5s Workshop Examples

Course Title 5s Japanese Good Housekeeping Practices

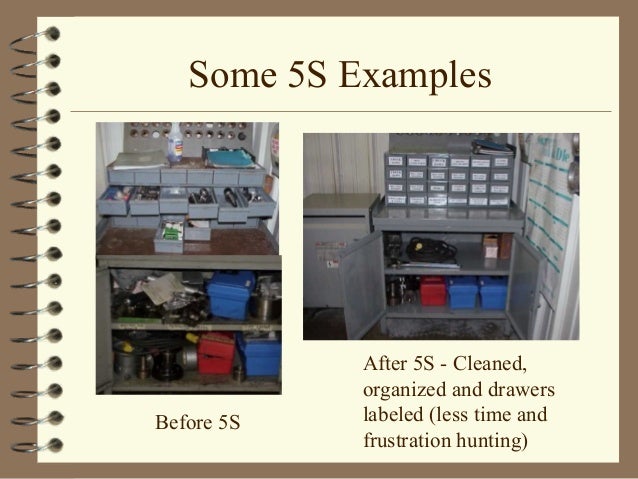

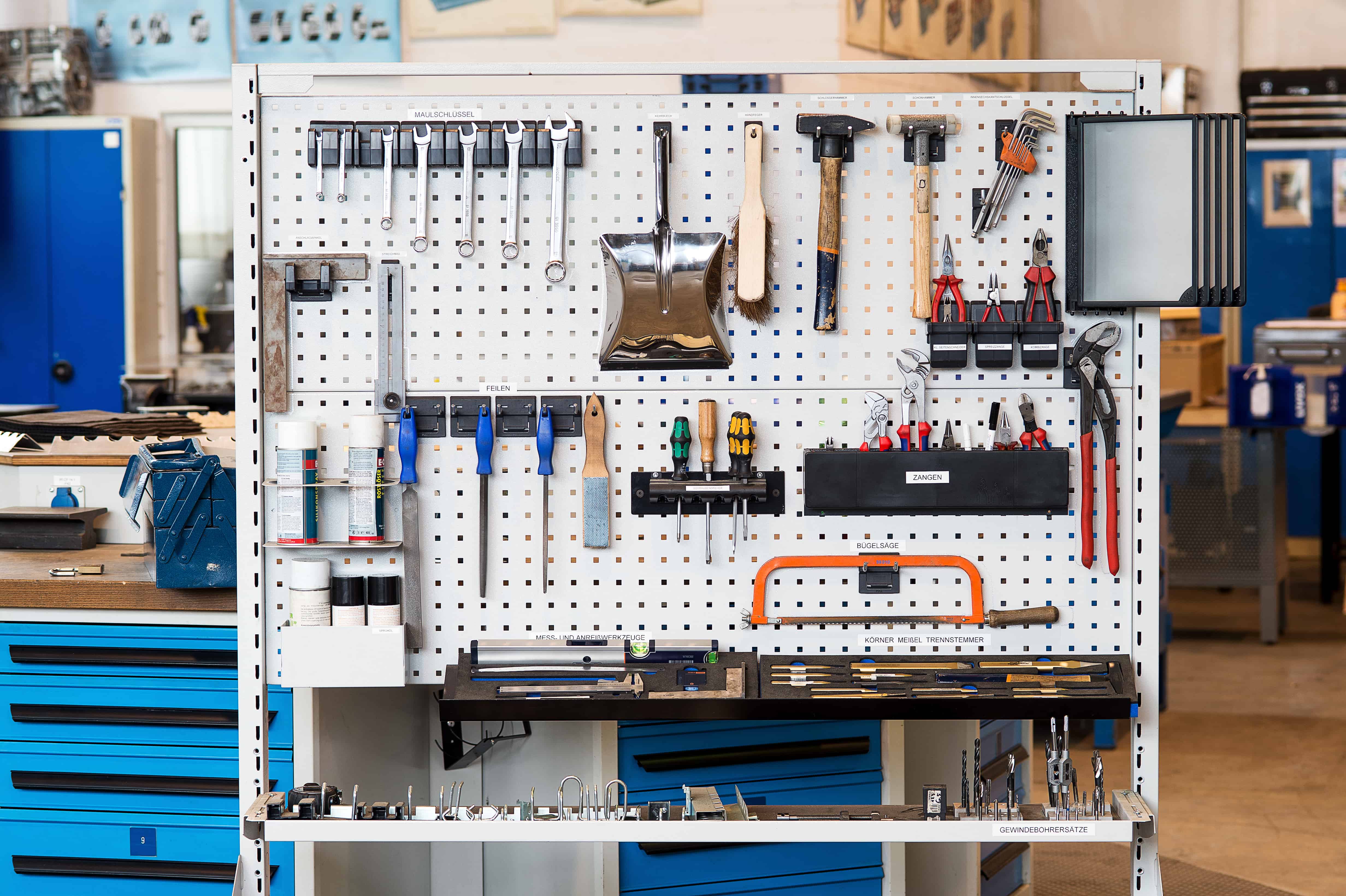

Some Images Of 5s Houskeeping In Factories Lean Manufacturing Visual Management Warehouse Design

The 5s System Lean Manufacturing Methodology

5s Your Workshop

Visual Management

5s Resources Creative Safety Supply

Course5Sdocx 18 June 10 Page 1 of 3 Introduction to 5S Training Workshop Welcome to the oneday 5S training course by Lifetime Reliability Solutions Introduction to 5S 5S is workplace management where the work area and workplace are organised and ritualised to minimise the loss of time and the use of movement.

5s workshop examples. A 5S can be applied to any work environment It could be a supply/store in a hospital, a repair truck for a telecom company, a CSR desk/work area in a call center, the baggage claim area of an airline or a laptop computer. Learn more about 5S workplace organization For more information, visit http//wwwimecorg/indexcfm. Why Use the 5S Integrated–withtheprocess Model?.

