Iso 12100 Risk Assessment

Risk Assessment

Safety Qr004 En P

Onorm En Iso 13 Safety Of Machinery General Principles For Design Risk Assessment And Risk Reduction Iso 10 Austrian Standard

En Risk Assessment Tecnical Standards Industrial Machinery

Annex B Different Frameworks Of Risk Assessment Prosafe

Une En Iso 12 Safety Of Machinery General Principles For Design Risk Assessment And Risk Reduction Iso 10 European Standards

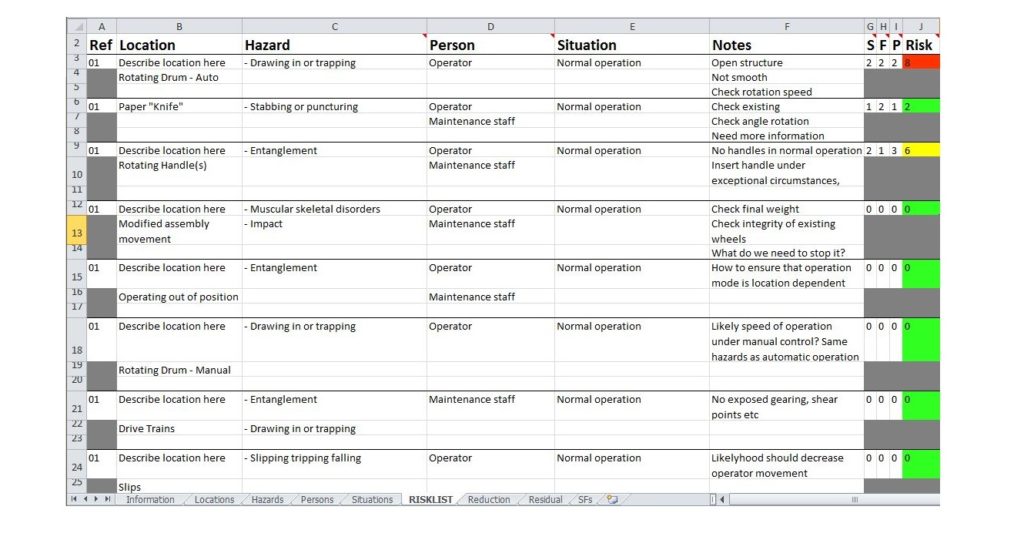

