Hygienic Factory Design For Food Processing

Complying With Fsma For Pet Food Manufacturing 19 09 17 Food Engineering

Hygienic Design Is Mandatory Hbm

Design And Facilities

Assessment And Management Of Seafood Safety And Quality

Hygienic Design Of Piping For Food Processing Support Systems In Food Factories Sciencedirect

2

Sanitary and hygienic design helps equipment manufacturers and, subsequently, food processing plants, remain compliant with the latest regulations and recommended best practices In addition to ensuring the safety of the food supply, sanitary and hygienic design principles simply make practical (and economic) sense.

Hygienic factory design for food processing. Avoid product contamination with chemicals eg, cleaning agents, lubricants, peeling paint, etc and particles eg, glass, dust, iron, etc;. Food processing, including dairy, meat & cheese processing and readytoeat (RTE) food preparation requires hygienic air handling as a critical element of the food processing environment Too often, the focus of engineering is concentrated on the hygienic air handler with insufficient consideration given to the air delivery system. Robust Design 316 SS wetted parts are standard on the Jabsco FIP for food processing pumps, coupled with high grade flexible impellers, mechanical seals, and extremely robust drive systems ensure the longevity of these pumps in the factory environment Jabsco pumps are regarded by industry as the best of their type in the market cleanability.

Considering the importance of hygienic design of equipment used in food processing industry, it is important to use the right materials and design techniques The designer, firstly, should determine the requirements, that can keep the equipment from causing contamination. FoodInfonet> Topics > Food Engineering > Hygienic Engineering > EHEDG Documents Hygienic Design Guidelines (As published by EHEDG) The EHEDG (European Hygienic Engineering and Design Group) is a consortium of equipment manufacturers, food industries, research institutes, universities and public health authorities, founded in 19 with the aim to promote hygiene during the processing and. The hygienic processing of food concerns both potential hazards in food products and the regulation, design, and management of food processing facilities This second edition of Hygiene in Food Processing gives a revised overview of the practices for safe processing and incorporates additional chapters concerning pest control, microbiological environmental sampling, and the economics of food.

Hygienic Design Hygienic design impacts all elements of the food manufacturing infrastructure, including equipment, the facility, buildings and grounds This section outlines key principles of hygienic equipment and facility design with illustrative examples frozen food companies can implement to best address Listeria monocytogenes (Lm) risks. Hygienic layout design of a foodprocessing plant that is particularly useful in production engineering and design for food processing companies that face a large number of product changes. Campden BRI Updates Guidance on Food Factory Hygiene Campden BRI has updated guidance on the design, implementation, and control of cleaning and disinfection of food factories The revised version will help food and drink manufacturers ensure their factories are cleaned and disinfected effectively so that they maintain a high hygienic standard and continue to produce safe products.

Beverage production facility Food manufacturers face all of the usual challenges when designing a new facility or expanding an existing one market uncertainty, return on investment hurdles, and capital constraints, to name a few But in addition, food manufacturers must meet very high standards for food safety and sanitary design While it may seem that approaches to ensuring food safety and. Hygienic spray dryer design for processing food ingredients Hygienic spray dryer designs which exceed 3A Sanitary Standards are increasingly being specified for the processing of food ingredients used in sensitive applications such as infant formula Optimized hygienic plant layout. 5 Ways to A Hygienic Processing Facility Design What are five key considerations for food and beverage manufacturers when it comes to hygienic plant design?.

Gough Econ designs, engineers, and manufactures bulk material handling equipment that helps food manufacturers manage the integrity of their end products Ou. Considering the importance of hygienic design of equipment used in food processing industry, it is important to use the right materials and design techniques The designer, firstly, should determine the requirements, that can keep the equipment from causing contamination. Life Cycle for Equipment in a Plant Sanitary Design Opportunities •Produce 2 billion meals •Train 250 employees on how to clean •Introduce and train 80 production supervisors •Spend up to 33,000 hours cleaning it •Spend 2500 hours doing preop inspections •Not produce up to 295 Million lbs of food •Generate 15 million gallons of effluent BOD.