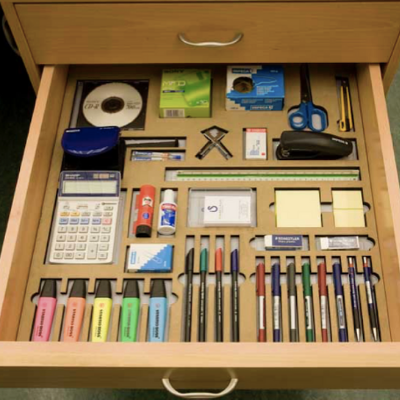

A 5S basics, interesting, fun 1day Introduce to 5S Workplace Management for Shopfloor People, Supervision and Managers You get 5S training workshop material containing a 5S PPT PowerPoint Presentation of foundational 5S knowledge, and a 5S game people play that puts them into a 5S Simulation where they continually improve and learn the value of 5S. Implementing 5S in Knowledge Work If you think that 5S is only applicable to tangible work items, think again As I mentioned earlier, this concept is a mindset It can even be applied to knowledge work Let’s take a look at the following example Take a look at your files and software tools. The Origins of 5S – 5S & Lean Manufacturing 5S began as part of the Toyota Production System (TPS), the manufacturing method begun by leaders at the Toyota Motor Company in the early and midth centuryThis system, often referred to as Lean manufacturing in the West, aims to increase the value of products or services for customers.

