5s Approach In Workshop Keeping

How To Design A Lean Storeroom Layout For Your Job Shop A Perfect 10 Methodology Part 1 Productivity Engineering Services Llc

5s Presentation For Beginners And Professionals For Implementation

Good Housekeeping Through The Implementation Of 7s Venvi

5s Lean Housekeeping Sort Set Shine Standardise Sustain

5s World Class Housekeeping Agile Lean Business Solutions Albs Hands On Lean Consultants Bangalore India

3

# Plastic drawer for keeping parts in factory Similar Images Add to Likebox # 5S methodology management with circle arrow line roll diagram Vector # 5S methodology management with circle arrow chart and icon banner Vector Similar Images.

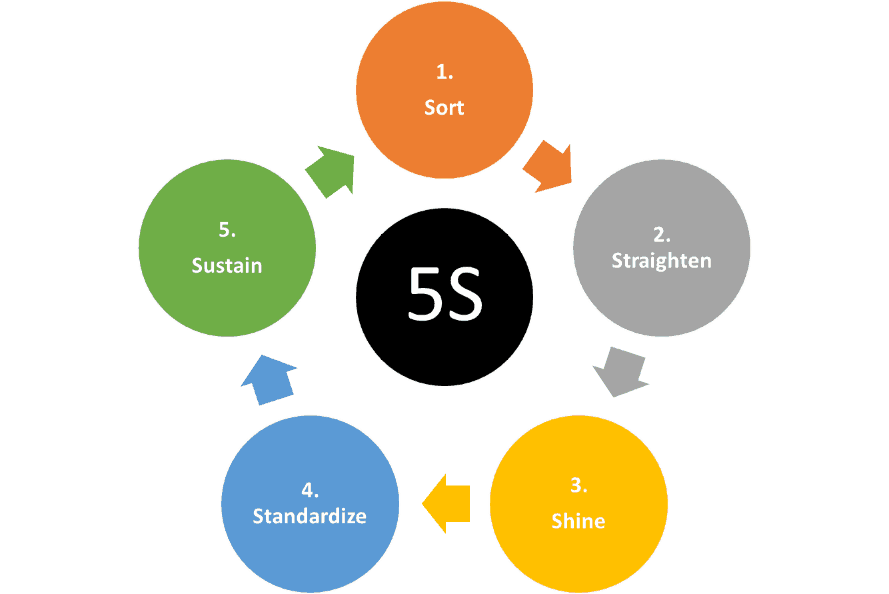

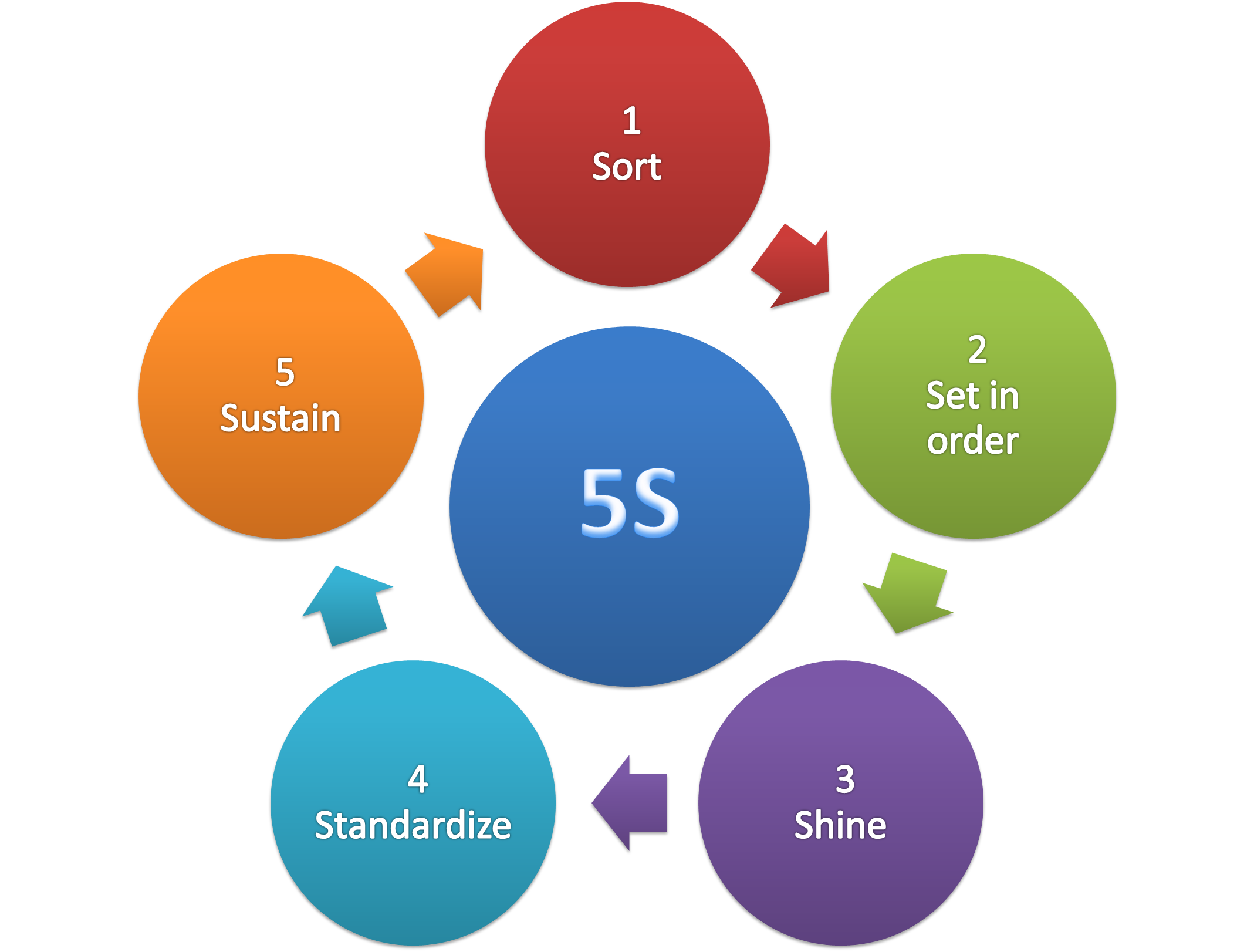

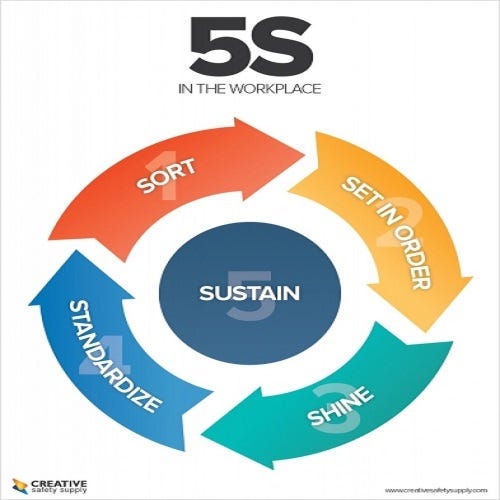

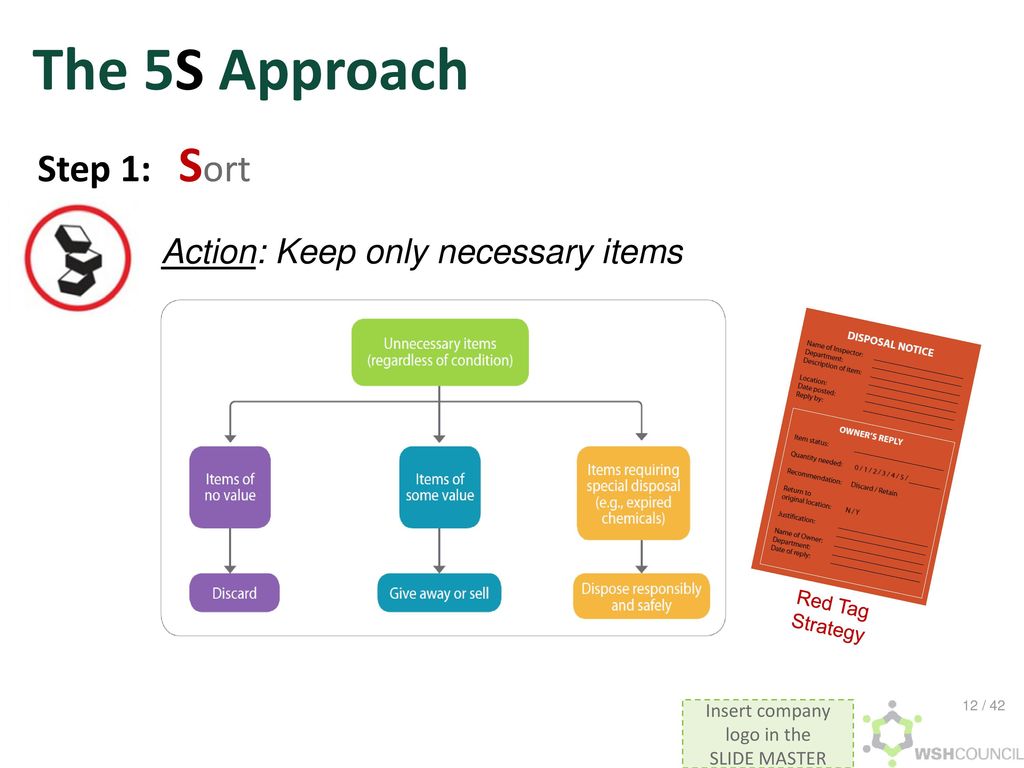

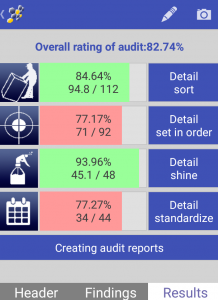

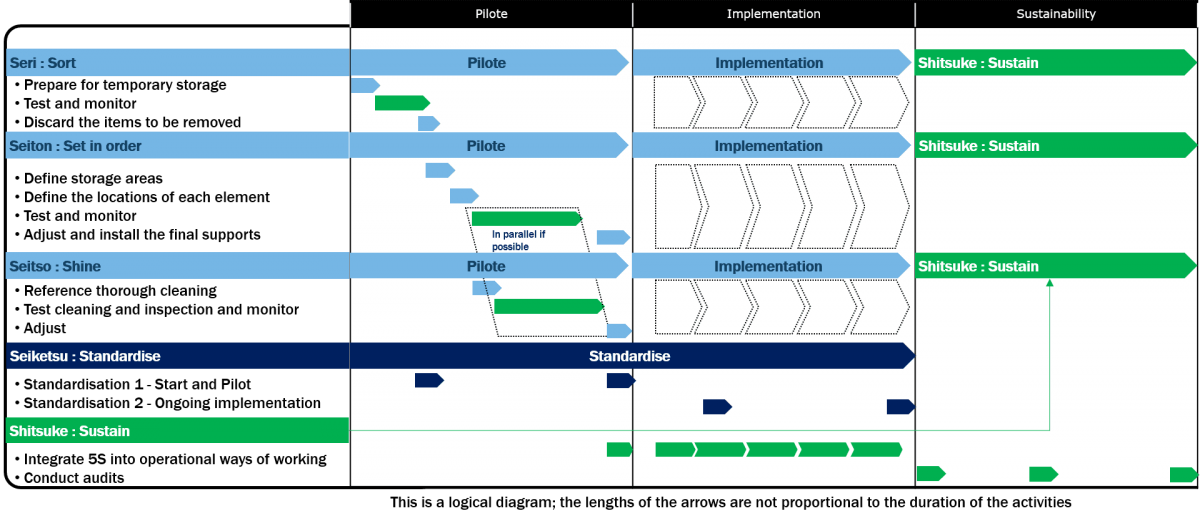

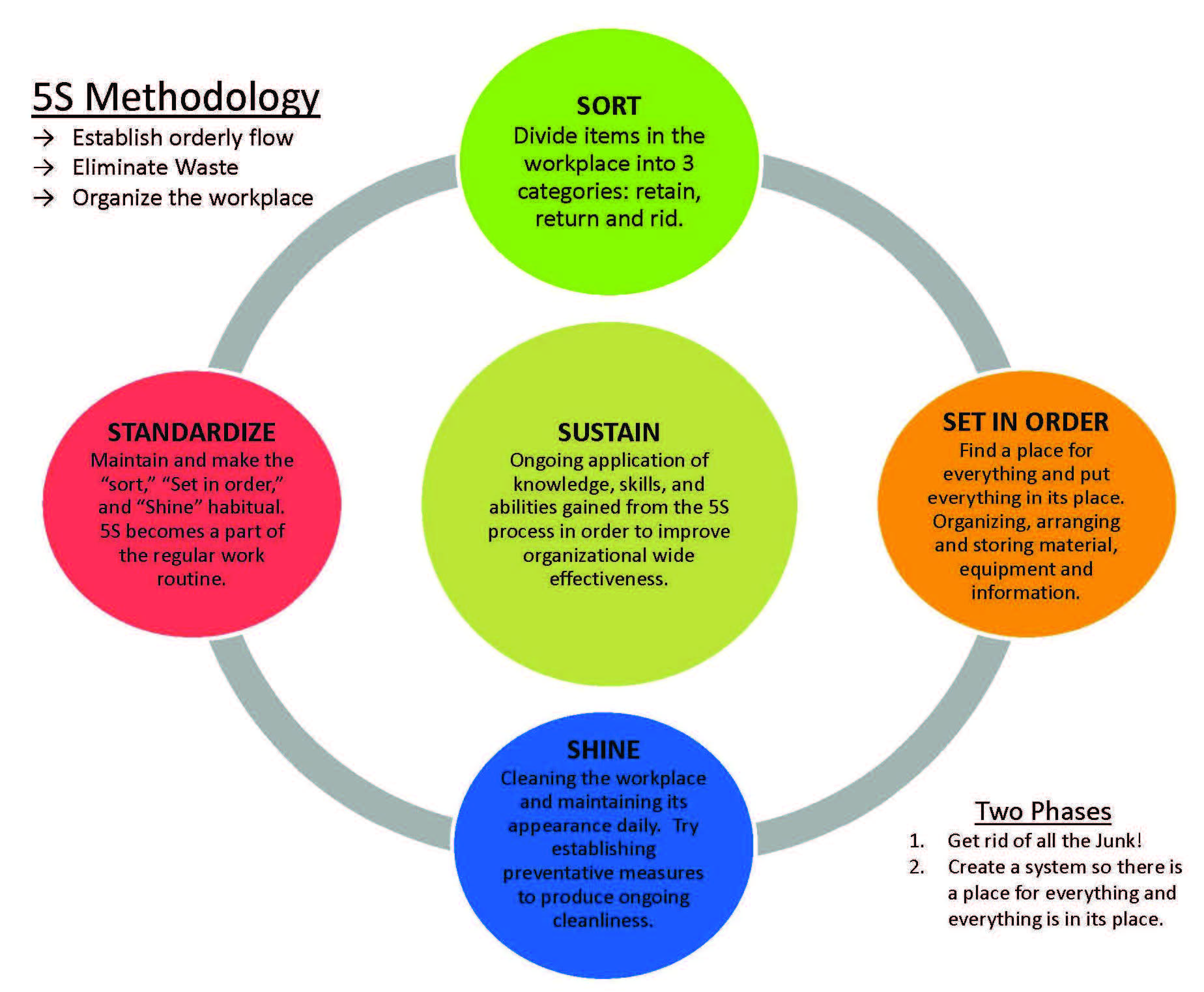