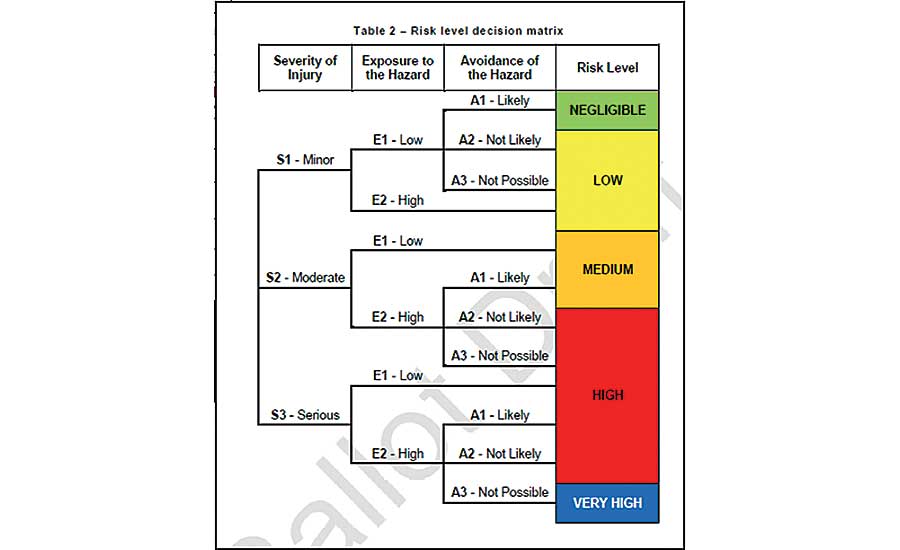

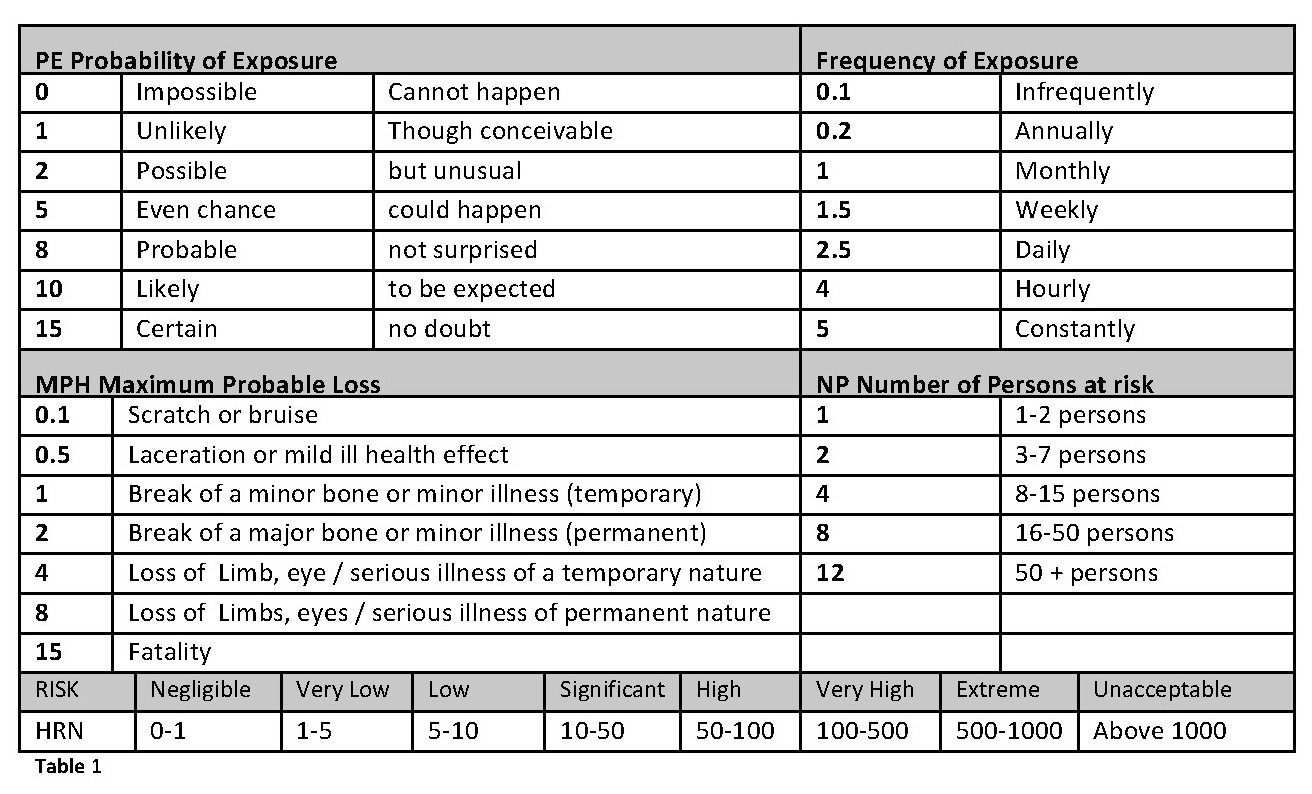

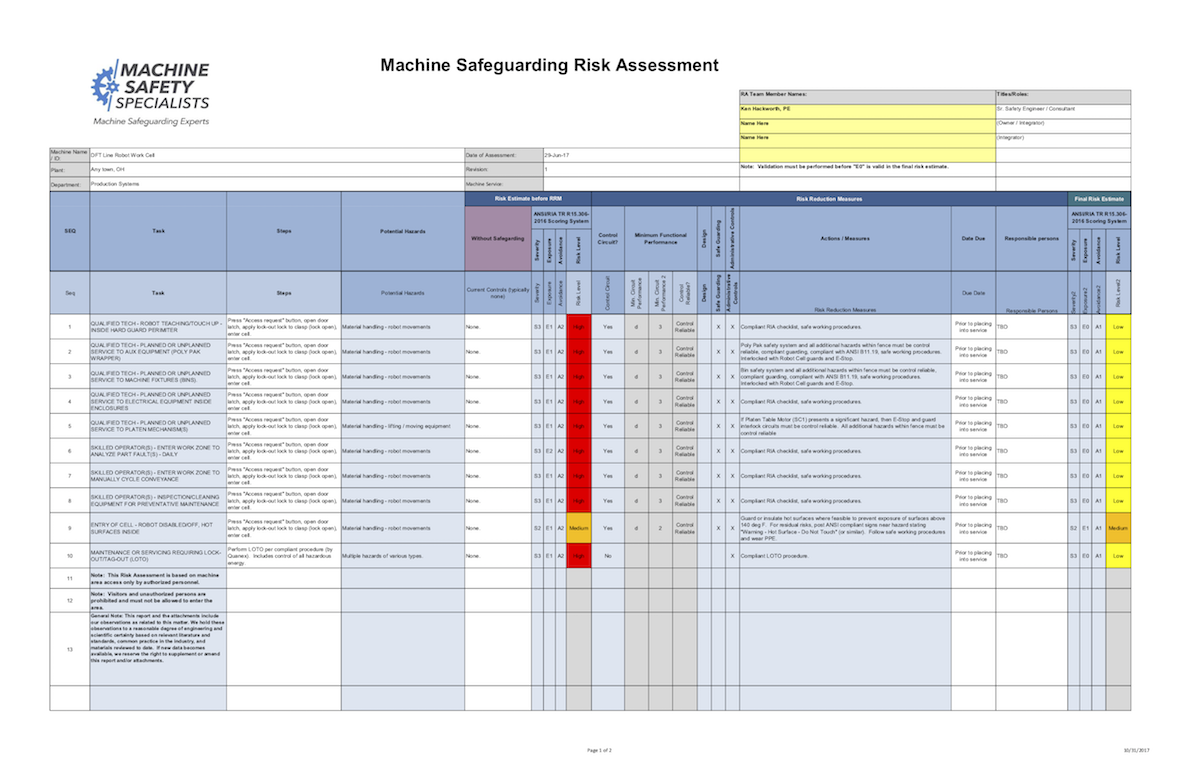

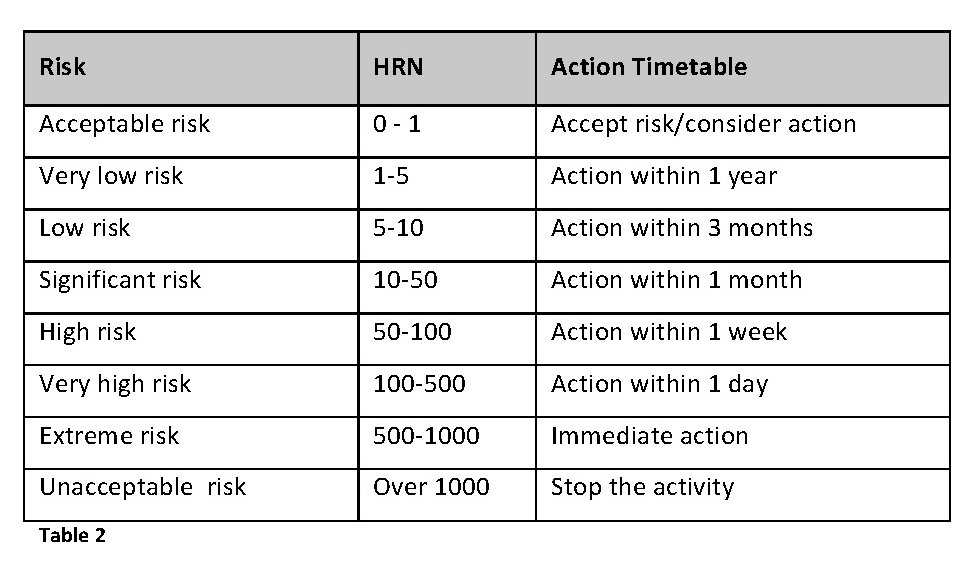

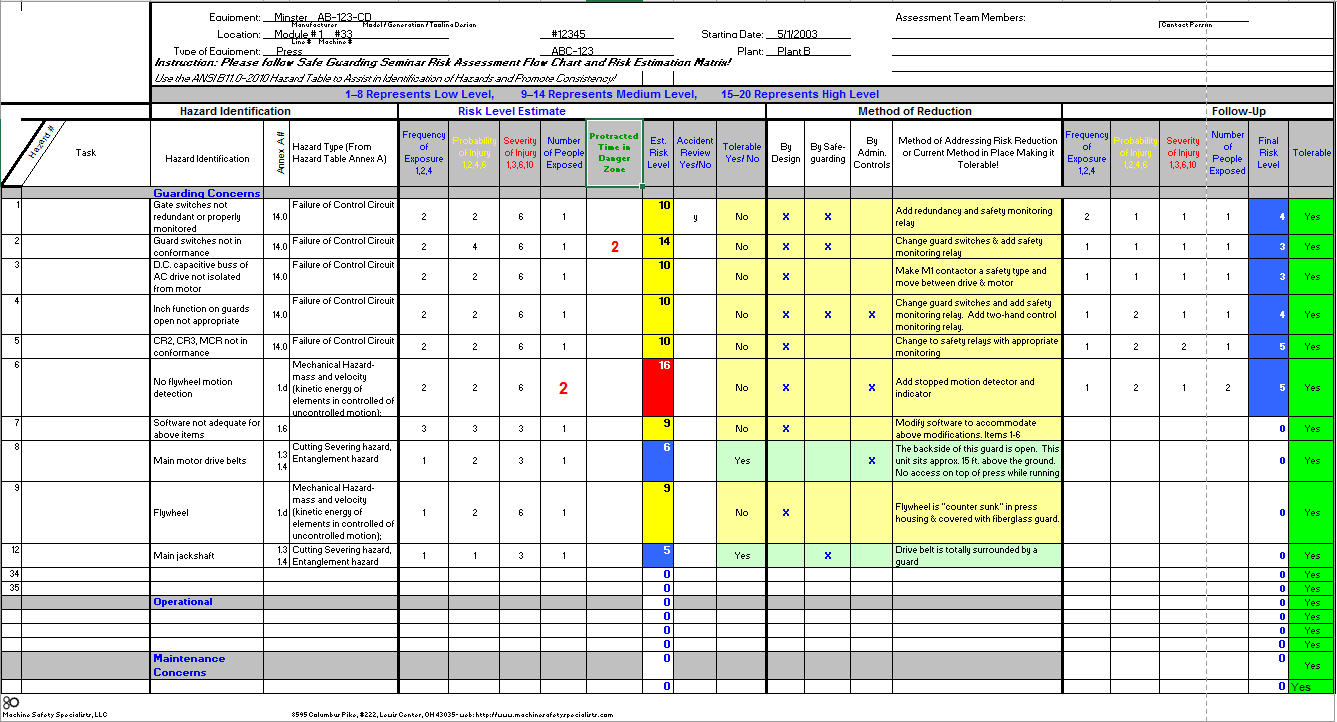

This machine has been assessed with guidance from BS EN ISO The risk assessments are quantative assessments, with ratings assigned, to identify potential risks to exposed persons and any additional safety measures required to eliminate or control the risks to an.

