvement and a manufacturing strategy based on “ Lean Manufacturing ” (waste removing) concepts 5S help reduces clutter, reduces the time it takes to look for tools and equipment.

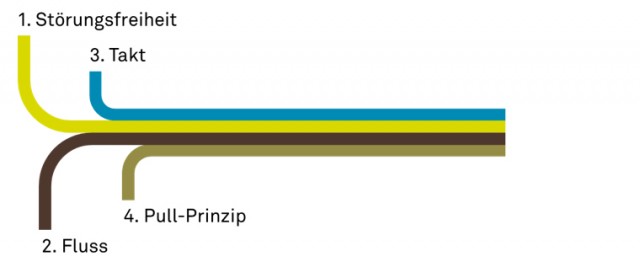

What is 5S Standardization Standardization can be the thought of as the means by which we maintain the first three 5S concepts There is a danger in any improvement activity that once the focus is removed and another top priority arises, things go back to the way they were before (the informal system). Nowadays also seen as a paraphrase of the Japanese concept of "5S" Alles hat seinen Platz und alles ist an seinem Platz. Lean was born out of manufacturing practices but in recent time has transformed the world of knowledge work and management It encourages the practice of continuous improvement and is based on the fundamental idea of respect for people Womack and Jones defined the five principles of Lean manufacturing in their book “The Machine That Changed the World”.

Machines causes are in equipment, such as machinery, computers, tools, instruments, technology. Applying 5S is a way of implementing ISO clauses 713 and 714, which address Infrastructure and Environment for the Operation of Processes According to clause 713, the infrastructure required to produce a product or provide a service should be maintained Maintenance can be additionally ensured through following good practices.

5s Methode Das Kondo Prinzip Fur Den Arbeitsplatz Kloepfel Magazin

Was Ist 5s Die Erfolgsmethode Fur Verschwendungsfreies Arbeiten Pdf Free Download

5s Mehr Als Ordnung Und Sauberkeit

5s Methode Quality De

5s Eliminieren Sie Verschwendung In Ihrem Unternehmen Unternehmensberatung Axel Schroder

Das 5s Prinzip Wie Du In Nur 5 Schritten Fur Ordnung Im Buro Sorgst

5s Methode Agiles Prinzip Fur Immobilienmakler Flowfact

Mit Dem 5s Prinzip Den Buroalltag Organisieren Karriereletter

5 S Methode

Das 5s Prinzip Wie Du In Nur 5 Schritten Fur Ordnung Im Buro Sorgst

Frau Handschrift Element Der 5s Prinzip Auf Weissem Hintergrund Fur Die Bei Der Herstellung Verwendet Lizenzfreie Fotos Bilder Und Stock Fotografie Image

Management Aufgaben Arten Tipps Und Methoden

5s Methode Das Kondo Prinzip Fur Den Arbeitsplatz Kloepfel Engineering Gmbh

5s Methode Der Prozessoptimierung Ingenieurburo Drimas

5s Im Buro Lean Methode 5s Arbeitsplatzorganisation

Organisation Im Buro Metro At

Frau Handschrift Element Von 5s Prinzip Auf Weissem Hintergrund Fur Bei Der Herstellung Verwendet Lizenzfreie Fotos Bilder Und Stock Fotografie Image

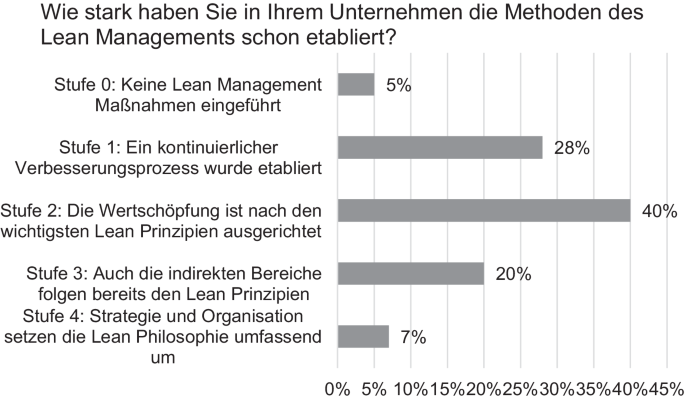

Die 360 Analyse Ein Werkzeug Zur Ganzheitlichen Beurteilung Der Einfuhrung Und Nutzung Von Lean Management Methoden Springerlink

