Pc Abs Stress Strain Curve

Performance Of Recycled Plastic Based Concrete Journal Of Materials In Civil Engineering Vol 27 No 2

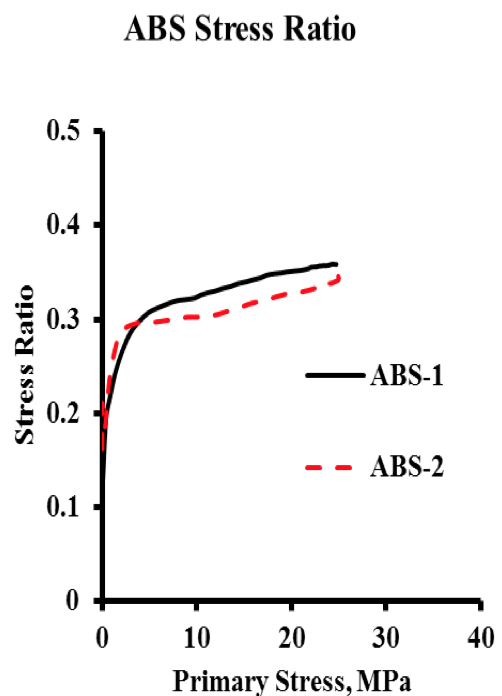

Www Dynalook Com Conferences 15th International Ls Dyna Conference Constitutive Modeling Modeling Of Crazing In Rubber Toughened Polymers With Ls Dyna R

Strength At Break Tensile

Evaluation Of Fracture Toughness Of Ultraviolet Irradiated Polycarbonate Using The Essential Work Of Fracture Method

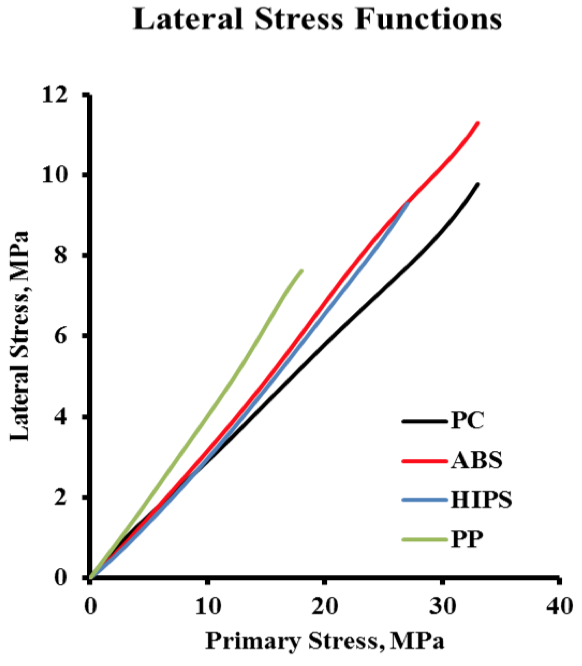

Lateral Stress And Density Measurements For Pc Abs Hips And Pp Bulk Resin Feed Stock Spe Extrusion Division 1 0 Wiki

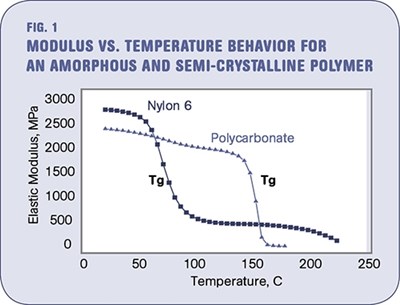

Thermoplastic Wikipedia

An effective stress‐effective plastic strain curve was constructed for each strain rate imposed and fitted with a power law Thus, the tensile stress–strain curve could be predicted in a very accurate way for every strain rate examined and various types of off‐axis specimens.

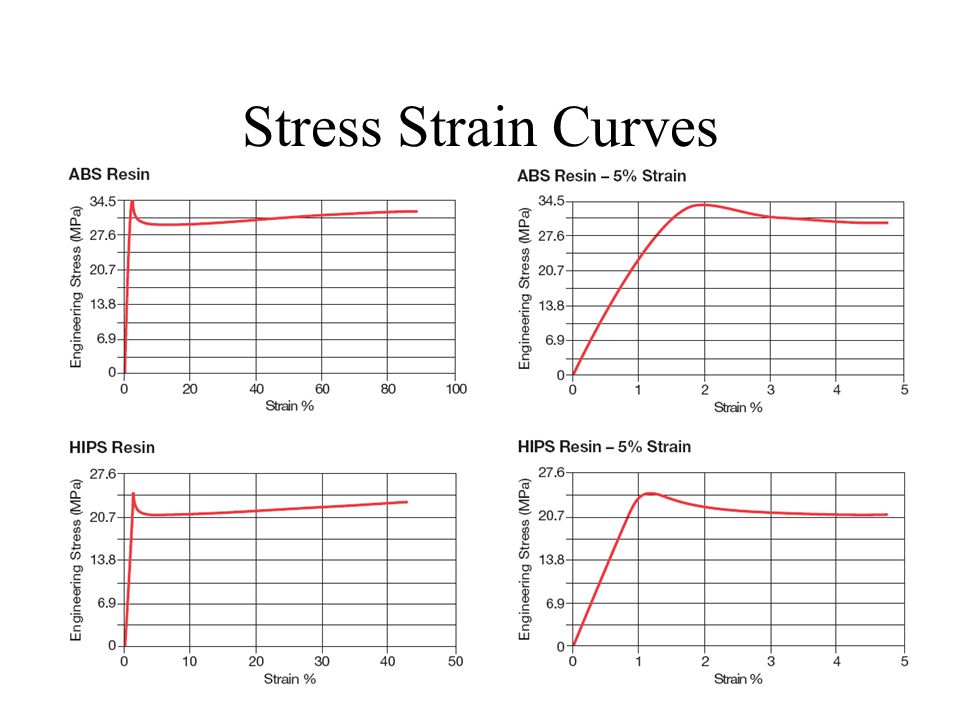

Pc abs stress strain curve. The socalled proportional limit While strains at yield typically range from 3% to 10% for most thermoplastics, the strain at the proportional limit rarely exceeds 1% and for many materials it is less than 05%. PC is a polycarbonate FDM® filament that brings the attributes of this industrial plastic to 3D printing applications PC is characterized by its high strength and impact resistance, coupled with dimensional stability and heat resistance. However, measurement of these properties as sample dimensions approach the size scale of an individual polymer chain has been severely limited Recently, we developed The Uniaxial Tensile Tester for UltraThin films, enabling the direct measurement of the complete stress–strain relationship for the.

