Atex Zone 1 Classification

Explosion Safe Ar 050 Zone 1 Air Conditioner Artidor

Led Lighting Fixtures For Use In Hazardous Areas Airfal

Atex Iecex Directives

Overview Of Hazardous Areas Expo Technologies

How To Achieve Safe Motion Control In Atex Environments Parker Pneumatics

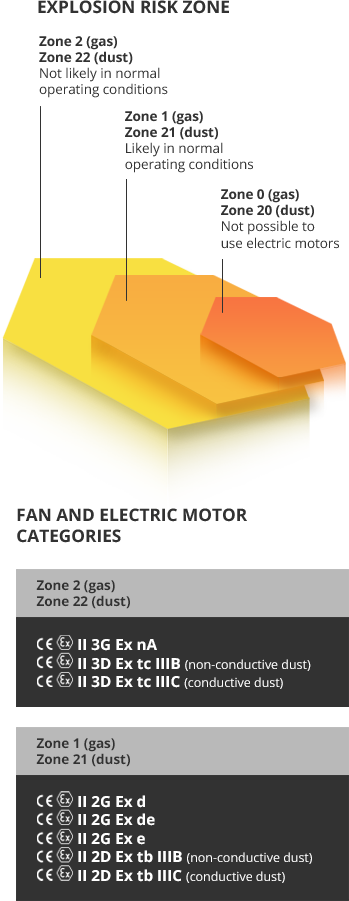

Overview Of Atex Zones And Equipment Ex Machinery Atex Blog

For use in ATEX zone 1, category 2 explosionproof equipment is required Does this make sense?.