5s Methode

5s Wikipedia

5s Methode In 5 Schritten Zum Optimalzustand

5s Methode Fur Kvp

5s Zur Arbeitsplatzgestaltung Mit Der 5s Methode Den Arbeitsplatz Und Unternehmensinterne Prozesse Optimieren Das Buro Und Die Organisation Auf Vordermann Bringen Ebook Tundermann Maximilian Amazon De Kindle Shop

5s Methode Business Management Tools

5s Audit Und Kreidekreischeckliste Das Lean Prinzip

Q Tbn And9gctgaa8rkb4qr2gbjjp4 Tklrfg1y8o6euqeqrregviqciyxe6r7 Usqp Cau

Die 5s Methode Die 5s Methode Saubermachen Und Sonst Nix Oder Ein Weiterer Schritt Auf Der Leiter Der Kontinuierlichen Verbesserung Pdf Kostenfreier Download

5s Methode Auf Dem Weg Zum Lean Management Weka

Kaizen Mappei

Die 5s Methode Ordnung Als Prinzip

Lean Werden Aber Wo Fange Ich An Sehen Lernen Lean Produktivitat Und Selbstmanagement

5s Strategie Schema Mit Englisch Beschreibung Fototapete Fototapeten Prinzip Aufrecht Umsetzung Myloview De

5s Methode Prozessverbesserung Leichter Gesagt Als Getan

Frau Handschrift Element Von 5s Prinzip Auf Weissem Hintergrund Fur Bei Der Herstellung Verwendet Lizenzfreie Fotos Bilder Und Stock Fotografie Image

5s Audit Und Kreidekreischeckliste Das Lean Prinzip

Was Ist Die 5s Methode Buro Und Was Ist Eine Clean Desk Policy

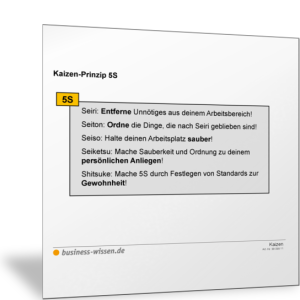

Kaizen Prinzip 5s Vorlage Business Wissen De

5s Arbeitsgestaltung Schnydrig Consulting

Taschenkarte T04 5s Methode Cetpm

Frau Handschrift Element Von 5s Prinzip Auf Weissem Hintergrund Fur Bei Der Herstellung Verwendet Lizenzfreie Fotos Bilder Und Stock Fotografie Image

Methode 5s Erklarungen Beispiel Lean Sesa Systems

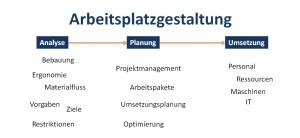

Arbeitsplatzgestaltung Mit Der 5s Methode

Kaizen 5s Fokussierten Verbesserung Von Papier Prinzip Andere Png Herunterladen 940 470 Kostenlos Transparent Png Herunterladen

