Alloy 600

The Chemical Composition Of The Inconel 600 Alloy Work Material Download Scientific Diagram

Haynes 556 Alloy For High Temperature Chemical Processes Tech Brief

Research Progress Of Nickel Based Corrosion Resistant Alloys Www Pipelinedubai Com

Inconel 600 Tube Alloy 600 Tubing China Guanyu Stainless Steel Tube

A Study Of Metal Dusting Corrosion On Fe And Ni Based Alloys

Inconel 600 Round Bars Alloy 600 Round Bar W N 2 4816 Round Bars

When it comes to nickel content, Inconel 625® falls between the 330 and 600 alloys at 58% minimum nickel At 23%, chromium is the next most abundant element in this alloy The addition of columbium and molybdenum adds to the alloy’s performance at various temperatures—which is why Inconel 600® is noted for having superb strength and.

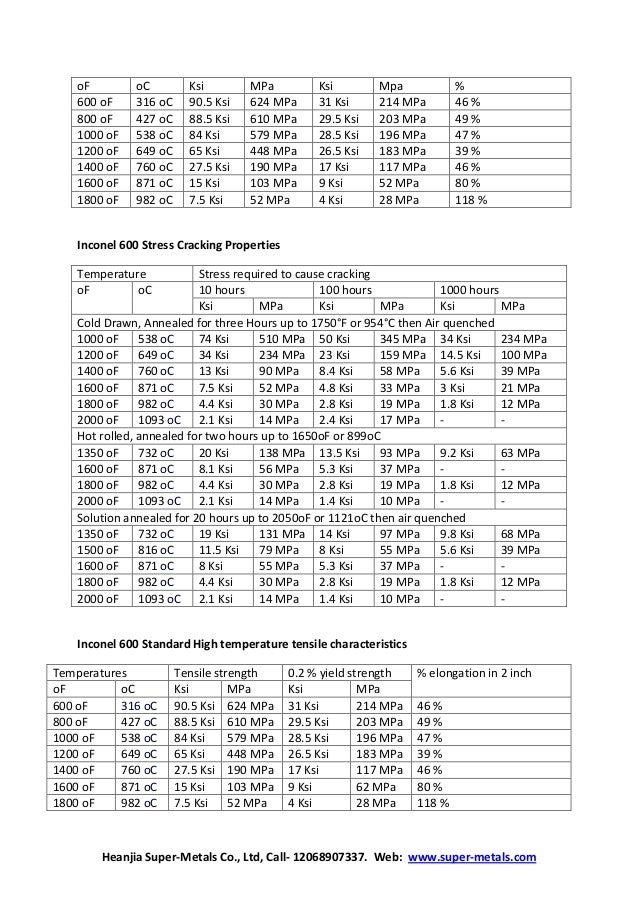

Alloy 600. INCONEL® Alloy 600 / UNS N A nickelchromium alloy with good oxidation resistance at high temperatures and resistance to chlorideion stresscorrosion cracking, corrosion by highpurity water, and caustic corrosion Used for furnace components, in chemical and food processing, in nuclear engineering, and for sparking electrodes. Alloy 600 is a nonmagnetic, nickelbased high temperature alloy possessing an excellent combination of high strength, hot and cold workability, and resistance to ordinary form of corrosion This alloy also displays good heat resistance and freedom from aging or stress corrosion throughout the annealed to heavily cold worked condition range. When it comes to nickel content, Inconel 625® falls between the 330 and 600 alloys at 58% minimum nickel At 23%, chromium is the next most abundant element in this alloy The addition of columbium and molybdenum adds to the alloy’s performance at various temperatures—which is why Inconel 600® is noted for having superb strength and.

Similar in makeup to X750, nickel alloy 600 tubing has a nickel content of approximately 72% and exhibits resistance to a wide range of corrosive sources, in part due to its chromium content Inconel® 600 tubes are also very effective in high heat environments approaching 00 degrees F They also demonstrate excellent resistance to high purity water. Nickel Alloy 600 pipe, also known as Inconel® 600 pipe, is an extremely versatile nickelchromium alloy capable of resisting oxidation in temperatures up to 00 ºF (1093 ºC) It's also used in cryogenic environments, thanks to a minimum of 72% Nickel combined with chromium in its chemical composition It exhibits corrosion resistance to. What is Inconel 600 Plate?.

Check Inconel 600 melting point, Alloy 600 weight calculator, PED approved Inconel 600 material stockist Inconel 600 applications include furnace retort seals, fixtures and fans, roller hearths in carbon nitriding processes, radiant tubes, reactor vessels, heat exchanger tubes and other components in vinyl chloride production and in thermocouple sheaths and others. Alloy 600 Products Suppliers in Mumbai, India Alloy 600 is resistant to corrosion by many organic and inorganic compounds and also makes it virtually immune to chlorideion stresscorrosion cracking Alloy 600 is used extensively in the chemical industry for its strength and corrosion resistance. Difference Between Inconel 600 and 601 INCONEL 600 Nickel Alloy 600, also known as Inconel 600, is an extremely versatile nickelchromium alloy capable of resisting oxidation in temperatures up to 00 ºF (1093 ºC)Inconel 600 is a nonmagnetic nickelchromiumiron high temperature alloy with an excellent combination of high strength, hot and cold workability and high corrosion resistance.

Alloy 600 is a nickelchromiumiron, solid solution strengthened alloy used for applications that require corrosion and elevated temperature resistance Service temperatures for alloy 600 can be from cryogenic to 00°F This alloy also has good workability, weldability and high strength. Inconel® 600 (Alloy 600) Description Inconel® Alloy 600 is a nickelchromium alloy with excellent carburization and good oxidation resistance It was designed for use from cryogenic to elevated temperatures in the range of 00°F (1093°C) The high nickel content of the material provides exceptional resistance to chloride stress corrosion. Inconel Alloy® 600 is a nickelchromium alloy designed for use at cryogenic temperatures and up to 00˚F (1093˚C) The high nickel content of the alloy provides good resistance to reducing environments, while the chromium content provides resistance to weaker oxidizing conditions.