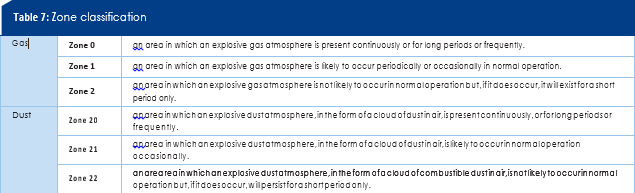

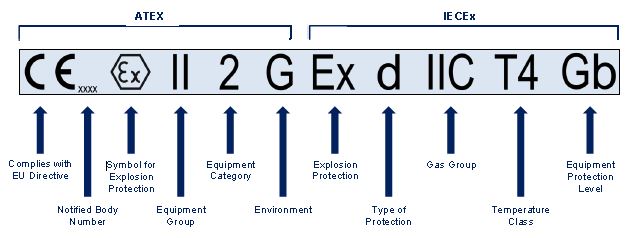

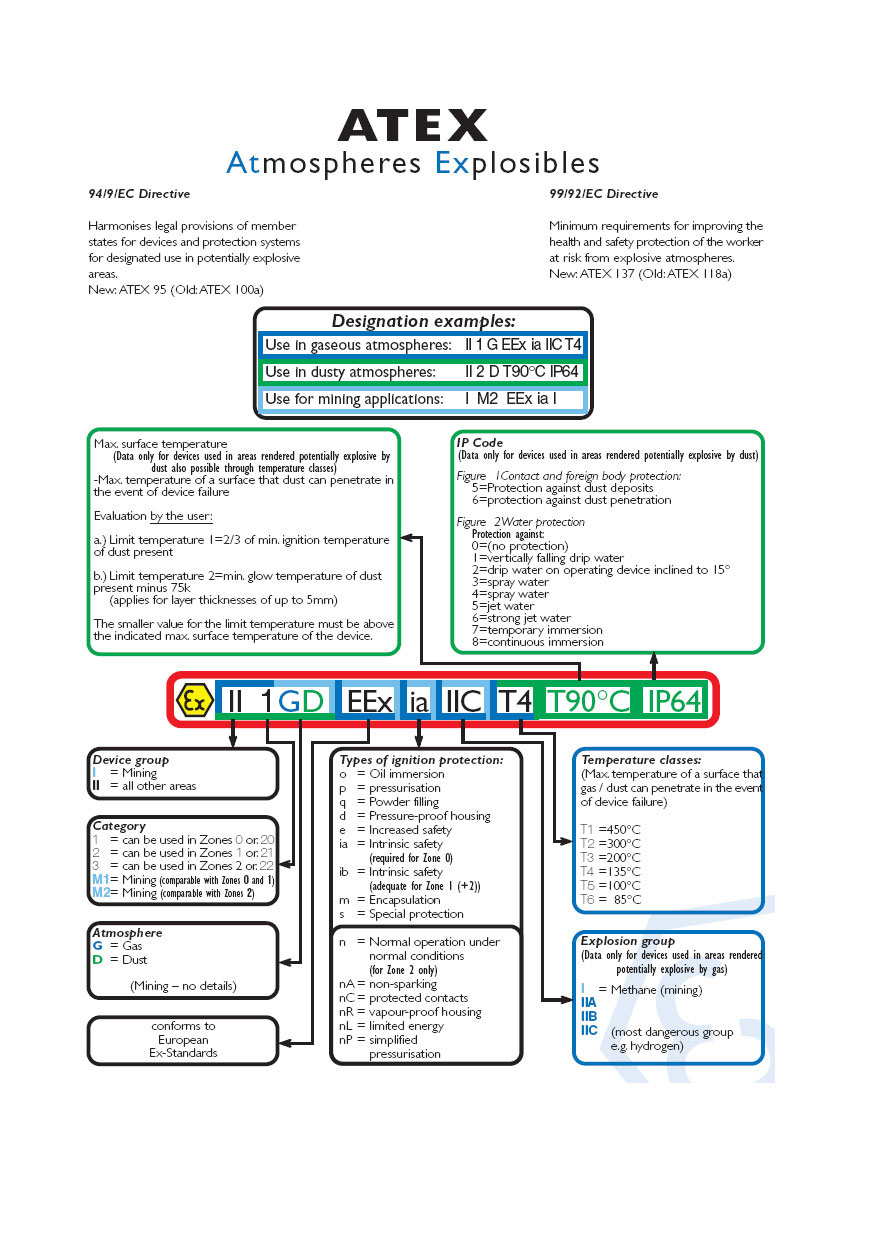

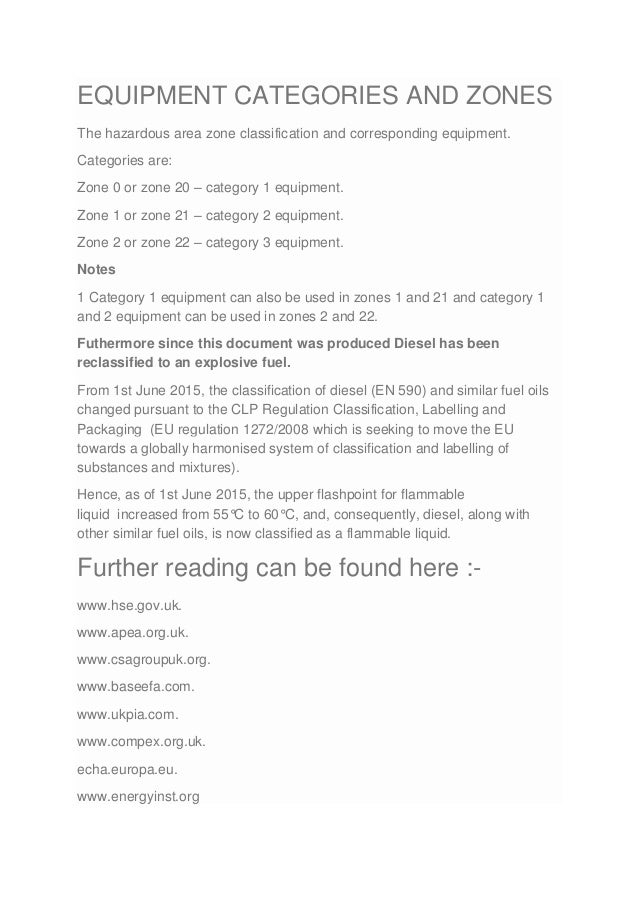

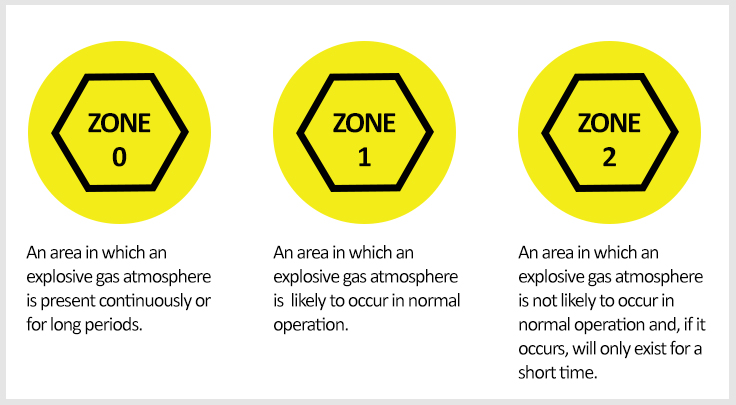

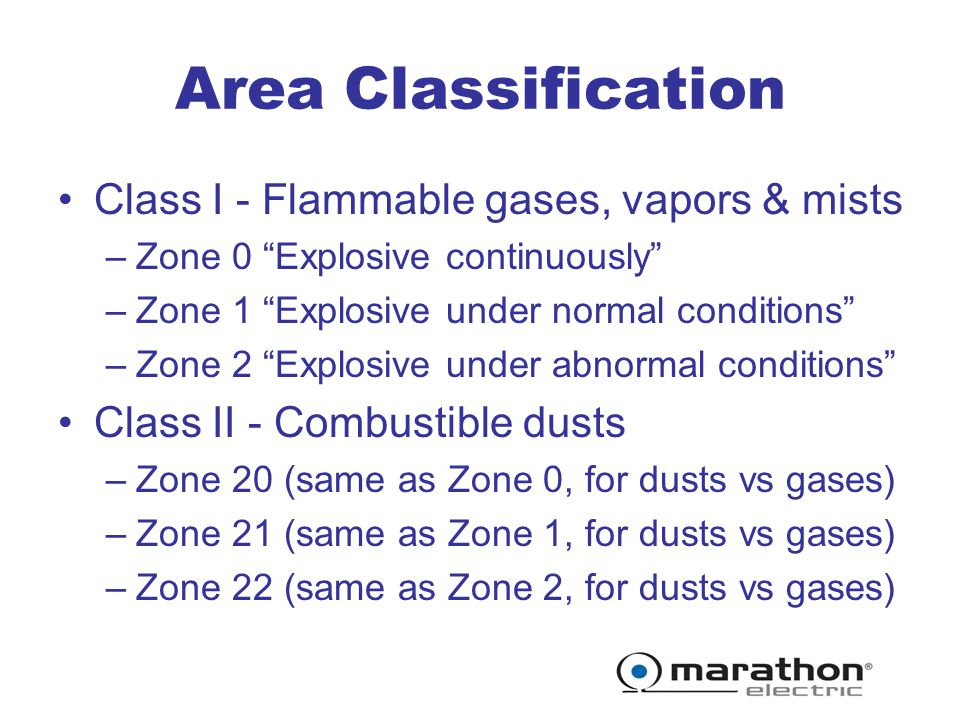

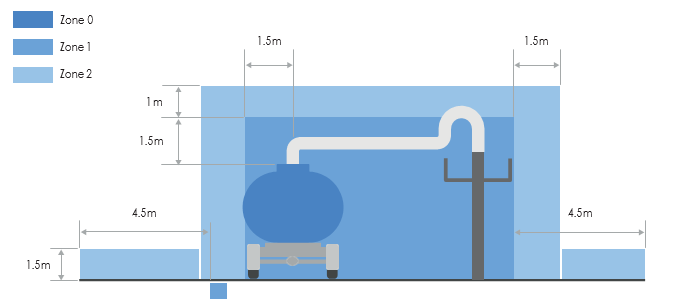

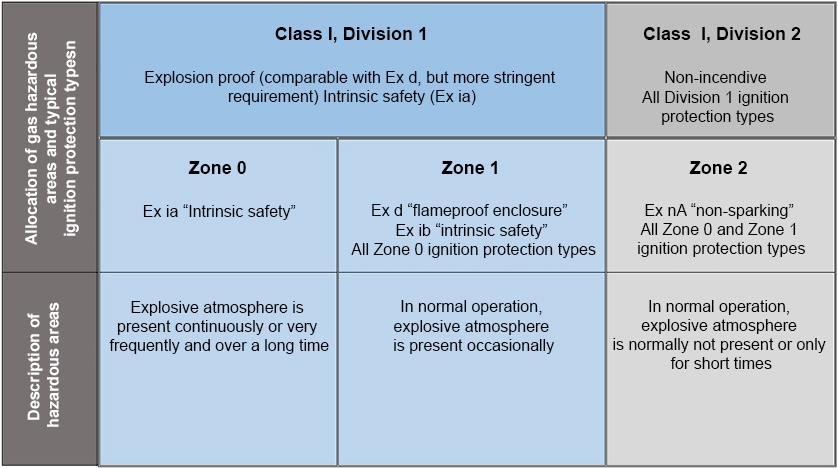

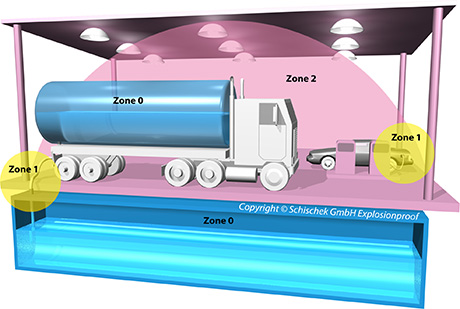

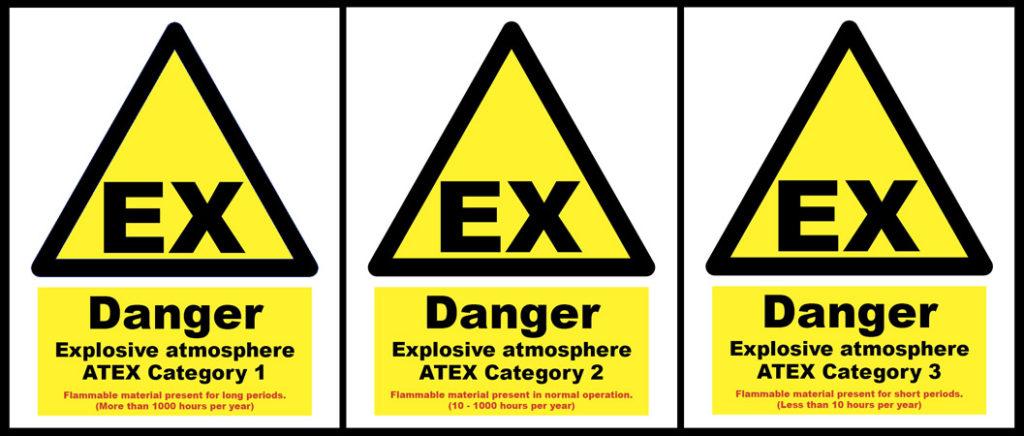

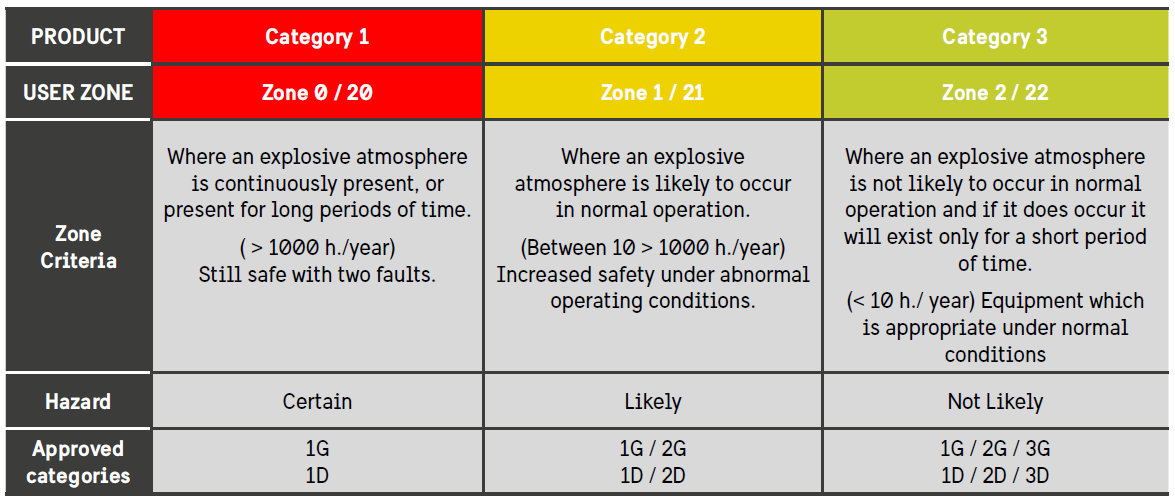

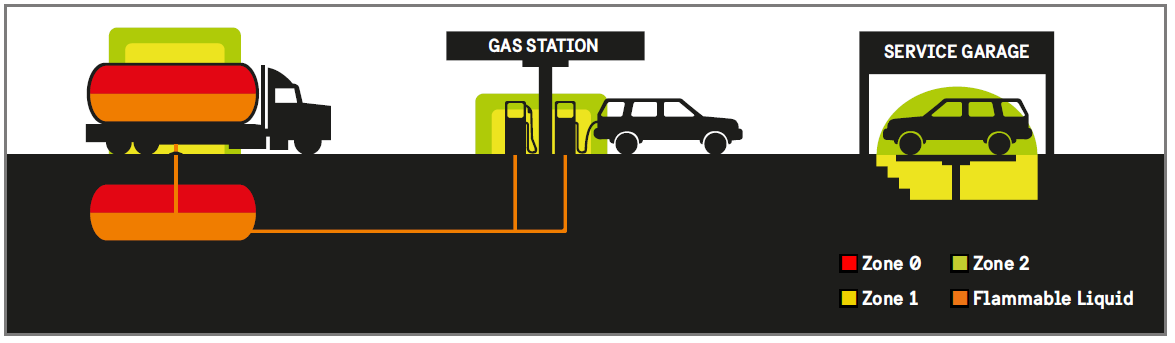

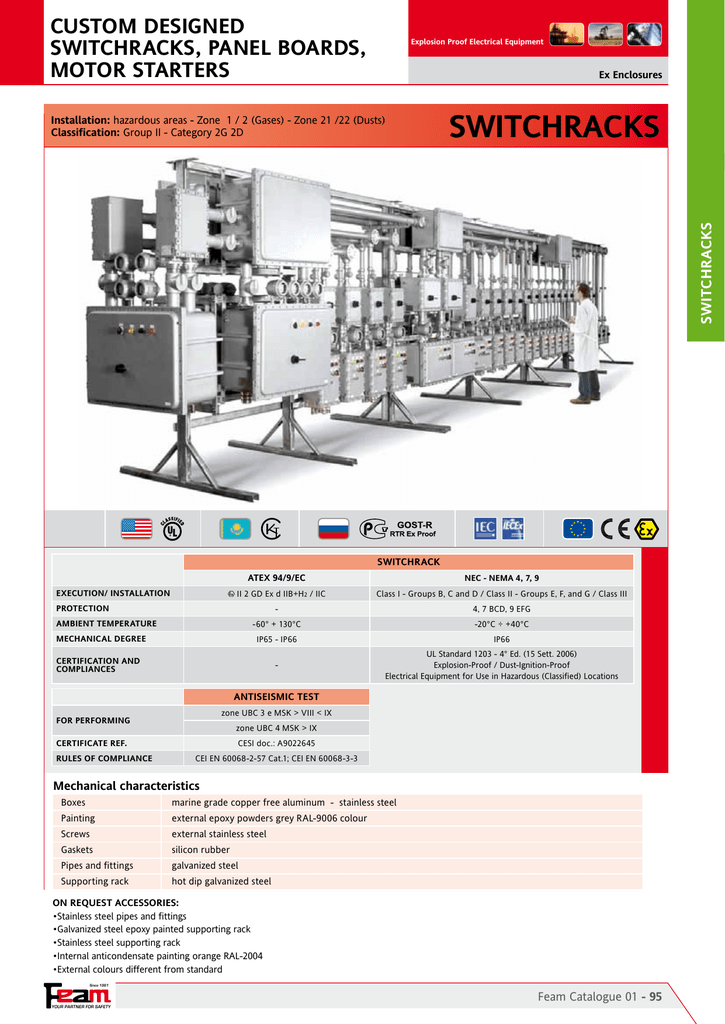

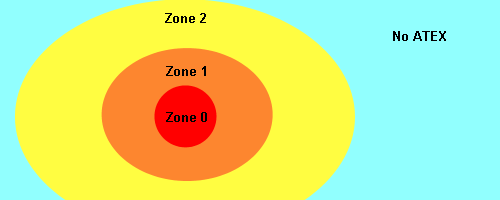

Atex zone 1 classification. Example of Zone Classification (Filling Station) Remark In Zone 0 – Exequipment must be designed for Category 1 use In Zone 1 – Ex equipment must be designed for Category 2 use In Zone 2 – Ex equipment must be designed for Category 3 use IP Classification’s – Ingress Protection to EN Definition 1st code index Code IP Class Code Definition 2nd code index. You probably don’t think so, but we promise you that there is an obvious explanation. The directive does not use Zone numbers in the classification of hazardous areas, preferring to refer to their definitions (eg ‘An area where an explosive atmosphere occurs frequently or continuously’ for Zone 0) but it is useful to understand the classification system commonly used to describe areas where explosive atmospheres may occur.

Equipment designation to zones Gas Ex Zone 0 Zone 1 Zone 2 ATEX category 1G 1G or 2G 1G or 2G or 3G IEC (EPL*) Ga Ga or Gb Ga or Gb or Gc Dust Ex Zone Zone 21 Zone 22 ATEX category 1D 1D or 2D 1D or 2D or 3D IEC (EPL*) Da Da or Db Da or Db orDc * EPL = Equipment Protection Level Classification of Hazardous Areas Slide 8 PConen. Zone 1 An area where an explosive atmosphere is likely to to occur in normal operation;. ATEX Zone 1 Definition – What is Zone 1?.