These features of high mechanical strength and toughness can be seen in this overlay of stressstrain curves of high viscosity Delrin ® acetal homopolymers and standard acetal copolymers of similar viscosity (Melt Flow Rate of 25 g/10 min at 190 ° C). The stress–strain response of LDPE across a range of strain rates is shown in Fig 2 and temperatures in Fig 3, where the varying temperature measurements were conducted at two different strain ratesThe stress–strain curve shows an initial linear elastic region followed by a nonlinear transition to global yield, which is followed by strain softening and then strain hardening. The impact strength of the PE/PC blend is related to the area under the tensile stressstrain curve, whereas for PS/PC blends no correspondence is found The variation in properties is related to the composition, morphology, interfacial adhesion at the phase boundary and failure surfaces of the various blends.

These features of high mechanical strength and toughness can be seen in this overlay of stressstrain curves of high viscosity Delrin ® acetal homopolymers and standard acetal copolymers of similar viscosity (Melt Flow Rate of 25 g/10 min at 190 ° C). Grade Count = 3. The dynamic true stress strain curves at high strain rates were compared with quasistatic curves obtained from static compression tests at low strain rates Results of dynamic compression tests show that FDM process parameter of build style has significant influence on the dynamic response of FDM made ABS and PC parts under high strain rate.

The cookie settings on this website are set to 'allow all cookies' to give you the very best experience If you continue without changing these settings, you consent to this but if you want, you can change your settings at any time at the bottom of this page. – Stressstrain curve HDPE, PP, PS, PVC, Nylon, PMMA, PC, ABS, PET Characteristics PP • Linear or branched structure • Easy TENSILE STRESSSTRAIN RELATIONSHIPS 29 TENSILE STRESSSTRAIN RELATIONSHIPS most desirable !. PCABS, Cycoloy* CX7240 resin is an injection moldable PC/ABS blend It contains nonbrominated and nonchlorinated flame retardant systems to meet UL94 V0 at 075mm, V1 at 06mm, V2 at 02mm and 5VB at 15mm respectively Excellent flow and impact.

Grade Count = 3 Mechanical Properties Hardness, Rockwell R 103 112 103 112 Average = 110;. 30 MECHANICAL PROPERTIES OF POLYMERS 31 SUMMARY. Toughness of a PC/ABS blend CHARACTERIZING PARAMETERS OF FRACTURE MECHANICS The J integral Rice 2 developed the pathindependent energy line integral, the J integral, which is an energybased parameter, to characterize the stressstrain field near a crack tip surrounded by smallscale yielding The J.

