Big Bag Tipping Station

Sugar Bulk Bag Dumping System Coffee Powder Big Bag Tipping Station China Bulk Bag Dumping System Sugar Bulk Bag Dumping System Made In China Com

Big Bag Unloading Station Flow Force

800 Bags Of Litter 17 Tonnes Of Fly Tipping One Big Clean For The Queen Sunrise Radio The Number One Asian Hit Music Station

How To Achieve Efficient Big Bag Tipping Processing Magazine

Discharge Station Mksb For Bags And Big Bags Buhler Group

Sugar Bulk Bag Dumping System Coffee Powder Big Bag Tipping Station China Bulk Bag Dumping System Sugar Bulk Bag Dumping System Made In China Com

Search for used big bag filling stations Find Pierret and Piovan for sale on Machinio.

Big bag tipping station. POWDER HANLING BIG BAG TIPPING STATION TO HSM 8430 (HS) Combi Line International SpA Italy 1 shipment matches bag tipping 70k shipments total CBM S PARE PARTS FOR BAG. Our bulk bag handling equipment is the epitome of efficiency and, more importantly, safety Imagine a food production worker opening and dumping hundreds of 50pound bags of ingredients a day – cutting them open and dumping them manually into a tipping station, bag after bag. Automatic BottomUp big bag packing line;.

Dust collection system of big bag discharge station is needed for preventing dust emission during big bag discharge Dust emissions from big bags are seen during cutting or untying of bag spouts, product discharge and removal of empty big bags Vacuum air supplied by dust collector, collects any dust in the region. By using a big bag discharge stations in the powder handling system, a significantly higher throughput can be achieved for transferring powder material into the production process, if compared to a standard bag tipping station Commonly operators can dump around 6t of powder material by using a big bag discharge station while maintaining the. Introducing the BBA series Big Bag filling station, exclusive on the market Throughputs 1 filling station, semiautomatic from 60 to 100 BB/hr The throughput will vary depending on the model of the equipment, the degree of automation of the installation and the type of product to be packed Once the tests with your product have been carried.

This structure is designed to fill Big Bags easily and safely (according to the feeder system) with sand, gravel, grain, plastic granules, etc This is a sturdy and stackable station (quick and easy stacking and unstacking operations) There are two possible configurations the flexible container is placed on a pallet underneath the hopper, or the Big Bag suspended in a holder is placed under. DPF0 in Spain customer site. What is a Big Bag tipping station Big Bag tipping stations (also named Big Bag unloading station, Big Bag emptying station, Super Sack unloading system in US) constitute an important process equipment since they will allow to bring to the process the raw materials necessary to manufacture the desired product.

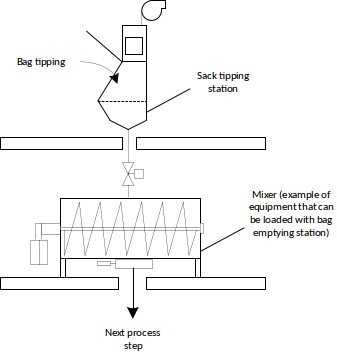

A Spirotech sack tip station is an invaluable piece of equipment when large quantities of materials are not required in a delivery When minor ingredients are purchased in 25kg bags a sack tip station provides a convenient way to store and transfer small quantities of product into the main process – whether transferring into a mixer or into a. Tetra Pak® Big Bag Tipping unit VB005 Working principle The bigbag is lifted and safely lowered on the unit The opening of the bigbag is connected easily and tightly at the inlet of the powder transport The vibrating support facilitates product extraction from the bigbag Until the bag is empty, no operator intervention is required. Sack Tip Stations Big Bag Dischargers Flex Feeders Electric Vibrators Screw Conveyors Vacuum Conveyors Automatic Sack Openers Big Bag Filling Stations Vacuum Sack Lifters Spare Parts Company Address Entecon Industries Limited 8 Lawrence Way Camberley, Surrey GU15 3DL United Kingdom Company Contact Phone 44 (0) 1276.

