G Code Programm

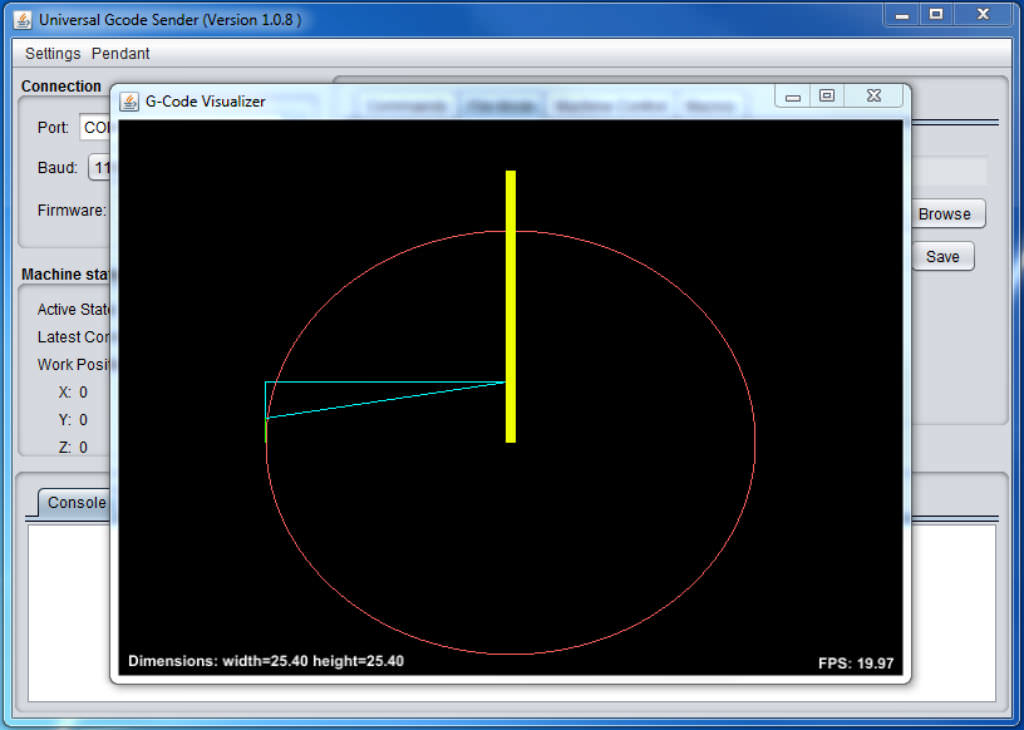

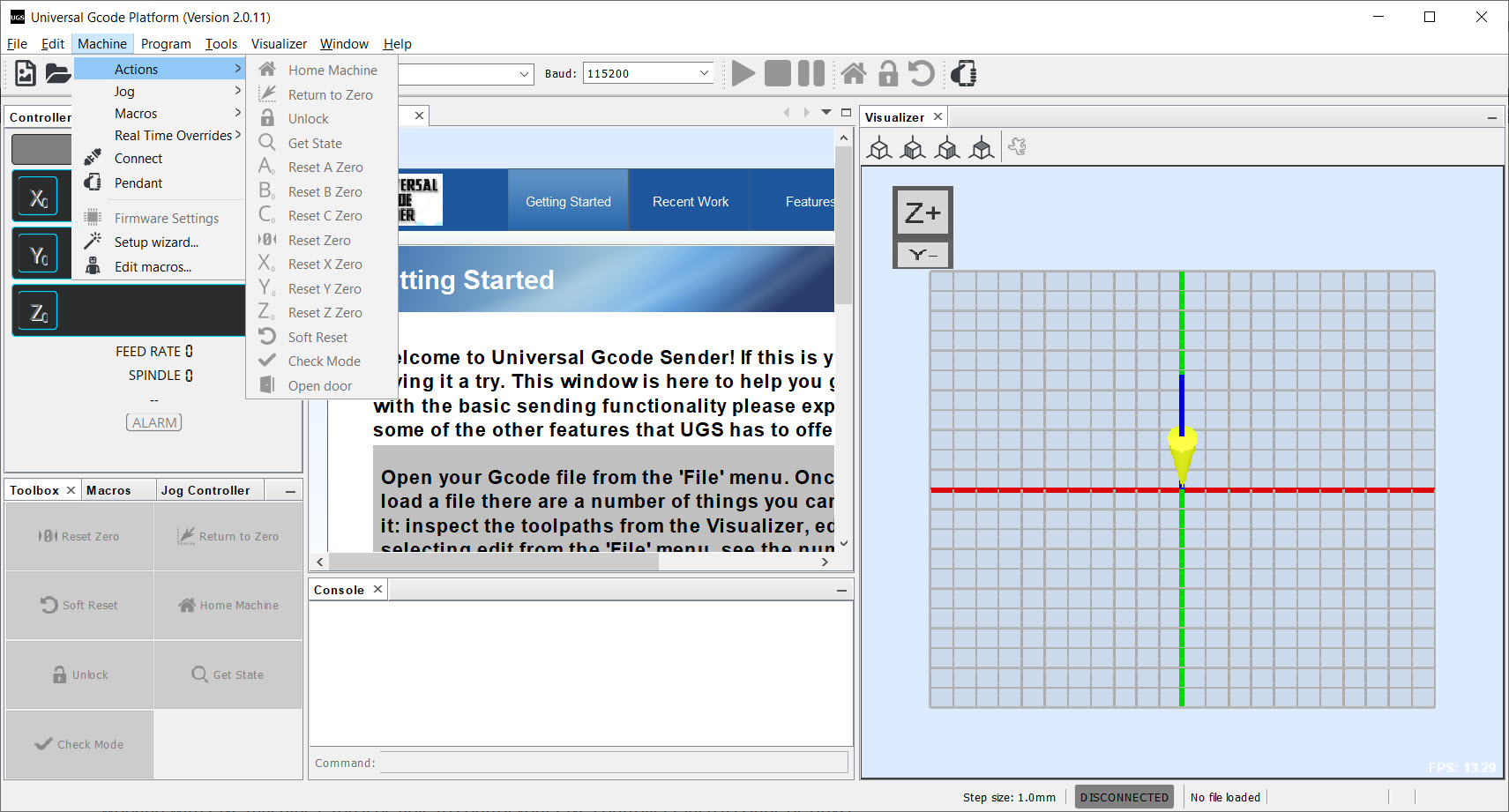

Gcodesender Shapeoko

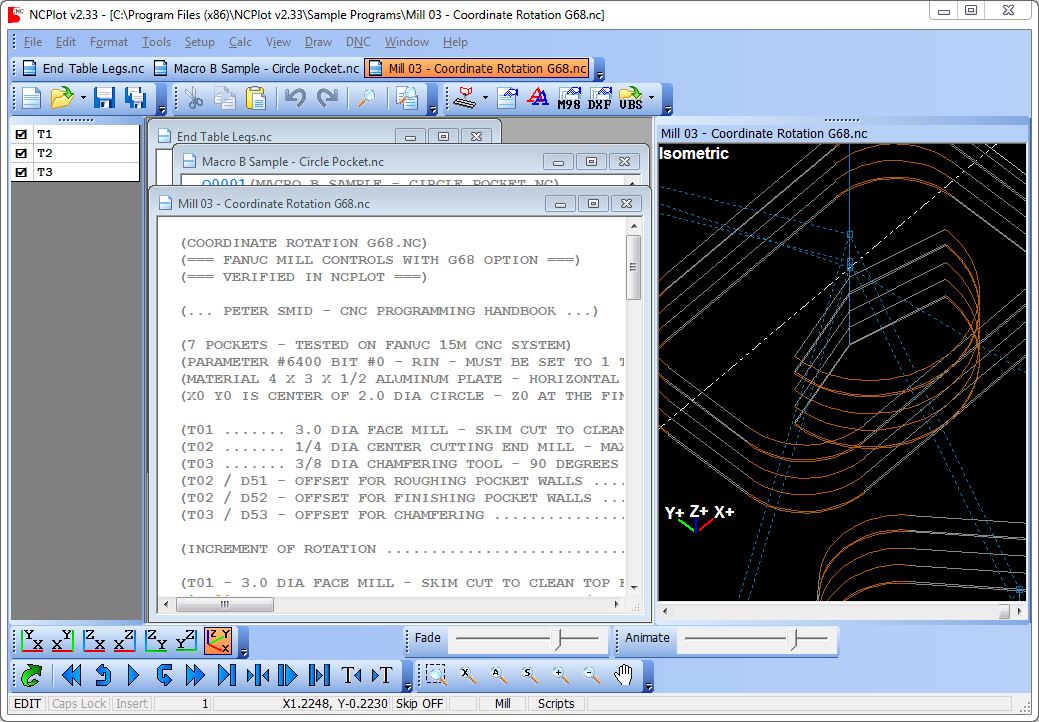

Ncplot Version 2 Features

2

How To Become A G Code Master With A Complete List Of G Codes

Cnc Iso G Code Mill Programming Youtube

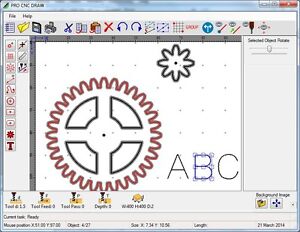

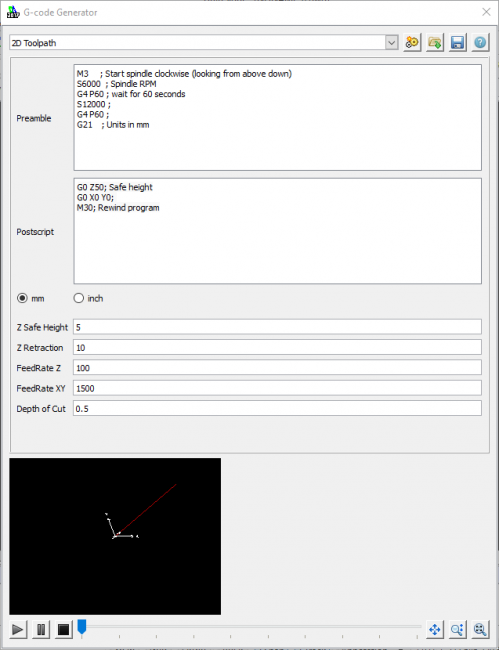

G Code Program For 2d Drawing Dxf Gerber To G Code For Cnc Usb License Dongle Ebay