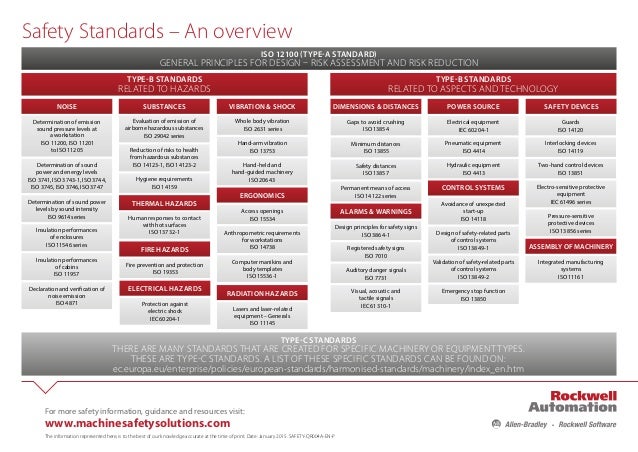

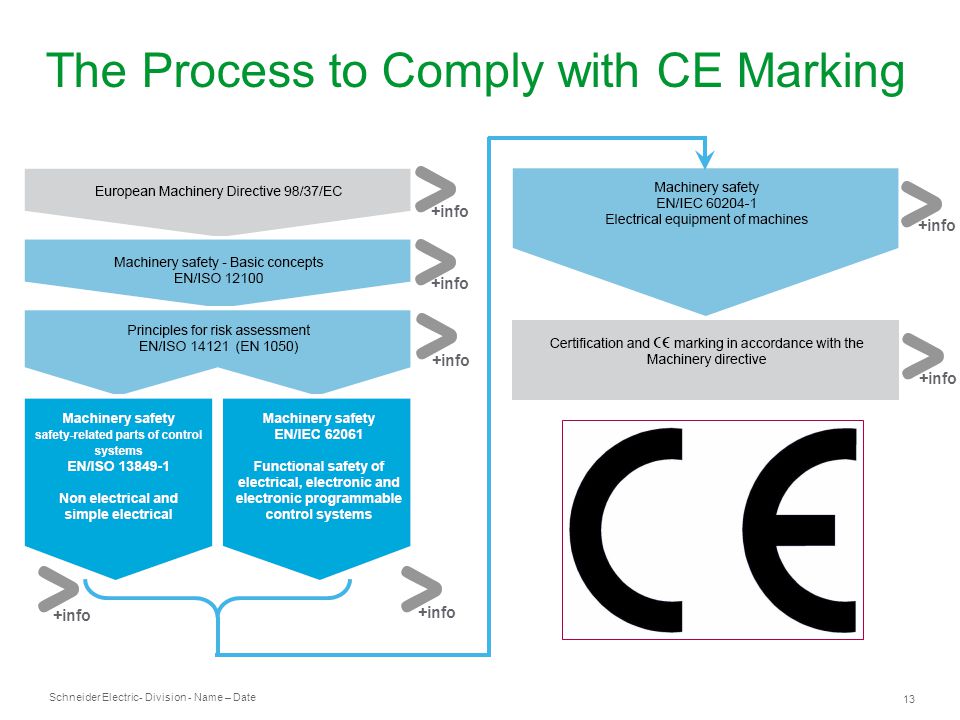

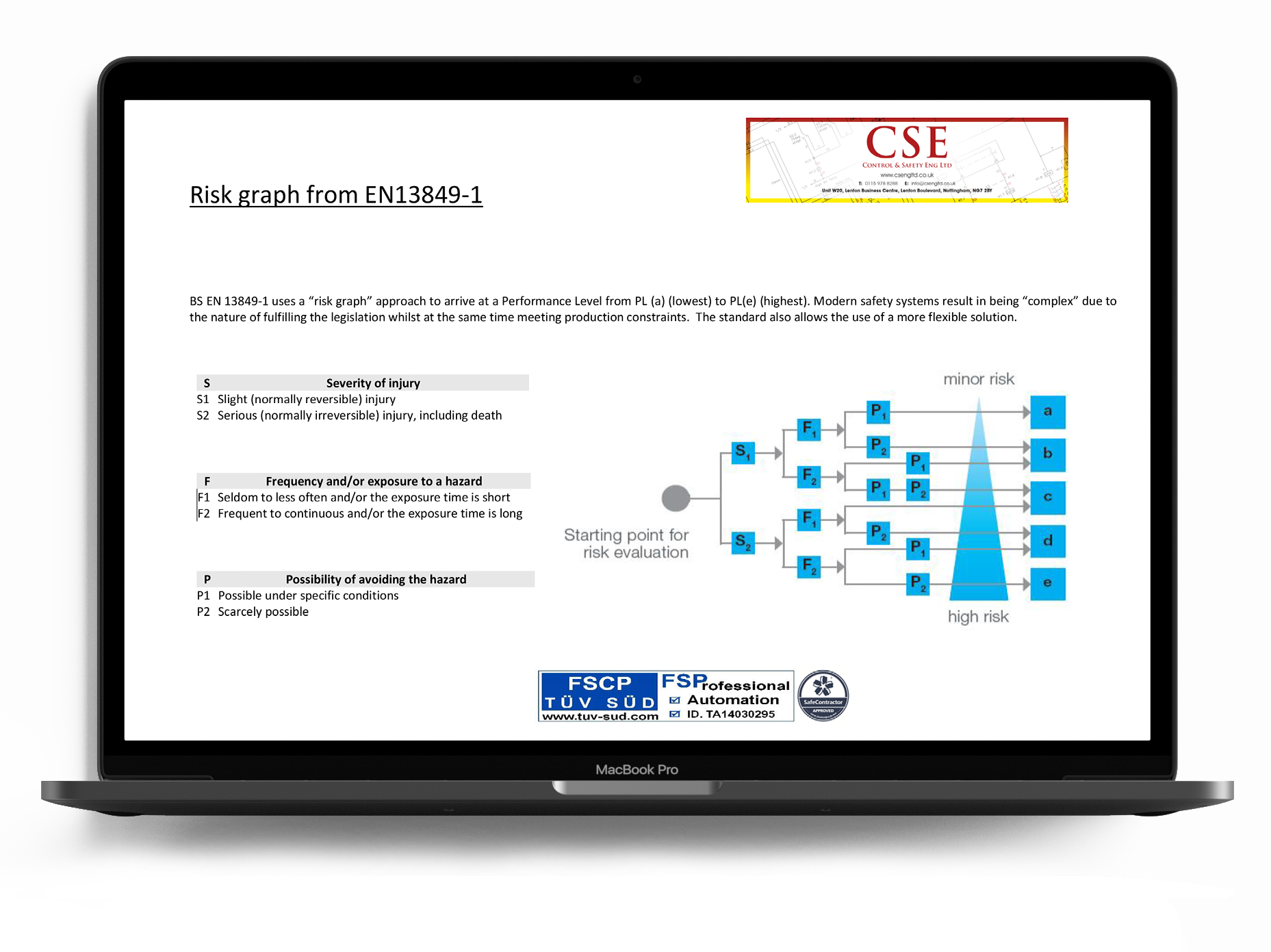

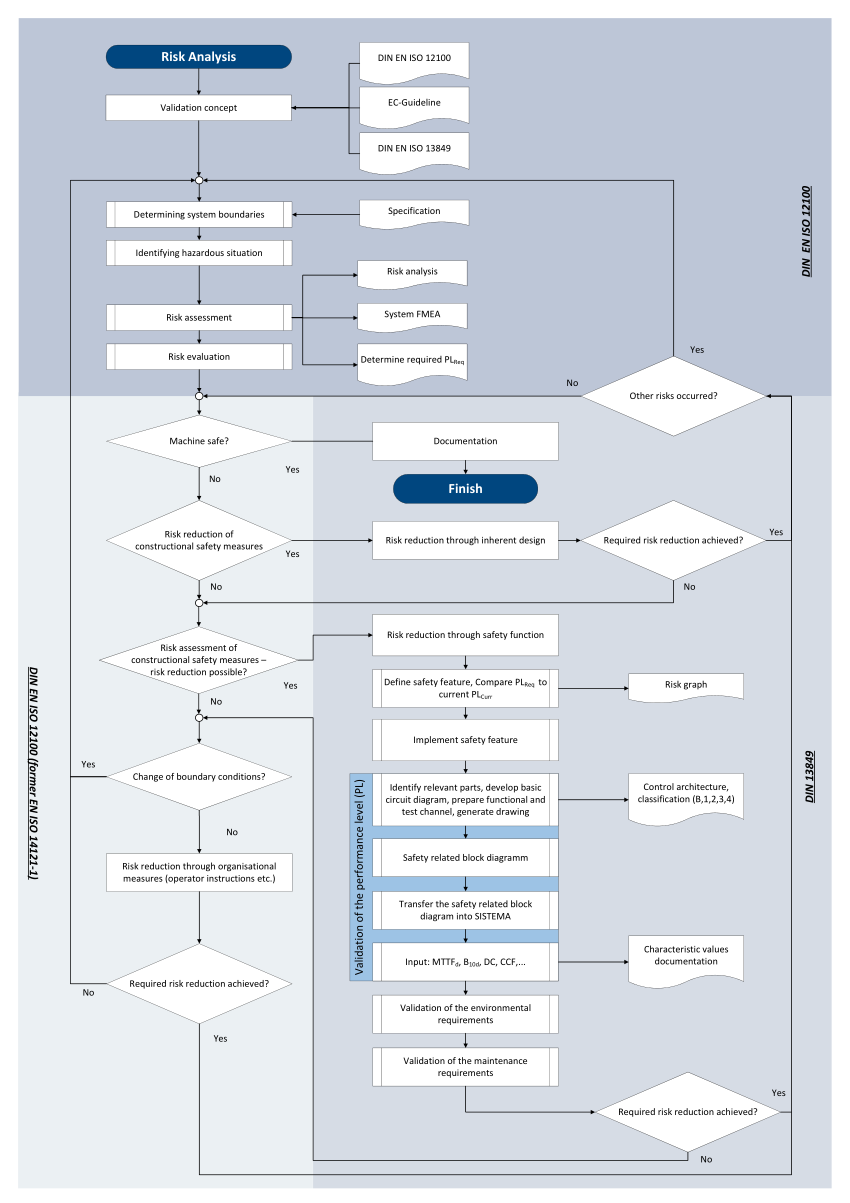

Iso 12100 risk assessment. EN ISO is a standard which focuses on the safety of machinery and how it can be designed with safety in mind to prevent or lower the risks of hazards to people. This article will take you through a risk assessment example by using procedures and methods from ISO and the old ISO Risk assessment is a way of finding risks and hazards in your machine design All machine designers have to make sure their machines are safe for humans to operate. Design and risk evaluation of the machine EN ISO Functional and safety requirements for safety related control systems Design and realisation of safety related electrical control systems EN ISO EN 661 Electrical safety aspects EN IEC 604.