Guidelines for the Hygienic Design, Construction and Layout of Food Processing Factories Guideline 39 Author Campden BRI Publisher Campden BRI food factory service providers and insurers to provide a harmonised approach to factory design Taking a systematic approach, the guideline considers a wide range of key factors including building. Campden BRI has updated guidance on the design, implementation, and control of cleaning and disinfection of food factories The revised version will help food and drink manufacturers ensure their factories are cleaned and disinfected effectively so that they maintain a high hygienic standard and continue to produce safe products. A high standard of hygiene is a prerequisite for safe food production, and the foundation on which HACCP and other safety management systems depend Edited and written by some of the world's leading experts in the field, and drawing on the work of the prestigious European Hygienic Engineering and Design Group (EHEDG), Hygiene in food processing provides an authoritative and comprehensive.

Hygienic Design of Food Processing Equipment Duration 4928 Perry Johnson Registrars Food Safety, Inc 1,278 views FABS Food & Beverage Solution (Factory Design) Duration 219. 11 Hygienic Building Design Checklist Introduction To ensure safe food and adequate sanitation programs, BOTH THE EQUIPMENT AND THE FACTORY used for processing and handling food products must be designed, fabricated, constructed, and installed according to sound hygienic design principles Hygienic food factory design provides. Food safety is vital for consumer confidence, and the hygienic design of food processing facilities is central to the manufacture of safe products Hygienic design of food factories provides an authoritative overview of hygiene control in the design, construction and renovation of food factories.

Hygienic Design Hygienic design impacts all elements of the food manufacturing infrastructure, including equipment, the facility, buildings and grounds This section outlines key principles of hygienic equipment and facility design with illustrative examples frozen food companies can implement to best address Listeria monocytogenes (Lm) risks. 5 Ways to A Hygienic Processing Facility Design What are five key considerations for food and beverage manufacturers when it comes to hygienic plant design?. Building and Sustaining Hygienic Design for Food ProcessingPerspectives for the new generation of food scientistsAlejandro Echeverry, PhD Assistant Professor Food Safety Department of Animal and Food Sciences Texas Tech University 3A SSI Annual Meeting –Milwaukee, May 16th19th, 16.

Food safety is vital for consumer confidence, and the hygienic design of food processing facilities is central to the manufacture of safe products. Hygienic design in food processing plays an important role in controlling the microbiological safety and quality of the products made This will prevent products from having undesirably high microbial counts, containing toxins or chemical residues, or from contamination from other nonfood substances. Food safety is vital for consumer confidence, and the hygienic design of food processing facilities is central to the manufacture of safe products.

"Food safety is the single greatest ongoing challenge for manufacturers, and we need to evolve to meet the everincreasing demands". Hygienic food factory design provides Defence against external factory hazards Defence against internal factory hazards no harbourage sites and ease of cleaning Internal flows of people, product, packaging, air and wastes to prevent crosscontamination Security against deliberate contamination The maintenance of hygienic conditions via structure rigidity ² appropriate foundations, steelwork, floor slabs The Maintenance of hygienic conditions via material durability. Product contamination occurs not only at the equipment level but also at factory level Incorporation of hygienic design into your food processing facility can prevent development of pests and microbiological niches;.

The above text deals with only a fraction of hygienic equipment for processing of food products For a description of the requirements for hygienic design of equipment, see EHEDG guideline no81 and for meeting these requirements, see Hygiene in food processing Principles and practice2 Hygienic design of factory buildings. HYGIENIC DESIGN October/November 10 Hygienic Design of Food Processing Facilities By Frank Moerman, MSc Increasing consumer demand for fresh foods has led to the development of processing and preservation methods that have minimal impact on either the nutritional or sensory properties of foods. Hygienic design and practices are thus two of the key factors in producing safe and wholesome foods Food processing equipment that is designed hygienically has three key advantages• Food quality Good hygienic design maintains product in the main product flow This ensures that product is not 'heldup' within the equipment where it could.