In metal processing industry furnance muffles. Nickel Alloy 600, also sold under the brand name Inconel® 600 It is a unique nickelchromium alloy that is known for its oxidation resistance at higher temperatures It is highly versatile and can be used in everything from cryogenics to applications that present elevated temperatures up to 00°F (1093°C) Its high nickel content, a minimum. Alloy 600 nickel pipe is a nickelchromium alloy with good oxidation resistance to 00 degree F Good strength and resistance to general corrosion in a variety of elements Resists stresscorrosion cracking Typical applications thermocouple, furnace muffles, heat exchangers, food processing Pipe Line Card PDF Download.

Alloy 600 Summary lnconel® 600 is a nickelchromium alloy designed for use from cryogenic to very high temperatures in the range of 00 °F (1093 °C) It is a standard engineering material for applications which require resistance to corrosion, oxidation, and elevated temperatures so it is used in a variety of corrosion resisting applications. Inconel 600 is a nickelchromium alloy with good oxidation resistance at high temperatures and resistance to chlorideion stresscorrosion cracking, corrosion by highpurity water, and caustic corrosion Inconel 600 is used for furnace components, in chemical and food processing, in nuclear engineering and for sparking electrodes. SMLS ALLOY 600 B163 1 OD X 065 WA.

Similar in makeup to X750, nickel alloy 600 tubing has a nickel content of approximately 72% and exhibits resistance to a wide range of corrosive sources, in part due to its chromium content Inconel® 600 tubes are also very effective in high heat environments approaching 00 degrees F They also demonstrate excellent resistance to high purity water. Check Inconel 600 melting point, Alloy 600 weight calculator, PED approved Inconel 600 material stockist Inconel 600 applications include furnace retort seals, fixtures and fans, roller hearths in carbon nitriding processes, radiant tubes, reactor vessels, heat exchanger tubes and other components in vinyl chloride production and in thermocouple sheaths and others. INCONEL® Alloy 600 (UNS N WNr ) is a standard engineering material for applications which require resistance to corrosion and heat The alloy also has excellent mechanical properties and presents the desirable combination of high strength and good workability The versatility of INCONEL® alloy 600 has led to its use in a variety.

Alloy 600 nickel pipe is a nickelchromium alloy with good oxidation resistance to 00 degree F Good strength and resistance to general corrosion in a variety of elements Resists stresscorrosion cracking Typical applications thermocouple, furnace muffles, heat exchangers, food processing Pipe Line Card PDF Download. Alloy 600 is relatively unattacked by the majority of neutral and alkaline salt solutions and is used in some caustic environments The alloy resists steam and mixtures of steam, air and carbon dioxide Alloy 600 is nonmagnetic, has excellent mechanical properties and a combination of high strength and good workability and is readily weldable. Alloy 600, commonly known as INCONEL® 600, is a nickelchromium alloy with good oxidation resistance at high temperatures and resistance to chlorideion stresscorrosion cracking The high nickel content enables it to retain considerable resistance to neutral and alkaline salt solutions and the use in caustic environments.

Welding Characteristics of Inconel 600 Generally, preheating is not required for Inconel 600 welding However, when the base metal temperature is lower than 15°C, the joint area of two sides with a length of 250 mm ~ 300 mm shall be preheated to 15°C ~ °C to avoid blow holes resulting from moisture condensing. Steelun Description of VDM® Alloy 600 H Nicrofer® 7216 H is a nickelchromiumiron alloy, characterized by good resistance to oxidation, carburization and nitridation, good resistance to stress corrosion cracking at both room and elevated temperatures, good resistance to dry chlorine and hydrogen chloride, good mechanical properties at subzero, room and elevated temperatures. INCONEL® 600 is combination of Nickel Chromium and Iron provides a standard material for the chemical industry and the automotive engine, aeroengine and airframe sectors Controlled chemical composition limits are applied in the nuclear industry to eliminate the risk of stress corrosion cracking by high purity water containing chloride ions.

Inconel® nickelchromiumiron alloy 600 is a standard engineering material for applications which require resistance to corrosion and heat The alloy also has excellent mechanical properties and presents the desirable combination of high strength and good workability. Alloy 600 is a nickelbased alloy with excellent carburization, and good oxidation resistance at elevated temperatures The alloy has long been used in the heat treating industry for many of the same applications as RA330® Alloy 600 has useful resistance to dry Cl 2 and HCl gases at moderately elevated temperatures. Alloy 600 is a nickelbased alloy with excellent carburization, and good oxidation resistance at elevated temperatures The alloy has long been used in the heat treating industry for many of the same applications as RA330® Alloy 600 has useful resistance to dry Cl 2 and HCl gases at moderately elevated temperatures.