Dec provides complete technical solutions for the filling of big bags directly out of process equipment like a dryer or a mixer for example The filling system can include sieving, milling and accurate dispensing The station will be adapted to the powder characteristics, the containment level, the layout and the required accuracy. Conveyor beltbag tipping stationIBCVacuum conveyorRPP Rorary premade pouch given packer;. For big bags with an inliner or inlet we have developed a special clamping system which prevents the inliner from slipping out of the big bag during emptying Disposable big bags without a discharge hose can be opened automatically with the optionally available cross knife For reusable bags there is the option of reclosing open big bags with.

The GERICKE BBU Big Bag Unloader® consists of standardised components, which can be combined to form applicationspecific solutions This not only enables us to build units exactly for your current needs, but also enables adjustment or modification of the unit later, if your requirements change. Tetra Pak® Big Bag Tipping unit VB005 Working principle The bigbag is lifted and safely lowered on the unit The opening of the bigbag is connected easily and tightly at the inlet of the powder transport The vibrating support facilitates product extraction from the bigbag Until the bag is empty, no operator intervention is required. Big bag discharging stations are designed for unloading of bulk bags in effective and safe way Different types of bulk materials can be handled, starting from free flowing granules to poorly flowing sticky fine powders Bulk bag discharge systems are designed to meet wide range of application requirements Type of bulk material, big bag size.

The milk powder (infant formula milk powder etc) is diverted from one big bag filling station to the other via a gravity divert valve (Trouser leg assembly) Due to the high capacity / volume of milk spray dryers then the control system is designed to give an approximate target weight in the bag est 1,000 kgs / 5g, with an accurate readout of. Scarica BigBag con paranco a catena BigBag discharger with chain hoist. For dimensions of Big Bags, please contact your local Tetra Pak representative Tetra Pak® Big Bag Tipping unit VB006 Working principle The Big Bag is lifted and safely lowered on the unit The opening of the Big Bag is connected easily and tightly at the inlet of the powder transport, thanks to a pneumatic BB closure system.

HIGH CAPACITY, BIN AND BAG FILLING SYSTEMS, BIN TIPPERS, HEAVY DUTY FEEDERS, BAG FILLING HOPPERS BIN AND BIG BAG HANDLING Big Bag / Bin Filling or Tipping Equipment Capacities Handled from 500kg to 5000kg. The semiautomatic big bag filling station makes it possible to fill big bags (FIBC flexible intermediate bulk container) with one, two or four loops and octabins with a filling station of 500 kg to 1500 kg At 150 big bags per hour, our big bag filling station is one of the fastest in the world The big bag filling station is. Shop for heavy bags, punching bags, speed bags and punching bag stands that fit your budget Big 5 Sporting Goods gets you ready to play!.

Big bag tipping stations must allow for the discharge of a bag without emitting dust to the environment to protect the operator and reduce the needs for cleaning as well as the risks related to dust explosion Both connecting and disconnecting the bag can lead to dust leakages, thus those two operations require specific designs and procedures. Bag Dump Stations are also known as Bag Dump Hoppers, Sack Tip Stations, Bag Tip Stations, Sack Unloaders, and Bag Unloaders but regardless of the terminology managing dust is always a consideration Dust problems caused by emptying bags of fine, aerated or volatile powders can be eliminated with a properly configured bag dump station. Our modular BigBag Unloading Station BBUone is optimized for dustfree operation together with Vacuum Conveyors It can be used for all sorts of materials and can be customized to make poor flowing materials come out of the big bag and bring them into all sorts of process areas without any contamination of product or surrounding.