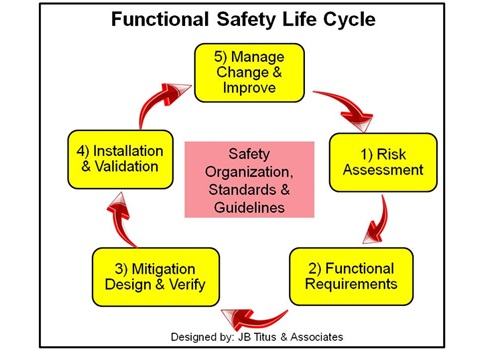

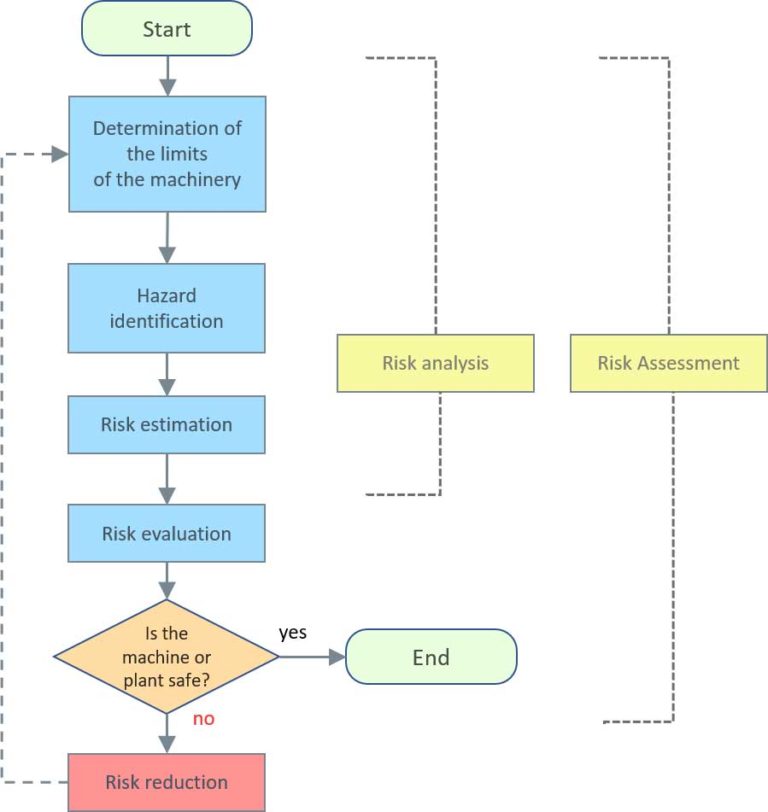

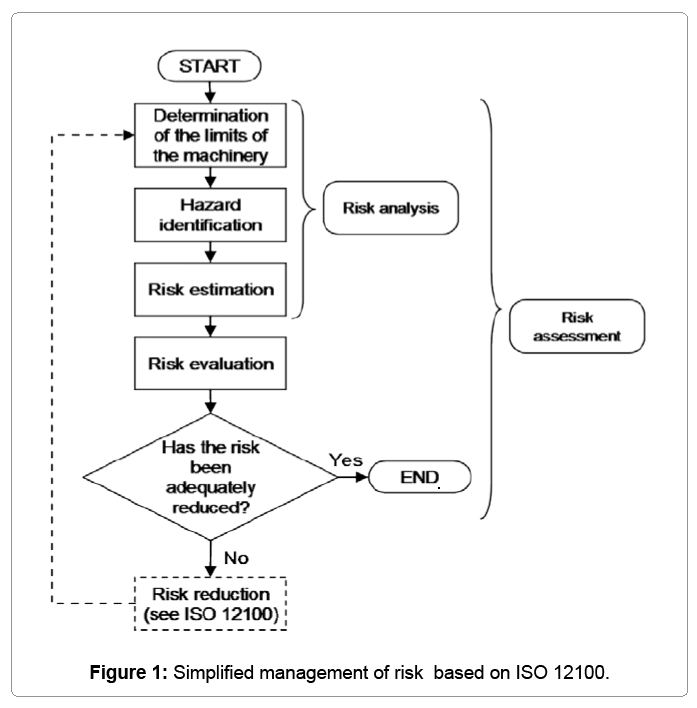

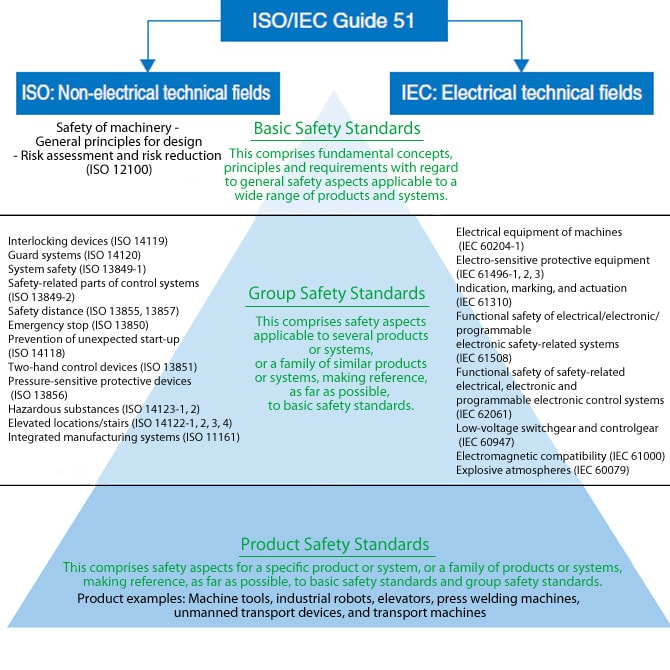

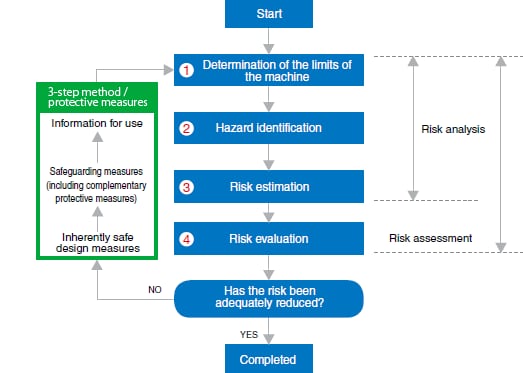

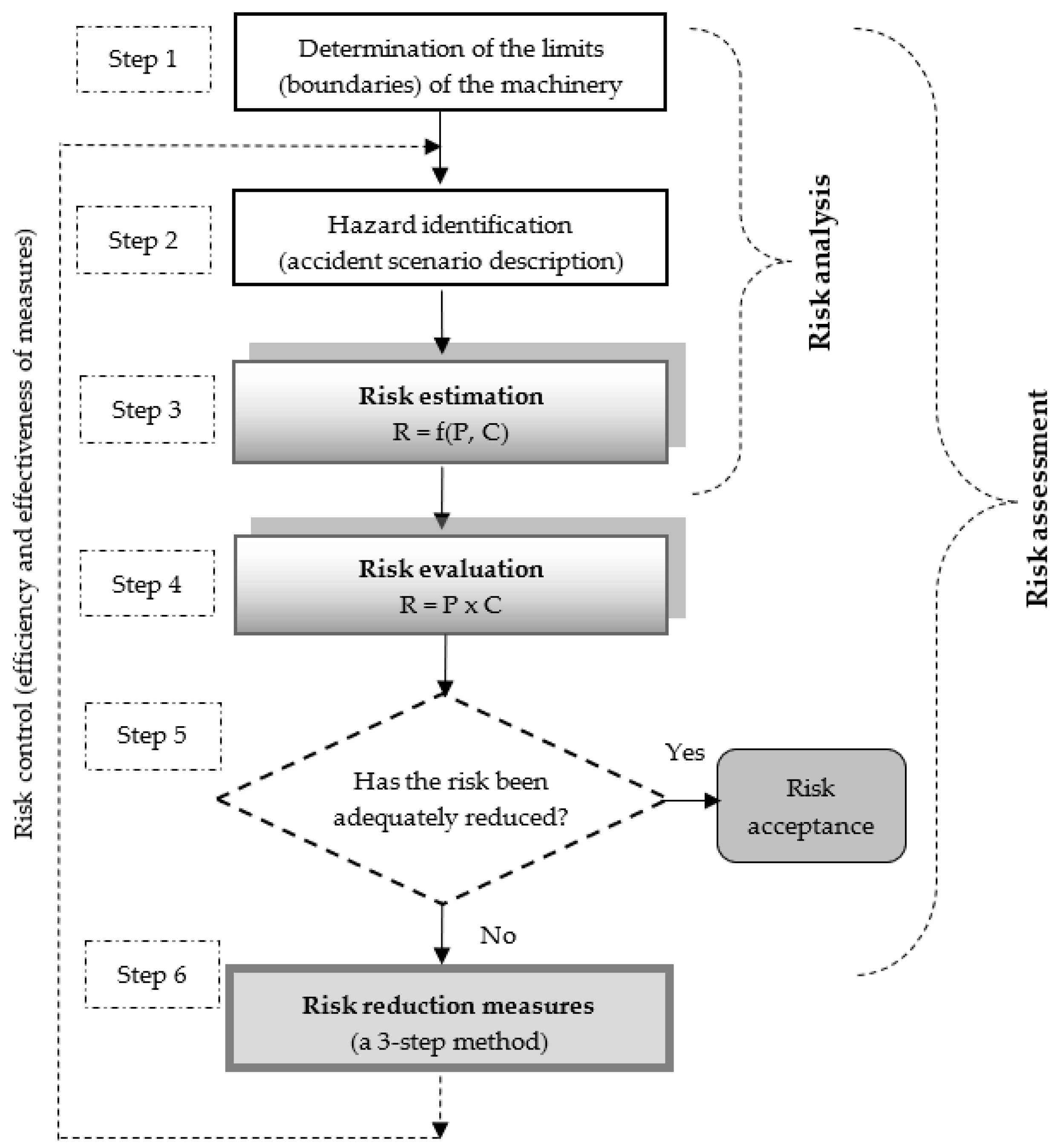

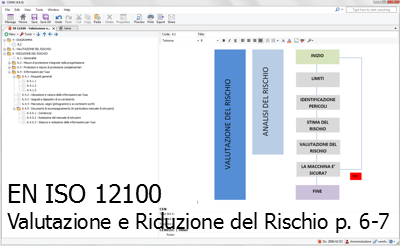

The following flowchart shows the risk assessment process established by ISO 1Determination of the limits of the machinery Risk assessment begins with the determination of the limits of the machinery, taking into account all the phases of the machinery life. EN ISO Safety of machinery General principles for design Risk assessment and risk reduction The main topic of EN , which went into effect on November 10, is Machinery Safety With this expression, the Norm defines as follow The ability of a machine to perform its intended function (s) during its life cycle where risk has been adequately reduced. The risk assessment process requires information related to the description of the machine, applicable standards and regulations, experience of use, and relevant principles of ergonomics The concept of risk as defined by ISO also implies the existence of a source of hazard and the probability that it could result in harm.