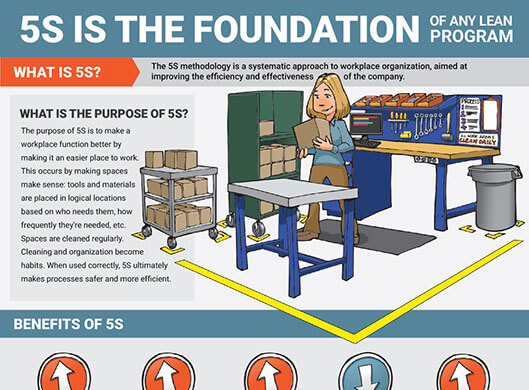

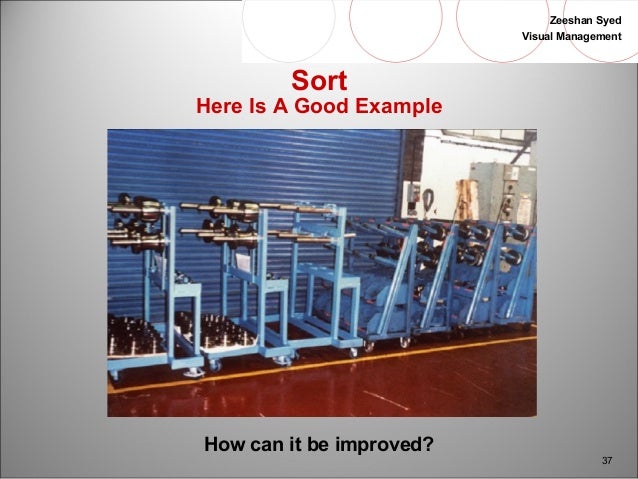

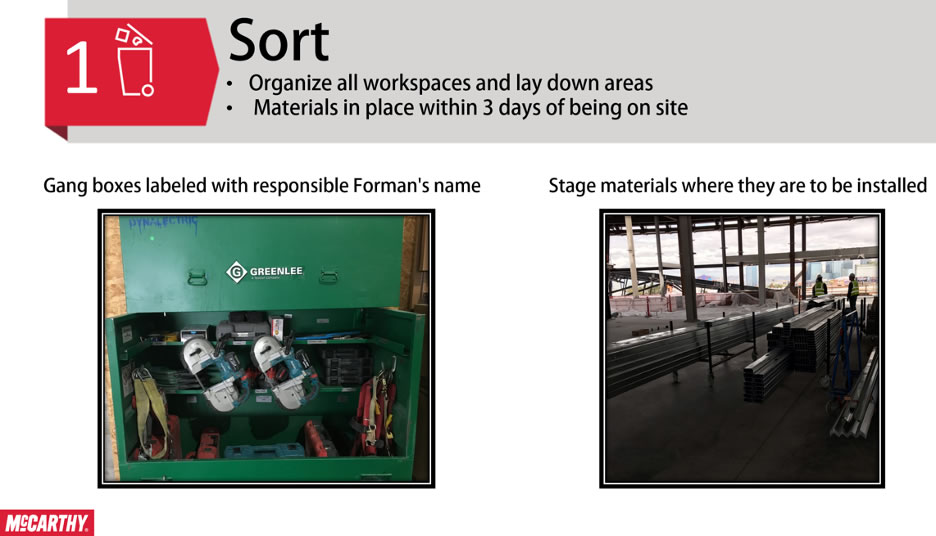

The 5S system is a powerful lean manufacturing tool with the potential to improve productivity and profitability The tenets are seemingly simple and straightforward Sort, Set, Shine, Standardize, and SustainSuccess stories, like Toyota’s, have inspired many companies to implement 5S as a means to become lean, yet many of those attempts end in failure. 5S is a Lean technique that involves activities designed to create and maintain a disciplined workplace It helps create a better working environment and can be implemented to eliminate waste and improve the flow of work 5S audits are often used to evaluate the performance of 5S implementation in any workplace This 5S audit checklist will help ensuring that 5S standards and workplace. 5S for your Warehouse Lean warehousing is the way of the future In its April 14 report, the Council of Supply Management Professionals identified Lean as a projected characteristic of the 25 India supply chainAccording to the report “The pressure to do more with less will not subside.

This workshop consists of two modules Module 1 covers the origins of 5S and its roots in Toyota This presentation shows through various media formats, such as photos, videos, examples and interviews how 5S is applied in several of the Toyota facilities around the world. Text in this Example 5S Audit Area Audit Date Manager Supervisor Category Score Average Sort Straighten Shine Standardize Sustain Total Points 5S Score No 1S SORT Points Area is free of unnecessary clutter Only the required tools are in the work area Only the required materials are in the work area All required Personal Protective Equipment is in the work area. Implementing 5S in Knowledge Work If you think that 5S is only applicable to tangible work items, think again As I mentioned earlier, this concept is a mindset It can even be applied to knowledge work Let’s take a look at the following example Take a look at your files and software tools.