For big bags with an inliner or inlet we have developed a special clamping system which prevents the inliner from slipping out of the big bag during emptying Disposable big bags without a discharge hose can be opened automatically with the optionally available cross knife For reusable bags there is the option of reclosing open big bags with. If requested the big bag discharge stations can also be equipped with a low level indication in order to make a timely big bag change possible Loading from sacks The vacuum extraction is started by opening the cover of the sack tipping hopper The sack is opened and the product is discharged into the hopper The dust is extracted and. If requested the big bag discharge stations can also be equipped with a low level indication in order to make a timely big bag change possible Loading from sacks The vacuum extraction is started by opening the cover of the sack tipping hopper The sack is opened and the product is discharged into the hopper.

HIGH CAPACITY, BIN AND BAG FILLING SYSTEMS, BIN TIPPERS, HEAVY DUTY FEEDERS, BAG FILLING HOPPERS BIN AND BIG BAG HANDLING Big Bag / Bin Filling or Tipping Equipment Capacities Handled from 500kg to 5000kg. The Gericke Sack Tipping units can be combined and integrated with other Gericke equipment, such as nibblers, rotary valves, sieving or conveying systems Also the conbiantion with big bag stations is possible for more flexibility Semi automatic sack opening systems additionally improve workplace ergonomics and safety. AZO big bag discharge stations make it possible to discharge big bags with little generation of dust and to feed products reliably into the closed production plant To improve efficiency and reduce costs even further, AZO has developed a modular concept for a big bag discharge station The required components such as frame, traverse, chain.

We can stuff and stuff a big pile of leaves into one bag, drag it or carry it there are two handles at the rim level and a third handle at the base, so a short person and a tall person can carry a bag together, or one can pick from the bottom when tipping the load out. The big bag is placed on the filling station 2 The big bag inlet is connected to the filling head by an inflatable gasket ensuring the sealing 3 Handling filled big bag is safe and without any tipping risk Support framework >caVi^c\ hZVa for a complete sealing Load cells See all our options. The discharge station is designed in a modular way and therefore available as a tipping station for bags as well as a combined discharge station for bags and big bags Both models are available in mild steel or stainless steel Aspiration for dustfree operation Both machine types can be aspirated via filter, external aspiration or direct pick.

Sack Tip Station (Bag Emptying Station 25/50 kg) ₹ 1 Lakh/ Unit Get Latest Price Usage/Application Bag Emptying for Process Plants Material Mild Steel / SS 304 / SS 316 Surface Treatment Mirror Finish / Bead blast versions on request No of Bags per hour Upto 0 bags per hour. Filler is the basic product of Elinpack,and we based on it to design and manufacture Semiauto auger filler,Automatic big bag bagger,Rigid container fillerThe auger filler is matched perfertly with VFFS packer,Doybag packer,Horizontal packer working together to form a automatic bagging system. By using a big bag discharge stations in the powder handling system, a significantly higher throughput can be achieved for transferring powder material into the production process, if compared to a standard bag tipping station Commonly operators can dump around 6t of powder material by using a big bag discharge station while maintaining the.

These big bag and sack filling systems can either be highly automated, semiautomatic or manually controlled SACK TIPPING Our sack tipping stations offer a safe and dustfree method, whereby powders and granules can be manually emptied from sacks, bags boxes into an automated process that will weigh, dose, feed and transfer to process line. The GERICKE BBU Big Bag Unloader® consists of standardised components, which can be combined to form applicationspecific solutions This not only enables us to build units exactly for your current needs, but also enables adjustment or modification of the unit later, if your requirements change. The FILL & WEIGH is a Big bag loading station with a palletscale, pneumatic lift, weighing terminal, and a ready wired “plug & play” design The operator places the bag loops into the loop holders, slides the bag socket over the loading spout and tightens the bag torque clamp.

The STB sack tipping station is a great solution when small amounts of materials have to be fed into the process The device is designed for loose products that are delivered in bags up to 50 liters Provides a convenient way to empty and feed small amounts of product into a main process – eg a mixer or a transport system between two remote. Our modular BigBag Unloading Station BBUone is optimized for dustfree operation together with Vacuum Conveyors It can be used for all sorts of materials and can be customized to make poor flowing materials come out of the big bag and bring them into all sorts of process areas without any contamination of product or surrounding. Our range of sack tipping stations provide a safe, dust free method of manually emptying bags and sacks containing powders and granules Systems typically include Dust extraction using reverse jet dust filters with fan – this provides a through draught of air, ensuring any dust from the sack is drawn up into the sack tip unit and away from.