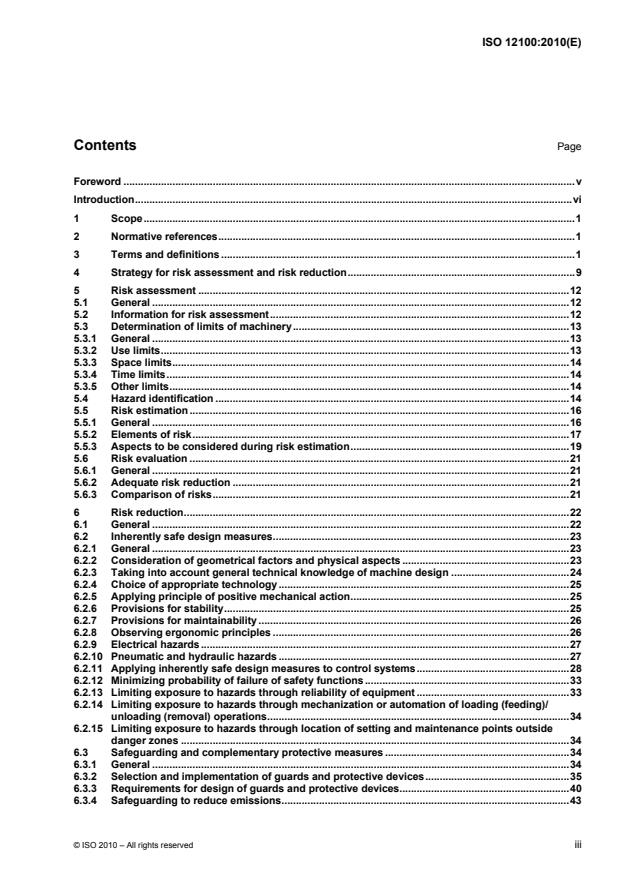

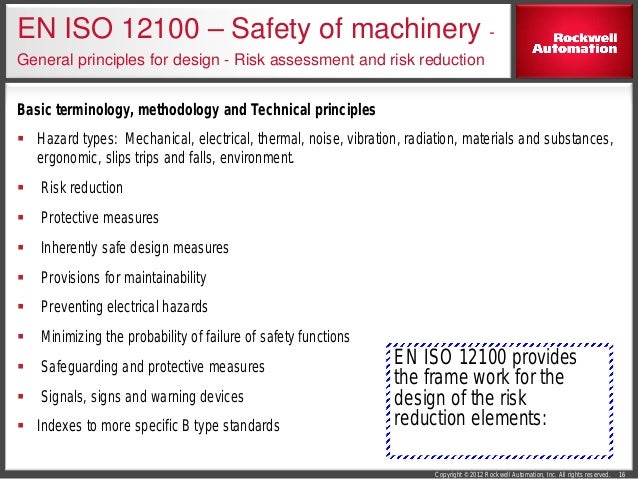

Safety of machinery General principles for design Risk assessment and risk reduction BS EN ISO Safety of machinery General principles for design Risk assessment and risk reduction – BSI British Standards. 1 GOST ISO Safety of machine tools General principles for design Risk assessment and risk reduction ISO PLEASE CONTACT RUSSIANGOSTCOM TO REQUEST YOUR COPY IN RUSSIAN, ENGLISH, GERMAN, ITALIAN, FRENCH, SPANISH, CHINESE, JAPANESE AND OTHER LANGUAGE. This International Standard specifies basic terminology, principles and a methodology for achieving safety in the design of machinery It specifies principles of risk assessment and risk reduction to help designers in achieving this objective These principles are based on knowledge and experience of the design, use, incidents, accidents and risks associated with machinery.

Guidance is given on the documentation and verification of the risk assessment and risk reduction process ISO is also intended to be used as a basis for the preparation of typeB or typeC safety standards It does not deal with risk and/or damage to domestic animals, property or the environment. Version 5 of the Procter Risk Assessment Calculator is based on BS EN ISO Safety of machinery General principles for design Risk assessment and risk reduction, which supersedes BS EN ISO , the previous British, European and International standard for machinery risk assessments Version 5 of the Procter Risk Assessment Calculator is, as with its predecessors, based on a Microsoft Excel spreadsheet, though only minimal knowledge of Excel is required to use the Calculator. Contact us for more information A proforma spreadsheet and guidance notes to assist in completing a risk assessment in accordance with EN ISO Requires Microsoft Excel The Machinery Directive requires manufacturers to perform an iterative risk assessment to determine the hazards that their machines present and implement measures to reduce these risks.

INTERNATIONAL STANDARD ISO (E) © ISO 10 – All rights reserved 1 Safety of machinery — General principles for design — Risk assessment and risk reduction 1 Scope This International Standard specifies basic terminology, principles and a methodology for achieving safety in the design of machinery. Guidance is given on the documentation and verification of the risk assessment and risk reduction process ISO is also intended to be used as a basis for the preparation of typeB or typeC safety standards It does not deal with risk and/or damage to domestic animals, property or the environment. General Requirements and Risk Assessment” are similar in many ways, but they also differ.

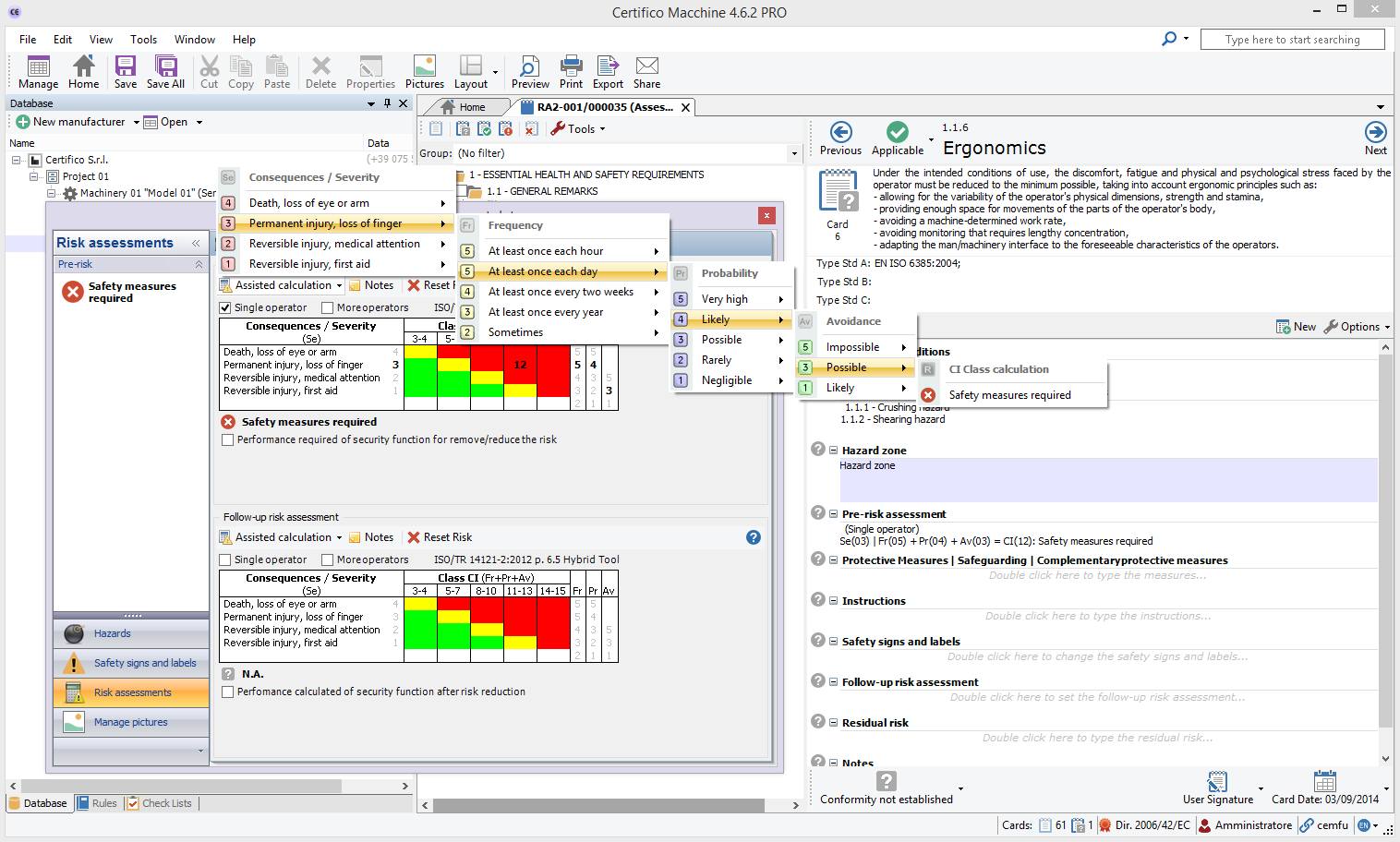

Risk assessment according to EN ISO Meets the requirements of the international standard EN ISO for the preparation of risk assessments for CE marking according to the Machinery Directive Determination of the limits of the machine, supported by construction drawings Supports a systematic approach to risk analysis. BS EN ISO sets the international standard for machinery safety It gives you the tools to design and develop reliable equipment that remains fit for purpose throughout its lifecycle BS EN ISO outlines the general principles of machinery safety and risk assessment and management. As end users, machine builders and Authorities Having Jurisdiction (AHJs) are becoming more familiar and comfortable with the latest machine safety standards, risk assessments are now being requested frequently to be in compliance with the applicable machine safety standards in North America and Europe, such as Risk Assessment Standards ANSI B for North America and/or ISO for Europe.