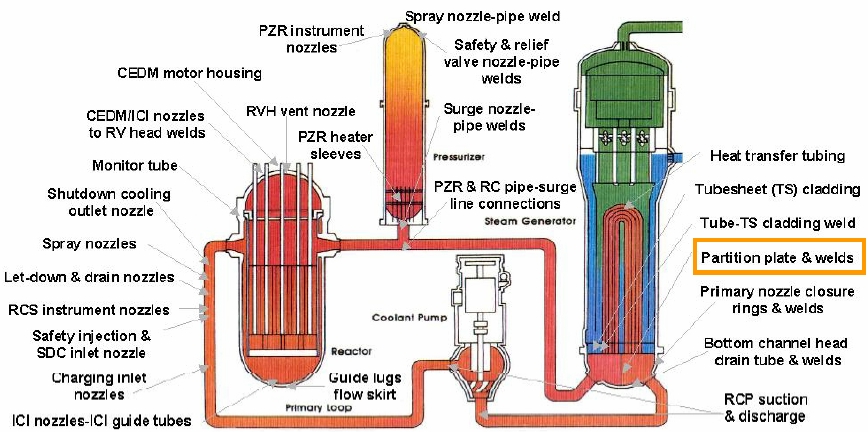

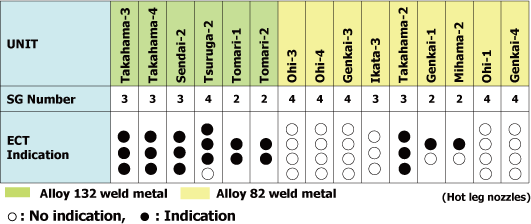

Alloy 600 is a nickelchromium alloy designed for use from cryogenic to elevated temperatures in the range of 00 deg F(1093 deg C) The high nickel content of the alloy enables it to retain considerable resistance under reducing conditions and makes it resistant to corrosion by a number of organic and inorganic compounds. Alloy 600 / is a nickelchromiumiron alloy Good resistance to oxidation, carburization and nitriding Good resistance to stress corrosion cracking Good resistance to dry chlorine and hydrogen chloride. Alloy 600 is a nickelbased alloy (72% Ni minimum, 14–17% Cr, 6–10% Fe) with high general corrosion resistance that has been widely used in light water reactor (LWR) power plants, ie, in PWRs and boiling water reactors (BWRs) In PWR plants, alloy 600 has been used for steam generator tubes, CRDM.

Alloy 600 is a nickel chromium iron alloy used for applications which require resistance to corrosion and heat This alloy has excellent mechanical properties and presents the desirable combination of high strength and good workability under a wide range of temperatures. UNS N //// Alloy 600 (UNS designation N0660) is a nickelchromium alloy designed for use in applications from cryogenic to elevated temperatures in the range of 2 000 °F (1 093 °C) Alloy 600 is nonmagnetic and readily weldable //// The alloy is used in a variety of corrosion resisting applications. Alloy 600 is relatively unattacked by the majority of neutral and alkaline salt solutions and is used in some caustic environments The alloy resists steam and mixtures of steam, air and carbon dioxide Alloy 600 is nonmagnetic, has excellent mechanical properties and a combination of high strength and good workability and is readily weldable.

Alloy 600 is a nonmagnetic, nickelbased high temperature alloy possessing an excellent combination of high strength, hot and cold workability, and resistance to ordinary form of corrosion This alloy also displays good heat resistance and freedom from aging or stress corrosion throughout the annealed to heavily cold worked condition range. INCONEL® Alloy 600 (UNS N WNr ) is a standard engineering material for applications which require resistance to corrosion and heat The alloy also has excellent mechanical properties and presents the desirable combination of high strength and good workability The versatility of INCONEL® alloy 600 has led to its use in a variety. INCONEL®(nickelchromiumiron) alloy 600 (UNS N/WNr ) is a standard engineering material for applications which require resistance to corrosion and heat The alloy also has excellent mechanical properties and presents the desirable combination of high strength and good workability.

Alloy 600 (UNS N) is a nickelchromium alloy designed for use from cryogenic to elevated temperatures in the range of 00°F (1093°C) Alloy 600 is nonmagnetic and readily weldable The alloy is used in a variety of corrosion resisting applications. Inconel Plates, Inconel® Alloy 600 CR Sheet Plate, Alloy 600 Sheets, DIN Plate Exporter, Inconel 600 Slitting Coils, ASME SB168 Inconel 600 Coil, Inconel® 600 HR Plate Sheet, UNS N Sheet Suppliers, Alloy 600 Plate, 600 Inconel Strip Manufacturers in Mumbai, India Testing. Alloy 600 is an extremely corrosion resistant material The high amounts of nickel in Alloy 600 give it the ability to resist corrosion, and in particular, chloride stress corrosion Alloy 600 also has high additions of chromium, which helps it resist oxidation Alloy 600 is a popular material choice for applications in the chemical industry.

Nickel Alloy 600 (N) is a nickelchromiumiron alloy with good oxidation resistance at high temperatures and resistance to chlorideion stress corrosion cracking corrosion by highpurity water, and caustic corrosion Alloy 600 also has excellent mechanical properties and has a desirable combination of high strength and good workability. Alloy 600 is a nickelbased alloy (72% Ni minimum, 14–17% Cr, 6–10% Fe) with high general corrosion resistance that has been widely used in light water reactor (LWR) power plants, ie, in PWRs and boiling water reactors (BWRs) In PWR plants, alloy 600 has been used for steam generator tubes, CRDM. Welding Characteristics of Inconel 600 Generally, preheating is not required for Inconel 600 welding However, when the base metal temperature is lower than 15°C, the joint area of two sides with a length of 250 mm ~ 300 mm shall be preheated to 15°C ~ °C to avoid blow holes resulting from moisture condensing.

Inconel600 (Nickel alloy 600) is a standard engineering material for applications that require resistance to corrosion and heat The alloy also has excellent mechanical properties and presents the desirable combination of high strength and good workability. Inconel® 600 (Alloy 600) Description Inconel® Alloy 600 is a nickelchromium alloy with excellent carburization and good oxidation resistance It was designed for use from cryogenic to elevated temperatures in the range of 00°F (1093°C) The high nickel content of the material provides exceptional resistance to chloride stress corrosion. Inconel® nickelchromiumiron alloy 600 is a standard engineering material for applications which require resistance to corrosion and heat The alloy also has excellent mechanical properties and presents the desirable combination of high strength and good workability.