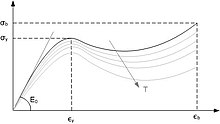

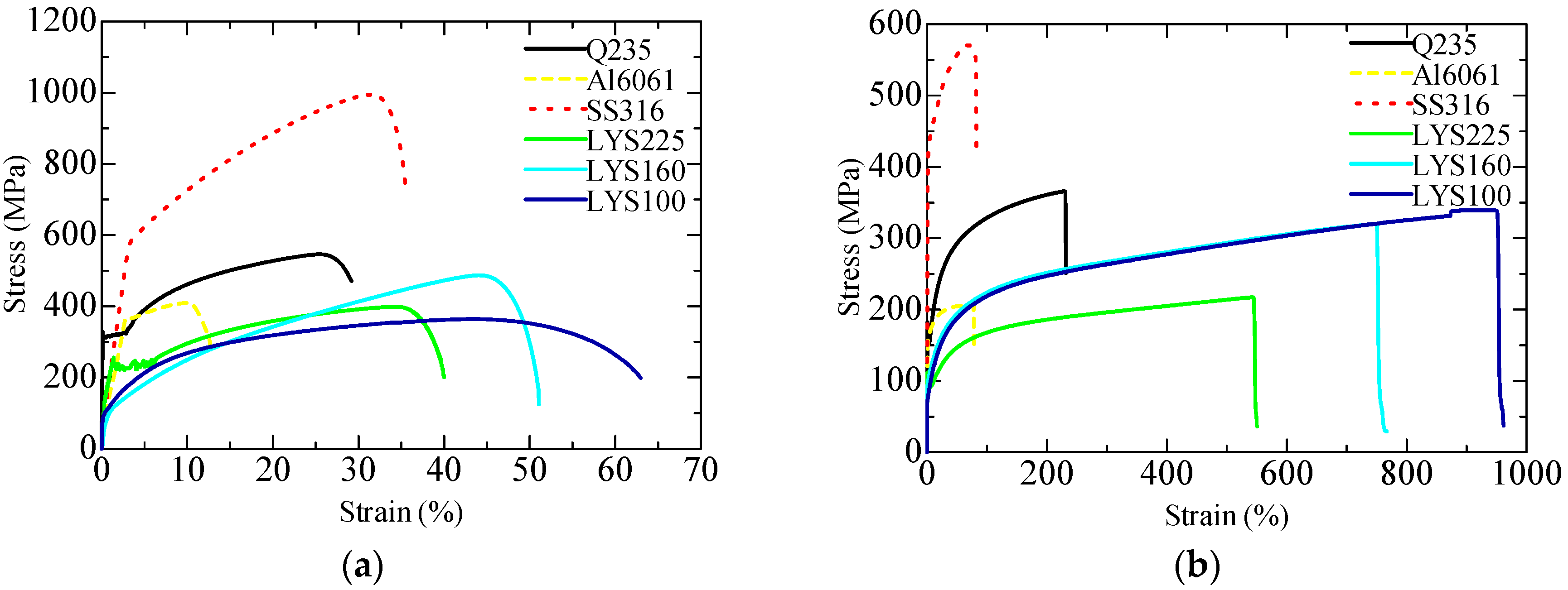

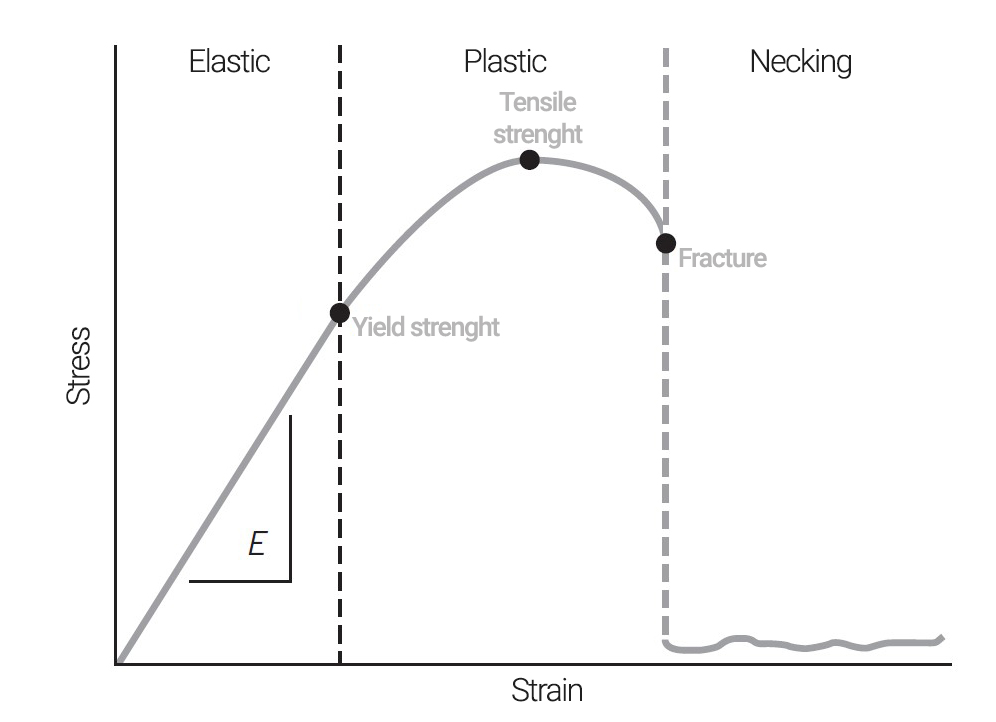

Polymers exhibit a wide range of stressstrain behaviors as shown in the figure below The brittle polymer (red curve) elastically deforms and fractures before deforming plastically The blue curve is a plastic polymer and is similar to curves for many metals Its behavior begins in the linear elastic deformation region. The mechanical properties of bisphenolA polycarbonate (BPA PC) have been extensively studied;. The yield stress is about 32 MPa, at the lowest strain rate, 11 × 10 3 s 1, and when the strain rate goes to 55 × 10 3 s 1, the yield stress reach 591 MPa, almost twice as much as the lowest strain rate With regards to the yield strain, there is not very clear trend, it appears that yield strain increases slightly with increasing strain rate, which means the CMDB is ductile at quasistatic loading.

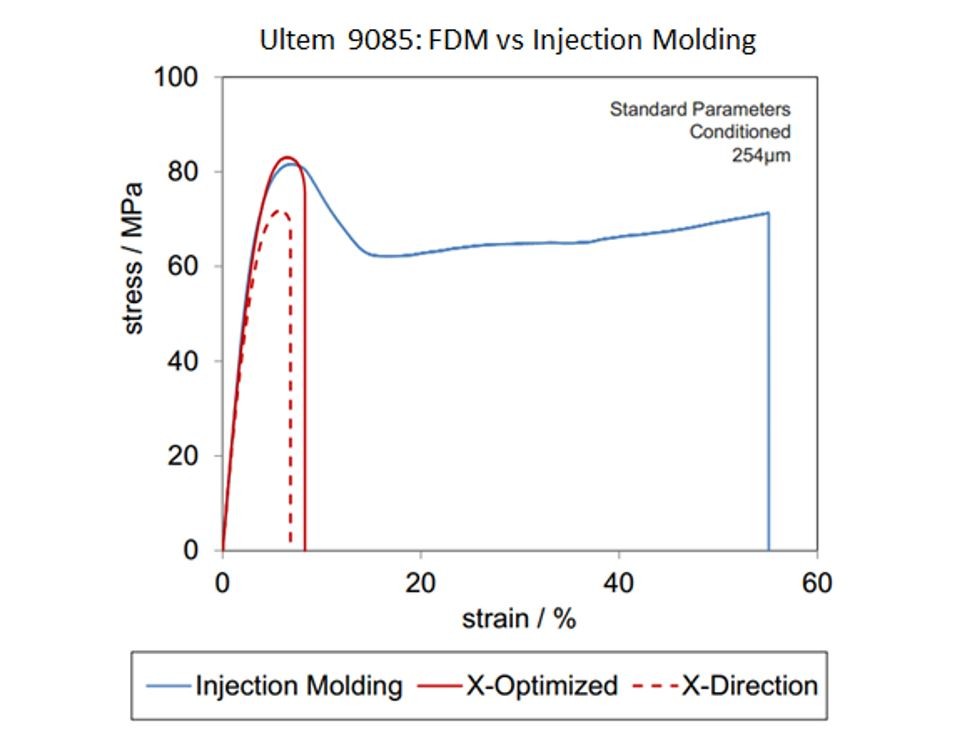

The dynamic true stress strain curves at high strain rates were compared with quasistatic curves obtained from static compression tests at low strain rates Results of dynamic compression tests show that FDM process parameter of build style has significant influence on the dynamic response of FDM made ABS and PC parts under high strain rate. Resistant to a variety of bases and acids;. Test, a plane strain stress cracking test is performed Figure 3 shows the test results Figure 3 Stress rupture curves on five commercially available geomembranes At the higher loads (stresses) breaks occurred in a ductile mode to generate the shallow slope segment of the curve However, at some critical lower stress, the curve.

The socalled proportional limit While strains at yield typically range from 3% to 10% for most thermoplastics, the strain at the proportional limit rarely exceeds 1% and for many materials it is less than 05%. ABS plastic remains hard, rigid and tough even at low temperatures It is available in fireretardant, heatresistant and platable grades Impact strength varies by grade See the chart below for ABS yield strength, Young’s modulus (ABS elasticity), tensile yield strength of ABS plastic, mechanical properties of ABS plastic, and other properties. PCABS, Cycoloy* CX7240 resin is an injection moldable PC/ABS blend It contains nonbrominated and nonchlorinated flame retardant systems to meet UL94 V0 at 075mm, V1 at 06mm, V2 at 02mm and 5VB at 15mm respectively Excellent flow and impact.

Where L 0 is the original length of a bar being stretched, and L is its length after it has been stretched ΔL is the extension of the bar, the difference between these two lengths Using measurements of tensile stress and tensile strain, the stiffness of different materials is compared by Young’s modulus, EE is constant and does not change for a given material. Large deformation performances of polycarbonate (PC) and PC/ABS (Acrylonitrile Butadiene Styrene) have been investigated experimentally in this paper The displacement fields of these polymers are measured with a system based on digital image correlation (DIC) method The variations of strains during tension are measured and the true stressstrain curves are presented. As the stress increases, the strain caused by it varies according to the properties of a material The relationship can be limned by a graph, and this graph is referred to as the stressstrain curve, where stress is plotted on the Yaxis and strain is plotted on the Xaxis.

PCABS with distinct localisation is shown below The two curves show a stressstrain curve developing for different measurement lengths This issue is treated in 1 and 3 in greater detail Figure 3 Stressstrain diagram for different measurement scales for two experiments and plastic. The cookie settings on this website are set to 'allow all cookies' to give you the very best experience If you continue without changing these settings, you consent to this but if you want, you can change your settings at any time at the bottom of this page. I cannot recall ever seeing SN curves for plastics I believe it's because fatigue failure modes of soft materials (relative to metals) are better characterized using "straintofailure" fatigue data, as opposed to "stresstofailure" (typically seen on SN curves for metals), probably because the area can change so much (compared to metals), and it may be much easier to directly measure.