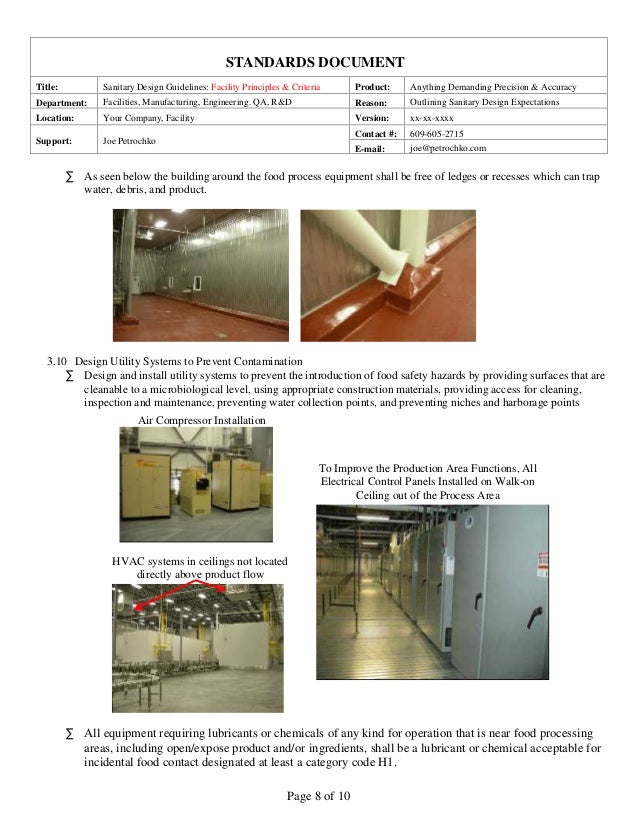

213 General hygienic requirements for food processing support piping within the factory 214 Specific hygienic design requirements for food processing support piping in rooms of different hygienic class Chapter 22 Hygienic design of exhaust and dust control systems in food factories Abstract 221 Introduction 222 Mechanical ventilation. Design, lay out and construct food premises, so that there is sufficient space to allow for good food hygiene practice in all operations, as well as the carrying out of adequate maintenance, cleaning and / or disinfection operations are protected from contamination at all stages of food production, processing,. The first step to creating a hygienic facility is to look at the construction of the facility itself Examine your layout — does the design allow the processing and packaging of the food product to flow in the same direction, or do you have to move back and forth to complete everything?.

Hygienic design and practices are thus two of the key factors in producing safe and wholesome foods Food processing equipment that is designed hygienically has three key advantages• Food quality Good hygienic design maintains product in the main product flow This ensures that product is not 'heldup' within the equipment where it could. Facilitate cleaning and sanitation and preserve hygienic conditions both during and after maintenance. FoodInfonet> Topics > Food Engineering > Hygienic Engineering > EHEDG Documents Hygienic Design Guidelines (As published by EHEDG) The EHEDG (European Hygienic Engineering and Design Group) is a consortium of equipment manufacturers, food industries, research institutes, universities and public health authorities, founded in 19 with the aim to promote hygiene during the processing and.

Hygienic Design of Food Factories Book Description Food safety is vital for consumer confidence, and the hygienic design of food processing facilities is central to the manufacture of safe products Hygienic design of food factories provides an authoritative overview of hygiene control in the design, construction and renovation of food factories. Using machinery designed with hygienic design principles in mind helps food manufacturers limit the risk of toxins or other microbiological organisms coming into contact with food supplies The good news is that sanitary and hygienic design doesn’t necessarily cost more than the same equipment would cost without these principles in mind That said, there is sometimes a higher upfront cost due to certain material choices, but the benefits of these choices reduce operating costs in the long. The Hygienic Design of Food Processing Plant Tony Hasting 37 Church Lane, Sharnbrook, Bedford, MK44 1HT, UK Search for more papers by this author Tony Hasting 37 Church Lane, Sharnbrook, Bedford, MK44 1HT, UK Search for more papers by this author Book Editor(s) James G Brennan MSc FIFST.