Big bag unloading station We have complete ranges of Bulk Bag equipment for unloading which comprises Electric Hoist, Forklift Load and Trolley Load helpful for bulk bags extending till 00kgs The modular design comes up with preassembled option that permits quick adaptability and installation for any suitable applications. Sack tip stations, bag dumping, Entecon, sack tip, safe, clean bag dumping, comfortable, unloading, big bags, sacks,. Sketch of Big Bag emptying station A buffer hopper, fitted with a discharge and metering unit is located underneath the container support framework An automatic system keeps a constant material level in the hopper by controling the emptying operation.

At any time existing stations may be extended due to the innovative modular design Trouble free integration with up and downstream conveyor technology is a simple task, rendering HUMBERT & POL’s BIGBAG station an important link in the production chain. The FlowMatic® 02 big bag filling station includes an inflatable containment seal and an adjustable big bag hanging deck in height via a pneumatic cylinder The entire adjustable structure allows the conditioning of big bags of different heights according to product densities without any risk of it tipping over Download the technical. Scarica BigBag con paranco a catena BigBag discharger with chain hoist.

Big bag filling stations The big bag is constantly increasing in significance in bulk materials handling The flexible handling of even bulk freightrequires the use of ever more powerful systems for dustfree filling of big bags Big bag filling system for plastic granulate. The semiautomatic Big Bag Filling Station enables the filling of Big Bags (FIBC) with one, two or four loops and Octabins with a filling weight from 500 kg to 1500 kg With 150 Big Bags per hour, our Big Bag filling station is one of the fastest in the world Additionally, the extremely stable construction and the high reliability characterize the Big Bag filling station. The big bag is placed on the filling station 2 The big bag inlet is connected to the filling head by an inflatable gasket ensuring the sealing 3 Handling filled big bag is safe and without any tipping risk Support framework >caVi^c\ hZVa for a complete sealing Load cells See all our options.

Station casing x x x Automatic big bag release Big bag under vacuum Big bag with single handle x F Basic specifications of big bag discharge stations and applicable options;adl gViZh VgZ \^kZc dg ^cdgbVi^dc dcan VcY XVc kVgn YZeZcY^c\ dc iZ igZViZY egdYjXi# High Flow Rate Customized model Duopal ® Big bag & sack discharging. Shop for heavy bags, punching bags, speed bags and punching bag stands that fit your budget Big 5 Sporting Goods gets you ready to play!. The Tetra Guerin BigBag Tipping Station is specifically designed to efficiently dump bigbags of granulated or powder components (freeflowing product) The station can be easily integrated into any powder handling installation Its overall dimensions assure a very small footprint The design integrates the latest improvements in hygiene standards by minimizing.

A bottom spout big bag unloading cutter system by D&H Equipment. Big bag emptying station consists of loadcells on main frame Weight of the big bag is continuously measured and user is informed System can send signal to another PLC automation system or system can control other equipment connected to the big bag unloader unit Sack tipping unit is installed on big bag discharge hopper Operator can. Bag tipping stations, also named bag dumping station, bag dumping platform or sacks tipping stations are often an indispensable process step for manufacturers to open and discharge bags of powder inside a process Indeed, many ingredients are still delivered in 25 and 50 kg sacks all over the industry.

Each big bag station is designed to measure In the 90s, ISERCO’s customers, widely from endusers part, getting bin activators working on cohesive powders, wished that the extraction techniques well known in the field of bin activator were extended to 1 ton pack container more commonly known as “big bag”. Bag Tipping StationVibration Sifter;.