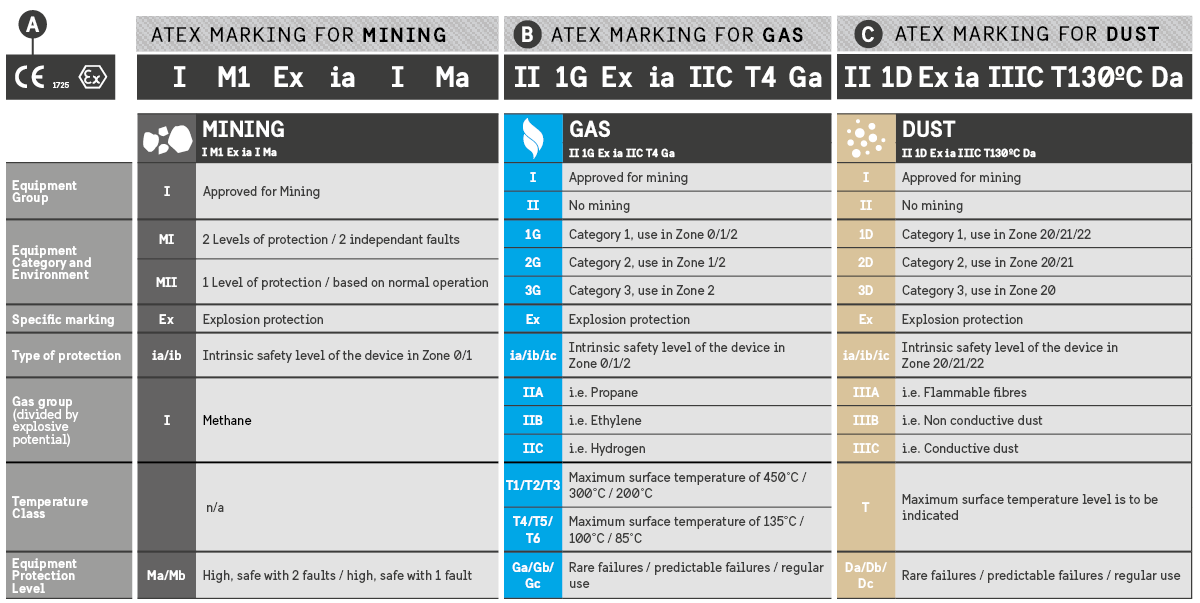

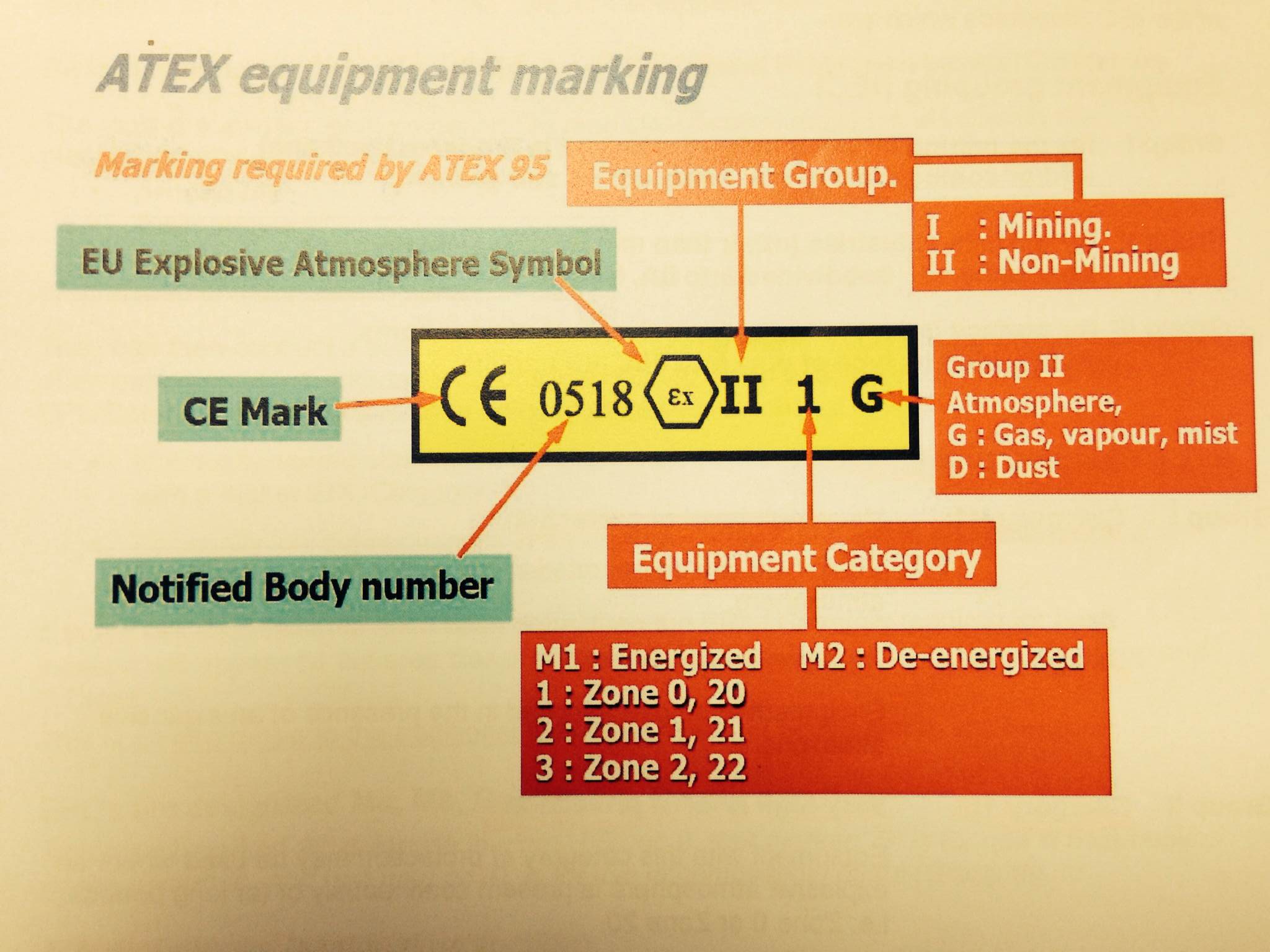

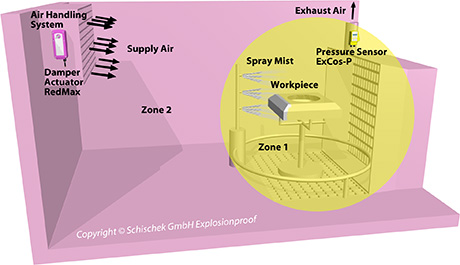

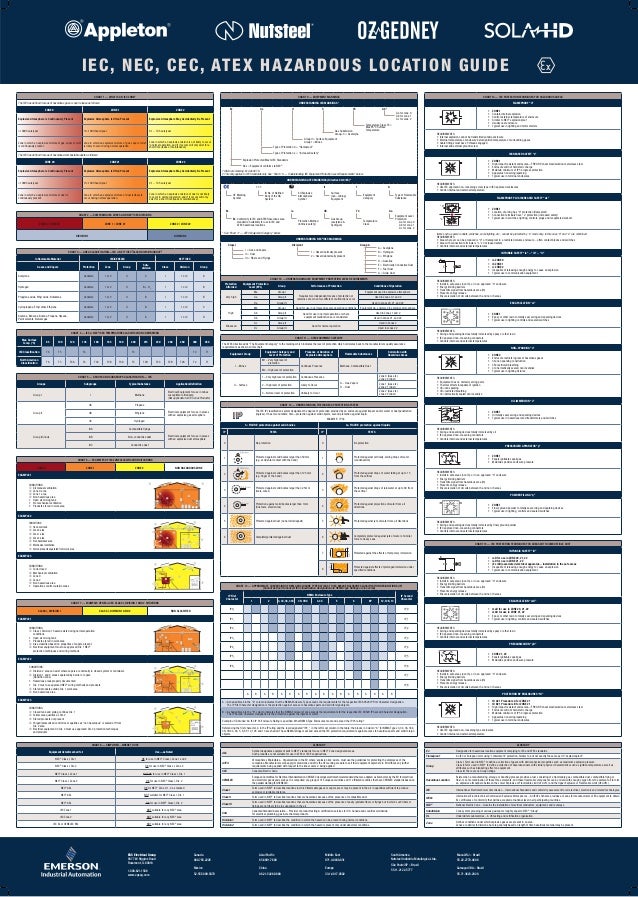

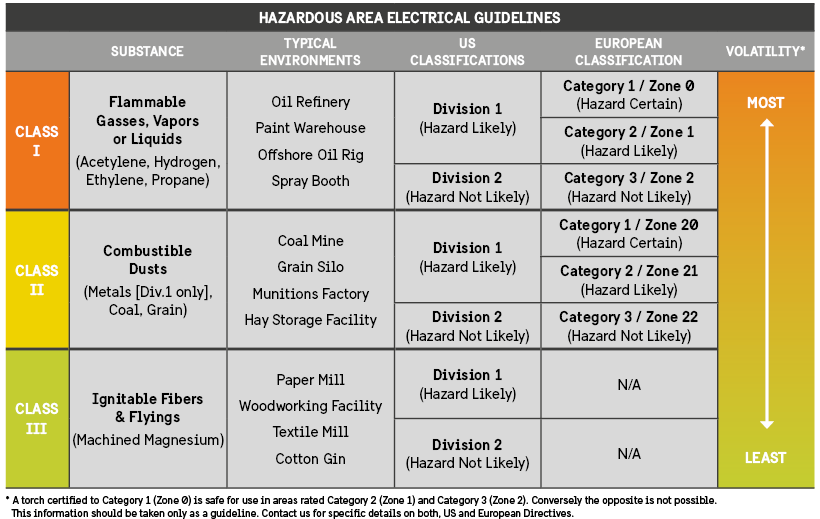

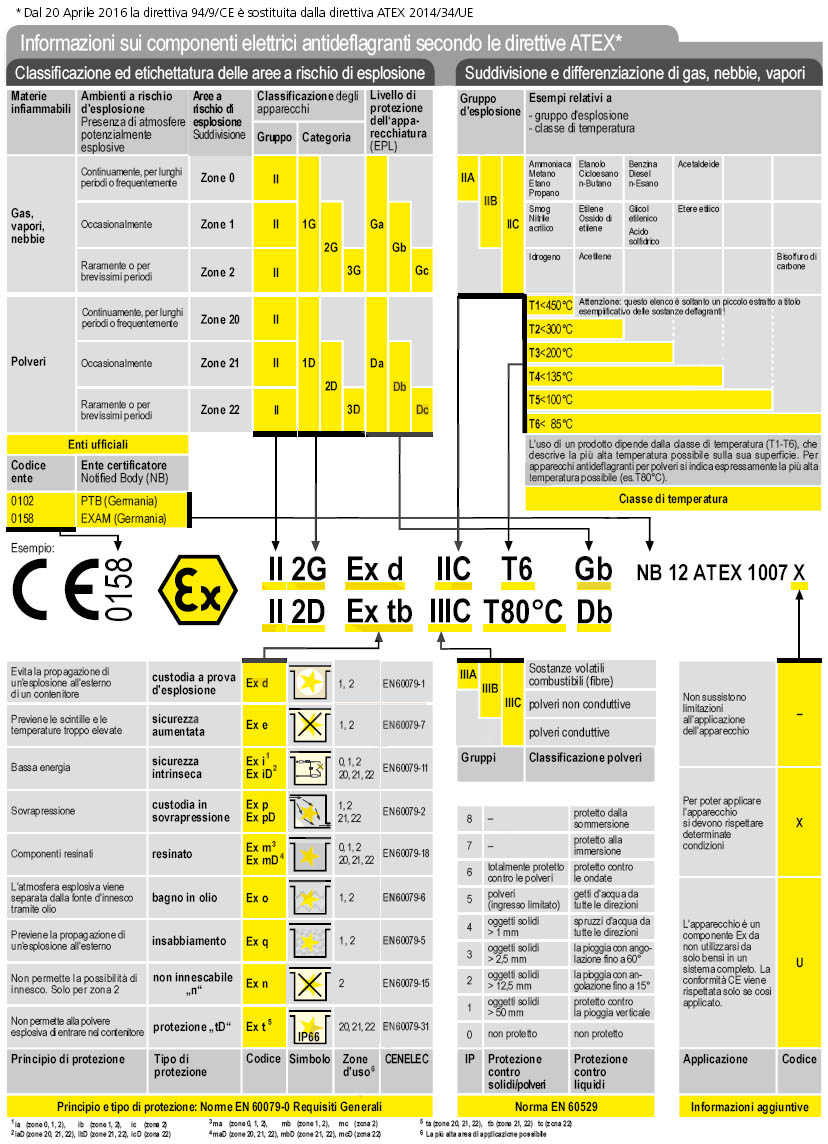

The ATEX standard also has a classification for explosive gases and dusts, with Group I referring to methane gases and coal dust (mining), while Group IIA to IIC gases and Group IIIA and IIIC dusts (above ground industries) have been categorised according to their different igniting power, with IIA/IIIA being the least dangerous and having the highest ignition temperature and IIC/IIIC the most dangerous with the lowest ignition temperature. Every hazardous environment with a risk of combustion is given a zone rating dependant on the type of hazard You should only use equipment specified for the zone you’re working in The following combinations are possible 1 – Can be used in zones 0 or ;. ATEX Directive 14/34/EU is a «new approach» directive that applies to protective systems against explosions as well as all equipment used in or related to explosive atmospheres, such as electrical and nonelectrical equipment, components and safety devices, control and adjustments necessary for the safe operation of this equipment and protective systems.

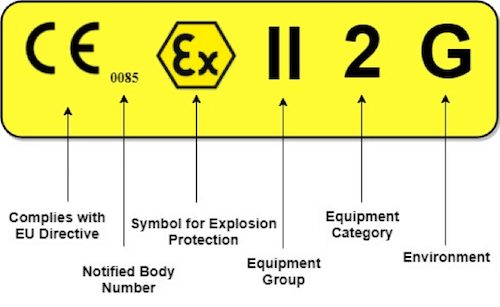

Start date Oct 24, 17;. In part 1 of our ATEX blog series, we set about demystifying the often confusing world of ATEX markings In this second blog, we will delve into ATEX equipment classification to add more clarity to the subject, while using Eyecon 2 as an example Equipment is classified as either suitable for underground mining ‘I’ operations or classified as ‘II’ for nonmining environments. 2 – Can be used in zones 1 or 21;.

ATEX, IECEx and US / Canada zones system US / Canada class / division system Gas / dust group Typical Substances Gas / dust group Typical Substances IIC Acetylene Class I, Group A Acetylene IIB H 2 Hydrogen Class I, Group B Hydrogen IIB Ethylene Class I, Group C Ethylene IIA Propane Class I, Group D Propane IIIC Conductive dust Class II, Group E. Understanding ATEX Zones for Gas & Dust This