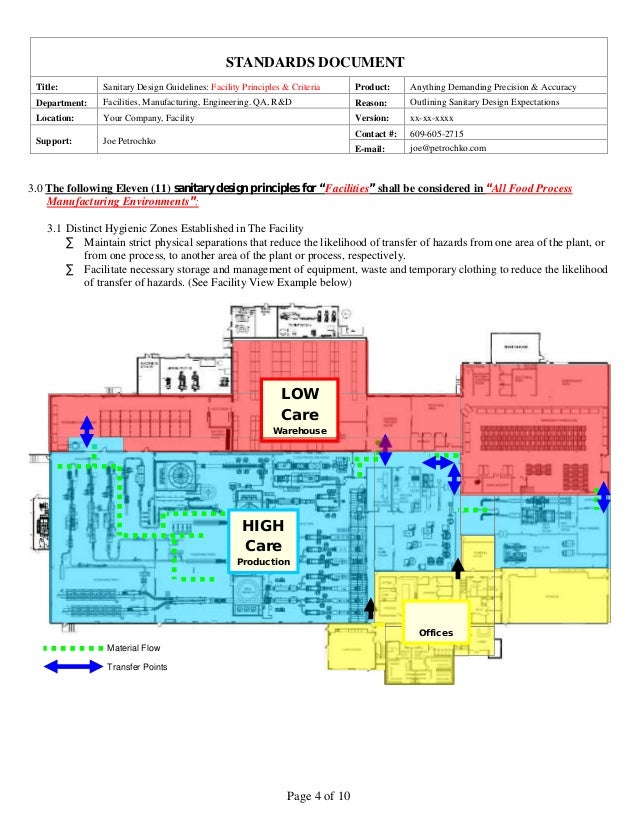

Hygiene in food production has always been a priority, even when production occurs under crisis conditions While the world stayed at home during the COVID19 pandemic and maintained social distance, the food industry had to find a way to ramp up production despite the dangers to its workforce of the highly contagious disease Due to the necessary close proximity required for some specific. During the design, construction or renovation of a food processing facility, a number of sanitary principles should be taken into consideration Bove was part of the American Meat Institute’s facility design task force, which developed 11 sanitary design principles to reduce food safety hazards Distinct hygienic zones established in the facility. Food safety is vital for consumer confidence, and the hygienic design of food processing facilities is central to the manufacture of safe products Hygienic design of food factories provides an authoritative overview of hygiene control in the design, construction and renovation of food factories.

Principles of Hygienic Design for Food Processing Facilities 08 July, 19 The American Meat Institute has come up with the following principles of hygienic design for food processing facilities These design principles have been created to reduce food safety hazards, keeping food safe Whether you're building a new facility, updating your existing one or onboarding new employees, take these principles of hygienic design into consideration to prevent food borne illness and product recalls. Evaluating Equipment and Buildings for Hygienic Design The principles of hygienic design can be readily applied to any piece of equipment or building The accompanying checklist has been developed specifically for farmbased produce handling equipment and buildings It is based on other, more extensive guides from the processing industry. Robust Design 316 SS wetted parts are standard on the Jabsco FIP for food processing pumps, coupled with high grade flexible impellers, mechanical seals, and extremely robust drive systems ensure the longevity of these pumps in the factory environment Jabsco pumps are regarded by industry as the best of their type in the market cleanability.

"Our PVC wall panels are specifically designed for the hygienic, lowmaintenance and durable environment required by food processing, food storage, or commercial facilities Easily versatile, the PVC wall panel system can be used to construct new rooms, or retrofit old structures. Non food production areas Factory barrier (2) Basic hygiene area Soiled raw materials, packed ingredients/finished products Medium hygiene area Ingredient preparation General processing High hygiene barrier (3) High hygiene area M icrobiologically decontaminated products, design risk assessed. Our experience in food processing plant design spans more than 15 years of factory builds, equipment installs and production line extensions From conveyors to packing machines to coolers and chillers, we work with both large and small clients in hygienic design, highcare and lowcare environments.

Our experience in food processing plant design spans more than 15 years of factory builds, equipment installs and production line extensions From conveyors to packing machines to coolers and chillers, we work with both large and small clients in hygienic design, highcare and lowcare environments. Food safety is vital for consumer confidence, and the hygienic design of food processing facilities is central to the manufacture of safe products Hygienic design of food factories provides an authoritative overview of hygiene control in the design, construction and renovation of food factories. The hygienic quality of the architectural and structural design of food processing factories is as critical as any process part in a hygienic production facility European legislation requires that handling preparation, processing, packaging, etc, of food is done hygienically, using hygienic equipment in hygienic areas.

Hygienic factory design is concerned with protecting ingredients, packaging, intermediate and finished products from contamination from the processing environment At a building design level, this involves the provision of a series of barriers to protect the product from the external environment and nonfood manufacturing activities and, within the food manufacturing environment, the segregation of incompatible ingredients, packaging, intermediate and finished products and other activities, eg. A good food factory design starts with the exterior and the manufacturer has to establish procedures to keep the exterior clean and tidy For example, The best solution for airborne contamination control to achieve total hygienic foodprocessing (02) email email protected Google Scholar Ortner news, 09. Moerman, F (11) “Hygienic design of piping for food processing support systems in food factories”, Chapter 21 in “Hygienic design of food factories” (eds) Holah, J and Lelieveld, H L M, Woodhead, Cambridge, England Google Scholar.