Figure 7 for several constant stress levels ranging from 2,900 psi to 8,700 psi HT and ST have been included at 8,700 psi for comparison The instantaneous deformation (strain at short creeptimes) correlates to the stressstrain relationship derived in a tensile test, accordingly creep curves start at higher elongations with increasing. Yield Strength can be seen on a stressstrain curve as the point where the graph is no longer linear Since it is quite difficult to determine an exact point where a line stops being linear, Yield Strength is usually the point where the value on the stressstrain curve is 02% off from what it would be if it was completely linear. The stress/strain curves and interphase shear modulus values were obtained from these composite systems under average shear strain rates (ASSR) in the range of 215–3278 (1/s) The results showed that the magnitude of the interphase shear modulus was sizing and strain rate dependent.

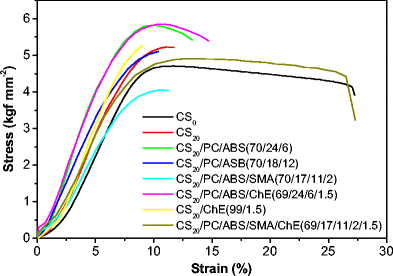

The impact strength of the PE/PC blend is related to the area under the tensile stressstrain curve, whereas for PS/PC blends no correspondence is found The variation in properties is related to the composition, morphology, interfacial adhesion at the phase boundary and failure surfaces of the various blends. Grade Count = 3. After ultimate stress, tested Stress – Strain curve had negative slope During preparation of material card it was a problem As solver doesn’t allow negative slope Curve was smoothening by Large tensile deformation behavior of PC/ABS alloy, Polymer 47, pp5174–5181, (06).

Assuming the toughness of each material to be approximated by the area beneath its respective stress/strain curve, the polymers would rank as follows, in order of descending toughness PC, ACR/PC, RPVC, and ABS. Toughness of a PC/ABS blend CHARACTERIZING PARAMETERS OF FRACTURE MECHANICS The J integral Rice 2 developed the pathindependent energy line integral, the J integral, which is an energybased parameter, to characterize the stressstrain field near a crack tip surrounded by smallscale yielding The J. Depending on your PCABS composition, you can find very accurate stressstrain curves online Try to find the main supplier's website whichever company your current company buys them from Or ask directly to the supplier to provide this data for you.

The stress/strain curves and interphase shear modulus values were obtained from these composite systems under average shear strain rates (ASSR) in the range of 215–3278 (1/s) The results showed that the magnitude of the interphase shear modulus was sizing and strain rate dependent. The difference in strain hardening is related to preservation of chain entanglement density in channel die compression and disentanglement in tensile drawing True stress−true strain curves for polymers having crystals with low plastic resistance and not cavitating are very similar in channel die compression and in tension. The characteristic look of the stressstrain curve of a plastic material is shown in Figure 21 As a result of experimental tests, behaviors like postyieldstrain softening PC/ABS blend production started in year 1977 under the trade name Cycoloy 4 22 Mechanical Proporties Polycarbonate (PC) is characterized for its high toughness.

Tensile modulus or Young's Modulus is the ratio of stress to strain within the elastic region of the stressstrain curve before the yield point Thermoplastic Characteristics ABS Acrylonitrile Butadiene Styrene strong and rigid;. The toughness of ABS is revealed by its high fracture strain in a tensile test, and high notched Izod impact fracture energy However, the fatigue resistance of ABS is less favourable. Title Residual toughness of poly(acrylonitrilebutadienestyrene) (ABS) af ter fatigue loading—effect of uniaxial fatigue loading Created Date.

The figure below shows how the secant modulus is obtaind at point A on the curve The secant modulus can be expressed as a percentage of the Young's Modulus (eg, 07E or 085E), and it is used to describe the stiffness of a material in the inelastic region of the stressstrain diagram Secant modulus is commonly denoted by E s. The difference in strain hardening is related to preservation of chain entanglement density in channel die compression and disentanglement in tensile drawing True stress−true strain curves for polymers having crystals with low plastic resistance and not cavitating are very similar in channel die compression and in tension. – Stressstrain curve HDPE, PP, PS, PVC, Nylon, PMMA, PC, ABS, PET Characteristics PP • Linear or branched structure • Easy TENSILE STRESSSTRAIN RELATIONSHIPS 29 TENSILE STRESSSTRAIN RELATIONSHIPS most desirable !.

This includes the point on the curve where the relationship between stress and strain becomes nonlinear;. ABS Material Data Sheet Physical Properties Metric English Comments Density 104 g/cc lb/in³ Grade Count = 3 Melt Flow 18 23 g/10 min 18 23 g/10 min Average = 213 g/10 min;. Stress or strain concentrations in the matrix may give rise The curve of the binary PC/ABS sys Polycarbonate/ AcrylonitrileButadieneStyrene (PC/ABS) is a polymer blend widely used in.

Yield Strength can be seen on a stressstrain curve as the point where the graph is no longer linear Since it is quite difficult to determine an exact point where a line stops being linear, Yield Strength is usually the point where the value on the stressstrain curve is 02% off from what it would be if it was completely linear. The mechanical properties of bisphenolA polycarbonate (BPA PC) have been extensively studied;. This includes the point on the curve where the relationship between stress and strain becomes nonlinear;.

The SHPB tests were carried out to study the deformation behavior of PC/ABS alloys with the ratios of PC to ABS being 80, 6040, 5050 and 4060 at elevated temperatures (293 K and 343 K) and high strain rates (8 × 10 2 s −1, 27 × 10 3 s −1 and 1 × 10 4 s −1), respectively, from which the curves of engineering stress and engineering strain and the true stress and true strain are obtained A modified model is developed to describe the relations among yield stress, temperature and. Grade Count = 3 Mechanical Properties Hardness, Rockwell R 103 112 103 112 Average = 110;. 30 MECHANICAL PROPERTIES OF POLYMERS 31 SUMMARY.

In engineering and materials science, a stress–strain curve for a material gives the relationship between stress and strainIt is obtained by gradually applying load to a test coupon and measuring the deformation, from which the stress and strain can be determined (see tensile testing)These curves reveal many of the properties of a material, such as the Young's modulus, the yield strength. ABS Material Data Sheet Physical Properties Metric English Comments Density 104 g/cc lb/in³ Grade Count = 3 Melt Flow 18 23 g/10 min 18 23 g/10 min Average = 213 g/10 min;. Some solvents and chlorinated hydrocarbons may damage the material.

PC is a polycarbonate FDM® filament that brings the attributes of this industrial plastic to 3D printing applications PC is characterized by its high strength and impact resistance, coupled with dimensional stability and heat resistance. Results •Effect of Environment – Shortens life from Shortens life from avg avg of 101 of 101 yr yr to to yryr •Effect of Residual Stress – Shortens life from Shortens life from avgavg of 94 of 94 yr yr to 28 to 28 yryr •Effect of Applied Stress – Shortens life from >100 Shortens life from >100 yr yr to average of to average of 61 61 yr yr depending on residual. StressStrain Curves The true stress is determined by dividing the measured force by the crosssectional area which is determined using the DIC analysis The true strain is also obtained from the DIC analysis as well The strain rate is therefore determined as the time derivative of the strain The true stressstrain curves are depicted in.