23 5S checklists, schedules and routines are defined and being used 24 Everyone knows his responsibilities, when and how 25 Regular audits are carried out using checklists and measures S5 – Sustain SHITSUKE 26 5S seems to be the way of life rather than just a routine 27 Success stories are being displayed (ie before and after. 5S also known as “Workplace Organization” is all about keeping the workplace neat, uncluttered, organized and safe So I was thinking, if more people practiced it at home, maybe we’d be more successful at doing it at work?. 5S is one of the first tools that can be applied in a company that is starting down the path of the continuous improvement culture A 5S implementation helps to define the first rules to eliminate waste and maintain an efficient, safe, and clean work environment.

The 5S Workshop can be taught in either the office or shop floor environment In keeping with Pinnacle's Lean QMS ® approach, the 5S program is sustained within the context and culture of your quality management system (QMS) or business operating system (BOS). The 5S system is a powerful lean manufacturing tool with the potential to improve productivity and profitability The tenets are seemingly simple and straightforward Sort, Set, Shine, Standardize, and SustainSuccess stories, like Toyota’s, have inspired many companies to implement 5S as a means to become lean, yet many of those attempts end in failure. (examples machine parts which may cause cut, crush or other injuries, moving parts such as gears, pulleys and chains) Safety Yellow for identifying caution (examples physical hazards such as tripping, falling, striking against and caughtin.

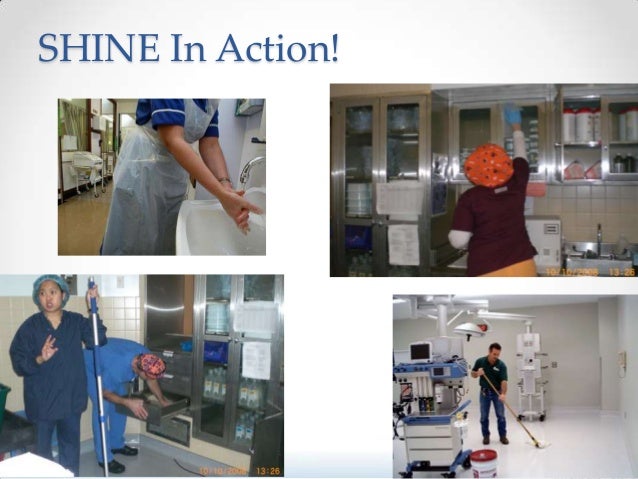

5S methodology has expanded from manufacturing and is now being applied to a wide variety of industries including health care, education, and government Visual management and 5S can be particularly beneficial in health care because a frantic search for supplies to treat an introuble patient (a chronic problem in health care) can have dire. Some organizations sustain their efforts by adding periodic audits of 5S practices This is commonly done with a simple and flexible checklist Gemba walks and leader standard work can also assist in sustaining elements of lean culture A Simplification of Lean 5S 3S is a simplified version of 5S containing only sort, sweep, and standardize. (examples machine parts which may cause cut, crush or other injuries, moving parts such as gears, pulleys and chains) Safety Yellow for identifying caution (examples physical hazards such as tripping, falling, striking against and caughtin.

See more ideas about shadow, custom build, custom. The greatest benefit from using 5S is realized when it is part of a larger initiative and the entire organization has adopted its principles 5S is more than a system;. Defining 5S 5S is a formulaic method you can use to straighten and organize a work area Using 5S reduces waste (a fundamental goal in lean manufacturing), improves safety (see our article on Lean 6S Safety), and otherwise improves your production process and work environment 5S is called 5S because their are 5 steps and each step begins with the letter “S” (and/or the sound “s”).