5s approach in workshop keeping. 1 Presentation of the 5S approach 2 Description of the 5 steps 3 Visual management 4 Workshop animation description 5 Key Success Factors to maintain 5S results and to set up continuous improvement 6 5S workshop on pilot project on a working area of your choice 7 Action plan with remaining tasks to be performed on the Pilot Project. The 5S system is often a starting place for implementing lean operations 5S in lean six sigma is the approach that ensures smart workspace organization known as ‘Good Housekeeping’ In order to be high performing, the organizational workplace should be clean, which is guaranteed through 5S. 5S is a methodology more commonly known in western cultures as “Lean Manufacturing” or just “Lean" Technically, however, 5S is slightly different from Lean Manufacturing 5S is a way of coordinating the workspace so that employees not only produce better results, but also practice and maintain safer working conditions.

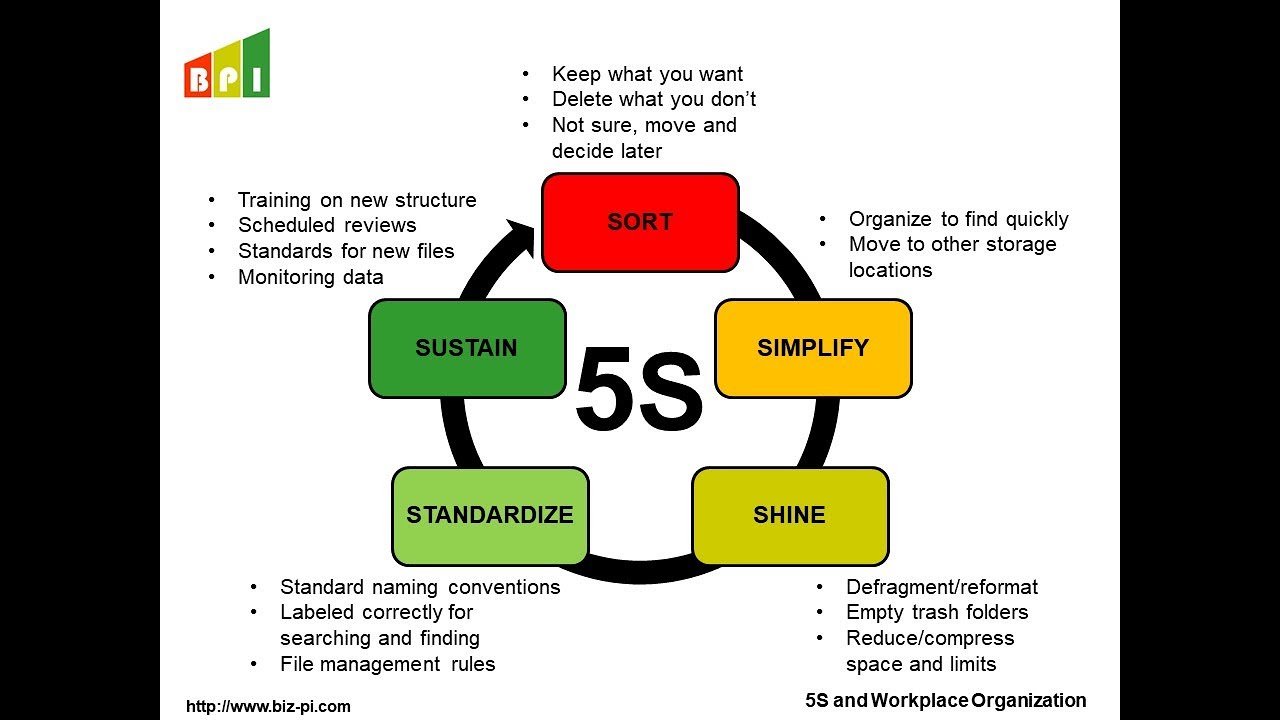