Was Ist 5s Wie Funktioniert Die 5s Methode Im Lean Management

Das 5s Prinzip Im Labor

5s Methode Agiles Prinzip Fur Immobilienmakler Flowfact

Das 5s Prinzip Wie Du In Nur 5 Schritten Fur Ordnung Im Buro Sorgst

5s Methodenkarte Buroorganisation Tipps Zeitmanagement Projektmanagement

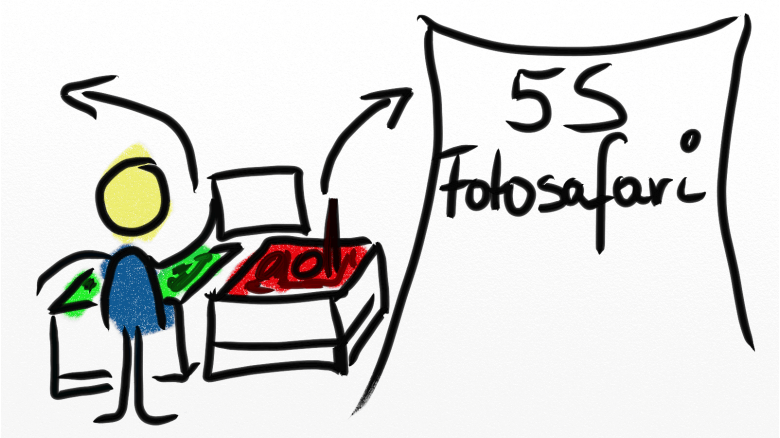

5s Fotosafari Visuelle Dokumentation Simplefactory

5s Audit Checkliste Zur Effizienzkontrolle Fur Schlanke Laborprozesse

Wertstrom Leitfaden Und 5s Leitfaden Das Lean Prinzip

5s Methode Prozessverbesserung Leichter Gesagt Als Getan

Was Ist 5s 5s Boards

Downloads Das Lean Prinzip

5s Methode Kostenloses E Book

Lean Management Bei Halstrup Walcher

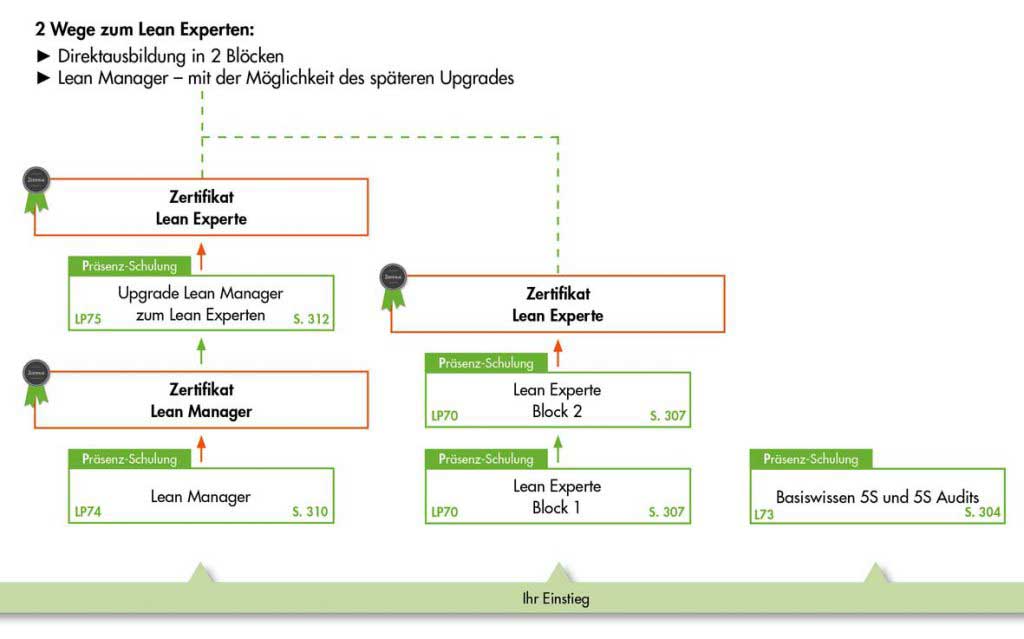

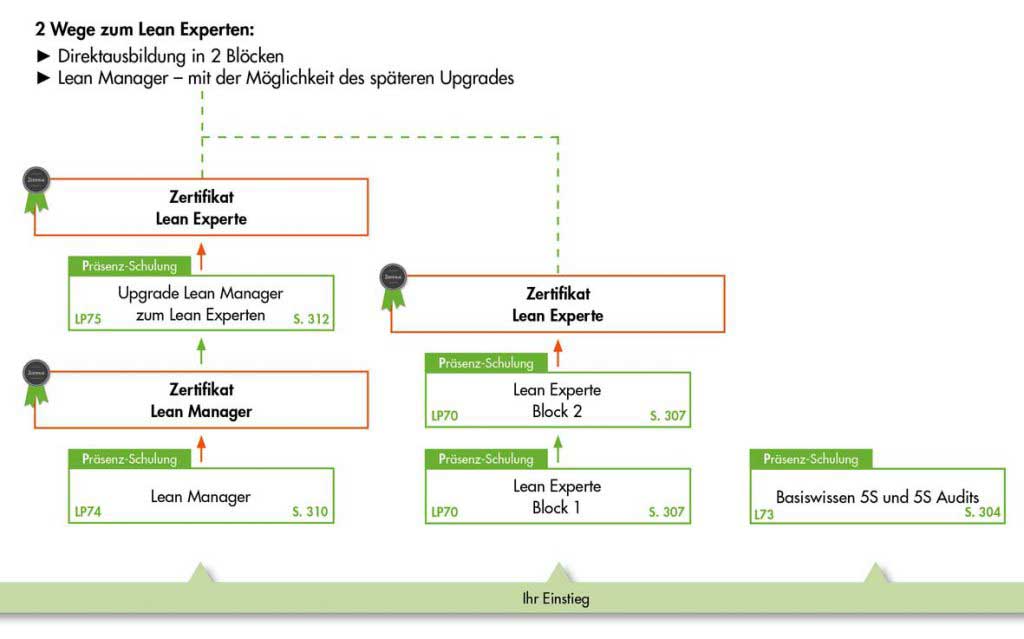

Ausbildung 5s Methode Comprei

Frau Handschrift Element Von 5s Prinzip Auf Weissem Hintergrund Fur Bei Der Herstellung Verwendet Lizenzfreie Fotos Bilder Und Stock Fotografie Image

Gemeinsam En Raum Fur Produktive Und Effiziente Zusammenarbeit Schaffen Jens Albat Auf In Eine Bessere Arbeits Welt Berater Trainer Speaker

5s Methode In 5 Schritten Zum Optimalzustand

Frau Handschrift Element Von 5s Prinzip Auf Weissem Hintergrund Fur Bei Der Herstellung Verwendet Lizenzfreie Fotos Bilder Und Stock Fotografie Image

5s Methode Definition Und Erklarung Microtech Gmbh

Holzkonstruktion Fur Arbeitsplatze Nach 5s Methode Wegmuller Attikon

Downloads Das Lean Prinzip

5s Die Erfolgsmethode Zur Arbeitsplatzorganisation Cetpm

5s Methode Lean Production Exp

5s Zur Arbeitsplatzgestaltung Mit Der 5s Methode Den Arbeitsplatz Und Unternehmensinterne Prozesse Optimieren Das Buro Und Die Organisation Auf Vordermann Bringen Ebook Tundermann Maximilian Amazon De Kindle Shop