A NickelChromium alloy with good resistance to oxidation and corrosion at high temperatures Inconel® 600 is also known as Nicrofer 716, Pyromet Alloy 600, and Nicrimphy 600. Inconel ® 600 is a unique nickelchromium alloy that is known for its oxidation resistance at higher temperatures It is highly versatile and can be used in everything from cryogenics to applications that present elevated temperatures up to 00°F (1093°C). Alloy 600 is a nickelbased alloy with excellent carburization, and good oxidation resistance at elevated temperatures The alloy has long been used in the heat treating industry for many of the same applications as RA330® Alloy 600 has useful resistance to dry Cl 2.

ASTM 66 Inconel Alloy 600 Buttweld Elbow, Inconel 600 Seamless Butt weld Fittings Exporter, Inconel 600 Long Radius Bend, Inconel 600 Pipe Fittings Supplier Amco Metals an ISO 9001 15 certified company, that offers a durable product line that embodies excellence along with innovation and quality We, at Amco, dedicatedly work on customer. Inconel 600® is a nonmagnetic nickel alloy that maintains many noncorrosive benefits This material is also heat resistant, strong and can be easily formed Magellan Metals is your Inconel 600® material experts. Difference Between Inconel 600 and 601 INCONEL 600 Nickel Alloy 600, also known as Inconel 600, is an extremely versatile nickelchromium alloy capable of resisting oxidation in temperatures up to 00 ºF (1093 ºC)Inconel 600 is a nonmagnetic nickelchromiumiron high temperature alloy with an excellent combination of high strength, hot and cold workability and high corrosion resistance.

Alloy 600 is popular engineering material for applications where resistance to both heat and corrosion is required Properties The excellent mechanical properties of the alloy give this material high strength and good workability Corrosion resistance is good, especially in alkaline environments, and can be used in both cryogenic and elevated temperature service. Alloy 600 (HB) alloy 600H (HB) =195 =185 Composition Nickel Chrome alloy Category Highly corrosion resistant alloys hightemperature resisting steels and alloys Structure Corrosion No translation!. Alloy 600 is a nonmagnetic nickelchromiumiron high temperature alloy with an excellent combination of high strength, hot and cold workability and high corrosion resistance It has good high temperature strength up to 1150ºC and displays freedom from stress corrosion.

About Inconel 600 Inconel 600 Industrial Nomenclatures Werkstoff Nr , Inconel 600, Nickelvac 600, Ferrochronin 600, Inco 600, Nickel 600, UNS N Inconel 600 is a typically engineered metallic material that offers outstanding heat, oxidation and corrosion resistanceThe highest service temperature of this super alloy goes up to 00oF and the lowest goes down to the cryogenic limits. Inconel 600 – application Alloy 600 is a versatile superalloy, which can be used in a variety of applications, involving hightemperature and corrosive conditionsOn the other hand, it is also used in cryogenic temperature Material is used In aviation engine and airframe components like exhaust liners, turbine seals and safety wires;. Alloy 600 is a nickel chromium iron alloy used for applications which require resistance to corrosion and heat The alloy also has excellent mechanical properties and presents the desirable combination of high strength and good workability under a wide range of temperatures.

Inconel 600 or as also referred to by its trade name UNS N is a nonmagnetic, highly corrosion resistant nickel based alloy Reckoned as a conventional engineering grade alloy, Inconel is a good fit for use across a wide temperature range. INCONEL® 600 is combination of Nickel Chromium and Iron provides a standard material for the chemical industry and the automotive engine, aeroengine and airframe sectors Controlled chemical composition limits are applied in the nuclear industry to eliminate the risk of stress corrosion cracking by high purity water containing chloride ions.