Www Globalpartnerdays Com Wp Content Uploads 02 Tetra Pak Powder Handling Pdf

Everlast Single Station Heavy Bag Stand Black Walmart Com Walmart Com

Big Bag Tipping Station With Conevalve Contact Guerin Systems Sas

Osaka Luggage Storage 5 Options Plus Locations And Costs Japan Cheapo

Sack Tip Station Hanningfield

Customized Sack Tip Station For Food Safety Sieving Machine

Big Bag Tipping Station With Conevalve Contact Guerin Systems Sas

Smartpick

How To Achieve Efficient Big Bag Tipping Processing Magazine

Bag Tipping Station Design Considerations Processing Magazine

Calendar Industrial Auctions For Sale Private Treaty About Industrialbid Types Of Auctions Auction Lingo Contact Us Iaa Login Logout Select Page Calendar Industrial Auctions For Sale Private Treaty About Industrialbid Types Of Auctions Auction Lingo

Big Bag Tipping Station With Conevalve Contact Guerin Systems Sas

Big Bag Gross Weight Weighing Filling Station Technipes

Big Bag Gross Weight Weighing Filling Station Technipes

Entecon Industries Ltd Entecon Team Handling

Big Bag Tipping Station With Conevalve Contact Guerin Systems Sas

How To Choose A Carry On Bag The New York Times

Container Discharge Unit For Big Bags Contact Neu Jkf

Discharge Station For Bags And Big Bags Mksb Pdf Free Download

Innovative Bag Tipping Station For Hand Fed Ingredients On Vimeo

Innovative Bag Tipping Station For Hand Fed Ingredients On Vimeo

Big Bag Discharger Archives Spirotech Group Ltd

Bag Dump Station Sack Unloader Bag Emptier Drum Discharger

Bag Tip Station Standard And Custom Hoppers For Bag Emptying

Tetra Pak Big Bag Tipping Unit Vb005 Contact Guerin Systems Sas

Discharge Station For Bags And Big Bags Mksb Pdf Free Download

Industrial Sieve For Big Bag Tipping

kruti Process Technologies

Someone Found A Big Bag Of Meth At A Sohum Gas Station Today Sheriff S Office Says Lost Coast Outpost Humboldt County News

A Detailed Guide To Myeongdong Shopping What And Where To Buy

China Sugar Bulk Bag Dumping System Coffee Powder Big Bag Tipping Station China Bulk Bag Dumping System Sugar Bulk Bag Dumping System

Big Bag Unloading System Accessories Polimak

How To Tip Around Europe Guidelines For 48 Countries

Big Bag Gross Weight Weighing Filling Station Technipes

Sack Tip Stations For Powders And Granules Gimat Engineering

Our Favorite Diaper Bags Reviews By Wirecutter

Bag Dumping Station Compact 3in1 Sieve Youtube

Daxner Bulk Solids Technology Big Bag Discharge Systems

Tetra Pak Big Bag Tipping Unit Vb005 Contact Guerin Systems Sas

Big Bag Discharging Station Sr 1000 Ra Italtech Http Www Italtech Biz Products Oborudovanie Dlya Raboty S Myagkimi Konteynerami Tip Kontejner Cement Upakovka

Sack Tip Station Hanningfield

Www Globalpartnerdays Com Wp Content Uploads 02 Tetra Pak Powder Handling Pdf

China Sugar Bulk Bag Dumping System Coffee Powder Big Bag Tipping Station China Bulk Bag Dumping System Sugar Bulk Bag Dumping System

Discharge Station Mksb For Bags And Big Bags Buhler Group

High Quality Jambo Bag Discharger System 1000kg Big Bag Unloading Machine Buy Big Bag Unloading Machine Bulk Bag Unloading Machine Big Bag Unloader Product On Alibaba Com

Daxner Bulk Solids Technology Big Bag Discharge Systems

Sack Tip Station Hanningfield

Old Ystral Com Fileadmin User Upload Unternehmen Fachartikel Dispersing With A Lighter Touch Pdf