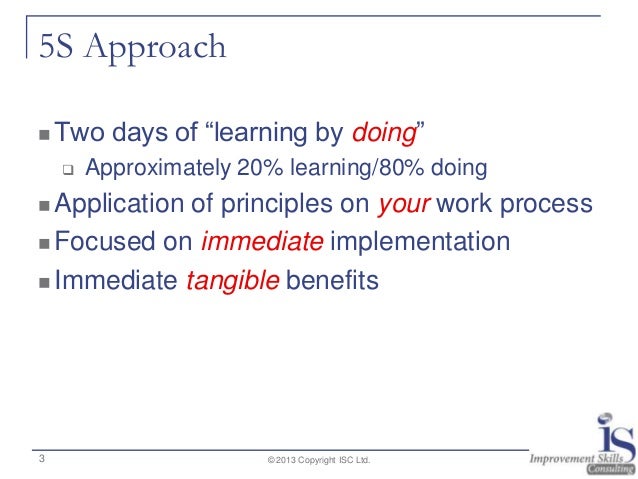

Sustain (shitsuke) – think longterm and make sure your culture supports 5S The last part, sustain, also has many great recommendations for keeping things in order in the long term Sustaining is all about building a remarkable culture and maintaining order and discipline in the workplace The last step in the 5S methodology, it recommends. The 5S methodology is a simple yet effective technique to improve the way your office functions Let’s explore how implementing this methodology can establish discipline, order, and efficiency in your workplace History of 5S 5S is believed to have started as early as the 16th century with the Venetian shipbuilders in Venice, Italy. 5S training & Workshop is designed to cater the needs of every level of staff in an organisation on keeping the workspace safe, pleasant and productive It is not all about housekeeping and cleaning But it is the simplest productivity improvement methodology.