Optimising hygiene and efficiency are key concerns when it comes to factory design Food manufacturers need to consider all aspects of a factory’s design – even the less glamorous ones – to optimise. The European Hygienic Design Group (EHEDG) is the primary organization for food equipment approval in Europe While EHEDG has published a series of guidelines for the construction and design of food processing equipment, they have chosen not to issue standards Acceptance for food processing equipment used in some European countries is based. Hygienic Design and Controls April 29, Established in 18, the Food Safety Modernization Act (FSMA) demands that food processors comply with advanced hygienic design standards FSMA represented a major shift in the industry, transferring priority from treating foodborne illness to preventing it entirely.

Hygienic Design For Food And Beverage Applications Psi Technologies

Hygienic System Design For Food Processing Facilities Panorama Consulting Engineers India

Hygienic Zoning In Food Manufacturing Factories Food Safety Magazine

Food Hygiene At Campden Bri

How Food Processors Can Choose The Right Floors Doors And Ceilings 18 02 Food Engineering

Improving Food Safety And Sanitation Through Facility Layout And Design 02 18 Snack Food Wholesale Bakery

Q Tbn And9gcriwc3buodtzfpmpfckemuu3je425blpbhdgex1khkcsvobrouo Usqp Cau

Www Ifst Org Sites Default Files J holah ifst hygiene 25th february Pdf

Hygienic Zoning In Food Manufacturing Factories Food Safety Magazine

Improving Food Safety And Sanitation Through Facility Layout And Design 02 18 Snack Food Wholesale Bakery

Sanitary Facility Design Guidelines Part 2 Of 2

Q Tbn And9gcsetl Ffxs4sj6n68l4ddclvsvct5dv3jxydpxxksq4l 53 M1g Usqp Cau

How To Design A Hygienic Food Processing Facility

A Guide For Conducting A Food Safety Root Cause Analysis The Pew Charitable Trusts

Hygiene Concepts For Food Factory Design Sciencedirect

The Impact Of Factory Layout On Hygiene In Food Factories Sciencedirect

Designing Your Plant For Petfood Safety

Sanitary And Hygienic Design Guide For Food Equipment Mpc

Designing Your Plant For Petfood Safety

Improving Food Safety And Sanitation Through Facility Layout And Design 02 18 Snack Food Wholesale Bakery

Washroom Staff Changing Areas Food Industry Rezahygiene Your Partner In Hygiene

Development Of A Layout Model Suitable For The Food Processing Industry

Sanitary Process Installation What To Ask When Selecting A Subcontractor Stellar Food For Thought

Baby Food Production Lines Cft Group

Hygienic Drainage Design Promotes Food Safety Aco Food

Hygiene Concepts For Food Factory Design Sciencedirect

Hygiene In Food Processing And Manufacturing Sciencedirect

Food Processors Must Be Proactive In Sanitary And Hygienic Design 19 10 14 Food Engineering

Handbook Of Hygiene Control In The Food Industry 2nd Edition

Hygienic Equipment Design For Low Moisture Food Manufacturing May 29th 14 At 12 00 Edt Kollmorgen

Sanitary Design Leads To Improved Food Safety 01 07 Food Safety Strategies

Hygienic Factory Design For Food Processing Sciencedirect

A Systems Approach To Hygiene In Food Processing Environments

Design Tips For Hygienic Floors In Food And Beverage Facilities

Q Tbn And9gcriwc3buodtzfpmpfckemuu3je425blpbhdgex1khkcsvobrouo Usqp Cau

Food Drink Manufacturing

Hygienic Flooring The Role Of Floor Coatings In Keeping Food Safe Process Expo 21

What Your Local Food Processing Factory Will Incorporate Soon Sanitary Valve World

Food Industry

The Standards For Manufacturing Food Factory For Rent Kizuna

Layouts

Factors To Consider In Designing Food Processing Equipment

Hygienic Conveyor Design In The Food Factory Youtube

Food Processors Must Be Proactive In Sanitary And Hygienic Design 19 10 14 Food Engineering