ABSM30 is 25 to 70 percent stronger than standard ABS, making it ideal for concept modeling, functional prototyping, manufacturing tools and end use parts With significantly stronger layer bonding than ABS and greater tensile, impact and flexural strength, ABSM30 parts are stronger, smoother and have better feature detail. The stress–strain response of LDPE across a range of strain rates is shown in Fig 2 and temperatures in Fig 3, where the varying temperature measurements were conducted at two different strain ratesThe stress–strain curve shows an initial linear elastic region followed by a nonlinear transition to global yield, which is followed by strain softening and then strain hardening. Polycarbonate (PC) is a widely used engineering material in aerospace field, since it has excellent mechanical and optical property In present study, both compress and tensile tests of PC were conducted at high strain rates by using a split Hopkinson pressure bar The highspeed camera and 2D digital speckle correlation method (DIC) were used to analyze the dynamic deformation behavior of PC.

However, measurement of these properties as sample dimensions approach the size scale of an individual polymer chain has been severely limited Recently, we developed The Uniaxial Tensile Tester for UltraThin films, enabling the direct measurement of the complete stress–strain relationship for the. ABS (ii) neat PC (i) ∆n Mixedmode interface failure takes place when a combination of normal and tangential stress reaches a critical value The specific work of separation of the PC–ABS interface (iii) is much smaller than that of PC or ABS 3 Results The distribution of stress in the direction of applied loading, shown below for two. STRESSSTRAIN CURVES David Roylance Department of Materials Science and Engineering Massachusetts Institute of Technology Cambridge, MA August 23, 01.

Stress Strain Curves Experiment And Models A Pc Abs B Pmma C Download Scientific Diagram

Www Mdpi Com 1996 1944 11 8 1333 Pdf

Comparison Of The Tensile Performance Of Polymer Pc And Pc Abs Scientific Net

Cdn Intechopen Com Pdfs 558 Pdf

Stress Strain Curves Of Material A 10 Wt Ncf Material B 12 Wt Download Scientific Diagram

Stress Strain Curves For The Three Materials Pp Pp40 And Pph With Download Scientific Diagram

Tensile Stress Strain Curves Of Printed Pa12 For X Y And Z Build Download Scientific Diagram

Tensile Behavior Of Acrylonitrile Butadiene Styrene At Different Temperatures

Typical Tensile Stress Strain Curve Of Abs Filament Used For Preparing Download Scientific Diagram

Formlabs Form Tough Resin Lay3rs 3dprinting

The Effects Of Stress Plastics Technology

Stress Strain And Deformation Of Poly Lactic Acid Filament Deposited Onto Polyethylene Terephthalate Woven Fabric Through 3d Printing Process Scientific Reports

The Shape Memory And The Mechanical And Thermal Properties Of Tpu Abs Cnt A Ternary Polymer Composite Rsc Advances Rsc Publishing

Hybridization Effect Of Talc Glass Fiber As A Filler In Polycarbonate Acrylonitrile Butadiene Styrene Composites Sciencedirect

Www Mdpi Com 1996 1944 11 8 1333 Pdf

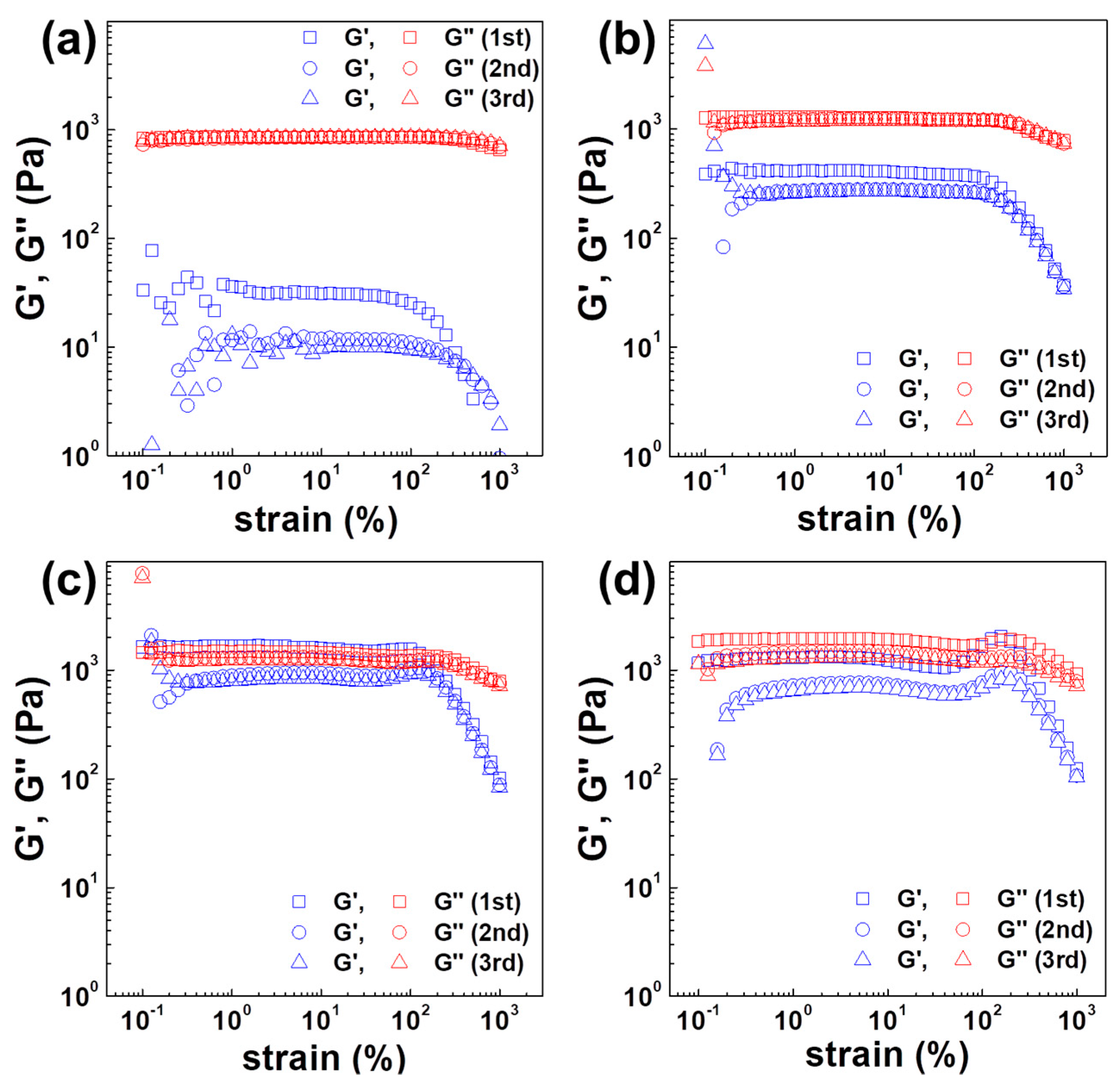

Characterisation Of Pc Abs Blend During Reprocessing Cycles And Subsequent Functionality Recovery By Virgin Additives Springerlink