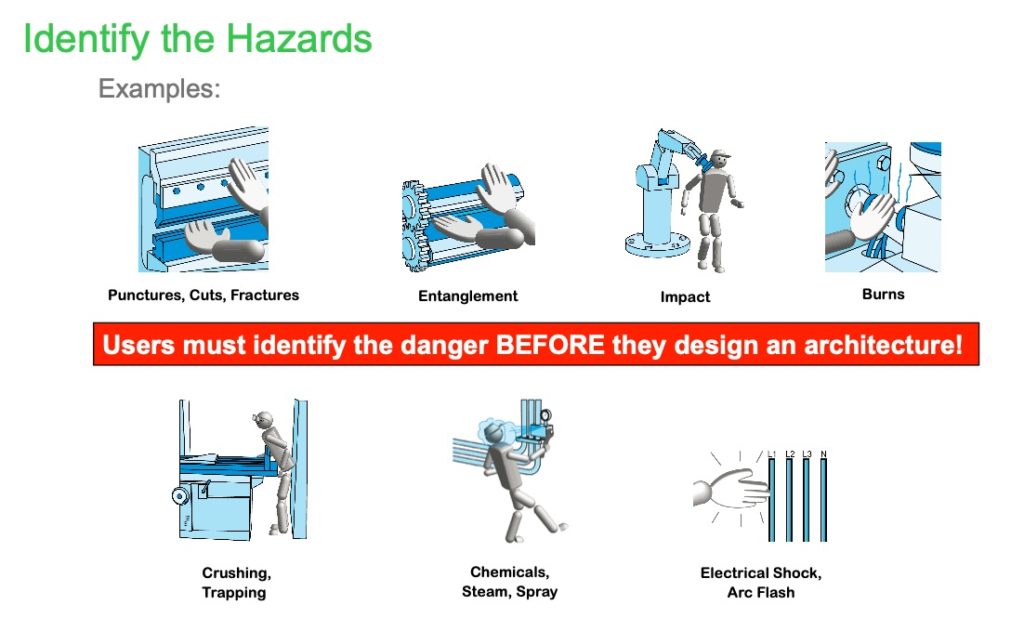

Understand the terminology, principles and processes of risk assessment and management BS EN ISO gives you the tools to design and develop safe machinery – hazard checklists and machine schematics make the standards easy to use and relevant to your needs And guidance on risk reporting will help you achieve internationally recognized BS EN ISO safety standards. Assessment 001 can complete the risk reduction process in accordance with ISO if accessing a point of operation is effectively prevented, for example by a hard guard which no longer allows exposure to hazard O (Occurrence) – Probability of a hazard occurring. • ANSI B Identifying tasks and hazards is a critically important part of the risk assessment process because hazards not identified can create substantial unknown risks There are many different approaches to identifying hazards Depending on the complexity of the machinery, useful methods may include but are not limited to.

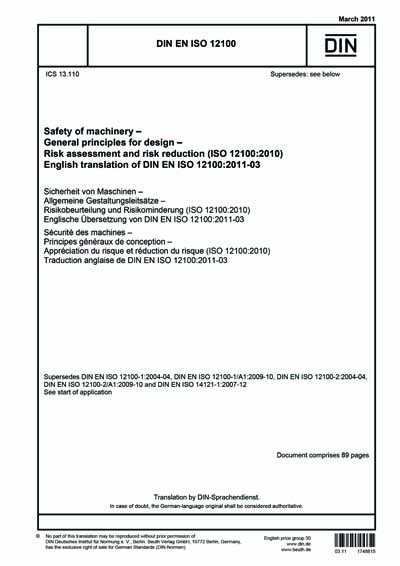

DIN EN ISO „Safety of machinery – General principles for design – Risk assessment and risk reduction“ is a harmonised standard for the Machinery Directive 06/42/EC The standard supports designers in producing safe machines – and thus plays a key role in the process to CE marking of machines. A summary of Safety of machinery – General principles for design – Risk assessment and risk reduction EN ISO is a standard which focuses on the safety of machinery and how it can be designed with safety in mind to prevent or lower the risks of hazards to people The standard aims to provide stage machinery designers with an overall framework and guidance in order to help them design machines that are safe for their intended use 1 The standard intends to incorporate the. This International Standard specifies basic terminology, principles and a methodology for achieving safety in the design of machinery It specifies principles of risk assessment and risk reduction to help designers in achieving this objective.

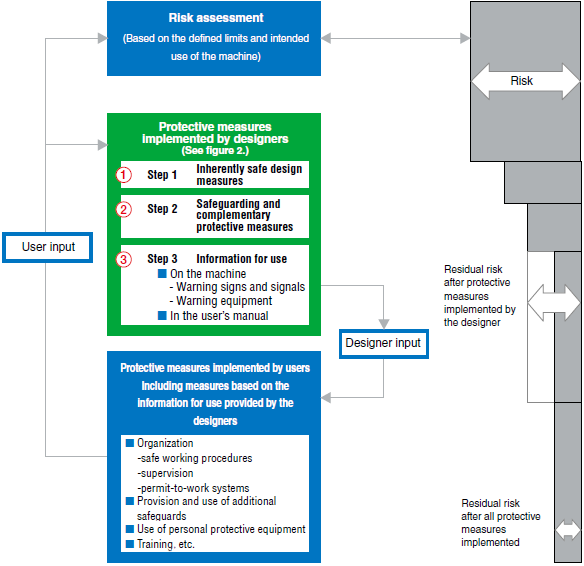

In terms of performing a risk assessment, the international standard ISO , and the North American standard ANSI B are similar in many ways, but they also differ ANSI B110 is a significant document for machinery safety and for the safety of endusers. • ANSI B Identifying tasks and hazards is a critically important part of the risk assessment process because hazards not identified can create substantial unknown risks There are many different approaches to identifying hazards Depending on the complexity of the machinery, useful methods may include but are not limited to. Risk reduction by and other protective measures (see 813 and figure 2) Risk reduction by.

On the subject of risk reduction, the recently published ISO/TR Safety of machinery Risk assessment Part 2 Practical guidance and examples of methods' is intended to assist designers in complying with EN ISO by providing additional guidance on the selection of appropriate protective measures for achieving safety. Risk assessment and risk reduction What is it?. ISO specifies basic terminology, principles and a methodology for achieving safety in the design of machinery It specifies principles of risk assessment and risk reduction to help designers in achieving this objective These principles are based on knowledge and experience of the design, use, incidents, accidents and risks associated with machinery.

Save 04 ISO _10 (, ÀÓ¼º¼ö) (Àμâ¿ë) For Later DSEn ISO Safety of Machinery – General Principles for Design – Risk Assessment and Risk Reduction Uploaded by. ANSI / ISO AMERICAN NATIONAL ADOPTION of an INTERNATIONAL STANDARD Safety of machinery — General principles for design — Risk assessment and risk reduction Adopted by the US TAG to ISO/TC199 through the ANSI B11 Accredited Standards Committee Secretariat and Accredited Standards Developer B11 Standards, Inc POB. Full Description ISO specifies basic terminology, principles and a methodology for achieving safety in the design of machinery It specifies principles of risk assessment and risk reduction to help designers in achieving this objective.

Risk assessment according to EN ISO Secutify Solo meets the requirements defined in EN ISO and is therefore perfectly suited for risk assessments according to the Machinery Directive 06/42/EC and other product safety directives. An introduction to the ISO global safety standard Start your risk assessment today with DesignSpark Safety, a free professional risk assessment t. I think there is an ISO that suggests the procedure of risk assessment as we conduct it on our applications The template from Robotiq is a good starting point, but don't get distracted by the examples contained therein that refer to collision risks only.

This machine has been assessed with guidance from BS EN ISO The risk assessments are quantative assessments, with ratings assigned, to identify potential risks to exposed persons and any additional safety measures required to eliminate or control the risks to an. The risk assessment guidelines provided in ISO are presented as a series of logical steps These will help designers to systematically determine the limits of the machinery;. And estimate potential dangers ranging from machine failure to human error.

ANSI / ISO AMERICAN NATIONAL ADOPTION of an INTERNATIONAL STANDARD Safety of machinery — General principles for design — Risk assessment and risk reduction Adopted by the US TAG to ISO/TC199 through the ANSI B11 Accredited Standards Committee Secretariat and Accredited Standards Developer B11 Standards, Inc POB. CECON Safety Risk Assessment Software Obtaining compliance certification for your products has never been easy, but now certifying your machinery according to the international ISO standard is easier than ever Gain safety certification and produce technical documentation quickly with builtin references to the relevant directives and a comprehensive database of safety standards. This second edition cancels and replaces ISO , ISO /Amd 1 09, ISO , ISO /Amd 1 09 and ISO of which it constitutes a consolidation without technical changes Documentation (eg risk assessment, typeC standards) based on these replaced.

Can the risk be reduced by administrative controls administrative controls/other measures?. In terms of performing a risk assessment, the international standard ISO , “Safety of machinery – General principles for design – Risk assessment and risk reduction” and the North Americancentric ANSI B, “Safety of Machinery;. EN ISO is a standard that is referenced (or reference is inferred via the standards it replaces) by most other machinery safety standards including (Safety of machinery, Safetyrelated parts of control systems, Part 1 General principles for design) and BS EN 661 (IEC 661) (Safety of machinery, Functional safety of safetyrelated electrical, electronic and programmable electronic control systems).