The 5S are defined with examples as shown on page 2 Identify, reduce and eliminate waste Enhance teamwork Enhance operation efffectiveness in a better working environment Form the basic advanced model for Productivity and Quality Improvement 5S Management Techniques 2 ANDING 5S 3 SORT. Text in this Example 5S Audit Area Audit Date Manager Supervisor Category Score Average Sort Straighten Shine Standardize Sustain Total Points 5S Score No 1S SORT Points Area is free of unnecessary clutter Only the required tools are in the work area Only the required materials are in the work area All required Personal Protective Equipment is in the work area. For example, if there's a line balance issue for whatever reason, there may be a temporary need for members of the team to flex and assist on 5S duties This should be encouraged to help rebalance the load and keep the whole work area to standard without negatively affecting throughput at the constraint.

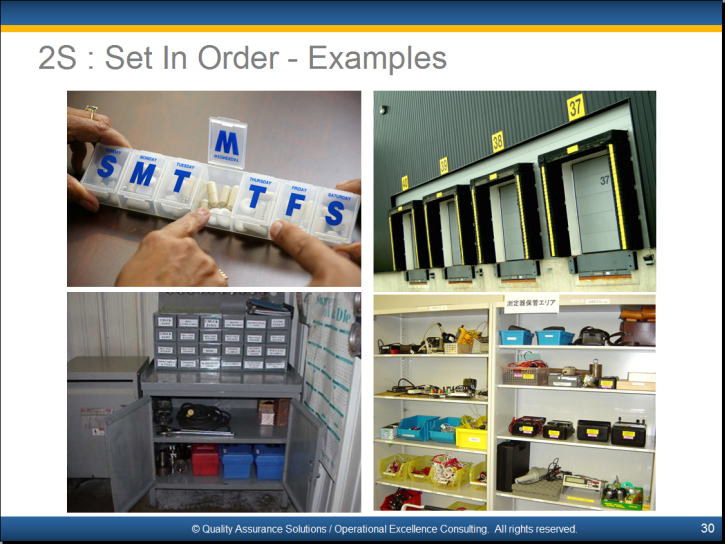

5S is sometimes called the five pillars because just like the physical pillars that hold up a structure, 5S has five elements that support the effectiveness of the system And just like the pillars of a building, if one was to weaken or fail, the entire structure would fall The five steps/pillars of 5S are 1 Sort 2 Set in Order 3 Shine. Previously, we have discussed 5S in general, the phases Sort and Straighen, and the phases Sweep and Standardizing in previous articles This article will discuss the final phase of 5S the sustain phase All these articles are coverd in the book Sustainable 5S The fifth and final S in the 5S model stands for SUSTAIN, and this is the most difficult of the stages to implement in practice. Make everyone happy 1) Form a comfortable workshop 2) Be aware that 5S benefits the worker, and that is its purpose 3) Involve all members Do not rush when performing 5S Take the initiative, do not wait for the next person to start Provide learning opportunities 1) Let everyone participate in problem identification and brainstorming.

Sep 29, Examples of the many custom built shadow boards we create for the workplace!. Defining 5S 5S is a formulaic method you can use to straighten and organize a work area Using 5S reduces waste (a fundamental goal in lean manufacturing), improves safety (see our article on Lean 6S Safety), and otherwise improves your production process and work environment 5S is called 5S because their are 5 steps and each step begins with the letter “S” (and/or the sound “s”). 2 Stick to the „5S‟ rules for proper workplace management 3 Encourage the participation of all, for consistency in „5S‟ activities 4 Perform „5S‟ activities periodically 12 Organization Introduction Menon Piston Ltd, Maharashtra, India inaugurated in 1969 MPL is a total engineering solution.

A 5S basics, interesting, fun 1day Introduce to 5S Workplace Management for Shopfloor People, Supervision and Managers You get 5S training workshop material containing a 5S PPT PowerPoint Presentation of foundational 5S knowledge, and a 5S game people play that puts them into a 5S Simulation where they continually improve and learn the value of 5S. Both 5S models shown in Table 1 have the same intent – deploying 5S – but the examples reveal that the integratedwiththe model process may be more effective as it provides timely feedback, visible accountability and the opportunity for immediate mitigationThe integration of the 5S elements into the core processes promotes the dynamic. # 5S methodology management with circle arrow line roll diagram Vector Similar Images Add to Likebox # Project Management Success in Tablet Form Similar Images Add to Likebox # Six Sigma The popular business improvement concept Similar Images.