Methoden Und Werkzeuge Fur Kaizen Kaizen Business Wissen De

5s Methode Awatex Hygiene Ch Webkatalog

Das 5s Prinzip Wie Du In Nur 5 Schritten Fur Ordnung Im Buro Sorgst

5s Im Office Gemeinsam E Ordnung Im Buro Schaffen Und Kontinuierlich Verbessern Jens Albat Auf In Eine Bessere Arbeits Welt Berater Trainer Speaker

5s Prinzip Know Now Vorlagen

5s Prinzip

5s Mehr Als Ordnung Und Sauberkeit

5s Wikipedia

Element Des 5s Prinzip Auf Weissem Hintergrund Fur Die Bei Der Herstellung Verwendet Lizenzfreie Fotos Bilder Und Stock Fotografie Image

5s Methode Auf Dem Weg Zum Lean Management Weka

Reinigungsboard

5s Methode Mappei

Das 5s Prinzip Bild Margie Photocase De Business Ladys

Lean 5s Youtube

5s Oder 5a Es Geht Los Ebook By Alireza Soltany Noory Rakuten Kobo United States

Die 5s Methode Zur Besseren Selbstorganisation Im Buro

Organisation And Visualisation With 5s Durable

5s Bei Rosenberger Hochfrequenztechnik Deutsch Youtube

5s Eliminieren Sie Verschwendung In Ihrem Unternehmen Unternehmensberatung Axel Schroder

Was Ist 5s Wie Funktioniert Die 5s Methode Im Lean Management

Alle Produkte Zur 5s Arbeitsplatzgestaltung Simplefactory

Methoden Und Werkzeuge Fur Kaizen Kaizen Business Wissen De

Ausmisten Mit Der 5s Methode So Funktioniert S

Kaizen Als Prinzip Und Was Es Bedeutet Kaizen Business Wissen De

Videokurs Uber 5s Im Buro Prinzipien Videos Unternehmungen

5s Methode So Sorgen Sie In 5 Schritten Fur Ordnung Im Betrieb Impulse

Das 5s Prinzip So Sorgen Sie Fur Einen Effizienten Arbeitsplatz

5s Methode Quality De