This first edition of ISO cancels and replaces ISO , ISO and ISO , of which it constitutes a consolidation without technical change It also incorporates the Amendments ISO /Amd109 and ISO /Amd109 Documentation (eg risk assessment, typeC standards) based on these replaced documents need not be updated or revised. This first edition of ISO cancels and replaces ISO , ISO and ISO , of which it constitutes a consolidation without technical change It also incorporates the Amendments ISO /Amd109 and ISO /Amd109 Documentation (eg risk assessment, typeC standards) based on these replaced documents need not be updated or revised. • ANSI B Identifying tasks and hazards is a critically important part of the risk assessment process because hazards not identified can create substantial unknown risks There are many different approaches to identifying hazards Depending on the complexity of the machinery, useful methods may include but are not limited to.

ISO –Process for Risk Assessment ISO/FDIS (E) 46 © ISO 06 – All rights reserved Key 1 starting point for evaluation of safety function’s contribution to risk reduction L low contribution to risk reduction H high contribution to risk reduction PLrrequired performance level Risk parameters. EN ISO is a standard that is referenced (or reference is inferred via the standards it replaces) by most other machinery safety standards including (Safety of machinery, Safetyrelated parts of control systems, Part 1 General principles for design) and BS EN 661 (IEC 661) (Safety of machinery, Functional safety of safetyrelated electrical, electronic and programmable electronic control systems). Risk assessment according to ISO END START ISO ANSI/ISO B11 TR3 Can the risk be reduced by guards, protective Devices?.

Iso Risk Assessment NOTE The absence of an accident history, a small number of accidents or low severity of accidents ought not to be taken as a presumption of a low risk Materials and substances or physical factors temperature, noise, vibration, radiation environment?. Until level of risk is acceptable Risk reduction (ISO ) Intrinsic design measures Safeguarding and complementary protective measures Information for use (signs, markings, instruction handbooks) The process of Risk Assessment is broken down into several stages (Ref Diagram V1) • Determination of the limits of the machinery, then, • An analysis to identify potentially hazardous phenomena, • Estimation of the degree of risk, followed by. Save 04 ISO _10 (, ÀÓ¼º¼ö) (Àμâ¿ë) For Later DSEn ISO Safety of Machinery – General Principles for Design – Risk Assessment and Risk Reduction Uploaded by.

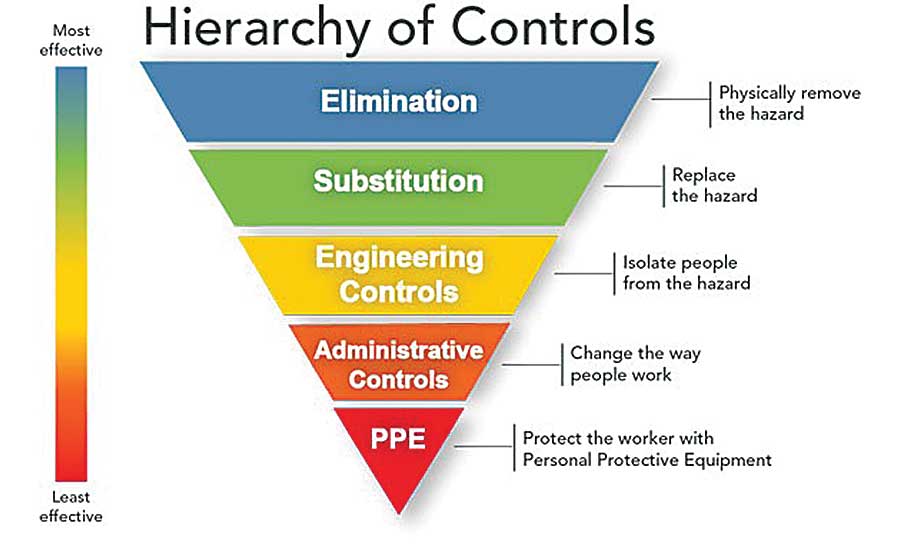

WEBINAR – RISK ASSESSMENT ACCORDING TO ISO by admin Jul 21, As part of our webinar series on machine functional safety, this webinar deals with the complexities of a risk assessments according to ISO and the relevant North American safety standards Duration 1hr. Suitable for machine risk assessments in the US and internationally When this spreadsheet is completed in compliance with ANSI B110, it will satisfy the requirements of ISO Includes automatic determination of Circuit Category and Performance Level (PLr) in accordance with ISO. Risk Reduction Engineering Controls (Safeguarding Technology) Awareness Means (Personal Protective Equipment) Training & Procedures (Administrative Controls) Protective Measures Eliminate the Risk • Design It Out • Process Substitution Physical Guarding Examples • Fencing or Barriers • Fixed Covers •Interlocks, Light Curtains, Safety Mats.

A risk assessment follows a series of logical steps to identify and examine any potential hazards associated with machinery This provides information for a risk evaluation, in which a decision is made on the safety of machinery for risks to be reduced where necessary The European Norm standard, EN ISO , outlines the hazard analysis/risk assessment procedure as follows Determination of the limits of the machinery Hazard identification. DIN EN ISO „Safety of machinery – General principles for design – Risk assessment and risk reduction“ is a harmonised standard for the Machinery Directive 06/42/EC The standard supports designers in producing safe machines – and thus plays a key role in the process to CE marking of machines. An introduction to the ISO global safety standard Start your risk assessment today with DesignSpark Safety, a free professional risk assessment t.

Every new machine placed on the market in Europe must be CE marked to the Machinery Directive 06/42/EC and a crucial step in CE marking is a Risk Assessment in accordance with EN ISO (BS EN ISO in the UK) Risk assessments might also be required if machines are being modified or upgraded, and risk assessments are often necessary when purchasing machinery or examining existing machines of uncertain provenance. ISO specifies basic terminology, principles and a methodology for achieving safety in the design of machinery It specifies principles of risk assessment and risk reduction to help designers in achieving this objective. ISO Safety of machinery General principles for design Risk assessment and risk reduction ISO specifies basic terminology, principles and a methodology for achieving safety in the design of machinery It specifies principles of risk assessment and risk reduction to help designers in achieving this objective.

• ANSI B Identifying tasks and hazards is a critically important part of the risk assessment process because hazards not identified can create substantial unknown risks There are many different approaches to identifying hazards Depending on the complexity of the machinery, useful methods may include but are not limited to. The risk assessment and risk reduction process This International Standard is also intended to be used as a basis for the preparation of typeB or typeC safety standards It does not deal with risk and/or damage to domestic animals, property or the environment. Identify risks of hazards such as crushing, cutting, electric shock, or fatigue;.

ISO Safety of machinery– General principles for design– Risk assessment and risk reduction Keep in mind as well that there are a number of industry standards requiring risk assessments that may provide additional insight, including – among many others – machinery, packaging machinery, semiconductor equipment, electrical systems, fire and consumer products. Until level of risk is acceptable Risk reduction (ISO ) Intrinsic design measures Safeguarding and complementary protective measures Information for use (signs, markings, instruction handbooks) The process of Risk Assessment is broken down into several stages (Ref Diagram V1) • Determination of the limits of the machinery, then, • An analysis to identify potentially hazardous phenomena, • Estimation of the degree of risk, followed by.

Risk Assessment With Iso Examples And Methods Anyone Familiar With Risk Assessment Plc

Global Functional Safety Standards How To Resolve Ansi And Iso Conflicts Reconciling Differences And Boosting Efficiency

Iso 10 Safety Of Machinery General Principles For Design Risk Assessment And Risk Reduction

1g8suuwvvw4213r2g2fl0vfe Wpengine Netdna Ssl Com Wp Content Uploads 06 Best Practices Guide On Risk Assessment Pdf

Din En Iso 11 Safety Of Machinery General Principles For Design Risk Assessment And Risk Reduction Iso 10 German Version En Iso 10

Iso 10 Safety Of Machinery General Principles For Design Risk Assessment And Risk Reduction

Cem4 Steps

Control Engineering Machine Safety Benefits Of Safety Assessments Risk Assessments

Cdn Sick Com Media Docs 2 92 292 Whitepaper Risk Assessment And Risk Reduction For Machinery Part 3 Conducting Risk Estimation En Im Pdf

Cdn Sick Com Media Docs 2 92 292 Whitepaper Risk Assessment And Risk Reduction For Machinery Part 3 Conducting Risk Estimation En Im Pdf