5S is amongst the first and fundamental steps implemented by an enterprise towards the path of implementing Total Quality Management and continuous improvement at the operation level 5S is a process designed to organize the workplace, keep it clean,. Example of 5s Checklist for Manufacturing Below is an example on how to generate a 5S checklist for manufacturing First column lists action items Column headings include the five housekeeping items of 5S, sort, straighten, shine, standardize, and sustain For each action item, the auditor who analyses the process can grade each item to. One of the most important part of a sustainable 5S culture is the 5S mini audit (Panneman, 19) There are hundreds of examples to be found on the web These are the three of the templates that I have found to be useful once you adjust them to your personal department/company needs.

Commonly, 5S events run for three to five days Reserve a facilitator for an upcoming event Preparation for Your 5S Event Running this event is fairly simple and, with a bit of preparation, a 5S event can offer some pretty impressive results What’s more, it is also great for team building and morale. 5S is amongst the first and fundamental steps implemented by an enterprise towards the path of implementing Total Quality Management and continuous improvement at the operation level 5S is a process designed to organize the workplace, keep it clean,. Course5Sdocx 18 June 10 Page 1 of 3 Introduction to 5S Training Workshop Welcome to the oneday 5S training course by Lifetime Reliability Solutions Introduction to 5S 5S is workplace management where the work area and workplace are organised and ritualised to minimise the loss of time and the use of movement.

While these are very useful, it is sometimes best to just take a look at some specific examples of 5S strategies to see how it could be used in a more practical situation The following is an example of a strategy for each of the 5 S’s to help give a better understanding of this important workplace improvement program. 5S is a methodology of management consisting of five steps that are repeated in a manufacturing or industrial setting to ensure quality, limit waste, and maximize employee time and efforts 5S was developed in Japan and was documented during a study of Japanese manufacturing methods in the late 1980’s. For example, when the barista finetunes the size of batches of brewed coffee, or does away with batches entirely.

5S Audit Checklist This 5S Audit Checklist is a tool used by area supervisors or plant managers to perform monthly or quarterly audits As a 5S audit form, this checklist can help ensure that 5S principles and set standards are being followed and implemented by workers. 5S is a fundamental first step for any manufacturing company, wishing to call itself world class We will understand this with step by step approach of its deployment The 5S program mandates that resources be provided at the required location and be available to support work activities. 5S is sometimes called the five pillars because just like the physical pillars that hold up a structure, 5S has five elements that support the effectiveness of the system And just like the pillars of a building, if one was to weaken or fail, the entire structure would fall The five steps/pillars of 5S are 1 Sort 2 Set in Order 3 Shine.

The 5S are defined with examples as shown on page 2 Identify, reduce and eliminate waste Enhance teamwork Enhance operation efffectiveness in a better working environment Form the basic advanced model for Productivity and Quality Improvement 5S Management Techniques 2 ANDING 5S 3 SORT. For example, when the barista finetunes the size of batches of brewed coffee, or does away with batches entirely. 5S is a Lean technique that involves activities designed to create and maintain a disciplined workplace It helps create a better working environment and can be implemented to eliminate waste and improve the flow of work 5S audits are often used to evaluate the performance of 5S implementation in any workplace This 5S audit checklist will help ensuring that 5S standards and workplace.

A set of slides from a workshop to launch 5S in an office Slideshare uses cookies to improve functionality and performance, and to provide you with relevant advertising If you continue browsing the site, you agree to the use of cookies on this website. 5S also known as “Workplace Organization” is all about keeping the workplace neat, uncluttered, organized and safe So I was thinking, if more people practiced it at home, maybe we’d be more successful at doing it at work?. The primary objective of 5S is to create a clean, orderly environment an environment where there is a place for everything and everything is in its place Beyond this, many companies begin their lean transformation with 5S because it exposes some of the most visible examples of waste it also helps establish the framework and discipline.