Effect Of Abs Pmma Ema Ternary Blending Sequence On Mechanical Properties And Surface Glossiness In Journal Of Polymer Engineering Volume 36 Issue 6 16

Pdf Fe Modelling Of Pc Abs Experimental Tests And Simulations Semantic Scholar

Part And Mold Design Guide 05 Pages 51 100 Flip Pdf Download Fliphtml5

Cdn Intechopen Com Pdfs 558 Pdf

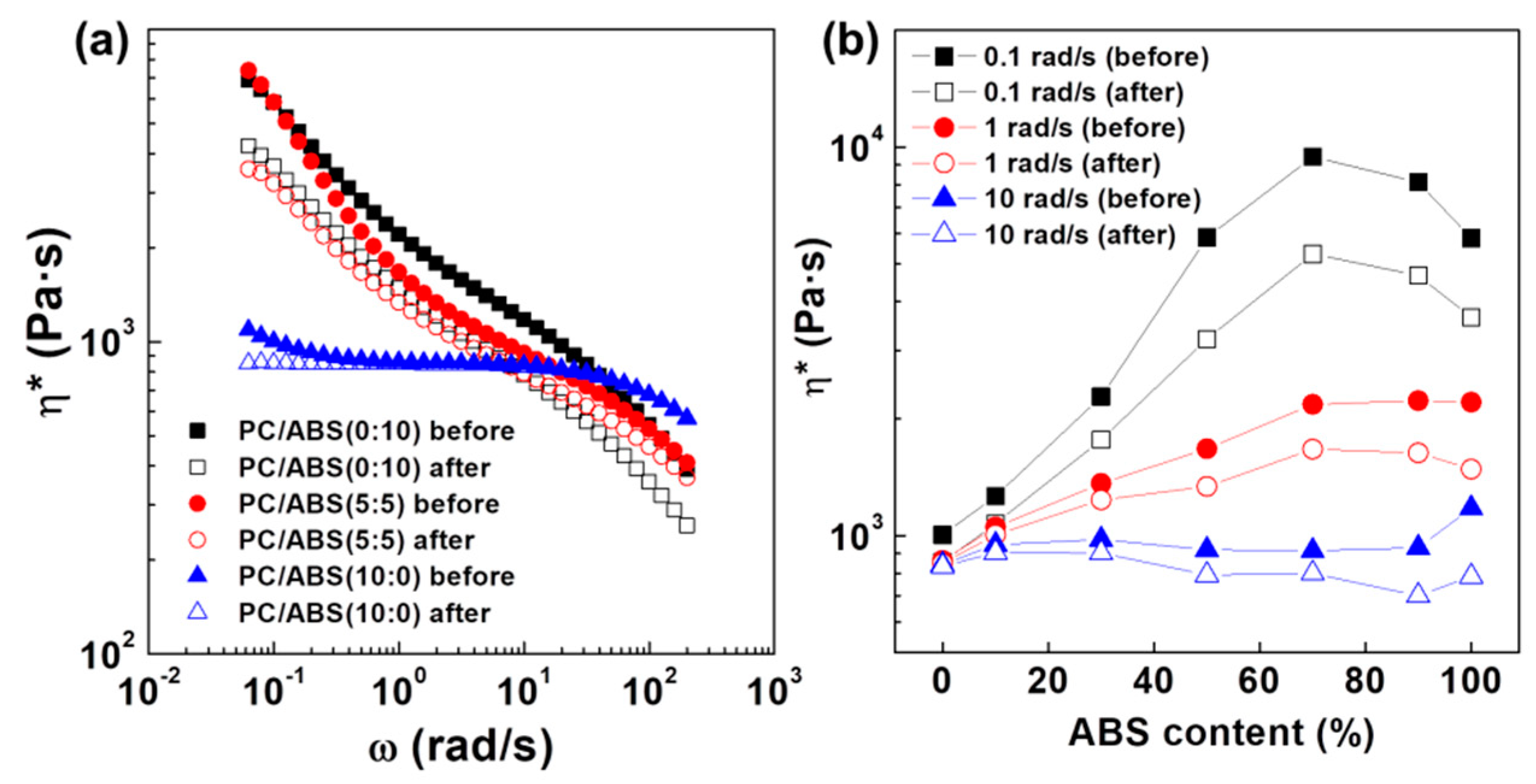

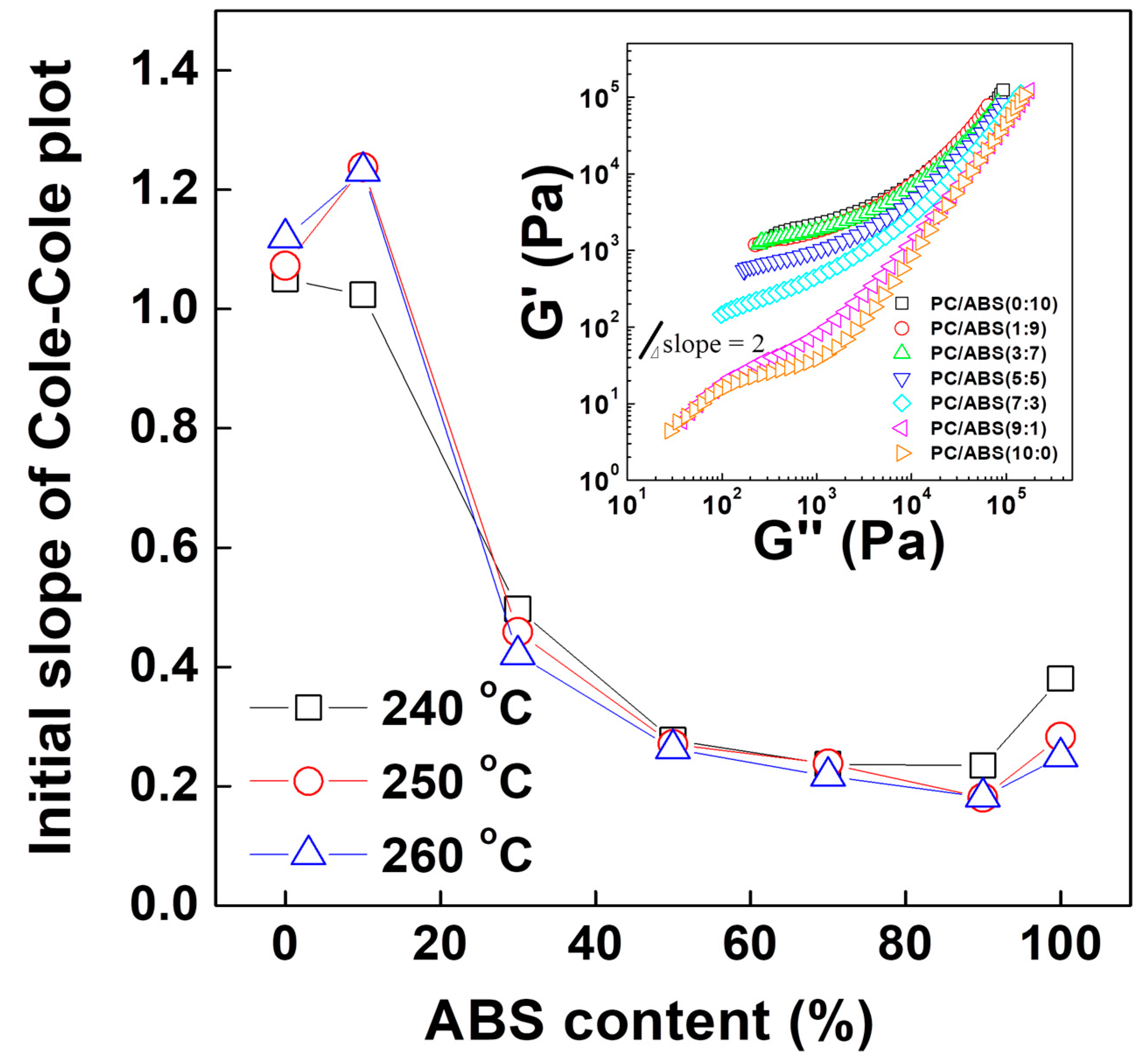

Polymers Free Full Text Rheological Investigation Of Relaxation Behavior Of Polycarbonate Acrylonitrile Butadiene Styrene Blends Html

Preparation Of Graphene And Its Application In Polycarbonate Acrylonitrile Butadiene Styrene Composites In Journal Of Polymer Engineering Volume 38 Issue 4 18

Http Web Mae Ufl Edu Rapidpro Pages 3d printing paper final manuscript Pdf

Rate Dependent Large Deformation Behavior Of Pc Abs Sciencedirect

Pdfs Semanticscholar Org D0da 47a3636cb30c51c761a66d22e23bd68a5b06 Pdf

Experimental And Modeling Study Of The Compressive Behavior Of Pc Abs At Low Moderate And High Strain Rates Sciencedirect

Q Tbn And9gcry5eg9vw0pulzgan6nm7ceakmw8q02uis6m 0h78lr4trsyvo1 Usqp Cau

Thermoplastic Material Selection For Injection Molding

New Polymer Concrete With Superior Ductility And Fracture Toughness Using Alumina Nanoparticles Journal Of Materials In Civil Engineering Vol 29 No 8

A Stress Strain Curve Of Abs And B Stress Strain Curve Of Pla Download Scientific Diagram

Abs Stress Strain Curve Drone Fest

3d Printing Vs Injection Tensile Strength Comparison

Tensile Behavior Of Acrylonitrile Butadiene Styrene At Different Temperatures

Q Tbn And9gcraq4usvwxd4w0bhnq8rcdeilgevkjqui8zprq8q8vm5yrdbegf Usqp Cau

Http Web Mae Ufl Edu Rapidpro Pages 3d printing paper final manuscript Pdf

Www Dynalook Com 8th European Ls Dyna Conference Session 16 Session16 Paper3 Pdf

Rate Dependent Constitutive Model Development Of Pc Abs Material Springerlink

Stress Strain Curves Experiment And Models A Pc Abs B Pmma C Download Scientific Diagram

How Tensile Strength Relates To 3d Printing Make Parts Fast

Typical Tensile Stress Strain Curves Of Ti Abs Joints With And Download Scientific Diagram

Iopscience Iop Org Article 10 10 1757 9x 377 1 Pdf

Tensile Behavior Of Acrylonitrile Butadiene Styrene At Different Temperatures

Www Interowa At Website File Top Biesterfeld Englisch Pdf

Http Web Mae Ufl Edu Rapidpro Pages 3d printing paper final manuscript Pdf

Understanding Creep Failure Of Plastics