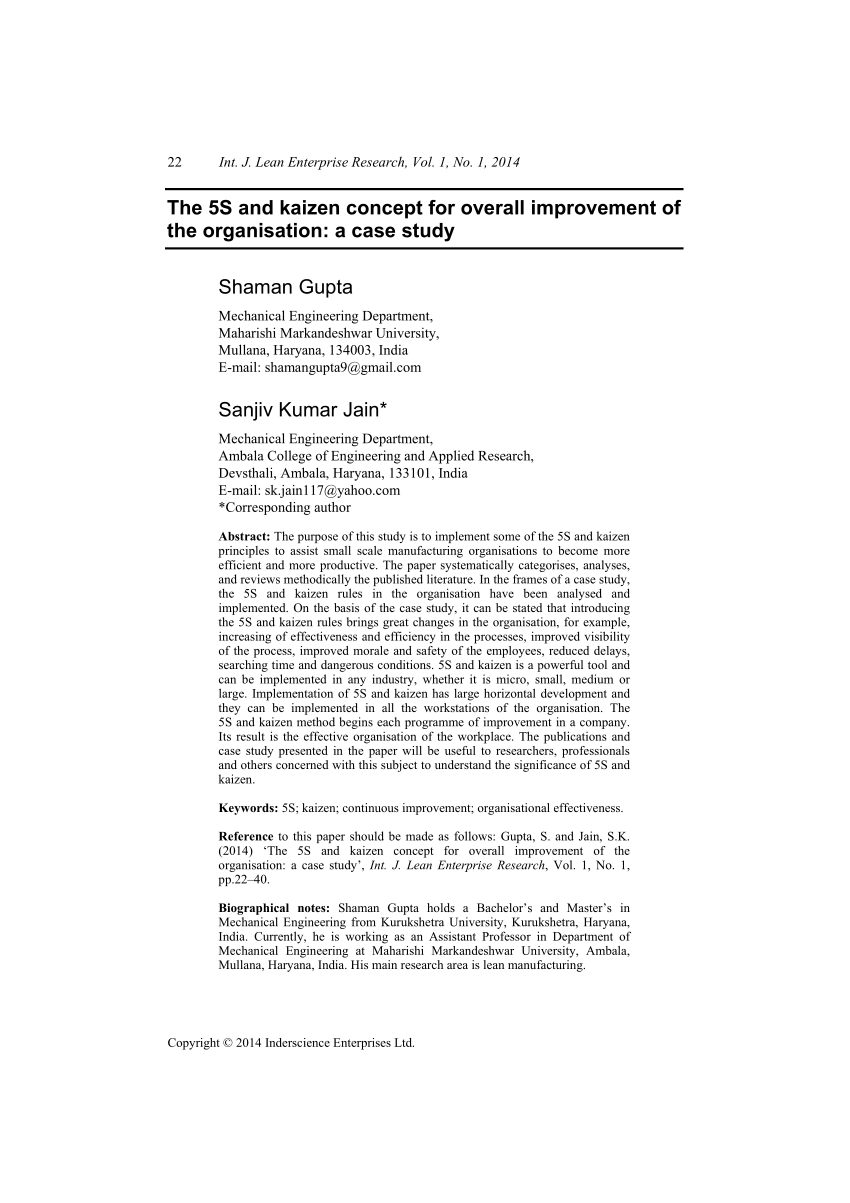

The 5S method is a structured program to implement workplace organisation and standardisation A well organised workplace motivates people, both on the shopfloor as well as others 5S improves safety, work efficiency, improves productivity and establishes a sense of ownership 5S is developed in Japan and stands for. Workshops and Presentations 5S METHODOLOGY 5S METHODOLOGY Citations (0) Keep up with your stats and more Access scientific knowledge from anywhere or. The 5S Action Team, which consists of workshop leaders and ordinary employees, is responsible for the nuts and bolts of 5S implementation The team members study 5S theory while putting it into practice in making 5Soriented improvements Step 2 Establish a 5S Implementation Plan.

5S Workplace organization and standardization 5S is a process of work place organization and house keeping which is carried out gradually and systematically The 5S method is a structured program to implement workplace organisation and standardisation A well organised workplace motivates people, both on the shopfloor as. 5S A Visual Control System for the Workplace gives a self study program for a commonsense lowcost approach to process management by providing a method for organizing a workplace, especially a shared workplace such as a workshop or an office space, and keeping it organized 5S is often referred to as being housekeeping, however this characterization can be misleading, as workplace organization. 5's workshop summary 1 5’S WORKSOP SUMMARY5S is a systematic approach to good house keeping It is gaining a strong supporting most industries in Japantoday, and there is an increasing number of companies which are implementing 5S with greater involvement ofpeople within the organisationWhy is it becoming popular among companies in Japan?.

The 5S system is a lean manufacturing tool that improves workplace efficiency and eliminates waste There are five steps in the system, each starting with the letter S By providing a systematic framework for organization and cleanliness, 5S helps facilities avoid lost productivity from delayed work or unplanned downtime The Steps of 5S. The 5S methodology was born at Toyota in the 60s under an industrial environment to achieve better organized, tidier, and cleaner workplaces to increase productivity and to obtain a better working environment The 5S methodology has been widely spread, and many companies and organizations are implementing it worldwide Although it is conceptually simple and does not require a complex training. Because 5S requires the involvement of everyone in the shop 5S is about creating the discipline, standard work, accountability and teamwork necessary to sustain It's the same discipline, standard work, accountability and teamwork it will take on everything else on the CI journey to transform the plant and then sustain worldclass performance.

5S is a philosophy and methodology for organizing and managing the workplace and work flow with the intent of improving efficiency by eliminating waste and improving flow Simply put, 5S is a method for organizing a workplace, especially a shared workplace (like a shop floor or an office space), and keeping it organized. In Japan, 5S originated as part of the famous Toyota production system, which is noted for its efficiency and lack of waste Regardless of the exact words, proponents of 5S all agree that it is a powerful but practical approach for transforming a shop or factory At Merritt Tool Co in Kilgore, Texas, 5S stands for. QUESTION One of the most basic practices of lean is 5S at each work station Though we have spent time to set up each work station using the 5S approach, we seem to fall short on the "Sustain" element We use audits to seek compliance and still struggle with this fundamental task.

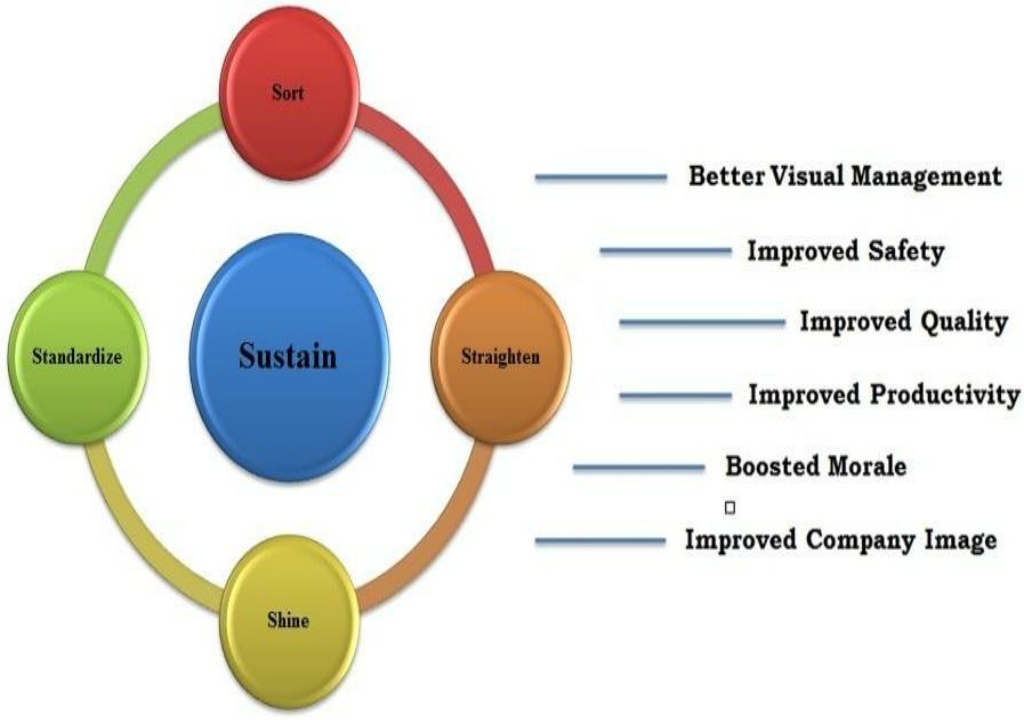

To summarize the connection between 5S Good Housekeeping practices and ISO 9001, let’s say that implementing 5S is a way of having a methodology to approach how to work with ISO 9001 clauses It gives you benefits by making it easy to track down and improve workspace inefficiencies. 5S in the Workplace Many manufacturing facilities have opted to implement the “5S” methodology to promote continuous improvement, organization, and lean manufacturing processes at the workplace The term refers to five pillars Sort Remove all items not needed for current production operations. 5S is a methodology of management consisting of five steps that are repeated in a manufacturing or industrial setting to ensure quality, limit waste, and maximize employee time and efforts 5S was developed in Japan and was documented during a study of Japanese manufacturing methods in the late 1980’s.