The premise of 5S is to help organize and improve the work conditions of a workplace However, this process can also be used for home as well for gettingand stayingorganized Step 1 Sort to get everything in your home up and out of the place of clutter Use a fourbin or bag system The four bag labels for sorting your clutter are "Throw. It is a business philosophy and should be integrated into the organization’s culture. A two day 5S training workshop is a good way to begin the implementation Some managers or directors should participate in the workshop so that operators see that the company is really committed The 30 seconds test is an easy way to make sure you have done a good job you should find any item, tool, information, document, or person in less.

5S is the perfect tool to identify the first improvement projects in your company to eliminate waste Although sometimes viewed as a housekeeping technique, it is actually an innovative management system that helps people think lean, paving the way for the adoption of Lean principles in the organization. The example on the right is a more abbreviated example and depicts a combination of pictures and areaspecific questions I found it in use in a factory in Turkey More examples of 5S audits can be found here The advantage of having a structured question list is that the answers to the questions can be scored and the overall scores can be tabulated The overall score of the 5S audit can serve as an indicator of the level of maturity of the area and the personnel being audited You can share. Commonly, 5S events run for three to five days Reserve a facilitator for an upcoming event Preparation for Your 5S Event Running this event is fairly simple and, with a bit of preparation, a 5S event can offer some pretty impressive results What’s more, it is also great for team building and morale.

The primary objective of 5S is to create a clean, orderly environment an environment where there is a place for everything and everything is in its place Beyond this, many companies begin their lean transformation with 5S because it exposes some of the most visible examples of waste it also helps establish the framework and discipline. Purpose To show an example of a cell 5S assignment board Main points This board is currently being used in some of the cells Everyone knows when and who is responsible for sweeping up the work area each day With clear responsibilities, cleanup has a greater chance of sticking 5S Workshop &Visual management Krishna Heda 1 Krishna Heda. A two day 5S training workshop is a good way to begin the implementation Some managers or directors should participate in the workshop so that operators see that the company is really committed The 30 seconds test is an easy way to make sure you have done a good job you should find any item, tool, information, document, or person in less.

Once an organization determines the 5S strategies are a good fit for the company, they need to start planning out how to implement 5S Proper implementation will require physical changes to the facility, as well as training employees and other parties to operate in accordance with the 5S methodology It can take quite some time before 5S is fully implemented, but there will be significant. For example, if there's a line balance issue for whatever reason, there may be a temporary need for members of the team to flex and assist on 5S duties This should be encouraged to help rebalance the load and keep the whole work area to standard without negatively affecting throughput at the constraint. Dave Visco and the team at the 5S store have been successfully servicing our organization for more than two years He has helped in a variety of areas, including new idea/best practice adoption, and implementation of key projects in both manufacturing and warehousing I highly recommend Dave and the 5S Store as a strategic addition to your team.

An Example of 5S Let’s take the example of a hospital floor cart The cart connects the nurse on the hospital floor to the supply/store of the hospital for common patient care supplies and special medical care supplies.

5s Lean Manufacturing And Six Sigma Definitions

5s Methodology Wikipedia

What Is The 5s System Definitions Core Concepts Principles Graphic Products

5s Posters Creative Safety Supply

5s Tools And Visual Management Tulip

What Is 5s 5s System Is Explained Including Tips On Getting A 5s Program Started

Upskilling Application Of 5s As Foundations Of Lean Business

Lean Manufacturing Lean Manufacturing Results Dynacast

Zen Cart The Art Of E Commerce Lean Manufacturing Workstation Workshop Organization

Lean Manufacturing Daniel Barreto

5s Training Course Online 5s Training Video

How To Apply 5s Lean Principles In A Service Department Flexpac

Improve Workplace Safety With 5s Realsafety Org

6s Is Just Cleaning Up Isn T It Innoval Technology Innoval Technology

Implementing 5s In Assembly Plants Implementing 5s In Assembly Plants 12 03 01 Assembly Magazine