Balance Between Bonding And Deposition During Fused Deposition Modeling Of Polycarbonate And Acrylonitrile Butadiene Styrene Composites Zhou Polymer Composites Wiley Online Library

Mechanical Properties And Impact Behavior Of A Microcellular Structural Foam

The Effects Of Temperature Plastics Technology

Lateral Stress And Density Measurements For Pc Abs Hips And Pp Bulk Resin Feed Stock Spe Extrusion Division 1 0 Wiki

Advanced Search Filament2print

Http Www Dynamore De De Download Papers Forum08 Dokumente D Iii 02 Pdf

Polymers Free Full Text Rheological Investigation Of Relaxation Behavior Of Polycarbonate Acrylonitrile Butadiene Styrene Blends Html

Deformation Of Pc Abs Alloys At Elevated Temperatures And High Strain Rates Sciencedirect

Strength At Break Tensile

Dynamic And Static True Stress Strain Curves For Pc And Abs With Fdm Download Scientific Diagram

Tensile Behavior Of Acrylonitrile Butadiene Styrene At Different Temperatures

Comprehensive Materials Testing System Me 44 Products Pasco

Mechanical Properties And Impact Behavior Of A Microcellular Structural Foam

Http Www Dynamore De De Download Papers Forum08 Dokumente D Iii 02 Pdf

Experimental Characterization Of The Mechanical Properties Of 3d Printed Abs And Polycarbonate Parts Emerald Insight

Solid Abs Stress Strain Curve Walley And Field 1994 Download Scientific Diagram

Experimental And Modeling Study Of The Compressive Behavior Of Pc Abs At Low Moderate And High Strain Rates Sciencedirect

Q Tbn And9gcru56gswv19ujpdprhkijgpdh7jwfg5grfpnje15picn9xgi9ht Usqp Cau

Http Jep Sagepub Com Content 48 2 164 Full Pdf

Hybridization Effect Of Talc Glass Fiber As A Filler In Polycarbonate Acrylonitrile Butadiene Styrene Composites Sciencedirect

Shear Stress Strain Curves A Through The Thickness And B In Plane Download Scientific Diagram

Core Ac Uk Download Pdf Pdf

Tensile Behavior Of Acrylonitrile Butadiene Styrene At Different Temperatures

Stress Strain Curves Of Material A 10 Wt Ncf Material B 12 Wt Download Scientific Diagram

An Experimental And Constitutive Modeling Study On The Large Strain Deformation And Fracture Behavior Of Pc Abs Blends Sciencedirect

An Experimental And Constitutive Modeling Study On The Large Strain Deformation And Fracture Behavior Of Pc Abs Blends Sciencedirect

Stress Strain Curves Of Pc And Composites Download Scientific Diagram

Tensile Stress Strain Diagrams Of The Abs Pvc Covering Layer Curve A Download Scientific Diagram

Stress Strain Curves Over A Range Of Temperatures For Pc At 5500 500s Download Scientific Diagram