5S is a Lean strategy that helps accomplish a basic objective making problems visible Having a clean and organized warehouse is about more than just looking great It’s about having more efficient fulfillment warehousing operations, excelling at training, and encouraging communication. Keep an organized database of 5S Lean audit results as reference for future 5S projects Top Industries That Benefit from 5S Lean Initially gaining popularity through its usage in improving manufacturing processes, companies outside of the manufacturing industry discovered that the 5S methodology was versatile enough to be used for other types. The 5S Action Team, which consists of workshop leaders and ordinary employees, is responsible for the nuts and bolts of 5S implementation The team members study 5S theory while putting it into practice in making 5Soriented improvements Step 2 Establish a 5S Implementation Plan.

Housekeeping is housekeeping, not 5S 5S is a visual system and a system for engaging employees 5S must be a team effort and the results must enable anyone to "tell at a glance" what is right and what is out of place It also must make doing the work easier Implementing 5S occurs in two phases initial implementation and later refinement. 5S in lean six sigma is the approach that ensures smart workspace organization known as ‘Good Housekeeping’ In order to be high performing, the organizational workplace should be clean, which is guaranteed through 5S. Simply put, 5S is a systematic approach to workplace organization But it’s also much more than that 5S is about efficiency, competitiveness, and survival It is a deceptively simple system that creates an organized and productive workplace.

The 5S methodology is a tool to enhance continuous improvement of lean manufacturing processes and, as a lean methodology, it is to institute a highly efficient, clean, and safe working. 5S is a formulaic method you can use to straighten and organize a work area Using 5S reduces waste (a fundamental goal in lean manufacturing), improves safety (see our article on Lean 6S Safety), and otherwise improves your production process and work environment. 5S is a lean tool to eliminate or minimize waste 5S is commonly used by industrial world especially manufacturing industry 5S is a methodology for improving the quality of organisation 5S is a system to reduction waste, productivity optimization and quality through maintaining and organizing workplace.