week we look at ATEX zones for gases and dust to dig a little deeper into ATEX understanding If you are not sure whether you need an explosion proof ATEX fan or need to know the ATEX zone in which your application is classified, please consult an official authority in your country ATEX is an acronym derived from the words “Atmospheres. Zone 2 An area where an explosive atmosphere is not likely to occur in normal operation.

Class 1 / Division 2 ATEX Zone 2 Yellow Zone Industrial Computing for Class 1 / Division 2 and ATEX Zone 2 Where embedded electrical products are concerned, the requirement for harsh environment industries such as oil and gas will usually be certification to Class 1 / Division 2 and/or ATEX Zone 2. ATEX 137 Classification of Hazardous Areas In accordance with the 1999/92/EC Directive, hazardous areas are classified as A place in which an explosive atmosphere consisting of a mixture with air or flammable substances in the form of gas, vapour or mist is • Zone 0 (Category 1 equipment) present continuously or for long periods or. Groups IIA, IIB and IIC;.

Groups IIA, IIB and IIC;. The latest edition of the ATEX standard was published as EN on April 1, 16 The 18th December the third edition was published The ATEX standard EN is concerned with the classification of areas where flammable gas or vapour hazards may arise and may then be used as a basis to support the proper selection and installation of equipment for use in hazardous areas. Groups IIA, IIB and IIC;.

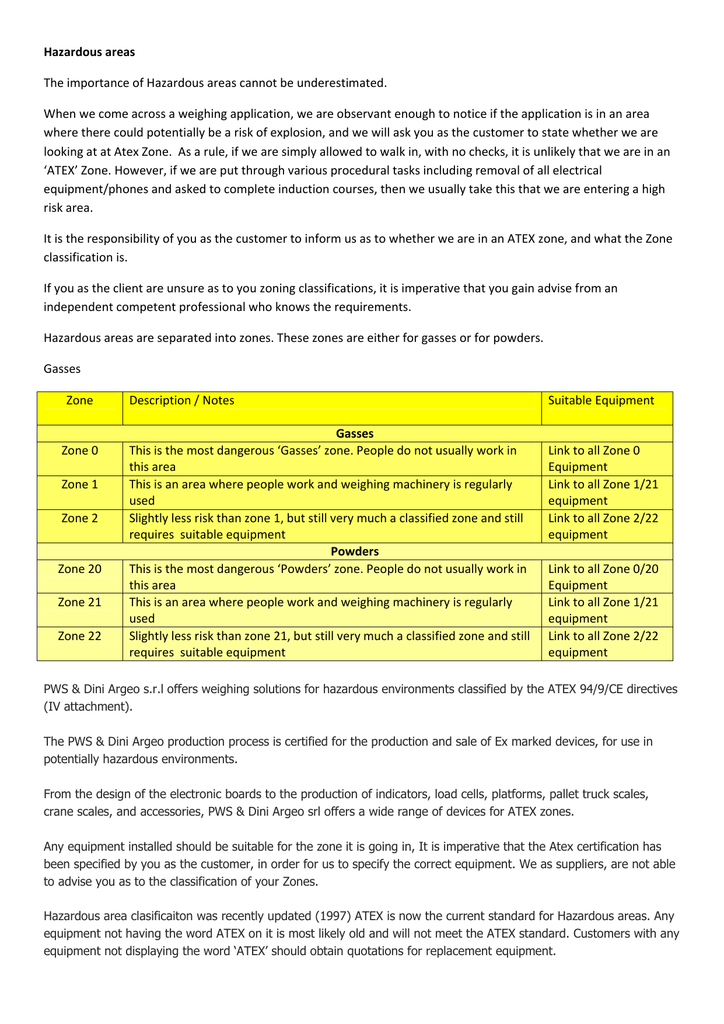

ATEX Classification Category 2 and 3 (gas);. Figure 1 Example of ATEX zoning classification for a bulk powder sack tipping station The zoning definition and the reasons justifying a particular zoning, or the absence of zoning, must be described in the ATEX risk analysis and the measures to put in place explained. Areas within these two kinds of explosive atmospheres are each divided into three subzones Although the zones characteristics are identical for both gas and dust, their numbering is different Zone 0, 1 and 2 refer to gas and Zone , 21 and 22 refer to dust Permanent presence of explosive gasses or combustive dust.