Www Stanelle De Pdf Stanelle Product Catalog Eng Pdf

China Dust Free Feeding Station Big Bag Unloading Station Tube Chain Conveyor Manufacturers Factory Rongxin

Sugar Bulk Bag Dumping System Coffee Powder Big Bag Tipping Station China Bulk Bag Dumping System Sugar Bulk Bag Dumping System Made In China Com

Zhongshan Elin Packaging Machinery Co Ltd Packing Machine Auger Conveyor

Tetra Pak Big Bag Tipping Unit Vb005 Contact Guerin Systems Sas

Nobody Likes To Drag A Big Or Hard To Carry Bag Around Traveltiptuesday Travel Tips Carry On Bag Travel

Big Bag Discharge Station Unloading Super Sacks

Big Bag Bosaltma Sistemi Modelleri Polimak

Bag Tipping Station Sacks Emptying Station An Engineering Guide

Big Bag Sack Discharging Dp0 Palamatic Process

Safety Sieving Nutraceutical Powders With Russell Finex

Bag Tipping Station Design Considerations Processing Magazine

Big Bag Tipping Station With Conevalve Contact Guerin Systems Sas

Package Vacuum Conveying Systems Simple Modular Packages For Dust Free Conveying Of Powders Granules Most Bulk Solids Brochure No Pdf Free Download

Gericke Sack Tip Station Youtube

Sonderkonst En

Daxner Bulk Solids Technology Big Bag Discharge Systems

Discharge Station For Bags And Big Bags Mksb Pdf Free Download

A Detailed Guide To Myeongdong Shopping What And Where To Buy

Amazon Com Baby Diaper Bag Backpack Baby Bag Multi Function Waterproof Travel Nappy Bag For Baby Care Large Capacity Durable And Stylish Changing Bag For Mom And Dad With Changing Pad B Grey

Sack Tip Station Hanningfield

Bag Tipping Station Sacks Emptying Station An Engineering Guide

Amazon Com Diaper Bag Backpack Mokaloo Large Baby Bag Multi Functional Travel Back Pack Anti Water Maternity Nappy Bag Changing Bags With Insulated Pockets Stroller Straps And Built In Usb Charging Port Gray Baby

Assets Tetrapak Com Static Documents Processing Big Bag Tipping Unit Vb006 Pdf

Big Bag Tipping Station With Conevalve Contact Guerin Systems Sas

Tetra Pak

Assets Tetrapak Com Static Documents Processing Big Bag Tipping Unit Vb006 Pdf

How To Tip Around Europe Guidelines For 48 Countries

China Sugar Bulk Bag Dumping System Coffee Powder Big Bag Tipping Station China Bulk Bag Dumping System Sugar Bulk Bag Dumping System

Automatic Big Bag Filling Station Flowmatic 02 Palamatic Process For Powders For The Food Industry

Home Bigbaginternational Bigbaginternational

Big Bag Gross Weight Weighing Filling Station Technipes

Big Bag Tipping Station With Conevalve Contact Guerin Systems Sas

Www Stanelle De Pdf Stanelle Product Catalog Eng Pdf

Daxner Bulk Solids Technology Big Bag Discharge Systems

Gericke Sack Tip Station Youtube

Smartpick

How To Achieve Efficient Big Bag Tipping Processing Magazine

Discharge Station For Big Bags Modular

Sabe Big Bag Station Agi

Bag Tipping Station Design Considerations Processing Magazine

Bag Tip Station Standard And Custom Hoppers For Bag Emptying

China Sugar Bulk Bag Dumping System Coffee Powder Big Bag Tipping Station China Bulk Bag Dumping System Sugar Bulk Bag Dumping System

Discharge Station Mksb For Bags And Big Bags Buhler Group

Big Bag Gross Weight Weighing Filling Station Technipes

Bag Tipping Station Sacks Emptying Station An Engineering Guide