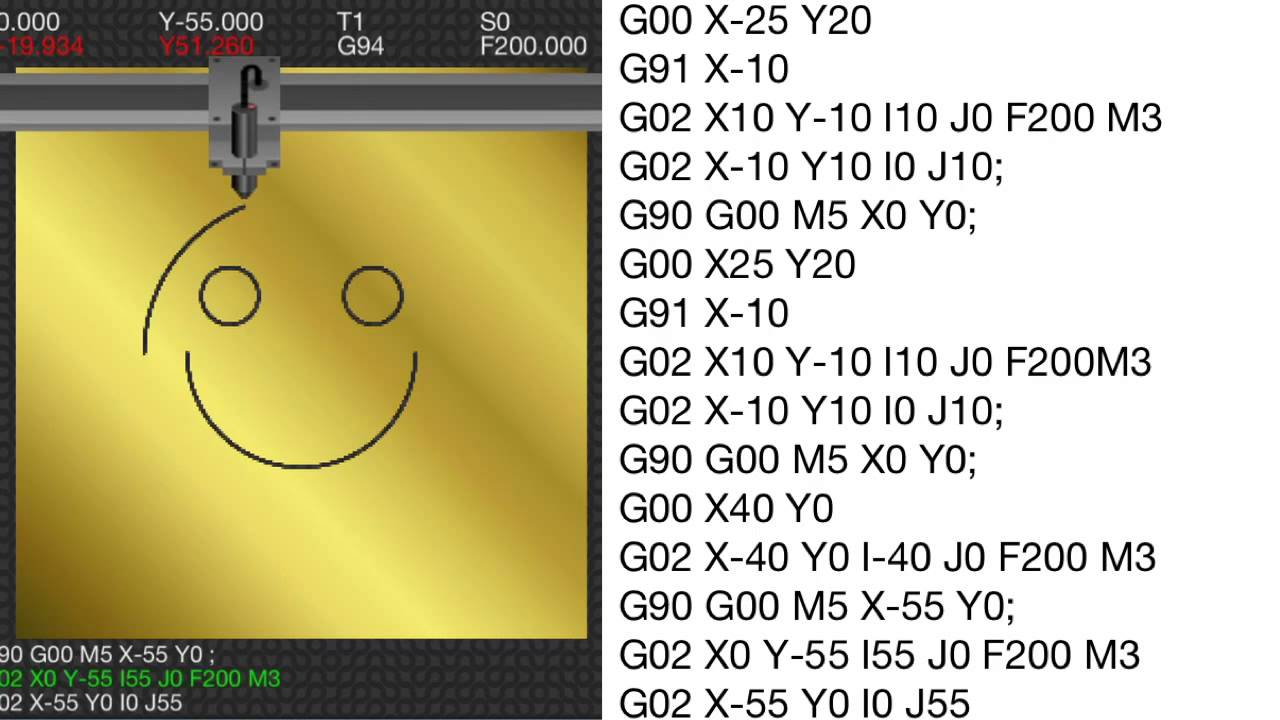

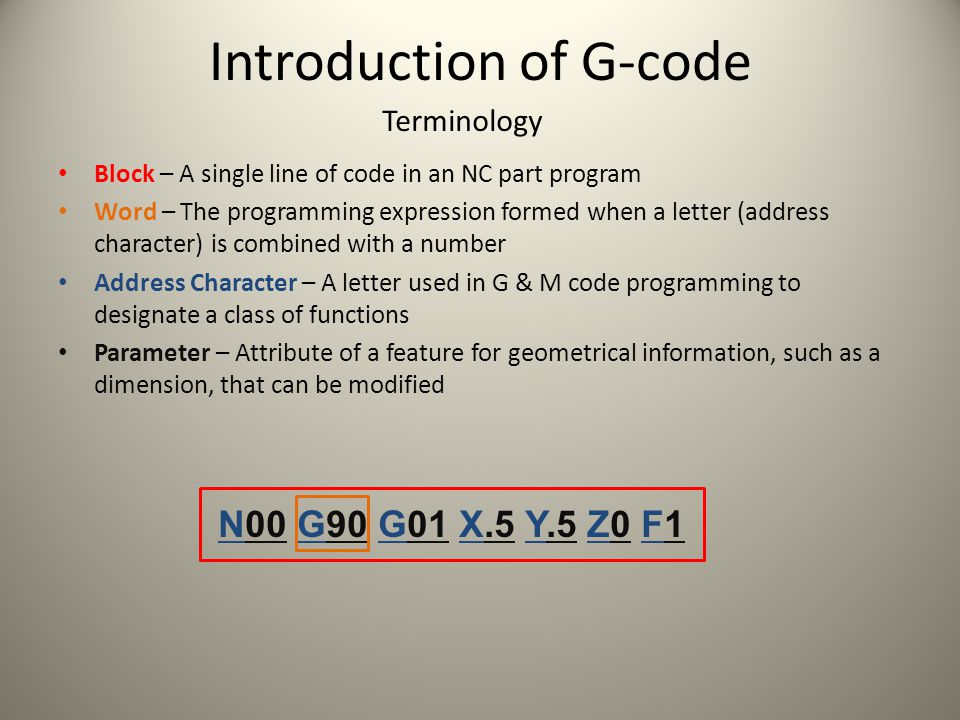

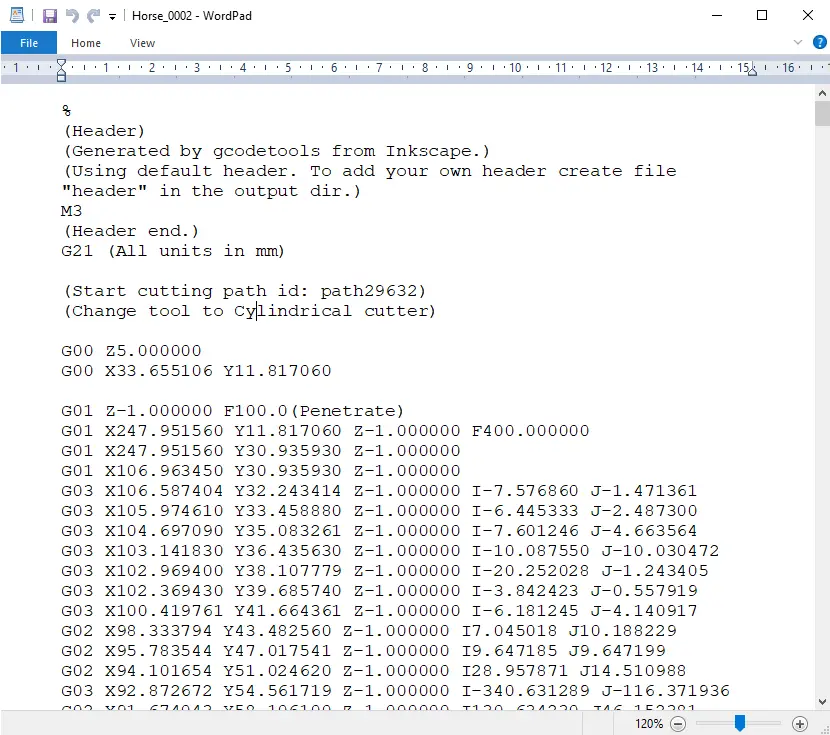

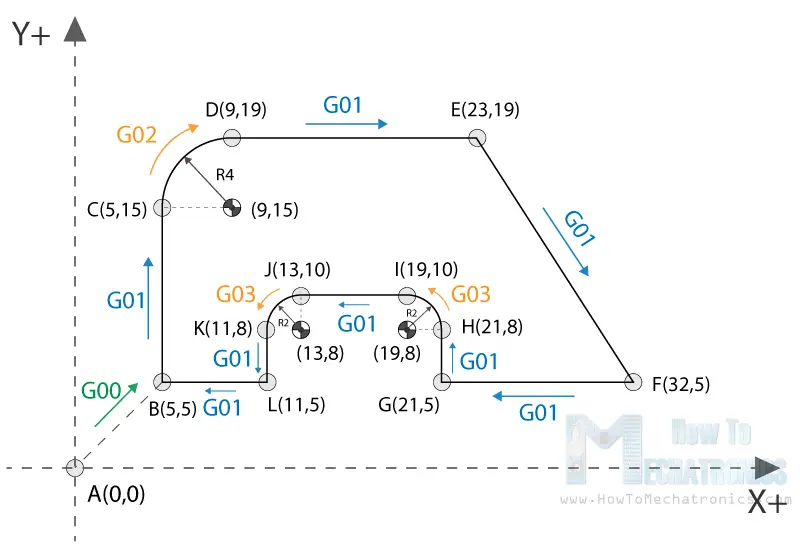

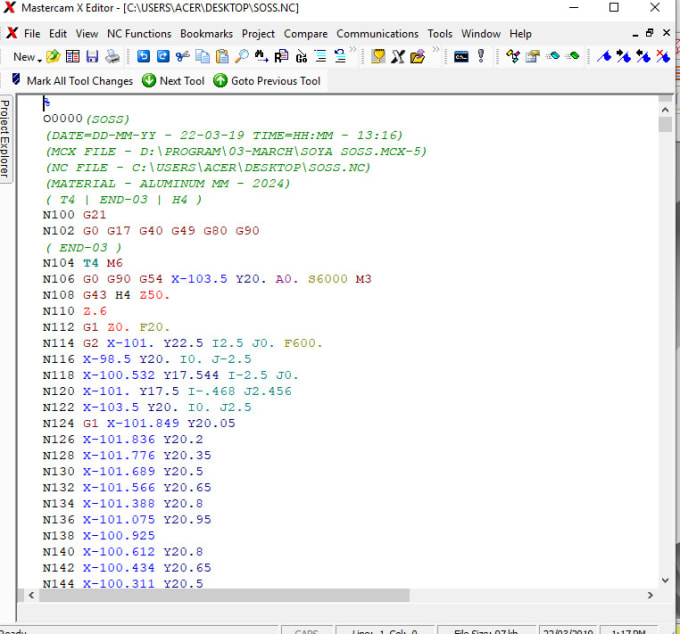

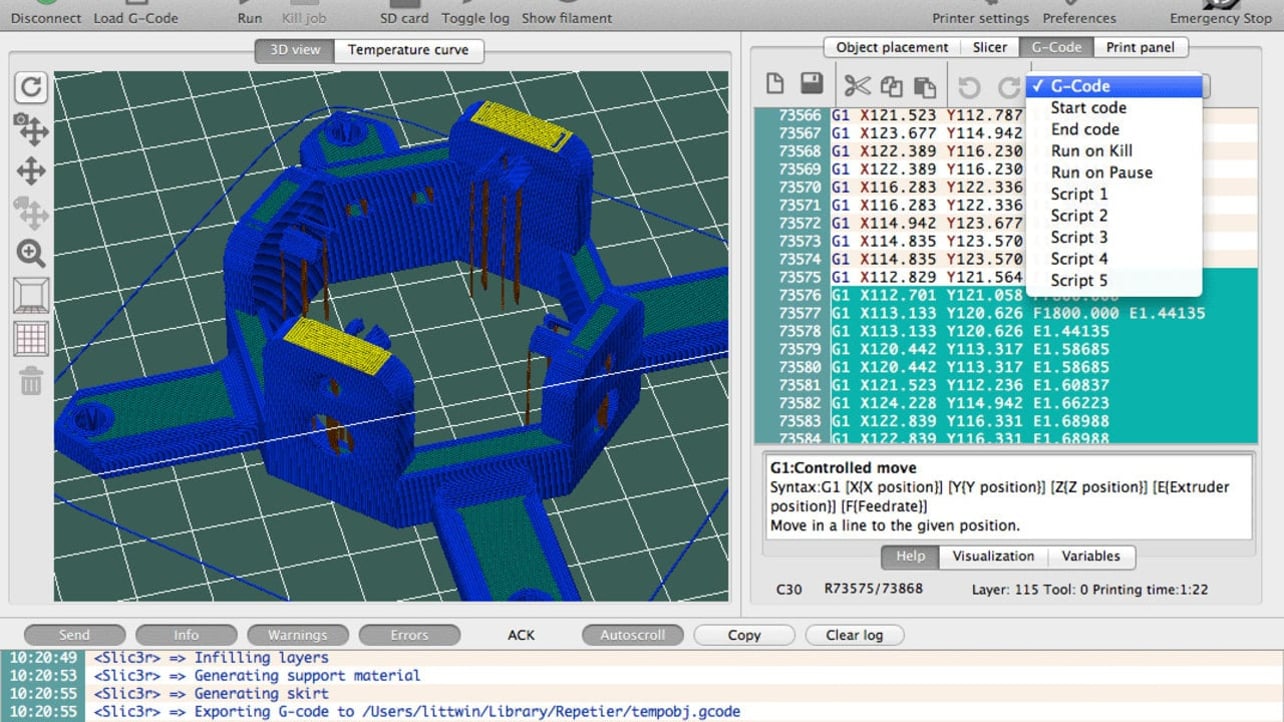

Introduction Gcode is used in a lot of automated manufacturing processes For example, CNC machines and 3D printers use Gcode to make parts Programming arcs and linear movement in Gcode can be a little tricky I've noticed that there aren't many sources on the internet that address this topic So, I decided to make my own guide.