Hygienic Factory Design For Food Processing Sciencedirect

Design Tips For Hygienic Floors In Food And Beverage Facilities

Eliminating Hygienic Hazards 15 11 25 Food Engineering

Www Myfoodresearch Com Uploads 8 4 8 5 Fr 18 149 Pdf

Aquatiq Guidelines For The Food Industry Hygienic Design Of Food Processing Equipment

How Food Processors Can Choose The Right Floors Doors And Ceilings 18 02 Food Engineering

Food Grade Products For A Hygienic Production Process

Productive Workflows

5 Factors That Matter The Most In Hygienic Equipment Design Profood World

The Importance Of Good Manufacturing Practices In The Food Industry Foodsafe Drains

Sanitary Facility Design Guidelines Part 2 Of 2

Www Ehedg Org Guidelines Tx Ehedgguidelines Guidelines 5bfiletodownload 5d File 3a6700 Tx Ehedgguidelines Guidelines 5bguideline 5d 8 Tx Ehedgguidelines Guidelines 5btitel 5d Hygienic design principles Tx Ehedgguidelines Guidelines 5blanguage 5d 1 Tx Ehedgguidelines Guidelines 5baction 5d Ajaxdownloadcounter Tx Ehedgguidelines Guidelines 5bcontroller 5d Guidelines Chash A50e63faaad23c6a08cc8578c2f4

Hygienic Floor Design Food Safety Bakerpedia

Food Plant Sanitation Choosing Flooring Walls Ceilings And Doors To Improve Food Safety Stellar Food For Thought

Choosing Hygienic Flooring For Your Food And Beverage Facility Food Quality Safety

Guidelines For The Hygienic Design Construction And Layout Of Food Processing Factories Ebook By Dr John Holah Rakuten Kobo Greece

Perfect Extreme Hygienic Control Hmi Pc For Food Pharmaceutical Healthcare Applications After Pandemic

Sanitary And Hygienic Design Guide For Food Equipment Mpc

Hygiene Concepts For Food Factory Design Sciencedirect

Hygiene Concepts For Food Factory Design Sciencedirect

Choosing Doors For Food Processing Facilities

Sanitary Design

Hygienic Factory Design For Food Processing Sciencedirect

Food Processing Wikipedia

Washroom Staff Changing Areas Food Industry Rezahygiene Your Partner In Hygiene

Use These Tips For Cleaning All Parts Of A Food Factory 18 12 14 Food Engineering

Perfect Extreme Hygienic Control Hmi Pc For Food Pharmaceutical Healthcare Applications After Pandemic

Www Ifst Org Sites Default Files J holah ifst hygiene 25th february Pdf

The Secrets Of Food Factory Layout Design Txm Lean Solutions

Plant Engineering 5 Key Questions To Answer During Hygienic Food Plant Design

Designing Your Hygienic Zoning Quality Assurance Food Safety

Hygiene Zoning Is Key For Pathogen Control In Dairy Processing

Hygienic Factory Design For Food Processing Sciencedirect

Sanitary Facility And Equipment Design 01 31 Food Safety Strategies

Sanitary And Hygienic Design Guide For Food Equipment Mpc

Q Tbn And9gcrqdcw5cspvtlxnjvojanzqcrxx7ihzhritymlryvti Y3ftbft Usqp Cau

Www Ifst Org Sites Default Files J holah ifst hygiene 25th february Pdf

Hygienic Factory Design For Food Processing Sciencedirect

Hygienic Design For Processing Equipment Food Quality Safety

Improve Food Safety Esi Group Usa

Hygienic And Functional Drainage Solutions For The Food Processing Industry

Pdf A Layout Planning Framework For The Food Processing Industry

Image Result For Food Processing Factory Layout How To Plan Factory Architecture Factory Design

Sanitary Facility And Equipment Design 01 31 Food Safety Strategies

Hygiene In Food Processing 2nd Edition

Design Tips For Hygienic Floors In Food And Beverage Facilities

Food Factory Design And Factory Layout At Campden Bri

Www Ifst Org Sites Default Files J holah ifst hygiene 25th february Pdf

Food Processors Must Be Proactive In Sanitary And Hygienic Design 19 10 14 Food Engineering

Food Processing 10 Ways To Ensure Food Safety Rentokil

Hygienic Design Of Food Factories 1st Edition

Sanitary And Hygienic Design Guide For Food Equipment Mpc

Hygienic Design Of Food Factories By John Holah

Food Factory Design Factoring In Hygiene And Efficiency