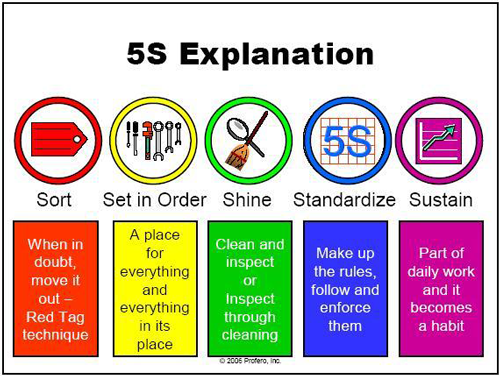

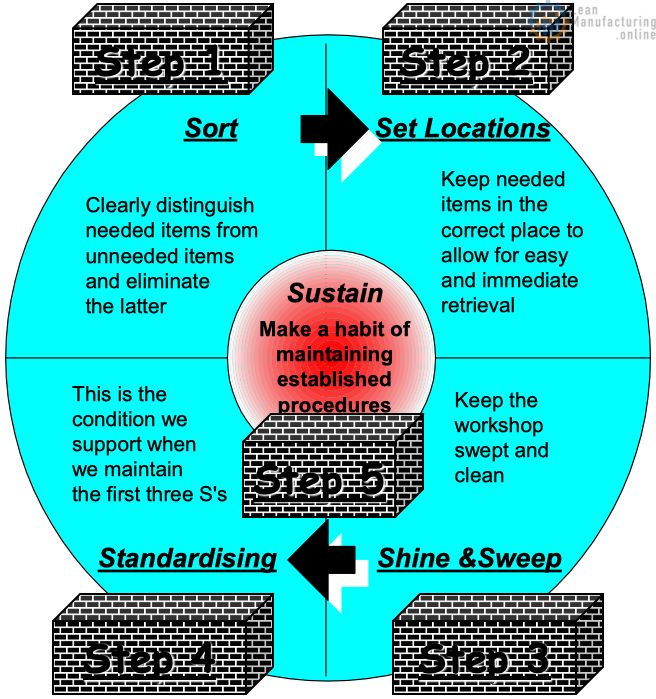

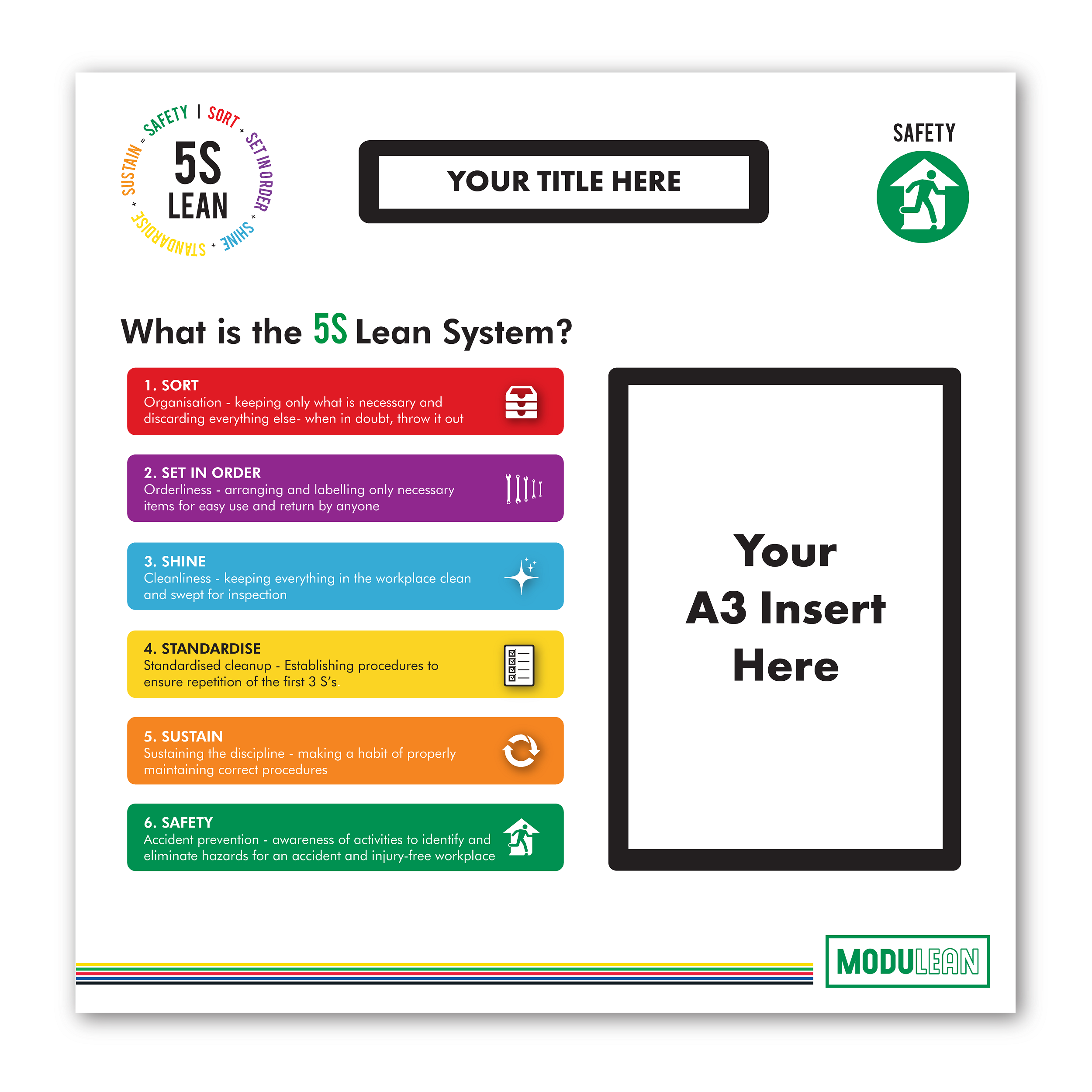

A 5S Visual Workplace Organization deployment is often the first step to a broader Lean Management initiative Workshop Benefits The benefits of applying the 5S Visual Workplace Organization methodology on a workspace or area are Reduction of waste, mainly defects, motion, waiting and transportation results in lower costs,. 11 What Is ‘5S’?. The five in a 5S workplace organizational and housekeeping methodology refers to five steps – sort, set in order, shine, standardize and sustain Safety should be the honorary sixth “S” Many manufacturing facilities have opted to follow the path towards a “5S” workplace organizational and housekeeping methodology as part of continuous improvement or lean manufacturing processes.

The fifth and final S in the 5S model stands for SUSTAIN, and this is the most difficult of the stages to implement in practice It is difficult because this stage circles back on all the prior stages to ensure that they are being appropriately maintained and updated as necessary. The 5S approach shows determination to organize the workplace, keep it neat and clean, establish standardized condition and maintain the discipline that is needed to do the job Now there have been multiple changes in 5S, it can be reduced to 4S or modified to 6S The 6th S can be Safety 1 Sort Separate out all that is unneeded and eliminate it. Successful 5S organizations know how to keep things interesting Look for areas that can be improved and ways to make cleaning fun and rewarding Pay attention to what other organizations are doing—new ideas and advances in the 5S System come along often Remember housekeeping is an ongoing practice.

5S is a methodology more commonly known in western cultures as “Lean Manufacturing” or just “Lean" Technically, however, 5S is slightly different from Lean Manufacturing 5S is a way of coordinating the workspace so that employees not only produce better results, but also practice and maintain safer working conditions. Simply put, 5S is a systematic approach to workplace organization But it’s also much more than that 5S is about efficiency, competitiveness, and survival It is a deceptively simple system that creates an organized and productive workplace It’s not just about cleaning up and eliminating toolboxes 5S creates. Keep only what you need and remove everything else Clear the clutter and assign places for everything Sort out your belongings and keep them where they should be 2 Stabilizing or Straightening Out (Seiton) Industrial There should be a place for everything and everything should be in its place The place for each item should be clearly indicated.