Class 1 Division 1 and Zone 1 Tablets The Aegex 10 intrinsically safe tablet is purposebuilt for use in the most extreme hazardous areas It features a large 101″ touchscreen and 4GB of Ram making it ideally suited for applications requiring a powerful device with a large display for user interface Incapable of producing sparks that may cause ignition of flammable vapor in Class 1 Division 1 and Zone 1 hazardous areas, this industrial device allows for superior mobile computing on. Atex Zones classified the level of explosion risk for any work area Miretti Ex Solutions are manufactured and tested to eliminate the ignition risk to keep workers and environment safe, in compiance with the norms ATEX, Ex, FM, NEC, IECEx, CNEx, EAC. A Zone 1 area is classified as a place in which an explosive atmosphere consisting of a mixture with air or flammable substances in the form of gas, vapour or mist is likely to occur in normal operation occasionally These are typically process areas where gases are more likely to be present.

Regarding ATEX 99/92/EC Directive, the requirement is that Employers must classify areas where potentially explosive atmospheres may occur, into zones The classification given to a particular zone, and its size and location, depends on the likelihood of an explosive atmosphere occurring and its persistence if it does. The classification given to a particular zone, and its size and location, depends on the likelihood of an explosive atmosphere occurring and its persistence if it does Schedule 2 of DSEAR contains descriptions of the various classifications of zones for gases and vapours and for dusts. For use in ATEX zone 1, category 2 explosionproof equipment is required Does this make sense?.

Class I Division 1 (Gases) Zone 21 (Dusts) "D" An area in which an explosive mixture is likely to occur in normal operation Class II Division 1 (Dusts) Zone 2 (Gases) "G" An area in which an explosive mixture is not likely to occur in normal operation and if it occurs will exist only for a short time Class I Division 2 (Gases) Zone 22 (Dusts) "D". 3 – can be used in zones 2 or 22. Figure 1 Example of ATEX zoning classification for a bulk powder sack tipping station The zoning definition and the reasons justifying a particular zoning, or the absence of zoning, must be described in the ATEX risk analysis and the measures to put in place explained.

1 G 0, 1, 2 Explosive Atmosphere 2 G 1, 2 3 G 2 D is added after G in the certification class number D = Dust (ie GD) if device is dust category approved also 1 D , 21, 22 2 D 21, 22 3 D 22 Explanation of the categories 1 Very high safety = device safety must be guaranteed even in case of rare device failures, eg. First of all, Zone 2 certified equipment is not allowed to be carried through a Zone 1 environment, not even when the Zone 2 equipment is powered off Secondly, if there is an emergency, all zones are automatically upgraded to a Zone 1, immediately making all Zone 2 equipment in violation with the guidelines. Atex Zones classified the level of explosion risk for any work area Miretti Ex Solutions are manufactured and tested to eliminate the ignition risk to keep workers and environment safe, in compiance with the norms ATEX, Ex, FM, NEC, IECEx, CNEx, EAC.

Zone 1 (gas) Zone 21 (dust) Zone 2 (gas) Zone 22 (dust) COMPLIANCE Compliance with the ATEX Directive 94/9/EC can be demonstrated by using the Harmonised European Standards Reference to these standards relating to the various methods of electrical protection can be found on Eaton’s MTL flammable facts poster or the EU ATEX website listed. Zone 0 An area where an explosive atmosphere is present continuously or for long periods;. In Zone 1 – Ex equipment must be designed for Category 2 use In Zone 2 – Ex equipment must be designed for Category 3 use IP Classification’s – Ingress Protection to EN.

Zone Zone defines the general nature if it is a gas or dust and the probability of hazardous material being present in an ignitable concentration in the surrounding atmosphere The Zone system has three levels of hazard for gas or dust where the Division system has two Gases, Vapors and Mists Article 505 National Electrical Code (NEC). A Class I, Division 1 area encompasses the combination of Zone 0 and Zone 1 areas Zone 0 classified locations An area where ignitable concentrations of flammable gases, vapors or liquids are present continuously or for long periods of time under normal operating conditions. For hazardous areas involving dusts then the above classifications are prefixed with a "2", so zone 1 for dusts becomes zone 21, as below Zone A place in which an explosive atmosphere in the form of a cloud of combustible dust in air is present continuously, or for long periods or frequently.

It is worth noting that ATEX maintenance and repair obligations depend on the category of the equipment rather than the zone in which it is installed Therefore, putting Category 1 equipment, which has a very high level of safety and is designed for use in Zone 0 or Zone areas, into a Zone 2 area could have longterm financial implications. Classification of Hazardous Areas Slide 7 PConen INTERNAL 07/15/16 Equipment designation to zones Gas Ex Zone 0 Zone 1 Zone 2 ATEX category1G1G or 2G1G or 2G or 3G IEC (EPL*)GaGa or GbGa or Gb orGc Dust Ex Zone Zone 21 Zone 22 ATEX category1D1D or 2D1D or 2D or 3D IEC (EPL*)DaDa or DbDa or Db orDc. ATEX The ATEX directive uses zones to classify potentially explosive gas and dust.

Figure 1 Example of ATEX zoning classification for a bulk powder sack tipping station The zoning definition and the reasons justifying a particular zoning, or the absence of zoning, must be described in the ATEX risk analysis and the measures to put in place explained. Copy link Copy link Discuss ATEX zone 1 classification in the Electrical Forum area at ElectriciansForumsnet K ksa74fReaction score 0 Oct 24, 17 #1 Welcome to ElectriciansForumsnet The American Electrical Advice Forum. T3 IEC Classification Zone 1 and 2;.

Area Classification Increase safety and lower costs with accurate Area Classification Of all the fields covered by ATEX and DSEAR, hazardous area classification is perhaps the most misunderstood Inexperienced practitioners in area classification simply review areas and allocate a classification in accordance with codes of practice (for example, Zone 1 for 1 meter then Zone. A atex zone 1 is similar to a zone 0 However, a zone 1 is a place in which an explosive atmosphere is likely to occur in normal operation occasionally, instead of a continuously presence of a hazardous atmosphere Atex zone 2 In a atex zone 2, a explosive atmosphere is not likely to occur in normal operation. D1xB2 range Class I & II Division 1 , Zone 1 & 21 Xenon strobes and LED beacons D2xB1LD3 and D2xC2LD3 UL1971/UL464 Class I & II Division 2 , Zone 2 & 22 LED beacon & combination signal Product Catalogue.

With the old CENELEC (previous Directive), different areas were divided into three classifications Zone 2, Zone 1, and Zone 0 depending on the level of risk With the ATEX Directive, every Zone is associated to a Category, and every electrical equipment is classified according to these categories, certifying in which areas it can be safely used. Atex zone 1 A atex zone 1 is similar to a zone 0 However, a zone 1 is a place in which an explosive atmosphere is likely to occur in normal operation occasionally, instead of a continuously presence of a hazardous atmosphere Atex zone 2 In a atex zone 2, a explosive atmosphere is not likely to occur in normal operation. ATEX The ATEX directive uses zones to classify potentially explosive gas and dust atmospheres Classifications range from an ignitable condition being an unlikely occurrence (Zones 2 and 22) to continuously present (Zones 0 and ) > Gas / Vapour / Mist Zone 0, Zone 1, Zone 2 > Powder / Dust Zone , Zone 21, Zone 22 ExProof.