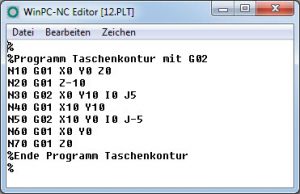

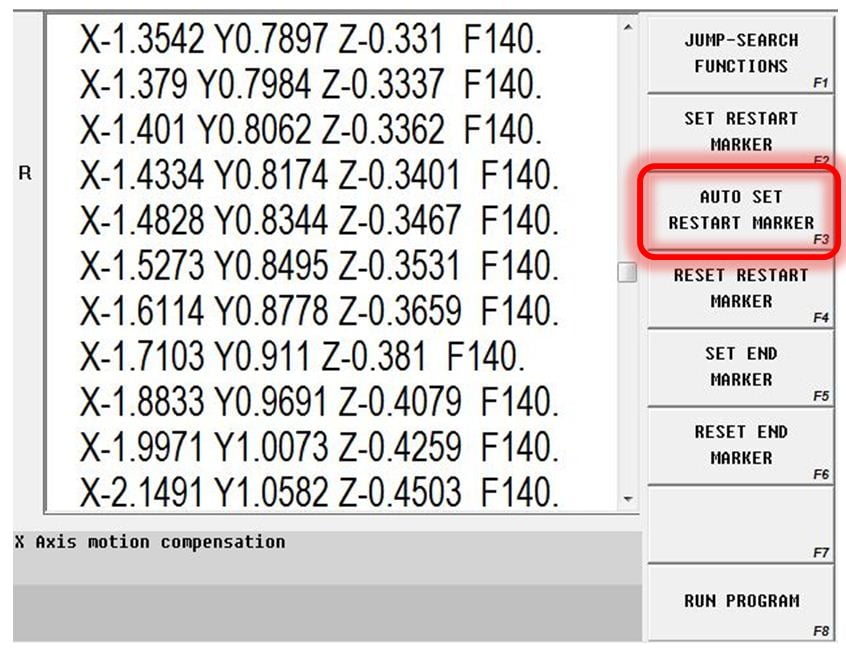

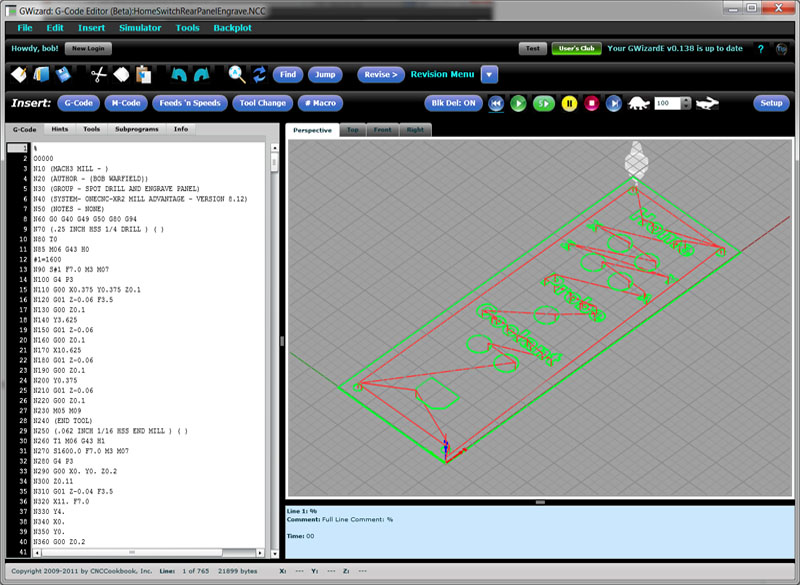

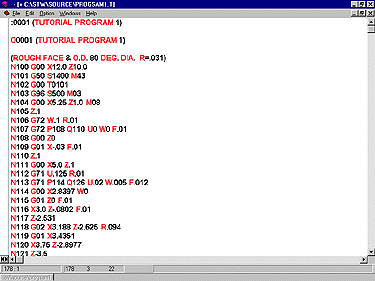

G code programm. G code Programming for Beginners Learning G code programming is not that difficult Read and learn about a G code Understand how that G code work Then make a simple G code example drawing Make program for that example Run the program on your cnc machine (Safety first, keep a professional around). Gcode generator for milling a rectangle Program can create Gcode tool path for milling (cutting) of the rectangle. G & Mcodes will make up the bulk of your CNC program Codes that begin with G prepare your machine to perform a specific type of motion The most common G codes that you’ll encounter time and time again in every CNC program include G0 – Rapid Move This code tells a machine to move as fast as possible to a specified coordinate position.

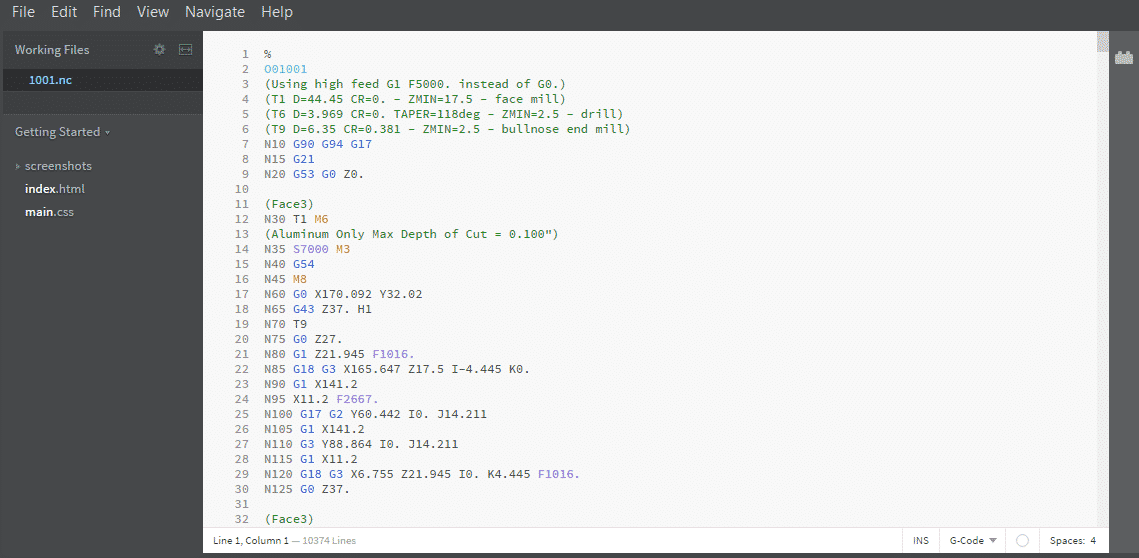

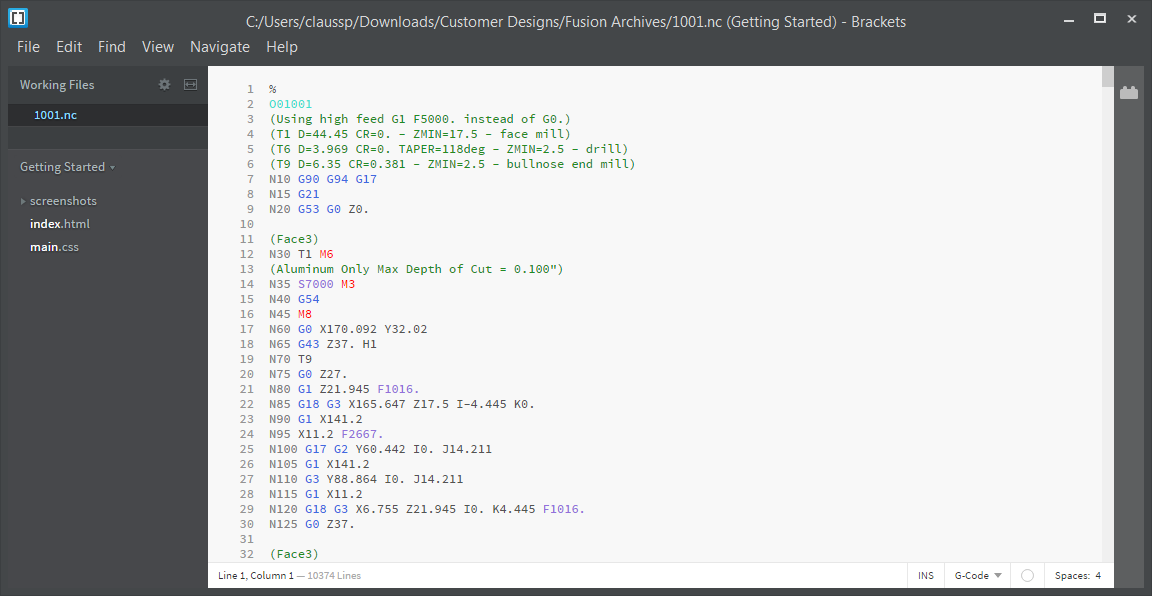

M06 = tool change;. One of the most basic programming software is the source code editor, which is used ubiquitously and continuously It is basically a text editor program designed for writing and editing programming code Code editor can either be a standalone application or built into a web browser or integrated development environment (IDE). The G code was programmed with the goal of being able to run on a 3018 cnc engraving machine These machines are the ‘lowest common denominator’, meaning, if the programs can be used on this machine, they can be used on any machine.

CNC G codes G00 Positioning at rapid speed;. Enable HighEnd CNC Functionality with Flexible GCode Programming SPiiPlus motion controllers can perform highend CNC functions through native GCode programming support Developed to meet the needs of demanding laser processing applications, ACS’ GCode capability includes rich motion profile generation options to maximize throughput and userdefinable GCodes which enable the machine. M03 = spindle on;.