Lean In To 5s 19 11 15 Quality Magazine

A Guide To The 5s Lean Production Method For Occupational Health And Safety

Method 5s Explanations And Example Of The 5s Lean Sesa Systems

Lean Warehousing And The 5s Strategy S W Betz

Lean 5s Seiri Sort Clearing Classify

How To Improve Service At Your Garage Industry Forum

5s Work Flow Management In Enterprise Excellence Deployment Bpminstitute Org

Johns Manville 5s Shine Youtube

Why You Should Launch A 5s Program At Your Workplace Formaspace

Kaizen Case Study Siemens Oostkamp Kaizen News Com

5s Lean Manufacturing And Six Sigma Definitions

5s Factory Makeover Preview Youtube

Practical Implementation Of 5s Method

5s Work Flow Management In Enterprise Excellence Deployment Bpminstitute Org

5s In The Laboratory What Why How

Five S 5s Training Webinar Brendan Healy Youtube

Development Of 5s Implementation Aids

5s Workplace Organization Images Google Search Lean Manufacturing Industrial Flooring Kaizen

How To Implement Lean Manufacturing Straighten And See 5s Part 2 Lean Manufacturing Update

5s Or 6s Lean Management Technique Possible Uses In Project Management Ipma International Project Management Association

Some Images Of 5s Houskeeping In Factories Total Quality Management

5s Certification

5s Methodology Wikipedia

Importance Of 5s In Six Sigma Quality Management

An Example Of Lean Manufacturing Projects By Imse 564 Students Download Scientific Diagram

Floor Marking For 5s Creative Safety Supply

%20-%20Bad%20-%20Clutter%20in%20Corner%20of%20Factory.jpg)

Bralla Com Lean Manufacturing

Teach This 5s Process With This 5s Ppt

5s Method Housekeeping Factory Systems

Keys And Tips To Implement The 5s Methodology

Three Keys To Sustainable 5s

Keys And Tips To Implement The 5s Methodology

Visual Management 5s In Lean T P S Workshop Slides

5s In Hospitals Workshop

Tools For 5s Lean Manufacturing Process Checklists And More Graphic Products

Lean 5s Seiton Straighten Simplify Set In Order Configure

Intro To 5s Emcc

5s And Visual Controls My Processes Are Talking Back

5s Lean Manufacturing And Six Sigma Definitions

Best Practices 5s And Your Warehouse Stickypaper Company

5s Lean Before After Google Search

3 Tips To Cross Functional 5s Projects Leancor A Transplace Company Leancor A Transplace Company

5s Training Presentation

5s For The Office By Operational Excellence Consulting Operational Excellence Lean Manufacturing Visual Management

5s Lean 3 Simple Tips To Deploy 5s On Your Jobsite

Seiso Is The Third Step Of The 5s Method

Lean Projects Lean Sensei International

5s Safety Lean 6s Safety Convergence Training

5s Examples In Action The Good The Bad Graphic Products

3 Tips To Cross Functional 5s Projects Leancor A Transplace Company Leancor A Transplace Company

5s Ing Vogel Bros Building Co Vogel Bros Building Co

5s Earth Consultants

Keys And Tips To Implement The 5s Methodology

5s Visual Workplace Problems Identified Problems Solved Association For Manufacturing Excellence

What Is 5s 5s System Is Explained Including Tips On Getting A 5s Program Started

The Importance Of 5s Manufacturing Net

Using The Steps For 5s Red ging Enna Com

Shitsuke Is The Fifth And Final Step Of The 5s Method

5s Method Housekeeping Factory Systems

5s Lean Principles The 5s Lean Methodology For Workplace Organisation

Seiso Means Shine In 5s Lean Methodology Click Here

5s Implementation At Superior Ind Example Of The 1st S Sort Lean Six Sigma Visual Management Lean Manufacturing

Table 1 From Application Of Lean Manufacturing Tools In The Food And Beverage Industries Semantic Scholar

5s Methodology Wikipedia

How To Implement Lean Manufacturing Straighten And See 5s Part 2 Lean Manufacturing Update

Lean 5s

How To Implement 5s In The Workplace Kanban Zone

5s Safetyculture

Some Images Of 5s Houskeeping In Factories Total Quality Management

Lean Reflections Time For 5s