Www M Ep Co Jp En Pdf Product Iupi Nova Physicality 03 Pdf

Experimental And Modeling Study Of The Compressive Behavior Of Pc Abs At Low Moderate And High Strain Rates Sciencedirect

Thermoplastic Material Selection For Injection Molding

Materials Plastics Ppt Video Online Download

Thermoplastic Material Selection For Injection Molding

Characterisation Of Pc Abs Blend During Reprocessing Cycles And Subsequent Functionality Recovery By Virgin Additives Springerlink

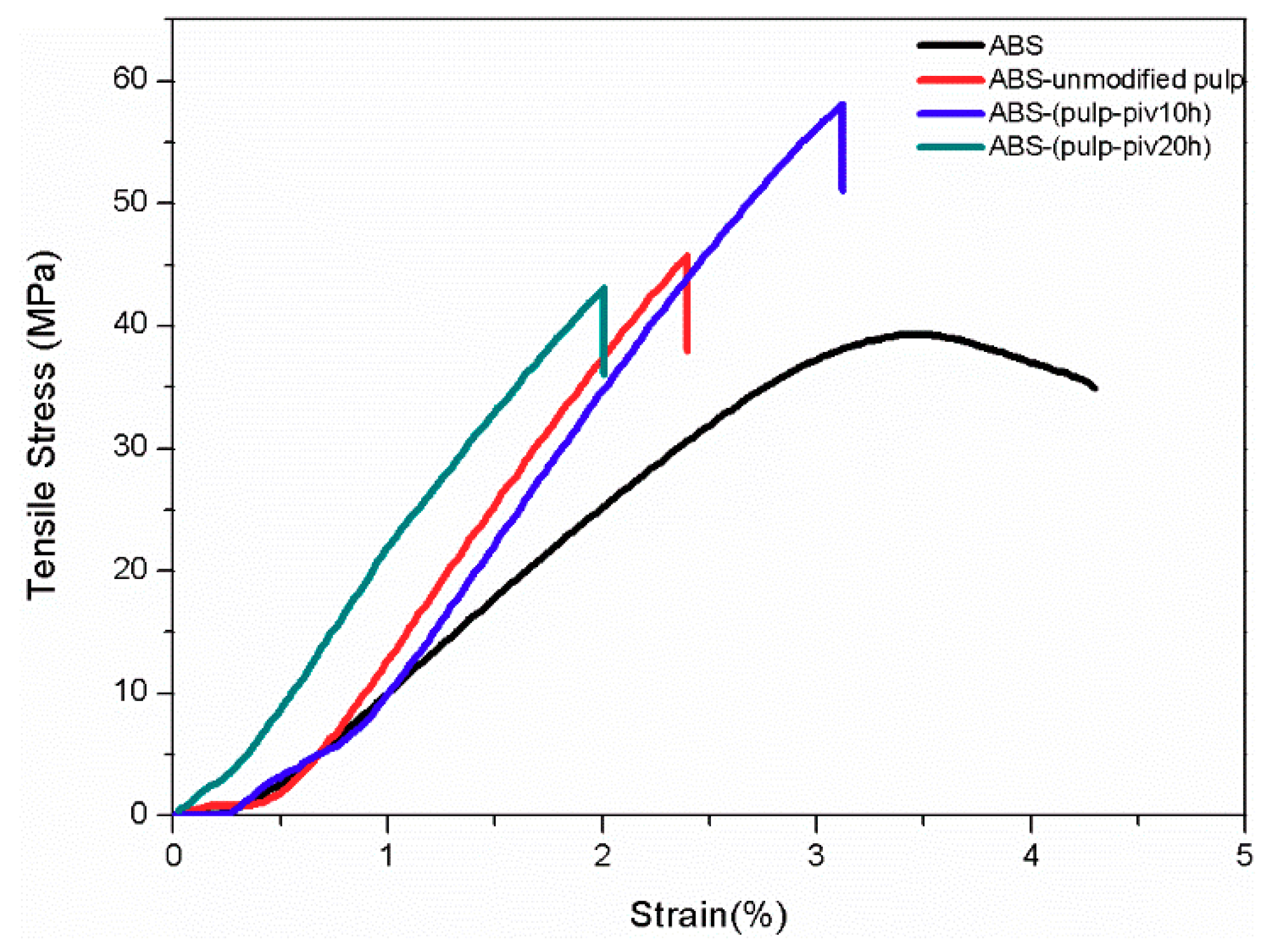

A Bioplastic With High Strength Constructed From A Cellulose Hydrogel By Changing The Aggregated Structure Journal Of Materials Chemistry A Rsc Publishing Doi 10 1039 C3taj

Http Web Mae Ufl Edu Rapidpro Pages 3d printing paper final manuscript Pdf

Http Troindia In Journal Ijapme Vol1iss6 33 37 Pdf

Iopscience Iop Org Article 10 10 1757 9x 377 1 Pdf

Experimental Investigation And Modeling Of The Tension Behavior Of Polycarbonate With Temperature Effects From Low To High Strain Rates Sciencedirect

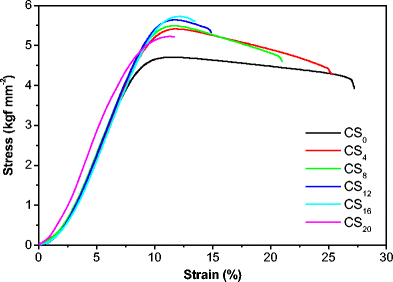

Polymers Free Full Text Interface Reinforcement Of Pulp Fiber Based Abs Composite With Hydrogen Bonding Initiated Interlinked Structure Via Alkaline Oxidation And Tert Butyl Grafting On Cellulose Html

Cowper Symonds Parameters Estimation For Abs Material Using Design Of Experiments With Finite Element Simulation

Consistency Analysis Of Mechanical Properties Of Elements Produced By Fdm Additive Manufacturing Technology

Www Mdpi Com 1996 1944 11 8 1333 Pdf

Mycourses lto Fi Mod Resource View Php Id

Http Troindia In Journal Ijapme Vol1iss6 33 37 Pdf

Http Web Mae Ufl Edu Rapidpro Pages 3d printing paper final manuscript Pdf

Mechanical Properties Of Thermoplastics An Introduction

Dynamic And Static True Stress Strain Curves For Pc And Abs With Fdm Download Scientific Diagram

Q Tbn And9gct6hyjp P Oj8af9mor2dlrahuh6zc9ggckkuvbsnrnd2duyq0a Usqp Cau

The Stress Strain Curves For The 5 Tio 2 Abs Nanocomposites The Download Scientific Diagram

Polymers Free Full Text Rheological Investigation Of Relaxation Behavior Of Polycarbonate Acrylonitrile Butadiene Styrene Blends Html

Consistency Analysis Of Mechanical Properties Of Elements Produced By Fdm Additive Manufacturing Technology