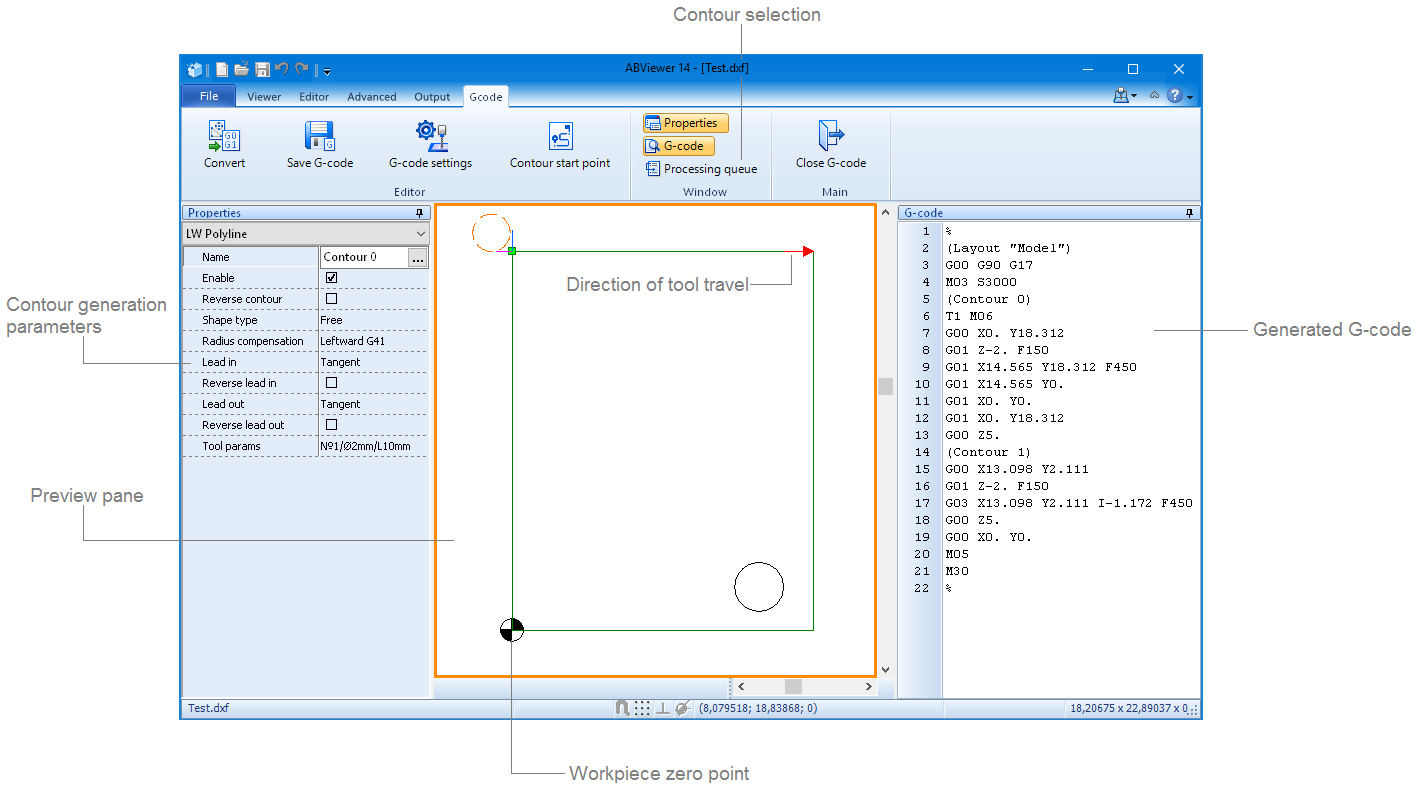

The Gcode is also known as the Numerical Code Programming Language This language is primarily used in computeraided manufacturing and 3D printing A Gcode carries all the necessary instructions which a 3D printer needs to create a physical 3D model. M97 = subroutine call;. Gcode is specifically designed for converting AutoCAD drawings into GCode programs for use with any 2D or 3D machine such as Wire EDMs, Laser Etchers, Flame cutting, Milling, Lathes Also Gcode.

Sorry for such a basic question but I've never had to do this before I have an Okuma LC40 lathe with an OSP5000 control I just got a bar puller and I've never used one before. Gcode is simple, and every machine uses it Commercial machines come with fancy software that adds some proprietary code to every program, but the basic commands are always the same I’ll translate some Gcode into English so you can see how it works Software for CNC Programming You don’t have to learn Gcode to create CNC programs. Basic Gcode question how to make my program repeat X number of times?.

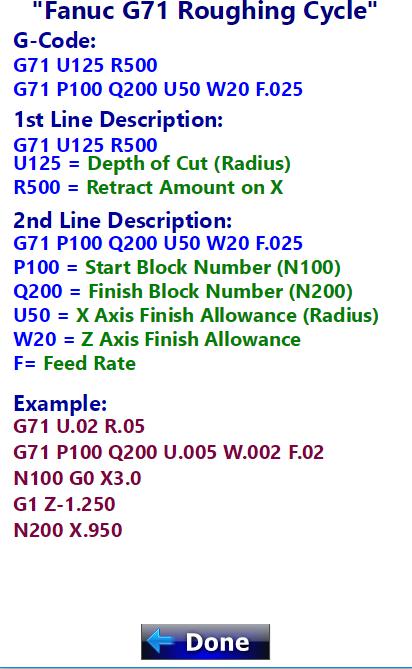

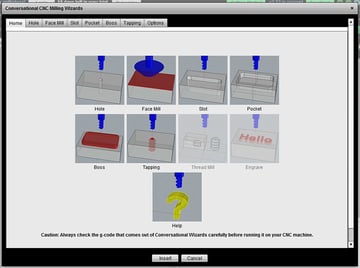

Make G Code for your 3 Axis CNC mill the easy way with Simple CNC Easier to learn and faster to use then writing it by hand or using a CAD/CAM programs You can't beat Simple CNC for your project needs. Return to Gcode list G70 & G71 Units Program G70 to use inches for length units Program G71 to use millimetres It is usually a good idea to program either G70 or G71 near the beginning of a program before any motion occurs, and not to use either one anywhere else in the program It is the responsibility of the user to be sure all numbers. To GCodes (*tap) for free (no watermarks, no file cuts) It has a userfriendly interface which allows one to drag&drop for the easiness of use You can also customise pregenerated GCodes, and quickly convert files by just dropping files on a given application icon.

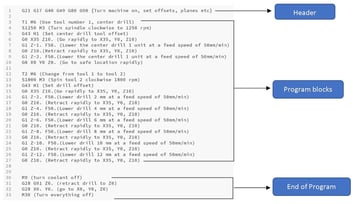

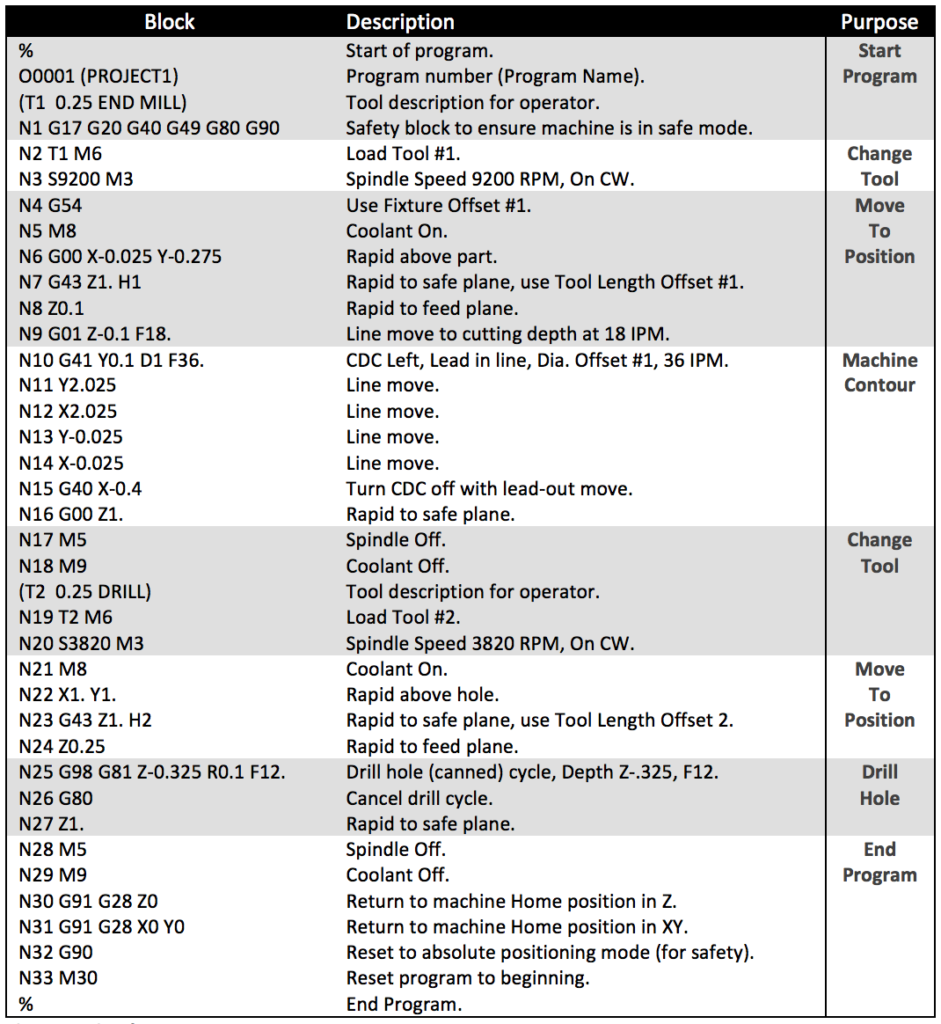

The question is a bit vague Remember that you will need to generate a model in a CAD program (if you are working in 3D), then transform the model to GCode using a CAM program, then use the GCode to operate your CNC mill or lathe For generating your 3D model, I recommend FreeCAD as an open source product. A Gcode program is made up of one or more lines of code Each line of code is called a block, and can include commands to the machine Blocks are collected into a file, which makes a program. Return to Gcode list G70 & G71 Units Program G70 to use inches for length units Program G71 to use millimetres It is usually a good idea to program either G70 or G71 near the beginning of a program before any motion occurs, and not to use either one anywhere else in the program It is the responsibility of the user to be sure all numbers.

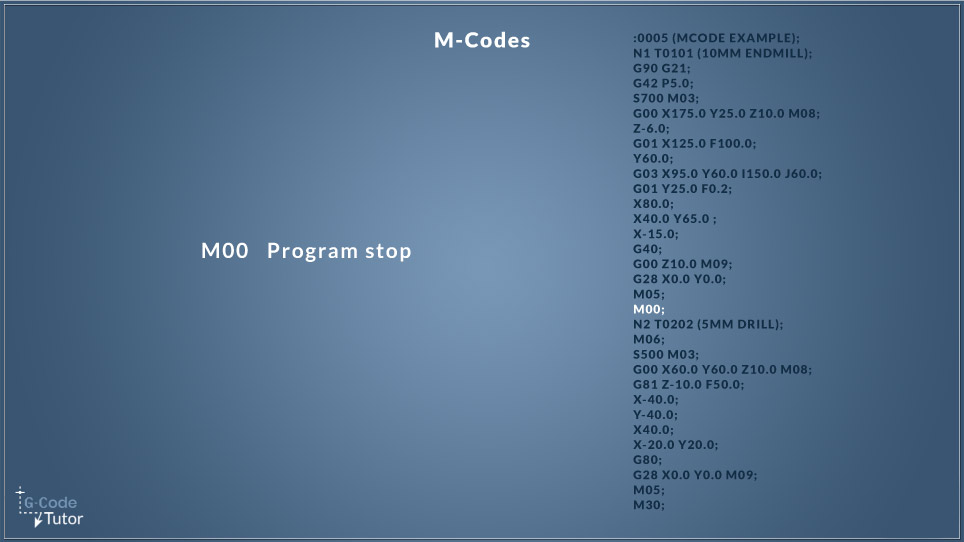

Mill and Lathe G01 Linear interpolation (machining a straight line);. In my article “G28 G code demystified” I explain program headers and footers You can use these for every program you write, just copy and paste whenever you need to write a new program. Description on G codes used for programming CNC Machines M00 = Program stop M01 = Optional program stop M02 = End of program (no rewind or return to start of program).

Sorry for such a basic question but I've never had to do this before I have an Okuma LC40 lathe with an OSP5000 control I just got a bar puller and I've never used one before. Gcode is everywhere, from 3D printing to CNC milling Easily learn the basics of CNC Gcode programming in just six simple steps. ANZEIGE CNC programming with Gcode – What is that actually?.