Area classification for gases and vapours, and its equivalent for dusts was published in 02as BS EN /3 These standards form a suitable basis for assessing the extent and type of zone, and can be used as a guide to complying with the requirements in DSEAR However, they cannot give the. Zonex Enclosures are designed and certified to meet ATEX Directive 94/9/EC as well as IECEx and AEx standards for increased safety in housing electrical components in Zone 1 and Zone 2 applications nVent HOFFMAN'S ATEX Ex e enclosures are not intended for use in explosionproof or flameproof applications. Classification of ATEX zones ATEX zones are classified according to two parameters the types of combustibles that may be encountered (dust or gas) the frequency or duration during which an explosive atmosphere is likely to occur Warnings Carefully read the Instructions for Use used in this technical advice before consulting the advice.

Class 1 Divisions 1 & 2 NFP96 Encapsulation – A method of exclusion of the explosive atmosphere by fully encapsulating the electrical components in an approved material Zones 1 & 2 EExm EN Zones 1 & 2 Exm IEC Oil Immersion – The electrical components are immersed in oil, thus excluding the explosive atmosphere from any sparks or hot surfaces Zones 1 & 2 EExo EN. ZONE 0 Area in which an explosive gas atmosphere is present continuously or for long periods or frequently ZONE 1 Area in which an explosive gas atmosphere is likely to occur in normal operation occasionally. Classification of equipment The ATEX directive classifies equipment into groups and categories which are defined by the marking on the equipment – see “Product marking” below Class I Division 1 (gases) Zone (dusts) Class II Division 1 (dusts) Zone 1 (gases) An area in which an explosive mixture is likely to occur in normal operation.

ATEX zone 1 classification Thread starter ksa74f;. Zone 1 (gas) Zone 21 (dust) Zone 2 (gas) Zone 22 (dust) COMPLIANCE Compliance with the ATEX Directive 94/9/EC can be demonstrated by using the Harmonised European Standards Reference to these standards relating to the various methods of electrical protection can be found on Eaton’s MTL flammable facts poster or the EU ATEX website listed. Groups IIA, IIB and IIC Pressurization Ex p HP 300 25,000Frames 315 up to 1000 ATEX Classification Category 3 (gas);.

You probably don’t think so, but we promise you that there is an obvious explanation. Zone 0 >1000 hours, Zone 2 < 10 hours and Zone 1 in between These were used in the old BS standard but then dropped and not referenced in the Atex standards as the absolute figures do not sit well with statistical risk analysis techniques but are still commonly erroneously quoted. ATEX zones for gases/vapour Zone 0 (gases/vapours) an area in which an explosive mixture is continuously present or present for long periods Zone 1 (gases/vapours) an area in which an explosive mixture is likely to occur in normal operation Zone 2 (gases/vapours) an area in which an explosive mixture is not likely to occur in normal operation and if it occurs it will exist only for a short time.

Zone 1 (21) and Zone 2 (22) hazardous area enclosures for instrumentation, small power or lighting applications – stainless steel, mild steel, glass reinforced polyester, aluminium and polycarbonate certified according to ATEX and IECEx Also high voltage junction boxes for jointing, terminating and connecting 33kV, 66kV, 11kV and 33kV power cables in Zone 2 hazardous area. E2x nonsparking devices now for Class I & II Division 2 and Zone 2, 22 applications D1xB2 range Class I & II Division 1 , Zone 1 & 21 Xenon strobes and LED beacons D2xB1LD3 and D2xC2LD3 UL1971/UL464 Class I & II Division 2 , Zone 2 & 22 LED beacon & combination signal. ATEX directive Classification of operating resources Components and solutions with ATEX certification for all steps in the automation process Legal directives such as NEC/CEC in the USA and Canada, and Europe’s 14/34/EU (ATEX) are in place alongside other regulations to reduce the risk of explosions in high risk operating areas and.

Zone 1 is an area that is classified ‘as a place in which an explosive atmosphere consisting of a mixture with air or flammable substances in the form of gas, vapours and mists is likely to occur occasionally during normal operation’, whereas Zone 2 is an area that is classified ‘as a place in which an explosive atmosphere consisting of a mixture with air or flammable substances in the form of gas, vapours and mists is not likely to occur in normal operation but if it does occur, it. ATEX Zone 21 average possibility of explosive atmosphere (between 10 and 1000 h/year) ATEX Zone 22 low possibility of explosive atmosphere (under 10 h/year) In particular, TAMA AERNOVA is capable to manufacture products suitable for installation in ATEX zones 22 and products that process directly dusts which can generate a potential explosive. • Area Classification and DSEAR (ATEX) Risk Assessment EquipmentandPlantInspections • Assistance in the design, supply and installation of safety and mitigation systems • Full support, service levels agreements and ATEX 137 / DSEAR Compliance Zone 1, 2 Zone 1, 2 AEx p.

Classification of ATEX zones Explosive atmosphere Gas type combustible substance Dust type combustible Present permanently or for long periods (more than 1000 h per year) ZONE 0 ZONE Present occasionally. T3 HP 400 ,000Frames 400. T3 IEC Classification Zone 2 and 22;.

Atex Guardian Telecom

Is 655 2 Atex Atex Instrinically Safe Zone Tablet Cctv Computer Camera Certified Hazardous What Is Atex

China Ip66 Or Ip67 Flame Proof Atex Zone 1 Zone 21 Led High Bay And Flood Light 100w 1w 150w 185w 0w Luminaires For Use In Hazardous Classified Locations China

Atex Zone 1 Cat 2g Miretti Ex Equipment And Conversion Atex Zone 1 Definition

Explosive Atmospheres Atex Sertec S R L

Atex كتالوج Peli

Standards And Regulations Ex Zones Atex Iecex

Hazardous

Explosion Protection Technical Principles Atex Article Atexdb

Understanding Atex Technical Specifications

Classification Of Atex Zones Petzl Other

Hazardous Location Areas And Explosion Proof Vehicles Certifications

Hazardous Areas Hazardous Area Zones Guide Explanation Definitions

Atex Hmi Isa Area Classification Zone Identification Download Table

Www Iecex Com Archive Gdansk Docs D2p2b r fraczek Pdf

Standards And Regulations Ex Zones Atex Iecex

Zone 1 Definition Atex 1999 92 Ec What Is A Zone 1 Hazardous Area

What Is Atex Jenson Atex Depot

Hazardous Areas The Importance Of Hazardous Areas Cannot Be

Overview Of Atex Zones And Equipment Ex Machinery Atex Blog

Explosion Proof Classification Divisions Zones Of A Spray Room And A Filling Station Explosion Groups Temperature Classes Fire Protection

Q Tbn And9gcrvsqtxmrkekxaqf2wzppgi44j1iwzmianqtnmn3lm6dltsq05q Usqp Cau

Atex And Iecex Standards For Intrinsically Safe Load Cells For Hazardous Areas Explained Crosby Straightpoint Uk Europe Usa

Ventilation In Classified Areas Cortem Group

Q Tbn And9gcqltmyan3aywhdm6dkhhjduqfl1d2bdon3i1s4pyps Usqp Cau

Atex Zones Miretti Ex Atex Zone 1 2 21 22 Area Classification

The 4 Important Selection Parameters For Atex Devices Burkert Fluid Control Systems Esi Enviropro

Hazardous

Industrial Iot In Hazardous Areas Microtronics Blog The World Of Iot And M2m

Atex From Our Newsletter Nr 1 Comecer

Useful Information On Atex

Standards And Regulations Ex Zones Atex Iecex

In General Atex Categories And Atex Zones Iwaki Nordic

What Is Atex Atex Approved Transfer Pump The Atex Directive Explai

Atex Iecex Approved Sensors

Frequently Asked Questions Atex Ecoquip Blasting Equipment Graco

Atex Explained Lgm Products

Www Interempresas Net Feriavirtual Catalogos Y Documentos Weg Weg Family Of Atex Motors Usaf1031 Brochure English Pdf

What Is Atex Zone 1 2 21 And 22 Hoist Uk

Explosion Proof Classification Divisions Zones Of A Spray Room And A Filling Station Explosion Groups Temperature Classes Fire Protection