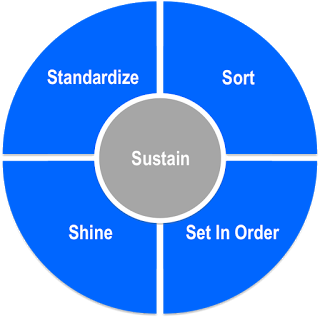

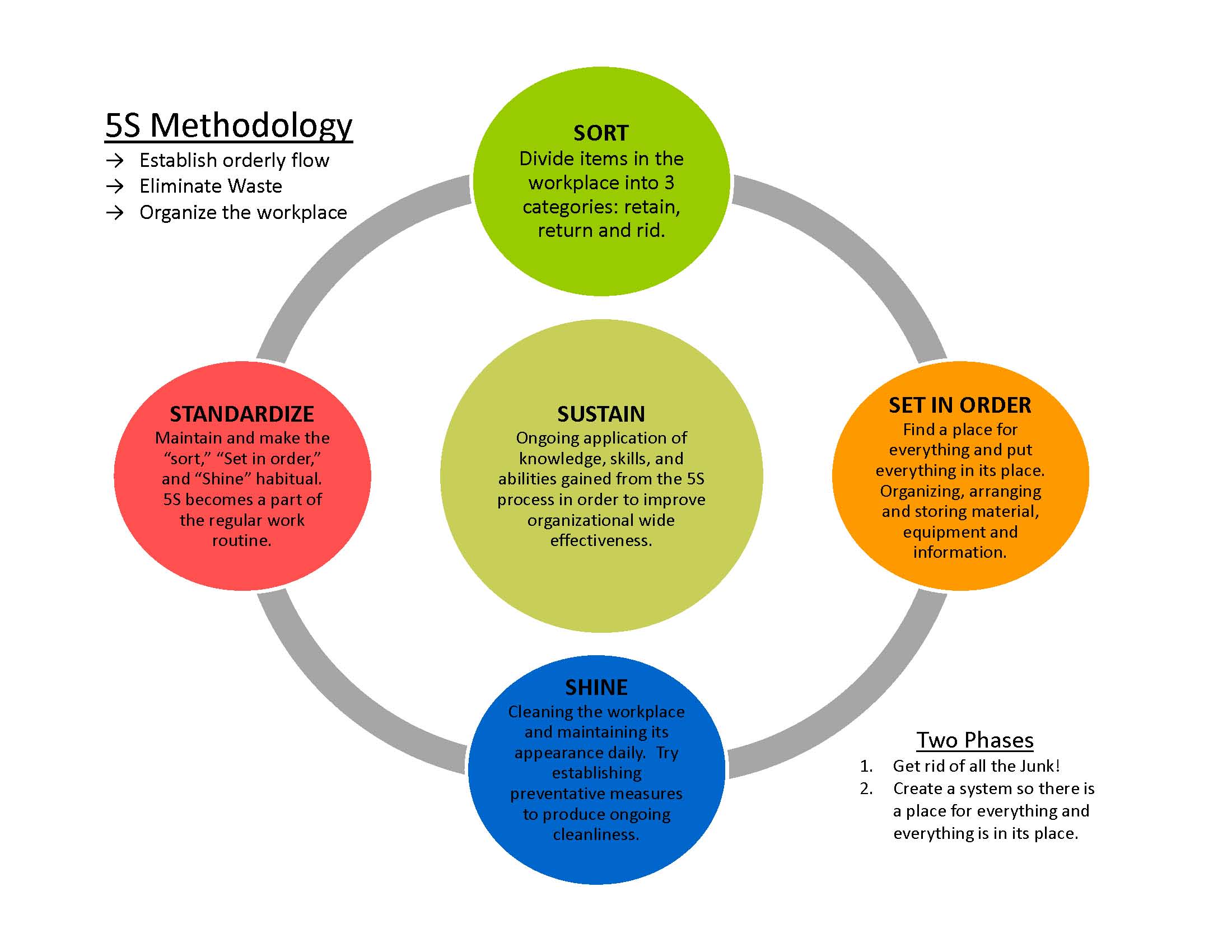

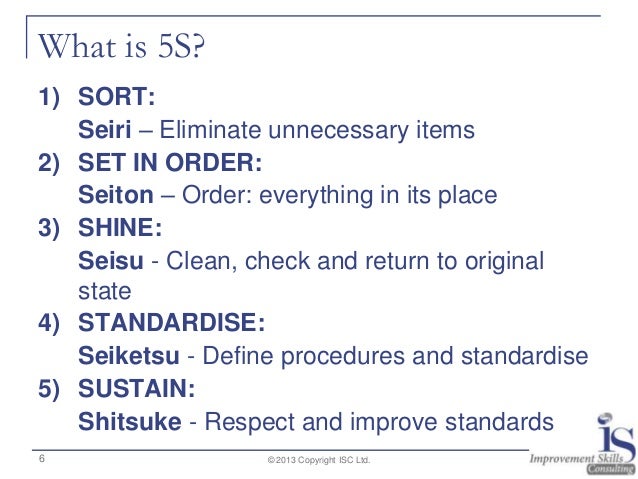

Let’s begin by getting those who haven’t heard of 5S up to speed Here are a few definitions of 5S to get you in the ballpark US EPA “ 5S is a system to reduce waste and optimize productivity through maintaining an orderly workplace and using visual cues to achieve more consistent operational results Implementation of this method “cleans up” and organizes the workplace. In simple terms, the five S methodology helps a workplace remove items that are no longer needed (sort), organize the items to optimize efficiency and flow (straighten), clean the area in order to more easily identify problems (shine), implement color coding and labels to stay consistent with other areas (standardize) and develop behaviors that keep the workplace organized over the long term (sustain). We get everything clean and looking like new, and we keep everything clean and looking like new A standardised method for cleaning and tidying any operational area so that nothing is out of place, nothing is dirty longer than a day, and anyone visiting the office cannot fail to be impressed with the cleanliness of the.

The 5S approach is highly effective at removing waste from your workplace and creating a safer, cleaner, and healthier work environment Simple techniques are used to develop and improve effective workplace organization, safety, visual communication, and general cleanliness and housekeeping 5S Workshop. Gemba Kaizen A Commonsense Approach to a Continuous Improvement Strategy by Masaaki Imai An essential resource sharing the system of kaizen His chapter on 5S is pithy yet densely packed with wisdom about why exactly this approach provides real traction on the improvement path Visual Workplace, Visual Thinking by Gwendolyn Galsworthy A. • 5S is a philosophy and a way of organizing and • NDP was designed to test TQM approach for health care quality and safety improvement • NDP was conducted in US (19 1990) and Japan (0004) identification of storage areas to keep necessary items.

5S is a systematic way to improve and maintain the level of housekeeping in the workspace This is because the cornerstone of efficiency is to have a clean and safe working environment But it isn’t enough to just say ‘oh, I’ll simply clean up after myself’. The 5S approach was never meant to be a onetime event, but an ongoing cycle This is key, because early successes in 5S can open the way for problems If open space becomes available in the Sort step, but afterward, tools and materials are allowed to gradually fill in that space without any organization, the end result can be an even bigger mess. 5S is amongst the first and fundamental steps implemented by an enterprise towards the path of implementing Total Quality Management and continuous improvement at the operation level 5S is a process designed to organize the workplace, keep it clean, maintain effective and standard conditions.

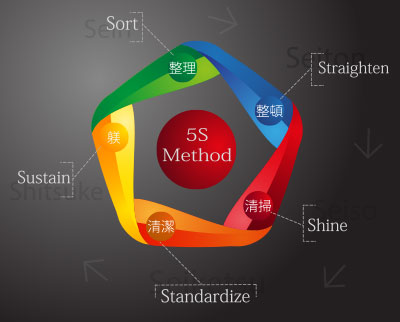

In simple terms, the five S methodology helps a workplace remove items that are no longer needed (sort), organize the items to optimize efficiency and flow (straighten), clean the area in order to more easily identify problems (shine), implement color coding and labels to stay consistent with other areas (standardize) and develop behaviors that keep the workplace organized over the long term (sustain). On top of it, 5S is also applied to keep workplaces safe at all times (free of falling objects or potential hazards) and maintain it through time The objective is to reduce costs, identify defects quickly and encourage selforganization Check how different industries are applying the 5S methodology 5S in industries 5S for restaurants 5S at. 5S training & Workshop is designed to cater the needs of every level of staff in an organisation on keeping the workspace safe, pleasant and productive It is not all about housekeeping and cleaning But it is the simplest productivity improvement methodology It can be successfully implemented by everyone, every day, everywhere – at every size of the organisation, whether it is a manufacturing, tool room, bank counter, restaurant, hospital, medical shop, IT company or be your home.

Housekeeping is housekeeping, not 5S 5S is a visual system and a system for engaging employees 5S must be a team effort and the results must enable anyone to "tell at a glance" what is right and what is out of place It also must make doing the work easier Implementing 5S occurs in two phases initial implementation and later refinement. 5S is a method of work organized in 5 stages with the goal of significantly improving the order and cleanliness 5S are particularly effective because they want to improve the housekeeping of your workshops and the rest of your premises in order to obtain the following advantages. • 5S is a philosophy and a way of organizing and managing the workspace and work flow with the intent to improve efficiency by eliminating waste, improving flow and reducing process unreasonableness It is for improvement of.

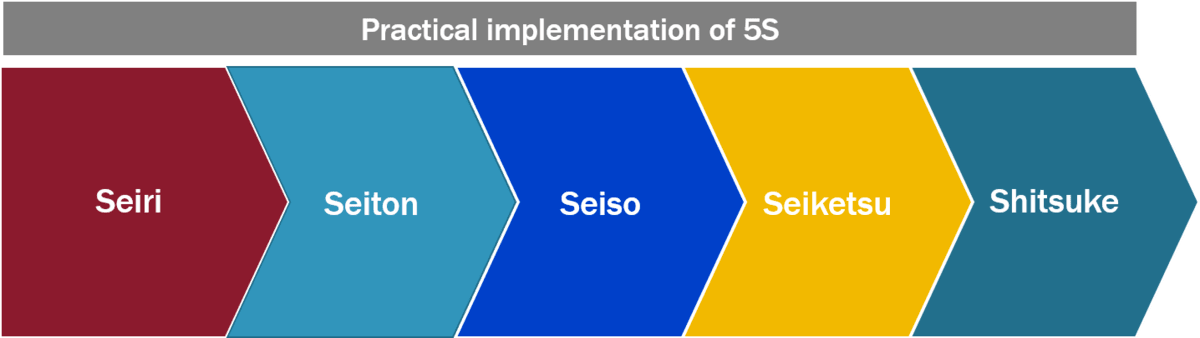

5S is a system to reduce waste and optimize productivity through maintaining an orderly workplace and using visual cues to achieve more consistent operational results. Course5Sdocx 18 June 10 Page 1 of 3 Introduction to 5S Training Workshop Welcome to the oneday 5S training course by Lifetime Reliability Solutions Introduction to 5S 5S is workplace management where the work area and workplace are organised and ritualised to minimise the loss of time and the use of movement. ‘5S’ in simple terms is a Japanese technique consisting of five ‘S’terms namely Seiri (sorting), Seiton (set in order), Seiso (shine), Seiketsu (standardize) and Shitsuke (sustain) having a deep sense for managing the work place.

5S is a philosophy and methodology for organizing and managing the workplace and work flow with the intent of improving efficiency by eliminating waste and improving flow Simply put, 5S is a method for organizing a workplace, especially a shared workplace (like a shop floor or an office space), and keeping it organized. „5S‟ is one of the Japanese techniques which was introduced by Takashi Osada in the early 1980s 2 It is basically a workplace management methodology which helps for improving working environment, human capabilities and thereby productivity 6 The word „5S‟ represents. The 5S methodology is a simple yet effective technique to improve the way your office functions Let’s explore how implementing this methodology can establish discipline, order, and efficiency in your workplace History of 5S 5S is believed to have started as early as the 16th century with the Venetian shipbuilders in Venice, Italy.