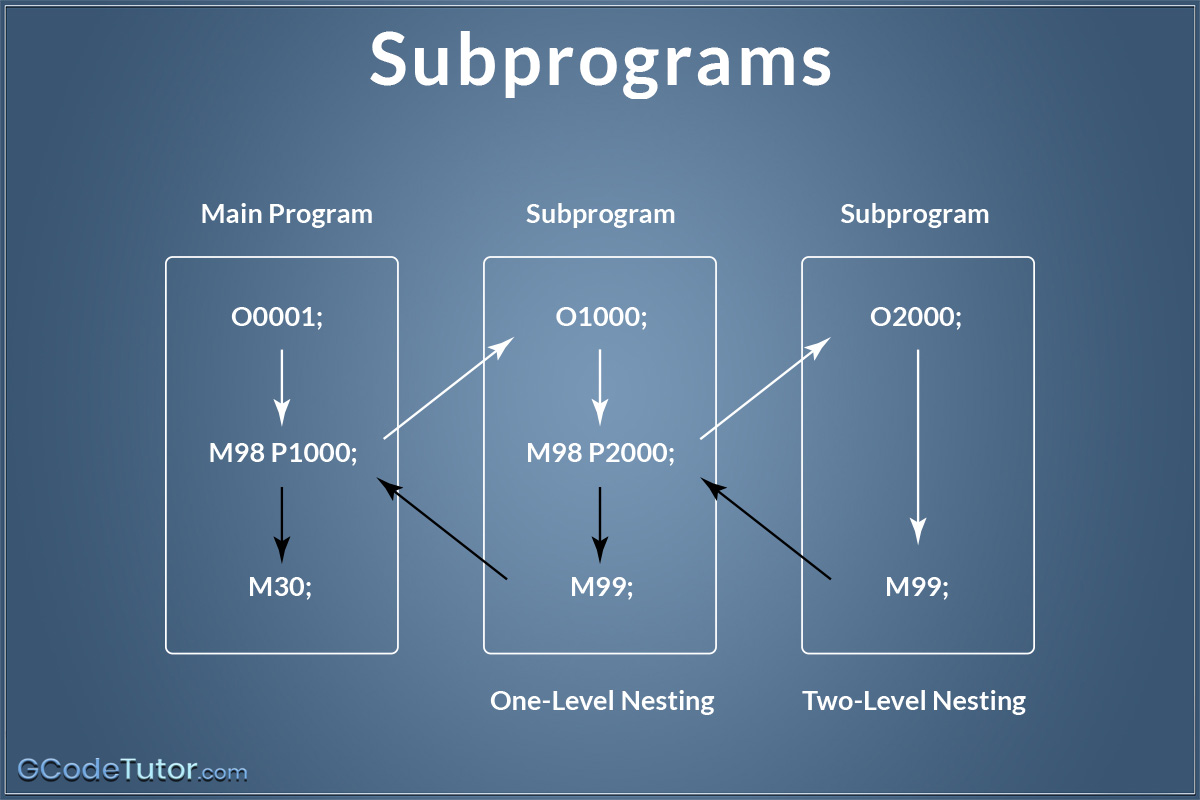

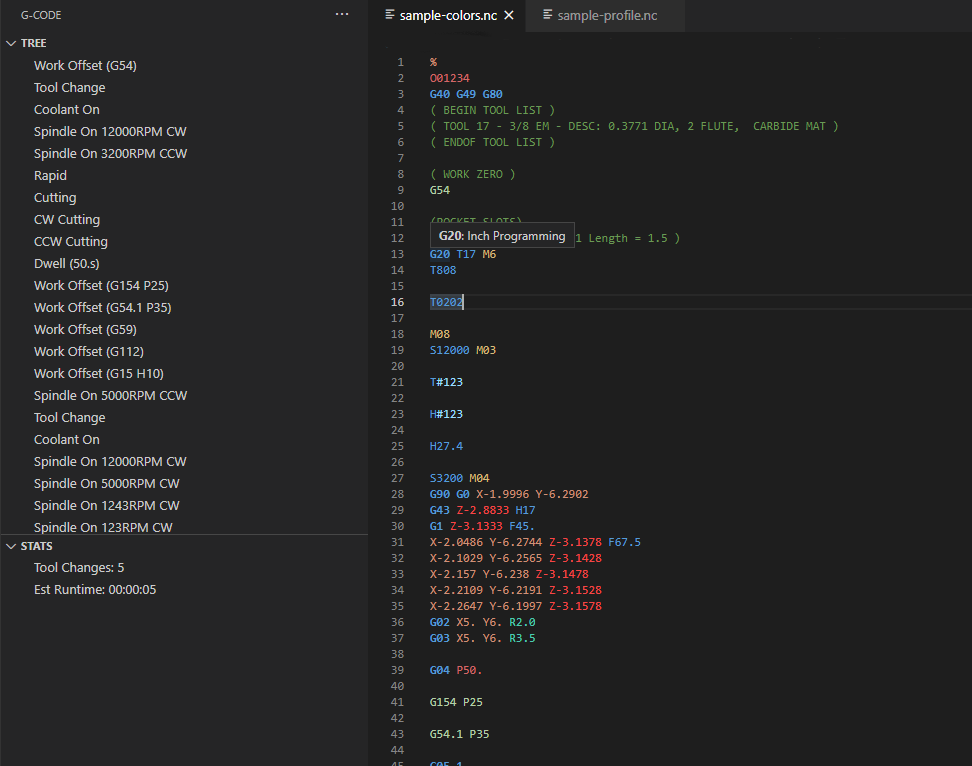

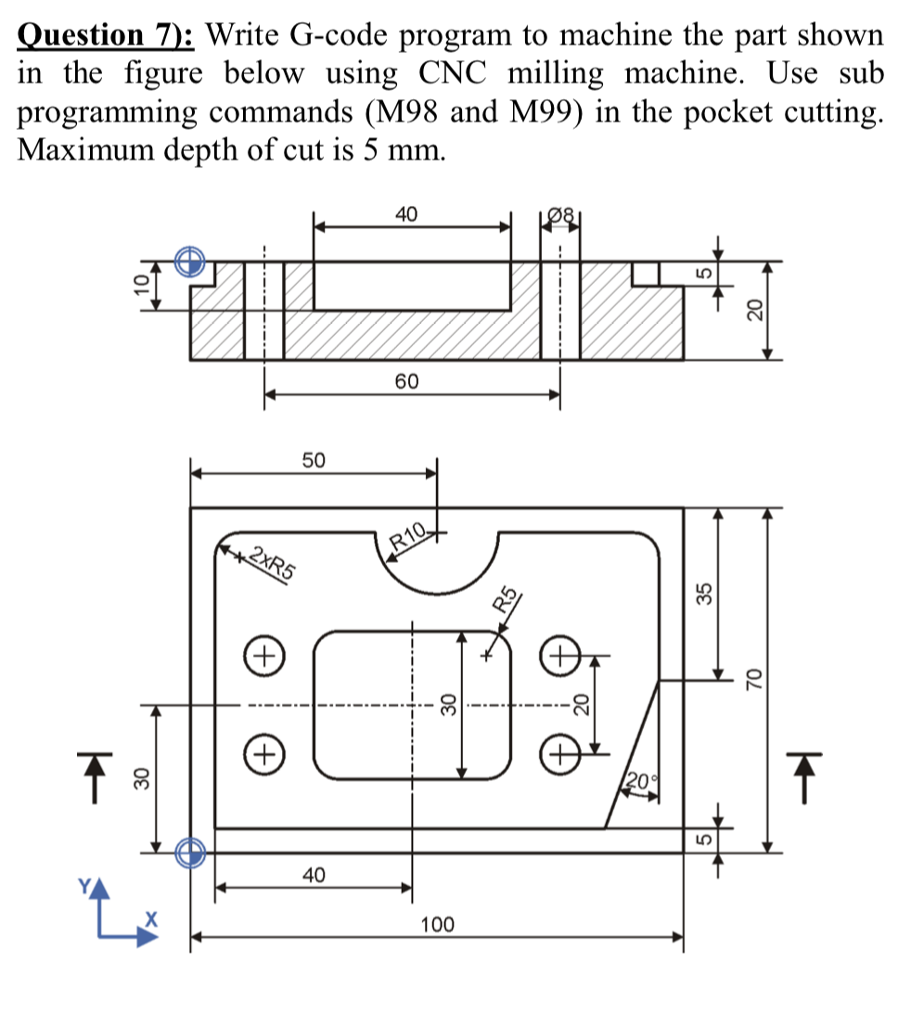

M98 = subprogram call;. M codes M00 = program stop;. The Gcodes are grouped into categories such as Group 01, containing codes G00, G01, G02, G03, which cause some movement of the machine table or head Group 03 includes either absolute or incremental programming.