How Sensors Work Atex Intrinsically Safe Sensors

Uc3 Equipment Obtains The Classification Of The Area As Non Hazardous Zone According To Atex Directives Utis

Is 655 2 Atex Atex Instrinically Safe Zone Tablet Cctv Computer Camera Certified Hazardous What Is Atex

Atex Hof Area Classification Result For The Basic Paint Mixing Unit Download Table

Explosive Atmospheres Atex Sertec S R L

Bartec Pixavi Zone 1 Vs Zone 2 Hazardous Areas

Abtech Visex Camera Housing Atex Zone 1 Hazardous Area

Classification Of Hazardous Areas Due To The Presence Of Gas Cortem Group

Q Tbn And9gctm Vig1iuruiviacx5yldx5uarjrds aslpomoax4otb Nka Usqp Cau

Atex Zone 2 Hazardous Duty Motors Ppt Video Online Download

Classification Of Atex Zones 12 Download Table

Hazardous

Hazardous Area Location Guide Iec Nec Cec Atex By Emerson Industr

Ctyk6bkd43uiwm

Atex Weighbridge Applications Kataskevastiki J Dimitriou Weighing Engineering

Atex Equipment And Zones Explained Sciencedirect

Atex Category 1 Equipment

Hazardous Area Equipment Certification Atex Zone 1 Zone 2 Iec Ex

Explosion Protection Technical Principles Atex Article Atexdb

Atex Catalog Peli

Explosion Proof Atex Guidelines Explained Atexindustries

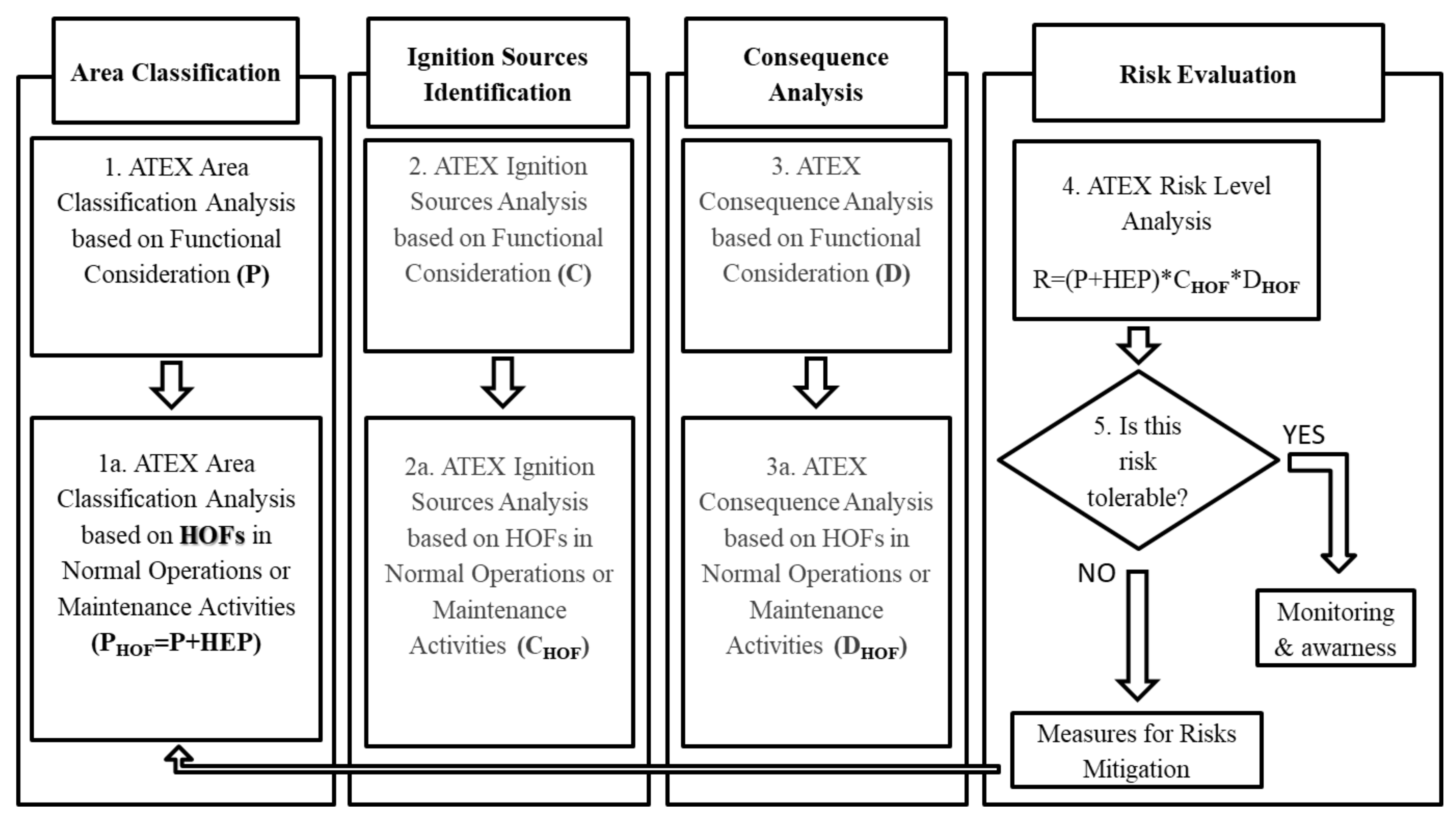

Safety Free Full Text Atex Hof Methodology Innovation Driven By Human And Organizational Factors Hof In Explosive Atmosphere Risk Assessment Html

The Difference Between The Zone And Division Model Wika Blog

Explosion Proof Classification Divisions Zones Of A Spray Room And A Filling Station Explosion Groups Temperature Classes Fire Protection

Hazardous Area Classifications What You Need To Know Exdirect Explosion Proof Instrument Enclosures

Ex Zone What Is An Ex Zone Atexor Knowledge Base

Atex Enclosures Index Hazardous Area Information

Atex Zone 0 Classification

Atex Catalog Peli

Atex Catalog Peli

Understanding Atex Zones

Identifying Zone 0 Zone 1 And Zone 2 Hazardous Areas Raytec Led Blog

Hazardous Areas Hazardous Area Zones Guide Explanation Definitions

Classificazione Zone Aree Atex

Overview Of Hazardous Areas Expo Technologies

Classification Of Atex Zones Petzl Other

Explosion Proof Atex Guidelines Explained Atexindustries

News Petzl Understanding Atex Markings Petzl Finland

Five Things You Should Know About Atex Pumps

Hazardous Areas Hazardous Area Zones Guide Explanation Definitions

Pressure And Flow Catalogue 16 17 By Oem International Issuu

Atex Zoning Support For Aerosol Machines R R Aerosol Systems Ltd

Atex Sodeca

Overview Of Atex Zones And Equipment Ex Machinery Atex Blog

Feam Enclosures Hazardous Area Enclosures Zone 1 Zone 2 Atex Iecex Inmetro Gost R Gost K Manualzz

Zone 0 1 2 Atex Explosion Proof Light Knowledge Shenzhen Cary Technology Co Ltd

Technetea Electrical Apparatus In Potentially Explosive Atmospheres

How Do We Define Hazardous Areas

China Ip66 Or Ip67 Flame Proof Atex Zone 1 Zone 21 Led High Bay And Flood Light 100w 1w 150w 185w 0w Luminaires For Use In Hazardous Classified Locations Photos

Standards And Regulations Ex Zones Atex Iecex

Atex Iecex Markings Explained

Identifying Zone 0 Zone 1 And Zone 2 Hazardous Areas Raytec Led Blog

Standards And Regulations Ex Zones Atex Iecex

Overview Of Hazardous Areas Expo Technologies

Hazardous Area Atex Certfied Light Guide Led Work Lights Unilite

Http Www Iecex Com Assets Uploads D1s4a Implementation Ei Installation In Haz Area Classification Phe Onwj Pdf

Ex Pressure Sensors And Transmitters For Atex Zone 0 Zone 1 Or Zone 2 Markings Of Pressure Instruments For Use In A Hazardous Area Wika Blog

Q Tbn And9gcqoby6hwzvjyil E53qpnwrbpicam Wro Prssijpohqkcfxx75 Usqp Cau