Understanding Risk Assessment In Compliance Magazine

Iso 1 Analysis Part 1 Start With Risk Assessment

Machinery Risk Assessment Cholarisk

Risk Assessment Example With Iso Plc Academy

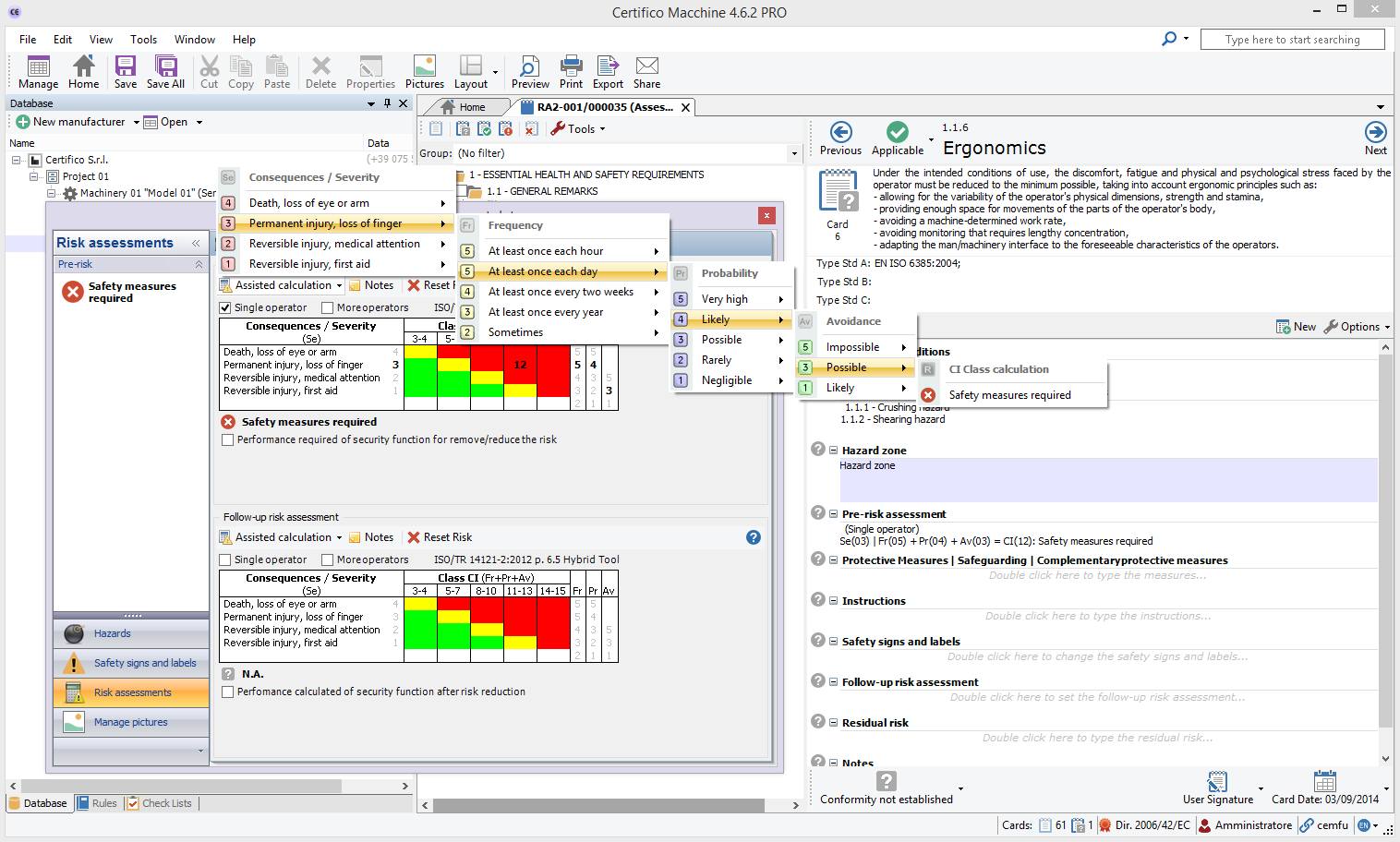

Machinery Risk Assessment Software Safety Of Machinery And Risk Assessment As Per Iso Tr 2 Second Edition 12 06 01 Accordance With Iso 10

Uni En Iso Pdf File Aefasr

Cem4 Risk Assessment En Iso Ehsr Md Youtube

Secutify Risk Assessment Software For Machinery Safety

Www Euromoulders Org Publications Item Download 12 639afcedba351bc744fa8fab09b

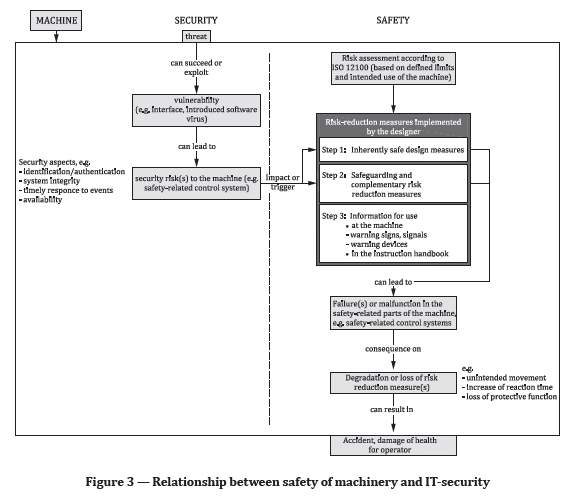

Phoenix Contact Risk Assessment Safety Vs Security

Uni En Iso Pdf Editor

Iso Dis 1 En Safety Of Machinery Safety Related Parts Of Control Systems Part 1 General Principles For Design

3 Step Method Safety Knowledge Keyence Malaysia

1

How To Conduct A Risk Assessment How To Guide Advertisement How To Conduct A Risk Assessment Atc Figure 1 Initially Risk Is Calculated By Using The 3 2 3 Rule To Quantify Hazards From Ria Tr R15 306 Atc Figure 2 Iso And Ansi B11 0 Indicate

Pilz Automation Safety Risk Estimation And Risk Reduction In Accordance With En Iso And En Iso

Risk Assessment Epsilon Engineering Limited

Ansi Iso 12 Safety Of Machinery General Principles For Design Risk Assessment And Risk Reduction

Sn En Iso Safety Of Machinery Snv

En Risk Assessment Tecnical Standards Industrial Machinery

Organizational Diagram Of Safety Standards Safety Knowledge Keyence International Belgium

Risk Assessment Epsilon Engineering Limited

Risk Assessment Example With Iso Plc Academy

Risk Assessment Process Of Iso Applied To Collaborative Download Scientific Diagram

Http Www Mmscience Eu Journal Issues April 08 Articles System Methodology Of Risk Assessment In Machine Tools Download

How To Conduct A Risk Assessment 18 03 01 Assembly Magazine

Machinery Directives 06 42 Ec En Iso Maschce

Risk Analysis Risk Assessment En Iso 3 Step Model

Procter Machine Safety Risk Assessment Calculator Updates

Main Steps In The Process Of Ppls Risk Assessment And Risk Reduction Download Scientific Diagram

Machinery Cyber Security Engal Services

Risk Estimation 25 Years On

Safety Functions Of Safety Components Technical Guide Australia Omron Ia

Risk Assessment Introduction Integrated Risk Assessment In Accordance With En Iso 1 And En Iso 10 Introduction Pdf Document

Risk Assessment In Accordance With En Iso And En Iso Pdf Free Download

Machinery Risk Assessment Software Youtube

Machinery Risk Assessment To Bs En Iso Control And Safety Eng Limited

The Meaning And Process Of Risk Assessment Safety Knowledge Keyence International Belgium

Procter Machine Safety Risk Assessment Calculator Updates

Risk Assessment

Uni En Iso Pdf

Nf En Iso Safety Of Machinery Snv

Pdf Quick Guide Towards A Risk Analysis According To Din En Iso And Din

1g8suuwvvw4213r2g2fl0vfe Wpengine Netdna Ssl Com Wp Content Uploads 06 Best Practices Guide On Risk Assessment Pdf

Iso 05 En Safety Of Machinery Fire Prevention And Protection

Silo Tips Download W09 Safety Risk Assessments

Nccru3ntqnpntm

Q Tbn And9gcqcsbmxmcwfik8v7fq1vz3q30isiodsew62tpbxq Lojcap4g22 Usqp Cau

Understanding Risk Assessment

Www Euromoulders Org Publications Item Download 12 639afcedba351bc744fa8fab09b

Risk Assessment In Accordance With En Iso And En Iso Pdf Free Download

En機械風險評估

Iso European Standards

Cdn Sick Com Media Content H18 Hae Pdf

Canton Inc

Machinery Risk Assessment To Bs En Iso Control And Safety Eng Limited

Understanding Risk Assessment In Compliance Magazine

Risk Assessment Example With Iso Plc Academy

Http Www Mmscience Eu Journal Issues April 08 Articles System Methodology Of Risk Assessment In Machine Tools Download

02 En Iso Rs Hazards Risk Management

Risk Estimation 25 Years On

Plant Engineering Machine Safety Webcast Your Questions Answered

Gost Iso 13 Pdf Document

Q Tbn And9gctxx7klagn6hemsvz8 Eeiikmhbquqcan9d6paqfnuu4vffqh Usqp Cau

Safety Management The Path To Safe Machines

2 3 Safety Of Machinery Risk Analysis And Risk Assessment Leuze The Sensor People

Ds En Iso 11 Safety Of Machinery General Principles For Design Risk Assessment And Risk Reduction

2

Iso Definitions And Steps In Assessing The Safety Of Machinery

Risk Assessment According To Din En Iso For Machines From Adt Zielke

Weka Manager Ce English Version

Uni En Iso Pdf Editor Lasopalovers

Certification Experts Com Wp Content Uploads 18 08 Safexpert 8 2 Information Flyer Pdf

Q Tbn And9gcr8xx 3x7mouur2a7zfna4zflr9gubspyfq4rd Qpzbkqnph4nb Usqp Cau

En Iso Risk Assessment P 5 6 File Cem

Bs En Iso 10

Machinery Safety

Risk Assessment Example With Iso Plc Academy

Iso Ts 10 Basic Procedure Of Risk Assessment Download Scientific Diagram

Free Risk Assessment Spreadsheet Machine Safety Specialists

Www Wernermn Com Wp Content Uploads 18 09 T02 Introductiontomachinesafetystandards We Min Pdf

Safety Engineering Risk Assessment According To En Iso I9s

En Iso 10 Preview

Www Vttresearch Com Sites Default Files Julkaisut Muut 18 Vtt R 18 Pdf

W09 Safety Risk Assessments Pls And Sils

Risk Assessment Firmus Innovation As

St Rk Iso 14 By Compielej Issuu

Safety Engineering Risk Assessment According To En Iso I9s