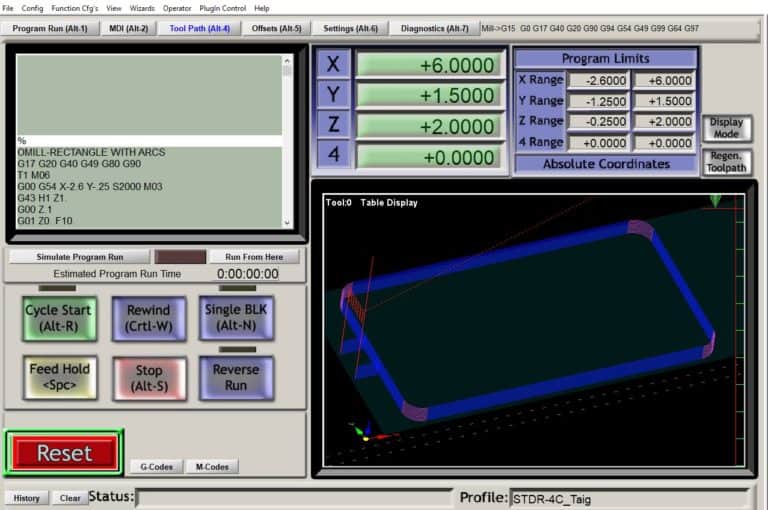

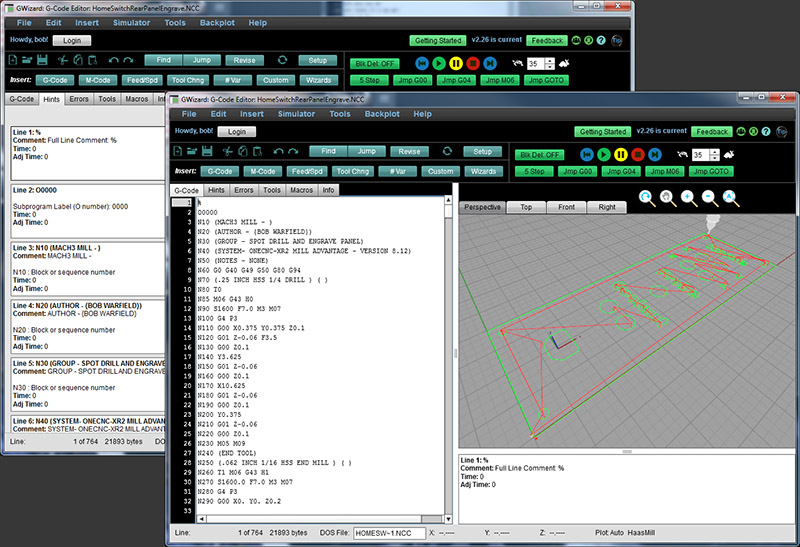

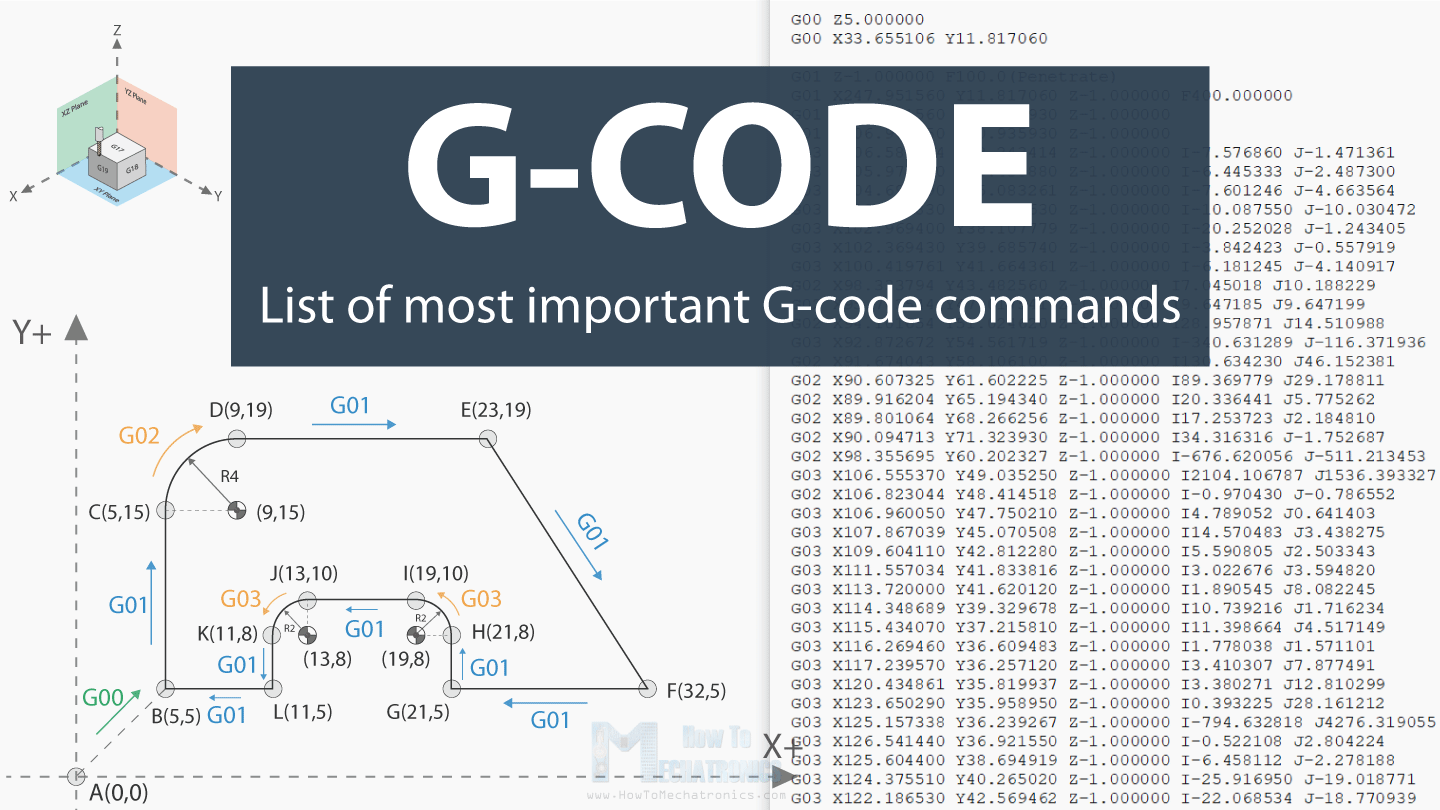

GCode is the most popular programming language used for programming CNC machinery Some G words alter the state of the machine so that it changes from cutting straight lines to cutting arcs Other G words cause the interpretation of numbers as millimeters rather than inches Some G words set or remove tool length or diameter offsets. GCode Q'n'dirty toolpath simulator Paste your gcode in the lefthand window or drop a file on the page and see the preview of your tool path on the right The righthand pane are interactive, drag them to change the point of view. Before we get you up to speed on programming with variables, logical statements and custom macros I recommend that you either have a good working knowledge of standard CNC programming or have completed at least one of the courses below CNC Lathe Programming CNC Mill programming Already know GCode but wish to learn the advanced stuff?.

GCode is a programming language that is used by CNC machines to turn the digital designs created by engineers into tangible parts and products If you want to harness modern computercontrolled manufacturing equipment effectively, understanding GCode is essential This brief guide will get you up to speed and provide the foundation for further studies. M99 = subprogram end;. The Gcode, also called DINcode, is a machine language with the help of which the programmer tells the CNC machine what it should do CNC stands for computerized numerical control and means that the machine is controlled by a computer The Gcode is called like this because many commands start with a G followed by a number (e.

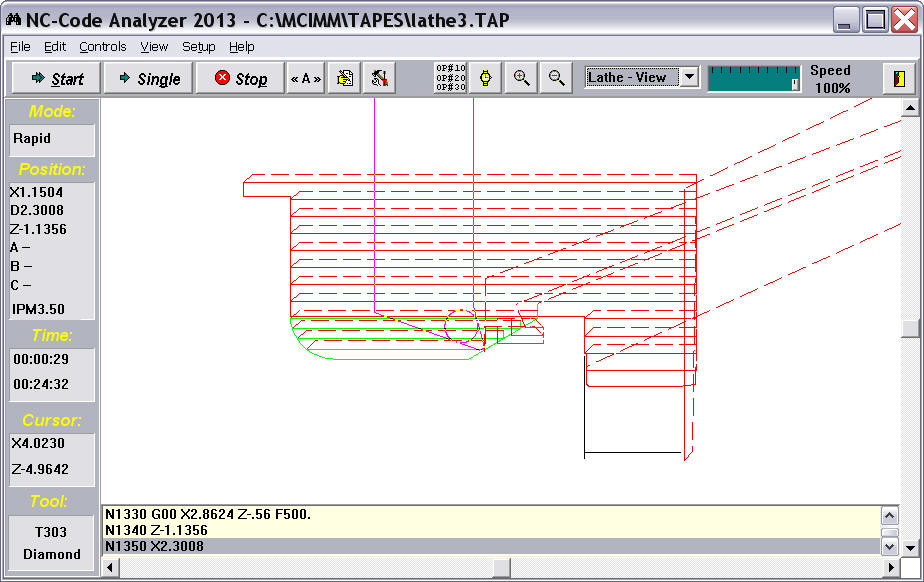

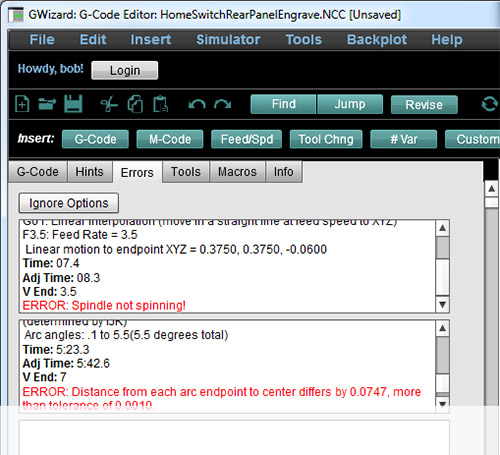

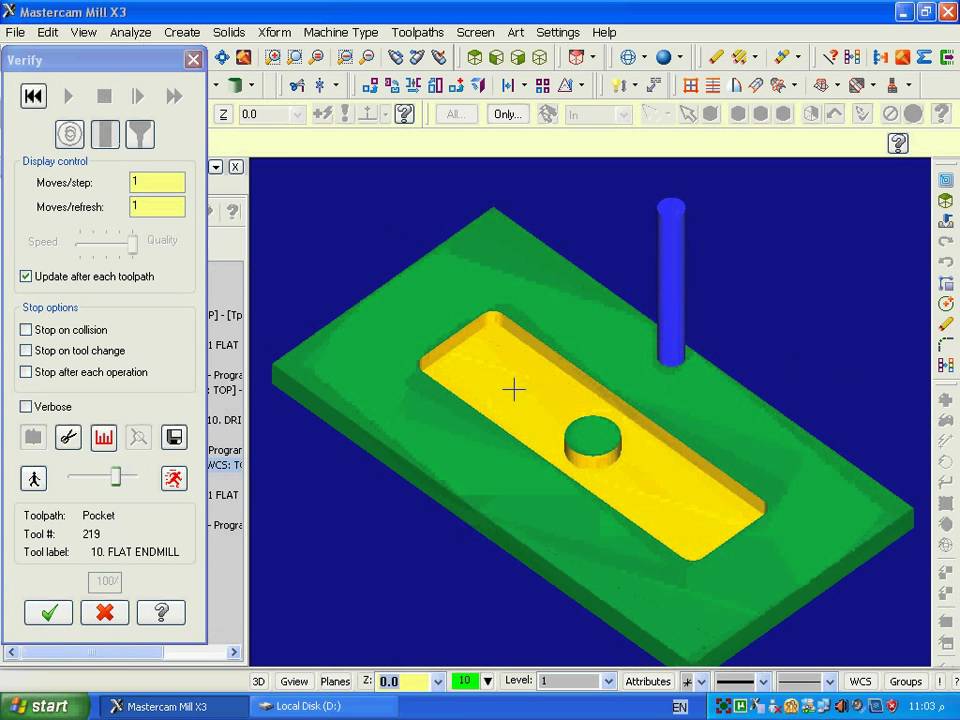

A good GCode simulator can make the difference between a successful manufacturing process or an expensive failure Here are some of the best simulators Debugging is a vital part of any programming task This is certainly true with programs that will interact with the physical world like those used to control CNC machines, 3D printers, and robotics Any mistake in the programming of these. Gcode is one of the most widely used programming languages used to control automated machine tools Most CNC machines execute Gcode, although other CNC languages exist, such as Heidenhain, Mazak, and other proprietary formats CNC machinists can either write Gcode from scratch, modify existing Gcode, or generate Gcode using CAM software. The Gcode and Mcode in CNC programming is for product designing and machines motion, to ensure exact shapes and dimensions be manufacturedIf you want to learn CNC programs, you need to understand the meaning of each Gcode and Mcode for CNC turning and milling Here is the introduction to the definition, difference and list of Gcode and Mcode, as well as how they work and write.

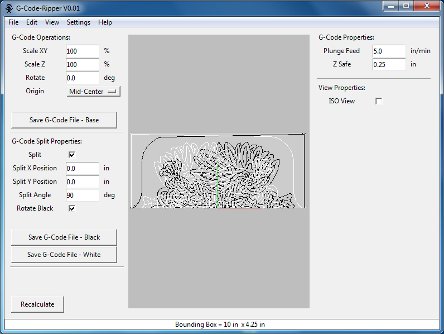

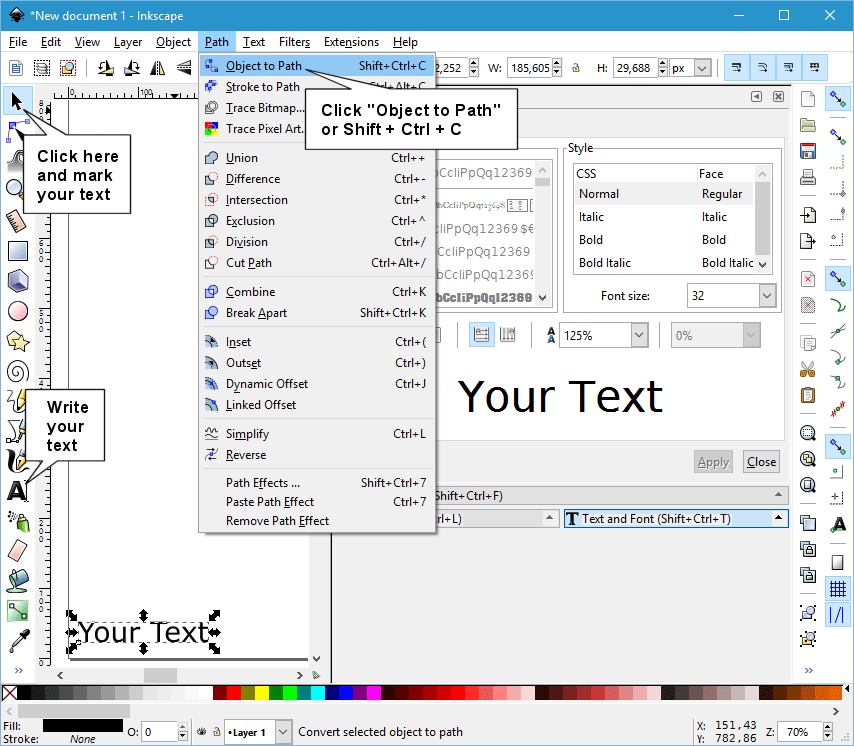

It will stop running the subprogram and return from to the previous program and continue to run from the line below the M98 line. GCODES are used in many DIY CNC machine to plot imagesThis video is to show HOW to make GCODE file of any image by using Inkscape software & i also show G. GCODES are used in many DIY CNC machine to plot imagesThis video is to show HOW to make GCODE file of any image by using Inkscape software & i also show G.