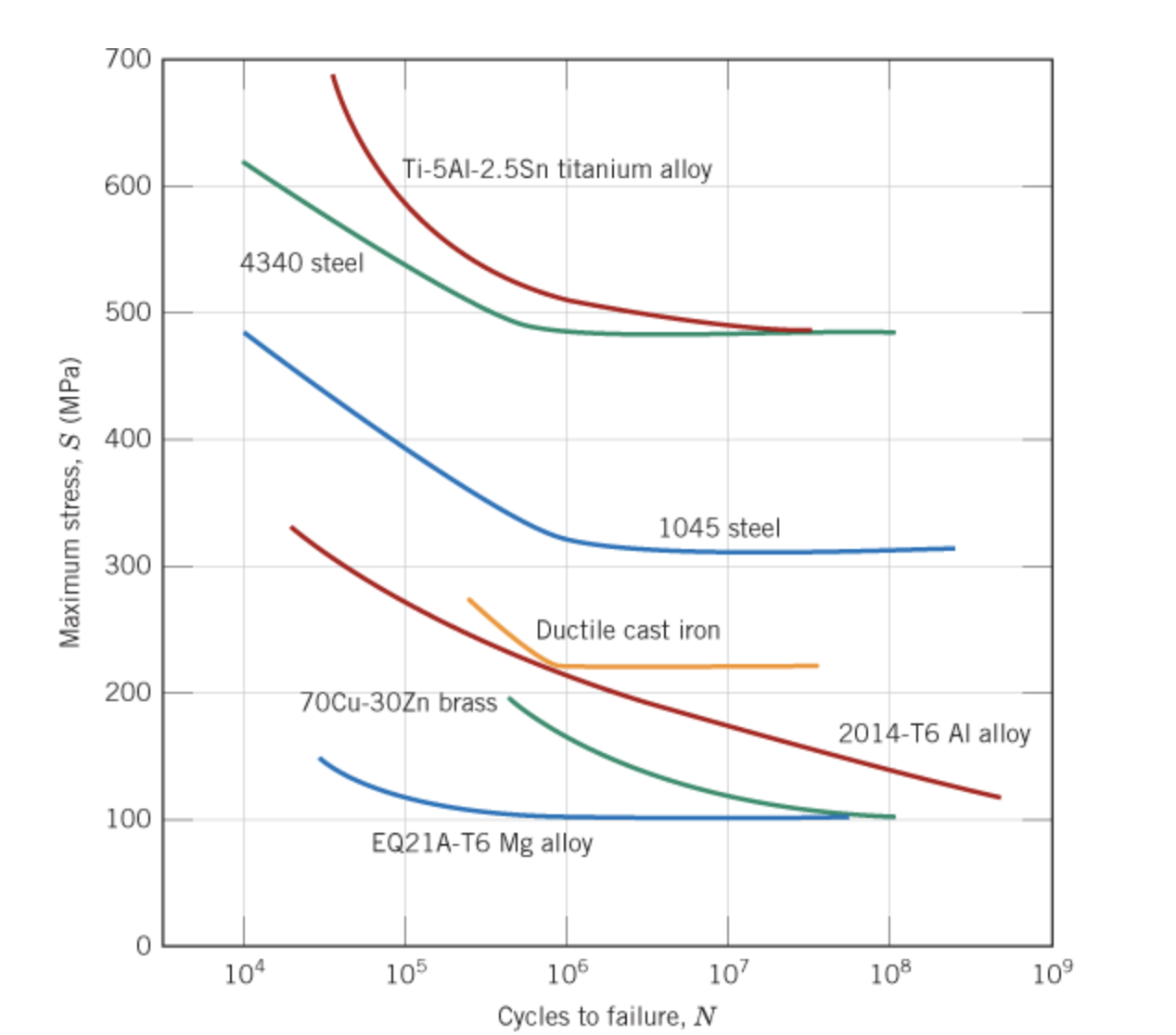

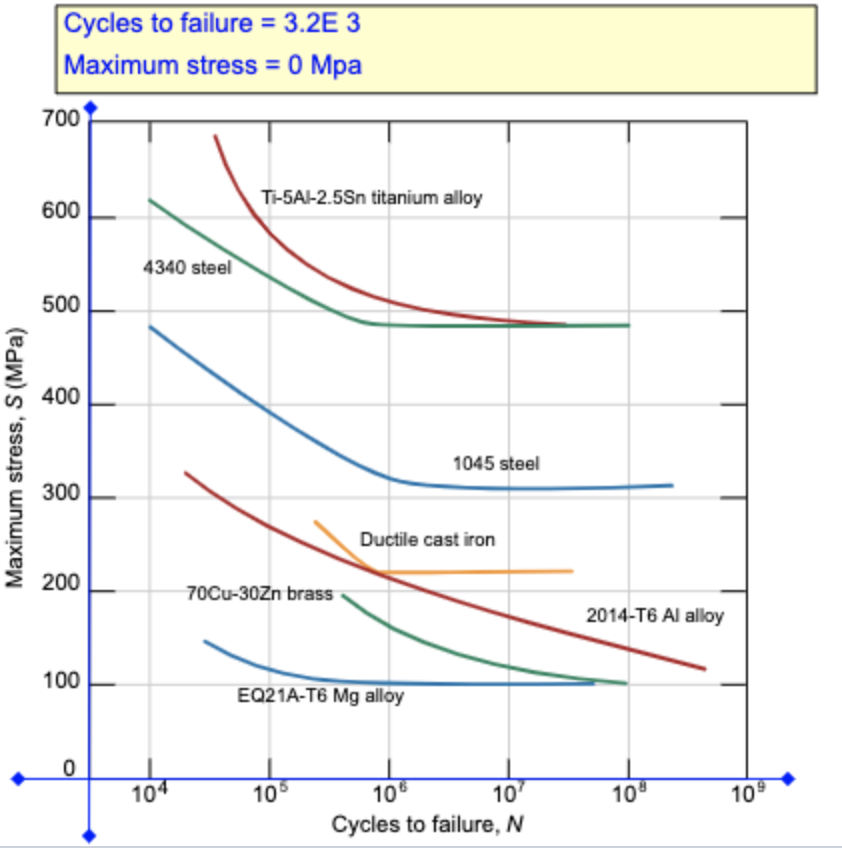

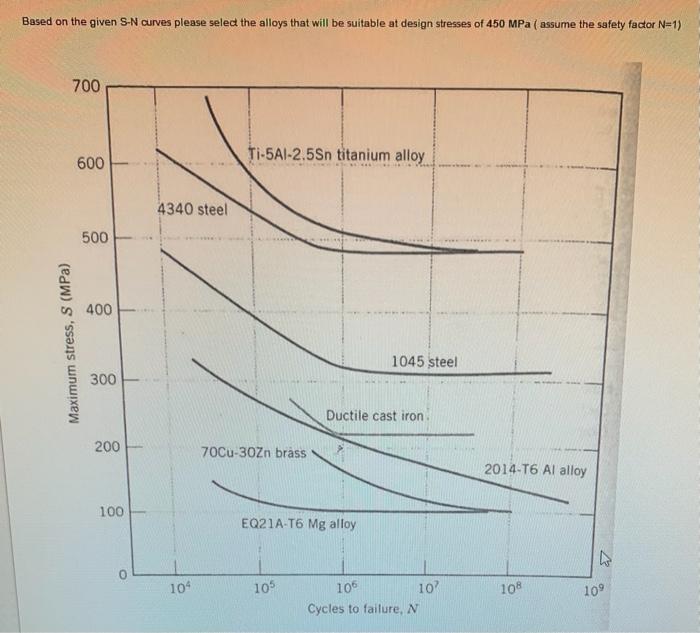

Answered 700 Ti 5ai 2 5sn Titanium Alloy 600 Bartleby

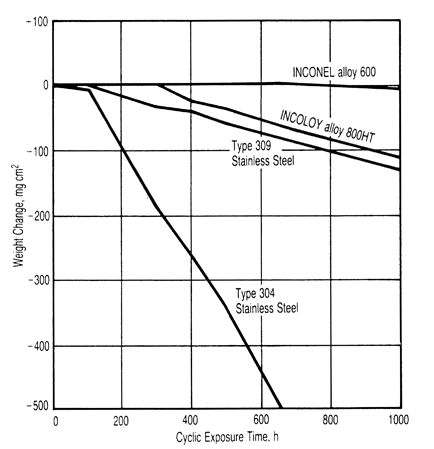

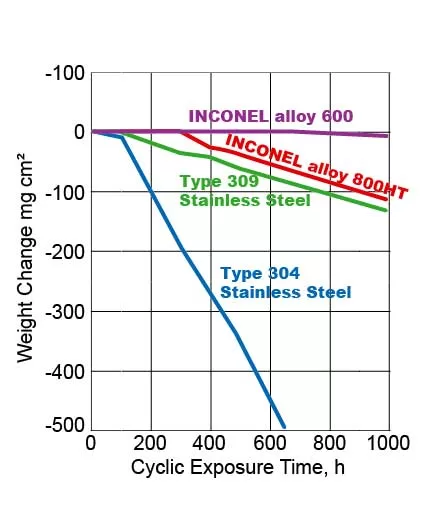

Selecting An Appropriate Heat Resistant Alloy 15 04 10 Industrial Heating

Inconel 600 Round Bars Inconel Alloy 600 Rods Bars In India

Alloy 600 Tubing Inconel 600 Tubes American Tube Technology Inc

Nickel Alloys Inconel Alloy 600 N

600 601

Inconel 600 Round Bar Uns N Rod Astm B166 Alloy 600 Hex Bar

Alloy 600 N Specification Of Nickel Alloys Stainless Steel

Inconel Alloy 600

7 Carbide Precipitation Diagram For Alloy 600 From 28 Download Scientific Diagram

Inconel 600 Pipe Alloy 600 Seamless Tube Uns N Tubing Supplier

Inconel Alloy 600 Sheets Plates Coils Pipes Tubes Fittings Flanges Welding Rods Wire Forging Fasterners

Inconel 600 Tube Alloy 600 Tubing China Guanyu Stainless Steel Tube