The fifth and final S in the 5S model stands for SUSTAIN, and this is the most difficult of the stages to implement in practice It is difficult because this stage circles back on all the prior stages to ensure that they are being appropriately maintained and updated as necessary. 5S SHINE – What is it?. 5S is a philosophy and methodology for organizing and managing the workplace and work flow with the intent of improving efficiency by eliminating waste and improving flow Simply put, 5S is a method for organizing a workplace, especially a shared workplace (like a shop floor or an office space), and keeping it organized.

Once an organization determines the 5S strategies are a good fit for the company, they need to start planning out how to implement 5S Proper implementation will require physical changes to the facility, as well as training employees and other parties to operate in accordance with the 5S methodology It can take quite some time before 5S is fully implemented, but there will be significant.

5s Method Housekeeping Factory Systems

5s Workplace Organisation Clic Cumbria Learning And Improvement Collaborative

Lean Thinking And Methods 5s Sustainability Us Epa

5s Workshop Lean Practice Group

5s Methodology Wikipedia

Implementing 5s Methodology The First Step Toward Workplace Efficiency Updated

Pdf The 5s Lean Method As A Tool Of Industrial Management Performances

What Is 5s In Lean Kanban Tool

Work In Progress Queensland Today S Agenda This Is Your Meeting Amsafety Brief Site Representative 9 05amintroduction To Lean And 5s Principles Ppt Download

19 5s Ideas Lean Manufacturing Visual Management Kaizen

Http Www Intracen Org Uploadedfiles Intracenorg Content Exporters Exporting Better Quality Management Assetpdf Bulletin eqm 5s Pdf

Method 5s Explanations And Example Of The 5s Lean Sesa Systems

3 Top Ways A 5s Event Brought Order To Our Metal Fabrication Shop Wiley Metal

Pdf An Application Of 5s Concept To Organize The Workplace At A Scientific Instruments Manufacturing Company

5s Methodology And Tips Youtube

Tpm Improves Equipment Effectiveness Lean Production

5s 5s Methodology Quality One

6s Housekeeping Workplace Organization Quality Management Selangor Malaysia Kuala Lumpur Kl Shah Alam Training Workshop

Http Ieomsociety Org Pilsen19 Papers 224 Pdf

Why Choose Aig For 5s Consulting By Advance Innovation Group Medium

Keys And Tips To Implement The 5s Methodology

5s A Quality Improvement Tool For Sustainable Performance Literature Review And Directions Emerald Insight

Pdf Implementation Of 5s Method For Ergonomic Laboratory

2

5s Oee Tpm Within Automotive Supply Company Pjr Lean Associates Ltd

Ppt Lean Six Sigma Dmaic Workshop Green Belt Part 6 Powerpoint Presentation Id

What Is 5s In Lean Kanban Tool

Key Benefits Of 5s Process Implementation Lean And Operational Excellence Support For Calgary Edmonton And Alberta Companies

Www Jica Go Jp Project Bangladesh 002 Materials Ku57pqgtcss Att Implementation Of 5s In Hospital Setting Pdf

Training Slides On Workplace Housekeeping Ppt Download

Www Jica Go Jp Activities Issues Health 5s Kaizen Tqm 02 Ku57pqpi3y4 Att Malaw 02 Pdf

The 5s System Lean Manufacturing Methodology

5s Stock Photos And Images 123rf

Www Theseus Fi Bitstream Handle Olli Nissinen Thesis Metropoliameng Pdf Sequence 1 Isallowed Y

Trainings And Workshops Service 5s Practice Service Consultants From Pune

Food 5s Certification Of Japanese Way Of House Keeping Hard Copy In Delhi Id

The 5s System Lean Manufacturing Methodology

What Is The 5s System Definitions Core Concepts Principles Graphic Products

Lean Six Sigma World Conference Ws Lean Six Sigma Yellow Belt Certification Workshop

Circle Design Clipart Text Line Diagram Transparent Clip Art

5s Lean Manufacturing And Six Sigma Definitions

Office 5s Implementation Workshop

Review This History Of 5s

Http Iopscience Iop Org Article 10 10 1757 9x 95 1 Pdf

Lean De Martin Ag Wangi

What Is 5s 5s System Is Explained Including Tips On Getting A 5s Program Started

Office 5s Implementation Workshop

Keys And Tips To Implement The 5s Methodology

5s 7 Wastes Online Version Coming Soon Center For Competitiveness

5s Continuous Improvement Blog

5s What Is A 5s Event Kaizen Event Lean Manufacturing

5s 5s Methodology Quality One

5s Methodology And Tips Youtube

5s Method Housekeeping Factory Systems

5s Workplace Organization Six Sigma Study Guide

Japanese Terminology For 5s Is Seiri Seiton Seiso Seiketsu And Shitsuke Continuously Improving Manufacturing

The Ultimate Guide To 5s Improving Workplace Efficiency Tulip

The 5s System Lean Manufacturing Methodology

5 S Workshop Summary

What Is 5s 5s System Is Explained Including Tips On Getting A 5s Program Started

Implementing 5s Methodology The First Step Toward Workplace Efficiency Updated

Modulean Shadow Boards 5s Information Board Shb001

Pdf Implementing 5 S Methodology In Pix Transmisssion Limited Nagpur

5s Lean Manufacturing Training Video

Practical Implementation Of 5s Method

Slogan 5s Gambaran

How To Apply 5s Method To Improve Shop Efficiency 18 12 06 Snips

A Practical Approach To The Successful Practice Of 5s

5s A Quality Improvement Tool For Sustainable Performance Literature Review And Directions Emerald Insight

5s Approach Wells Hygiene Specialists

Digital E Learning What Is 5s Methodology 5s Workplace Methodology 5s Lean Manufacturing 5s Workplace Organization Facebook

5s Program A Quality Tool Or Good Housekeeping

How To Implement Lean 5s Visual Workplace Organization Operational Excellence Consulting Llc

5s S Of Self Development

5s Method And How It Is Used To Organize Production

National Workshop For Coordinators In Management Of Quality Concepts Qcfi Quality Circle Lqc 5s Kaizen Total Quality Management Training Certifications

Ultimate Guide To Theory Of Constraints Smartsheet

Q Tbn And9gcsgkyuctoovyu8 Dv3rfc7cm Qd1ic281fteiisxua Usqp Cau

Q Tbn And9gcrswe5ngqqk7zdmrgtcuous Oo2xjplshwkur4nth Y6uxdk2dp Usqp Cau

Let S Get Organized How To 5s Your Desk Continuous Improvement Blog

Image Result For 5s Principles Of Housekeeping Workplace Lean Six Sigma Operations Management

Konmari 5s Goes Mainstream

Free 5s Training Presentations Ppt And Pdf To Download

Http Www Intracen Org Uploadedfiles Intracenorg Content Exporters Exporting Better Quality Management Assetpdf Bulletin eqm 5s Pdf

Jemds Com Latest Articles Php At Id 152

5s Continuous Improvement Blog

The 5s System Lean Manufacturing Methodology

5s Implementation Workshop

5s Safetyculture

Success With The 5s Method Hoffmann Group

5s In Hospitals Workshop

Office 5s Implementation Workshop

Q Tbn And9gctgaa8rkb4qr2gbjjp4 Tklrfg1y8o6euqeqrregviqciyxe6r7 Usqp Cau

Www Localenterprise Ie Discover Business Supports Lean Lean Implementation In Micro Small Enterprises Book Of Cases Digital Copy Of Book 1 Pdf Pdf

Practical Implementation Of 5s Method

5s Continuous Improvement Toolkit

What Is 5s 5s System Is Explained Including Tips On Getting A 5s Program Started

5s Method And How It Is Used To Organize Production