Description on G codes used for programming CNC Machines M00 = Program stop M01 = Optional program stop M02 = End of program (no rewind or return to start of program). Your CNC router reads GCode GCode is the language of CNC machines, it has been powering industry manufacture for over 60 years Fusion 360 outputs its tooling paths to GCode then it is then read by your machine to make your parts. M05 = spindle off;.

Gcode (also RS274) is the most widely used computer numerical control (CNC) programming languageIt is used mainly in computeraided manufacturing to control automated machine tools, and has many variants Gcode is a language in which people tell computerized machine tools how to make something The "how" is defined by Gcode instructions provided to a machine controller (industrial. The Gcode and Mcode in CNC programming is for product designing and machines motion, to ensure exact shapes and dimensions be manufacturedIf you want to learn CNC programs, you need to understand the meaning of each Gcode and Mcode for CNC turning and milling Here is the introduction to the definition, difference and list of Gcode and Mcode, as well as how they work and write. G91 = incremental programming;.

Make G Code for your 3 Axis CNC mill the easy way with Simple CNC Easier to learn and faster to use then writing it by hand or using a CAD/CAM programs You can't beat Simple CNC for your project needs. Basic GCode Programming Reference Coordinate Axis Direction This tutorial is designed to create a wireframe model of a part This tutorial will not simulate a full Gcode program for a 3D print because the program for a whole object is, at minimum, 15,000 lines long This is because of the. ANZEIGE CNC programming with Gcode – What is that actually?.

Gcode cnc 3018 free download GCode Syntaxhighlighter for NetBeans NetBeans Module for Syntaxhighlighting of GCode (CNC). Gcode is the operational language for CNC machining It tells numerically controlled lathes and machining centers how to move tools in order to perform various cutting operations It is equivalent to manual programming where each operation is spelled out linebyline and is separate from Mcode and Tcode, codes that control the machine and tooling. CNC G Code & M Code Programming for CNC Machining CNC G Code for CNC Programming A strong knowledge CNC G Code & M Code is helpful for CNC Machining CNC Machining programs can be written by hand or with a CAM system Carlson Manufacturing, Inc has decades of experience in cnc machining.

Replied by robh on topic ReG CODE FOR REPEAT PROGRAM if u just want to repeat a program or some code you can use O12 REPEAT10 some code O12 ENDREPEAT this will repeat any code between the tags repeat endrepeat 10 times, then drop out and process anything under. Nov 19, Teaching CNC G code programming See more ideas about cnc, cnc programming, diy cnc. M30 = end of program, rewind and reset;.

For CNC from JPG to GCode CNC machines like routers or milling machines make use of a series of preprogrammed commands to—in subtractive processes—take material from your piece The most popular programming language is GCode, the creation of which marked an important step in the history of CAM This language controls exactly how your. Description on G codes used for programming CNC Machines M00 = Program stop M01 = Optional program stop M02 = End of program (no rewind or return to start of program). M30 End of the program with a return to the top part of the program How to work with with the Gcode for the Endurance MakeBlock XY engraver G00 // positioning G04 P0 // pause, delay setting at 0 M05 S0 // laser off G90 G21 // step specifying in mm G00 X5 Y5 // positioning along X and Y.

Read the following sections as a Gcode reference Rapid Linear Motion (G00), Linear Motion at Feed Rate (G01), Arc at Feed Rate (G02 and G03), Dwell (G04), Set Offsets (G10), Plane Selection (G17, G18, G19), Length Units (G and G21), Return to Predefined Position (G28 and G281), Return to Predefined Position (G30 and G301), Straight Probe (G38x), Cutter Compensation (G40, G41, G42. The MCode M99 will tell the machine that the subprogram that it is currently running has come to an end, if the subprogram has run the number of times specified by the initial program call using M98 P____;. Basic Gcode question how to make my program repeat X number of times?.

M01 = optional stop;. CNC G Code & M Code Programming for CNC Machining CNC G Code for CNC Programming A strong knowledge CNC G Code & M Code is helpful for CNC Machining CNC Machining programs can be written by hand or with a CAM system Carlson Manufacturing, Inc has decades of experience in cnc machining. Sample G Code Program for Beginners Sample G code program example for cnc programmers / cnc machinists who work or want to learn cnc mill programming A similar G code example can be found here Simple G Code Example Mill – G code Programming for Beginners If you are interested in G code subroutine example (sub program) read CNC Mill Contour.

Gcode cnc 3018 free download GCode Syntaxhighlighter for NetBeans NetBeans Module for Syntaxhighlighting of GCode (CNC). Gcode is one of the most widely used programming languages used to control automated machine tools Most CNC machines execute Gcode, although other CNC languages exist, such as Heidenhain, Mazak, and other proprietary formats CNC machinists can either write Gcode from scratch, modify existing Gcode, or generate Gcode using CAM software. The Gcode, also called DINcode, is a machine language with the help of which the programmer tells the CNC machine what it should do CNC stands for computerized numerical control and means that the machine is controlled by a computer The Gcode is called like this because many commands start with a G followed by a number (e.

A Gcode editor is any program that allows one to create or alter GCode through linebyline text editing In some cases, this ability could be provided by addons that allow you to directly rewrite existing Gcode instead of recompiling using slicers or CAM software. Read the following sections as a Gcode reference Rapid Linear Motion (G00), Linear Motion at Feed Rate (G01), Arc at Feed Rate (G02 and G03), Dwell (G04), Set Offsets (G10), Plane Selection (G17, G18, G19), Length Units (G and G21), Return to Predefined Position (G28 and G281), Return to Predefined Position (G30 and G301), Straight Probe (G38x), Cutter Compensation (G40, G41, G42. Mill and Lathe G02 Circular interpolation clockwise (machining arcs);.

For CNC from JPG to GCode CNC machines like routers or milling machines make use of a series of preprogrammed commands to—in subtractive processes—take material from your piece The most popular programming language is GCode, the creation of which marked an important step in the history of CAM This language controls exactly how your. The question is a bit vague Remember that you will need to generate a model in a CAD program (if you are working in 3D), then transform the model to GCode using a CAM program, then use the GCode to operate your CNC mill or lathe For generating your 3D model, I recommend FreeCAD as an open source product. G Code is a special programming language that is interpreted by Computer Numerical Control (CNC) machines to create motion and other tasks It is a language that can be quite complex at times and can vary from machine to machine The basics, however, are much simpler than it first appears and for.

Gcodes typically instruct the machining functions of the lathe or mill, while M codes handle the operation of the machine itself, with additional letters representing addresses such as F for feed rate and S for spindle speed used throughout a typical program Although Gcodes are generally selfexplanatory, a number of conventions are used in. Nov 19, Teaching CNC G code programming See more ideas about cnc, cnc programming, diy cnc.

3

G Code Example How To Run Your First Cnc Program

G Code Text Engraving Milling Software Youtube

Cnc Working Check Program Output G Code Check Youtube

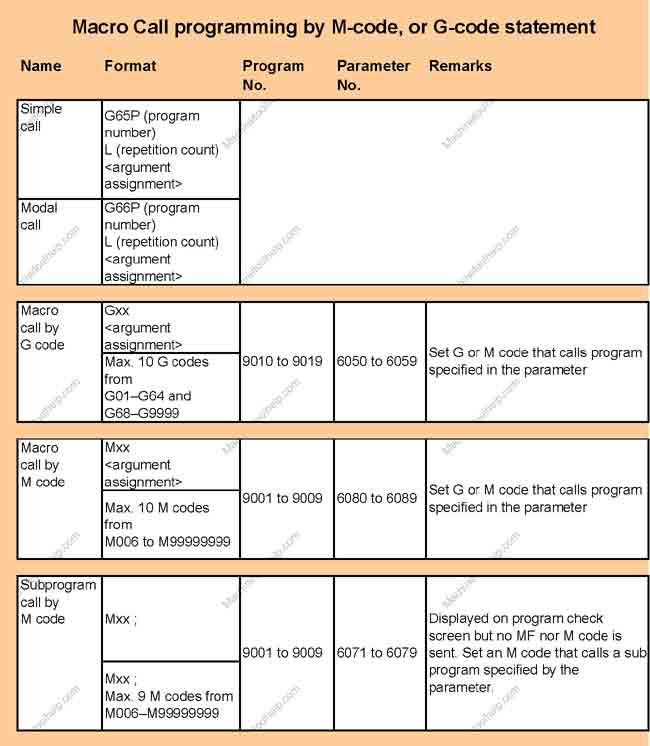

Macro Program Call By M Code Or G Code Statement G65

Milling Dxf To G Code With Kipwarem Youtube

G Code For Cnc And Fdm 3d Printing Programming Facfox Docs

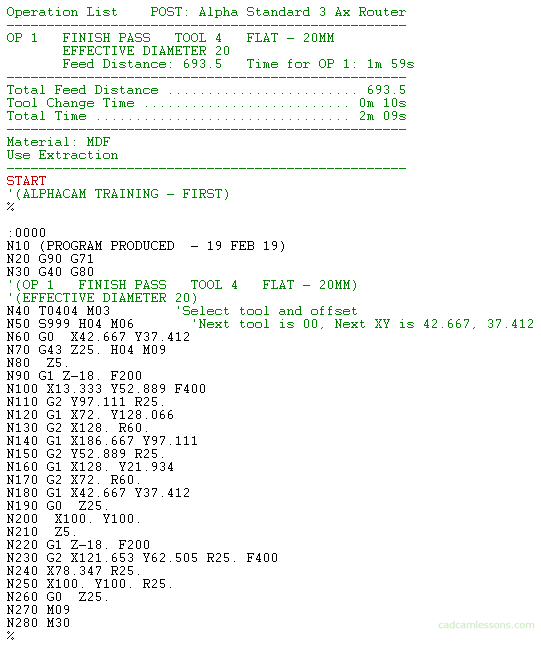

What Is G Code Alphacam Tutorial

Practical Machinist Largest Manufacturing Technology Forum On The Web

G Code Generator Program To Create Standard Tapers On A Cnc Lathe

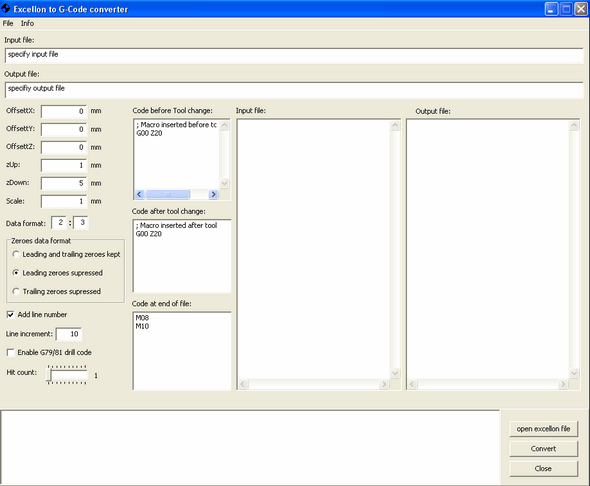

G Code Converter Program Electronics Projects Circuits

Conversational Cnc The Kipware Blog

Gui Of The Program To Visualize And Edit G Code For 3d Printing Download Scientific Diagram