Alloy 600 Heat Resistant Nickel Alloy Plate Sandmeyer Steel

Corrosion Of Alloy 600 Comment Of Our Reader

Sem Micrograph Of Grain Boundary Configuration Of Alloy 600 Etched In Download Scientific Diagram

Inconel 600 Evocd

Alloy 600 Inconel 600 Equivalent And Supplier Ams 5540 Uns N

Nickel Alloys Inconel Alloy 600 N

Nickel Alloy Fasteners Specialised Fasteners High Integrity Bolting

Effects Of Temperature And Ph On The Electrochemical Behaviour Of Alloy 600 In Simulated Pressurized Water Reactor Primary Water Sciencedirect

Chemical Composition Of Alloy 0 Alloy 0 Alloy 400 Alloy 600

Inconel 600 Bar Rod 625 Inconel Alloy Wire Billets Hex Supplier In Mumbai India

Crack Growth Rate Evaluation Of Alloys 690 152 By Numerical Simulation Of Extracted Ct Specimens Sciencedirect

Solved A Cylindrical Rod Of Diameter 9 5 Mm Fabricated Fr Chegg Com

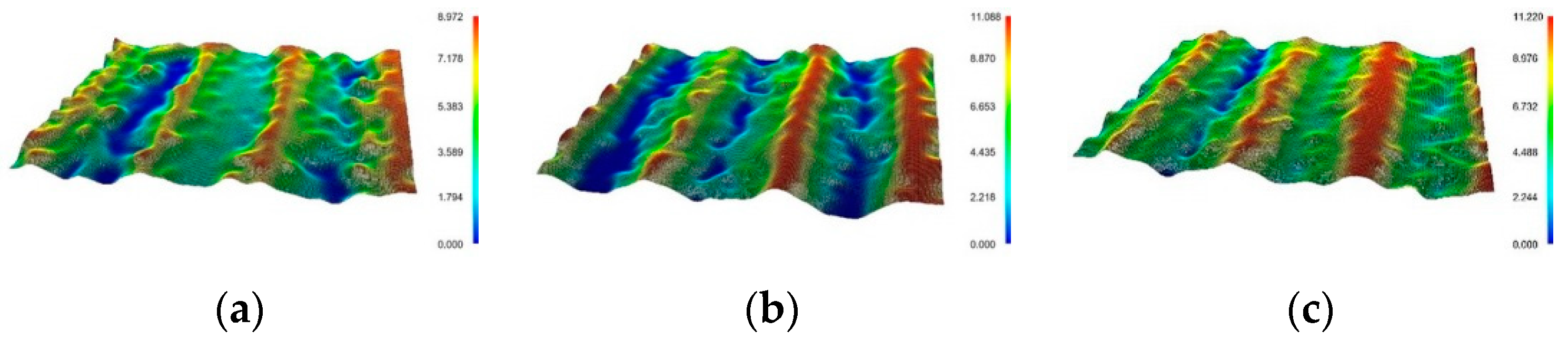

Materials Free Full Text The Effect Of The Static Load In The Unsm Process On The Corrosion Properties Of Alloy 600