M98 And M99 G Code Subprograms

3drag As A Cnc Milling Machine Creating G Code Via Eagle Software Open Electronics Open Electronics

Simple Cnc G Code Programming Software For 3 Axis Cnc Machining

Cnc G Code Wrapping

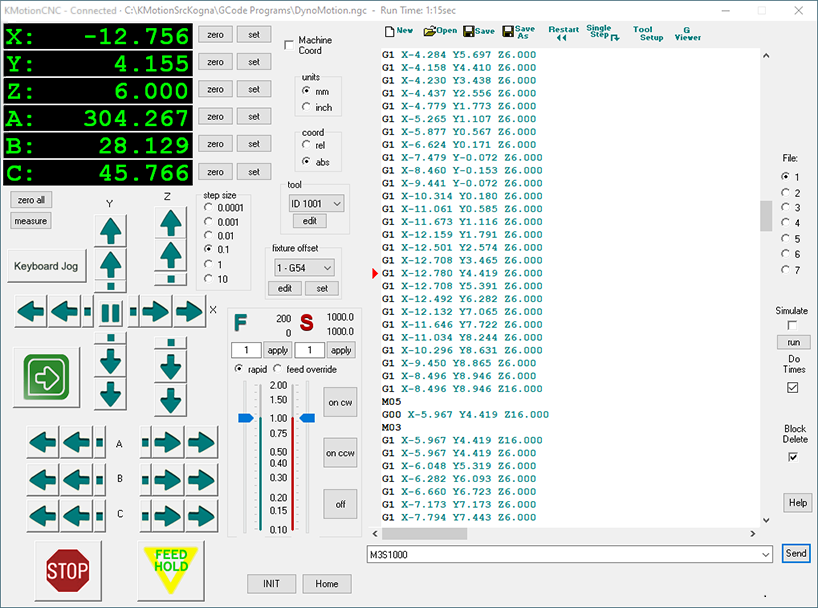

Kmotion Cnc

Nc Code Analyzer

Cad Cam G Code Cnc Programming Bobcad Cam

Kipware Companion Software Kentech Inc

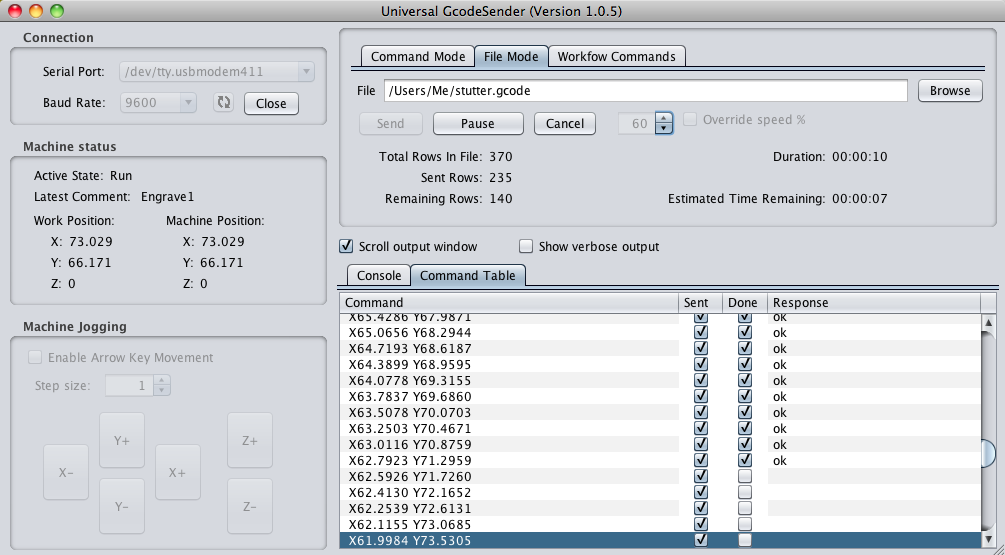

Mechanica Software Gcode Sender

G Code For Reprap Chris Meighan

Cnc Programming With G Code Definitive Free Tutorial 19

G Code Example How To Run Your First Cnc Program

What Are G Codes And How Is It That Makers Find Them Useful For Their 3d Printers

Cnc Programming

G Code Subroutines Using M99 Loops Examples Shown

Tkcnc Overview

.jpg?width=512&name=G-Code%20(2).jpg)

G Code And M Code What Do They Mean In Cnc Machining

How To Program Arcs And Linear Movement In G Code Manually 32 Steps Instructables

G Code Ripper

Q Tbn And9gcray0 Ocw2kdsvi96nyvncyeshi0qpnmfcmuswxzx Tbhgz3txv Usqp Cau

Repetier G Code Plugin For Inskscape Repetier Software

Cnc Programming Example In Inch Simple Cnc Lathe Program Helman Cnc

Editnc G Code Plotting And Editing Software Buykipware Com

Draftsight Professional G Code And Cnc Machines Draftsight Blog Draftsight Blog

G Code Syntax Visual Studio Marketplace

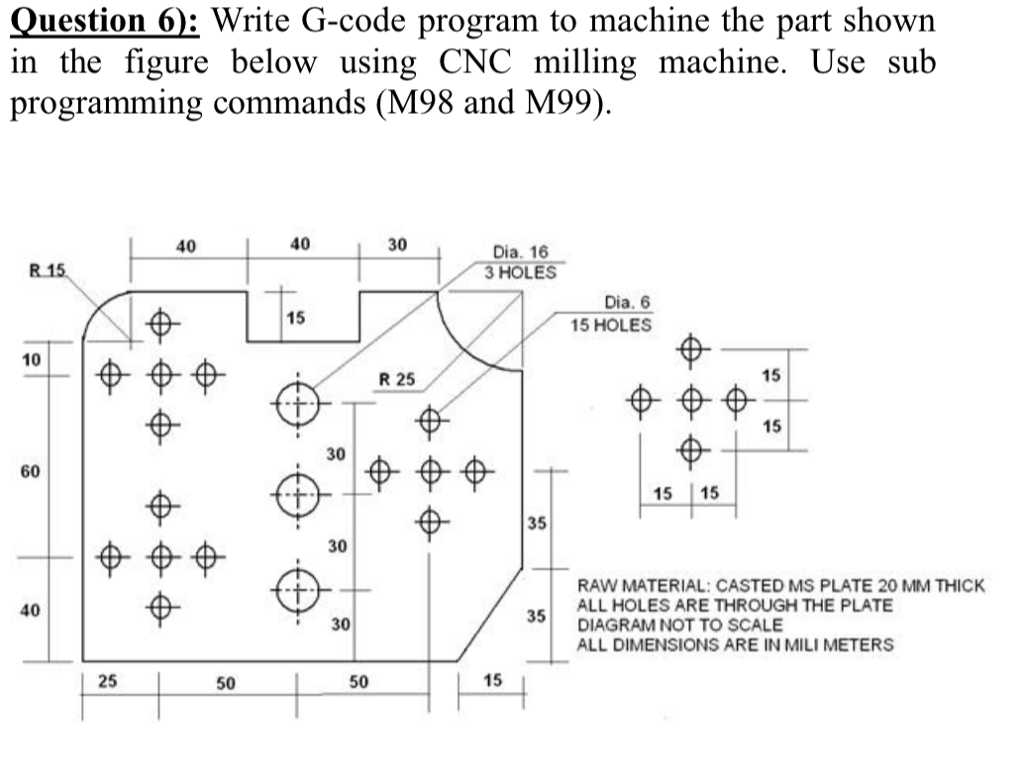

Question 6 Write G Code Program To Machine The P Chegg Com

Cnc G Code Programming Tutorial All3dp

Free Engraving Software Cnc Programming Software Includes Single Line Stick Type Engraving Font

G Code Sender Program Window And The Process Of Transferring Codes Into Download Scientific Diagram

Virtual Cnc Machining G Code Ppt Video Online Download

Cnc Programming With G Code Example Programs Commands

Mach 3 Cnc Program Peatix

Bobcad Cam Certifies Post Processors For Fagor Automation Controllers Bobcad Cam

G Code And Toolpath Simulation Freecad Cam Cnc

Cnc Programming

Simulator G Code Cnc Software For Mac Stlcool

Cnc Work Offsets G54 To G59 How To Use Them Cnc Training Centre

G Code Based Simulation Sprutcam 12 All Lang User Manual

Cnc Machining Blog Hurco Cnc Machine Tools Nc G Code Programming

G Code Lathe Programming Keyword Found Websites Listing Keyword Suggestions

Cnc Lathe Fanuc G Code Programming App List Haas For Android Apk Download

Best Cnc Forum Masso Top Cnc Forum Masso

G Code The Cnc Programming Language Fusion 360 Blog Cnc Programming Cnc Cnc Codes

G Code Program Rectangle Angle

Rapid Cnc G Code Generator Program Arcs Polygon Circle Rectangle

G Code Explained List Of Most Important G Code Commands

Cnc Programming With G Code Definitive Free Tutorial 19

Abviewer 14

Predator Cnc Editor Software Free Download Helman Cnc

Gcode Training Mode Ccam4 Software Legacy Cnc Woodworking

G Code Processing Example Engineering Books Pdf

Universal Gcode Sender 2 0 7 Free Download For Windows 10 8 And 7 Filecroco Com

Github Im Pro At Cncgcodecontroller Cnc Gcode Controller

Generation Of The G Code Program For Cnc Machining With A Download Scientific Diagram

Cnc M Codes

Guide To Cad For Cnc What Is G Code

What Is A G95 Gcode Feed Per Revolution Cnc Programming Cnc Com

Intuwiz G Code Generator Pocketing Cnc Software Coding Cnc Codes

Q Tbn And9gcqe Jrcvsy9lnx3gbm3k Coqt Xrrzfujlb3je1s8js Uw4pk Usqp Cau

5 Ways G Code Simulators Crush Cnc Errors Vids Free Sim

Make G Code Or Cnc Program For Your Design By Noorzikria

Cnc Milling Circular Interpolation G02 G03 G Code Program Example Helman Cnc

Predator Cnc Editor Software Backplot G Code Dnc File Compare

G Code Explained List Of Most Important G Code Commands

G Code For Cnc Programming Fusion 360 Blog

G Code For Cnc Programming Fusion 360 Blog

Mach3 How To Load A G Code Part Program Helman Cnc

10 Best G Code Editors Online Offline All3dp

G Code The Cnc Programming Language Fusion 360 Blog Cnc Programming Cnc Cnc Codes

G Code Explained List Of Most Important G Code Commands

Make Your Nc Program G Code For Your Cnc Milling Machine By Cnc Programer

G Code Wikipedia

10 Best G Code Editors Online Offline All3dp

Cam Editor

Dxf To G Code

Cnc Programming With G Code Definitive Free Tutorial 19

Solved Question 7 Write G Code Program To Machine The P Chegg Com

Pin On Artcam

G Code Generator For Milling An Arc Cnc G Code Generator Software

Editcnc Editcnc Has Many Powerful Features Designed Just For Cnc Programmers And Editors Cheap

Cad Cam G Code Cnc Programming Bobcad Cam

G Code Ripper Woodworking Software Cnc Software Learn Woodworking

Q Tbn And9gcqi1l6uhgss0fr7cbatutqju0yrqmoqfypkx55eh Egnuke Usqp Cau

Dxf2gcode Convert 2d Dxf Pdf Drawings To Cnc Machine G Code Windows Usb Ebay

Fab Lab Ncc Cnc G Code Programming