Alloy 600 Fasteners Including Hex Bolts Hex Nuts Washers

Solved Based On The Given S N Curves Please Seled The All Chegg Com

Preferred Supplier Of Inconel 600 Tube Alloy 600 N Inconel 600 Tubing Inconel 600 Pipe Inconel 600 Coiled Tubing Aesteiron Steel Pipes

Wire Products

P A Inc Has Provided Material Properties For Nickel22 To Inco 0

Inconel Washer Astm B166 Inconel Flat Washer Inconel Split Washer

Inconel Alloy 600 Plate Astm B168 Uns N Sheet Din 2 4816 Coil

Inconel 600 Pipes Tubes Inconel Alloy 600 Seamless Tubing Exporter Inconel 600 Welded Erw Pipes Manufactures Stockholder In Mumbai India

Inconel Alloy 600 Tubing Price In India Incoloy 800 Tube Price List Inconel 625 Pipe Price By Siddhagirimetals Issuu

Inconel Alloy 600 Mega Mex

Inconel Alloy 600 Equivalent Nickel 600 Weight Price Per Kg

Inconel 600 Alloy 600 Inconel Alloy 600

Inconel 600 Tube Alloy 600 Tubing China Guanyu Stainless Steel Tube

Morphology Evolution Of Grain Boundary Carbides In Highly Twinned Inconel Alloy 600 Scientific Net

Inconel Alloy 600 Seamless Pipe Alloy 600 Welded Pipe

Inconel Alloy 600 Pipes Inconel Alloy 625 Tubing Inconel Alloy Seamless Pipes Suppliers

Inconel 600 Pipe Alloy 600 Seamless Tube Uns N Tubing Supplier

Astm B167 Astm B163 Inconel 600 Seamless Pipes Manufacturer And Supplier India Uns N

Nickel Alloys High Performance Alloys Datasheet

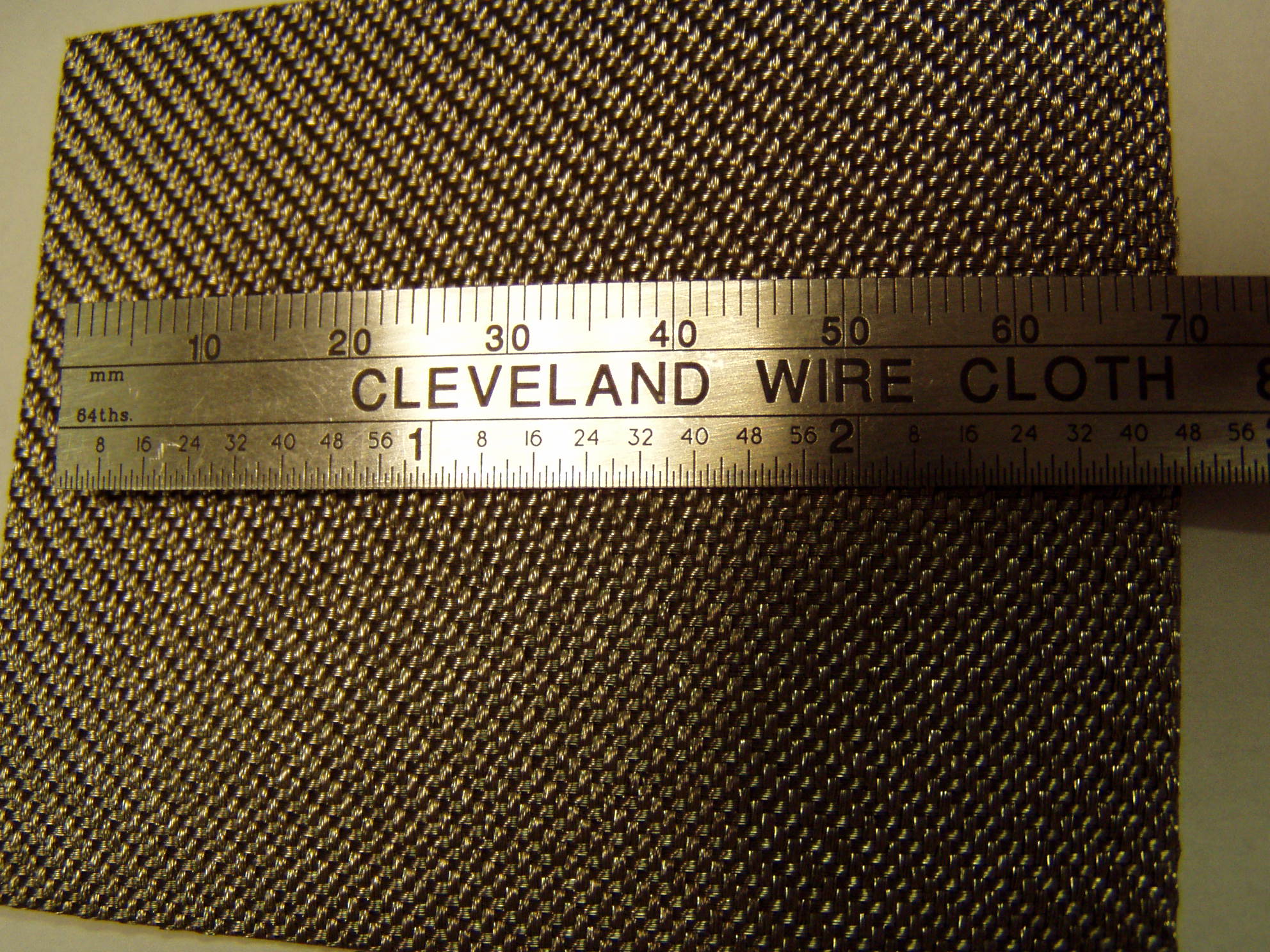

Inconel 600 Wiremesh Inconel Alloy 600 Wire Mesh Manufacturers Suppliers

Microstructure Of Alloy 600 Etched In 10 Oxalic Acid A As Received Download Scientific Diagram

Alloy 600 Tubing Inconel 600 Tubes American Tube Technology Inc

Astm B 167 Asme Sb 167 Astm B 163 Asme Sb 163 Inconel Alloy 600 Seamless Tube

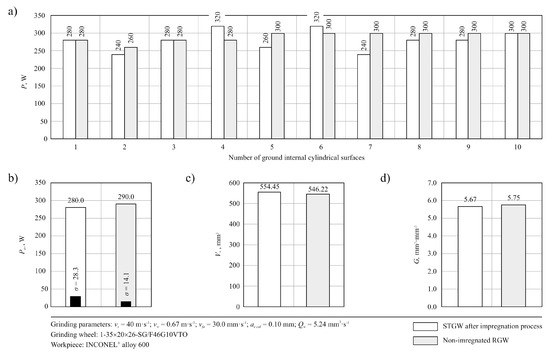

Micromachines Free Full Text Internal Cylindrical Grinding Process Of Inconel Alloy 600 Using Grinding Wheels With Sol Gel Alumina And A Synthetic Organosilicon Polymer Based Impregnate Html

Inconel Pipe Suppliers Inconel Alloy 600 Tube Inconel 625 Tubing

Inconel Alloy 600

Inconel Fasteners Alloy 600 Screw 625 Nuts Incoloy 800 Bolts Supplier

Alloy 600 Pipe On Continental Steel Tube Co

Inconel Alloy 600 Pipes Inconel Alloy 625 Tubing Inconel Alloy Seamless Pipes Suppliers

Inconel 600 Round Bar Astm B166 Inconel 600 Bright Bar Alloy 600 Hex Bar Manufacturers Suppliers

Astm B 167 Asme Sb 167 Astm B 163 Asme Sb 163 Inconel Alloy 600 Seamless Tube

Inconel 600 Round Bars Inconel Alloy 600 Rods Bars In India

Inconel 600 Seamless Tube Astm B163 Uns N Welded Tubing

Inconel 600 Seamless Tube Astm B163 Uns N Welded Tubing

Effects Of Temperature And Ph On The Electrochemical Behaviour Of Alloy 600 In Simulated Pressurized Water Reactor Primary Water Sciencedirect

Inconel 600 Buttweld Fittings Uns N Astm Asme 66 Sb366 Inconel 600 Buttweld Fittings Astm 66 Inconel Alloy 600 Buttweld Elbow Inconel 601 End Pipe Cap Suppliers Manufacturers Exporters Mumbai India

Inconel 600 Heat Exchanger Tubes Inconel Alloy 600 Condenser Tubes Alloy 600 U Bending Tube Supplier In India

Inconel 600 Evocd

Inconel 600 Tube Alloy 600 Seamless Tube N Tubing Supplier

Inconel 600 Angle Alloy 600 Channel Inconel Uns N Beam

Inconel 600 Fastener Inconel 600 Nuts Manufacturer Alloy 600 Bolts Exporter

Inconel 600 Round Bar Nickel Alloy 600 Rod N Hex Bar Suppliers

Inconel 600 Alloy 600 Nickel 600 Nickelvac 600 Ferrochronin 600

Inconel Alloy 600 Uns N0660

Alloy 600 Inconel 600 Equivalent And Supplier Ams 5540 Uns N

Inconel 600 Round Bar Astm B166 Inconel 600 Bright Bar Alloy 600 Hex Bar Manufacturers Suppliers

Effects Of Rotational Speed On The Al0 3cocrcu0 3feni High Entropy Alloy By Friction Stir Welding In High Temperature Materials And Processes Volume 39 Issue 1

Inconel Alloy 600

General Corrosion And Stress Corrosion Cracking Of Alloy 600 In Light Water Reactor Primary Coolants Sciencedirect

E Journal Of Advanced Maintenance Ejam

Inconel 600 Tube Alloy 600 Seamless Tubing Tubi Inconel 600 Welded

Astm B166 Inconel 600 Round Bar Supplier Manufacturer In India

Inconel Alloy 600 Cleveland Wire Cloth

Nickel Superalloy Market Size Share Industry Outlook 26

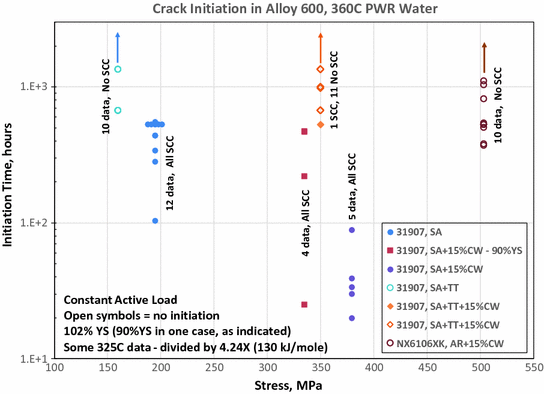

Crack Initiation Of Alloy 600 In Pwr Water Springerlink

7 Carbide Precipitation Diagram For Alloy 600 From 28 Download Scientific Diagram

Inconel Alloy 600 Equivalent Nickel 600 Weight Price Per Kg

Inconel 600 Flanges B564 N Alloy 600 Wnrf Flange Nickel 600 Sorf

Inconel Alloy 600 Composition Inconel 600 Suppliers

Inconel 600 Threaded Rod Inconel Alloy 600 Stud Bolts Inconel Alloy 600 Double Ended Stud Manufacturers Suppliers Exporters

E Journal Of Advanced Maintenance Ejam

Inconel Alloy 600