5s Workshop

5s Or 6s What S The Safe Choice

5s Workplace Organization And Standardization Supply Velocity

Factory Makeover 5s In 1 Day By Improvo Continuous Improvement Youtube

What Is 5s 5s System Is Explained Including Tips On Getting A 5s Program Started

Upskilling Application Of 5s As Foundations Of Lean Business

Bott Uk Did You Know Our Workplace Storage Systems Can Help With 5s Lean Processes Take A Look At How We Helped Still Materials Handling When They Moved Into Their

The 5S Program is a component of Lean Manufacturing, and is intended to help produce higher efficiency and quality and to reduce waste.

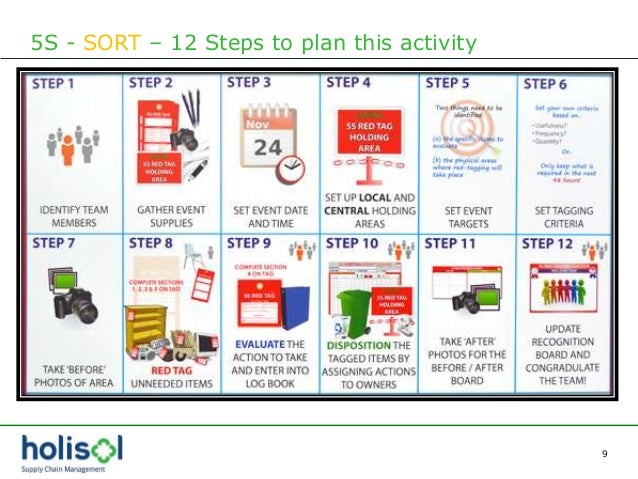

5s workshop. 5S is the perfect tool to identify the first improvement projects in your company to eliminate waste Although sometimes viewed as a housekeeping technique, it is actually an innovative management system that helps people think lean, paving the way for the adoption of Lean principles in the organization. The 5S training includes stepbystep guidelines for achieving the 5S’s as well as a roadmap to implement the 5S’s throughout the entire organization Many examples of 5S success stories are included throughout the training With this 5S training, participants will be able to go through each of the 5S’s on their own or as part of a team. 5S is a workplace organization method that uses a list of five Japanese words seiri (整理), seiton (整頓), seisō (清掃), seiketsu (清潔), and shitsuke (躾) These have been translated as "Sort", "Set In order", "Shine", "Standardize" and "Sustain".

Defining 5S 5S is a formulaic method you can use to straighten and organize a work area Using 5S reduces waste (a fundamental goal in lean manufacturing), improves safety (see our article on Lean 6S Safety), and otherwise improves your production process and work environment 5S is called 5S because their are 5 steps and each step begins with the letter “S” (and/or the sound “s”). Sustain – Maintain and review standards. Because 5S is just one of several elements that make up the Lean Methodology, it is usually done as part of the Lean Belt Certification Training Our focus is to educate our customers and deliver on their unique needs, so if the 5S training is the only interest of your organization, our program will be customized to do exactly that.

Shine – Clean the work area so it is neat and tidy;. 6 5S workshop on pilot project on a working area of your choice 7 Action plan with remaining tasks to be performed on the Pilot Project Validation The acquired knowledge is evaluated and validated at the end of the training through a quiz This test is selfcorrected with the participants and the trainer. What are the Five S's (5S) of Lean Quality Glossary Definition Five S’s (5S) 5S is defined as a methodology that results in a workplace that is clean, uncluttered, safe, and well organized to help reduce waste and optimize productivity.

The 5S Workshop can be taught in either the office or shop floor environment In keeping with Pinnacle's Lean QMS ® approach, the 5S program is sustained within the context and culture of your quality management system (QMS) or business operating system (BOS). Standardize – Set standards for a consistently organized workplace;. A 5S can be applied to any work environment It could be a supply/store in a hospital, a repair truck for a telecom company, a CSR desk/work area in a call center, the baggage claim area of an airline or a laptop computer.

5S Workshop Overview 5S, an acronym for “sort, setinorder, shine, standardize, sustain”, is a simple yet powerful method for transforming the physical workspace 5S is a simple but highly effective set of techniques that remove waste from your work environment through better workplace organization, visual communication and general. It is also about maximizing efficiency and profit 5S is a framework that emphasizes the use of a specific mindset and tools to create efficiency and value. Build organizational commitment so that 5S becomes one of your organizational values so that everyone develops 5S as a habit Integrate the 5S methodology into the performance management system Step 3 The Action Plan You can start implementing 5S by providing training to your staff to understand the system.

A set of slides from a workshop to launch 5S in an office Slideshare uses cookies to improve functionality and performance, and to provide you with relevant advertising If you continue browsing the site, you agree to the use of cookies on this website. 5S Defined 5S is one of the cornerstone practices of lean manufacturingIt is a systematic framework for workspace organization based on the idea that a better work environment results in better operations, which in turn leads to better products. 5S is a fivestep organization technique to create and maintain an intuitive workspace The five steps are Sort – Remove unnecessary items from the workplace;.

5S Workshop Overview 5S, an acronym for “sort, setinorder, shine, standardize, sustain”, is a simple yet powerful method for transforming the physical workspace 5S is a simple but highly effective set of techniques that remove waste from your work environment through better workplace organization, visual communication and general. Learn more about 5S workplace organization For more information, visit http//wwwimecorg/indexcfm. The 5S methodology is a way to cut waste, boost efficiency, and just generally improve the way everything is done within a facility 5S gets its name from the five Japanese words, Seiri, Seiton, Seiso, Seiketsu, and Shitsuke, which translate in English to Sort, Set in Order, Shine, Standardize, and Sustain.

5S began as part of the Toyota Production System (TPS), the manufacturing method begun by leaders at the Toyota Motor Company in the early and midth century This system, often referred to as Lean manufacturing in the West, aims to increase the value of products or services for customers. Management support – Without visible commitment from managers, the 5S processes won’t stick around Supervisors and managers should be involved in auditing the 5S work processes, and getting feedback from workers They also need to provide the tools, training, and time for workers to get their jobs done right. 5S is a systematic form of visual management utilizing everything from floor tape to operations manuals It is not just about cleanliness or organization;.

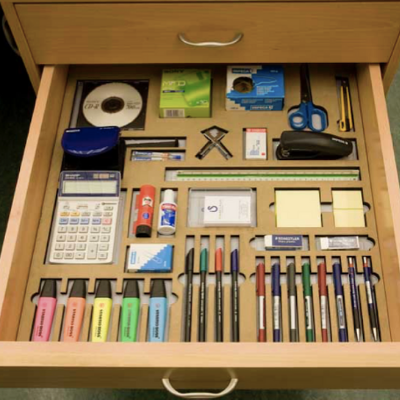

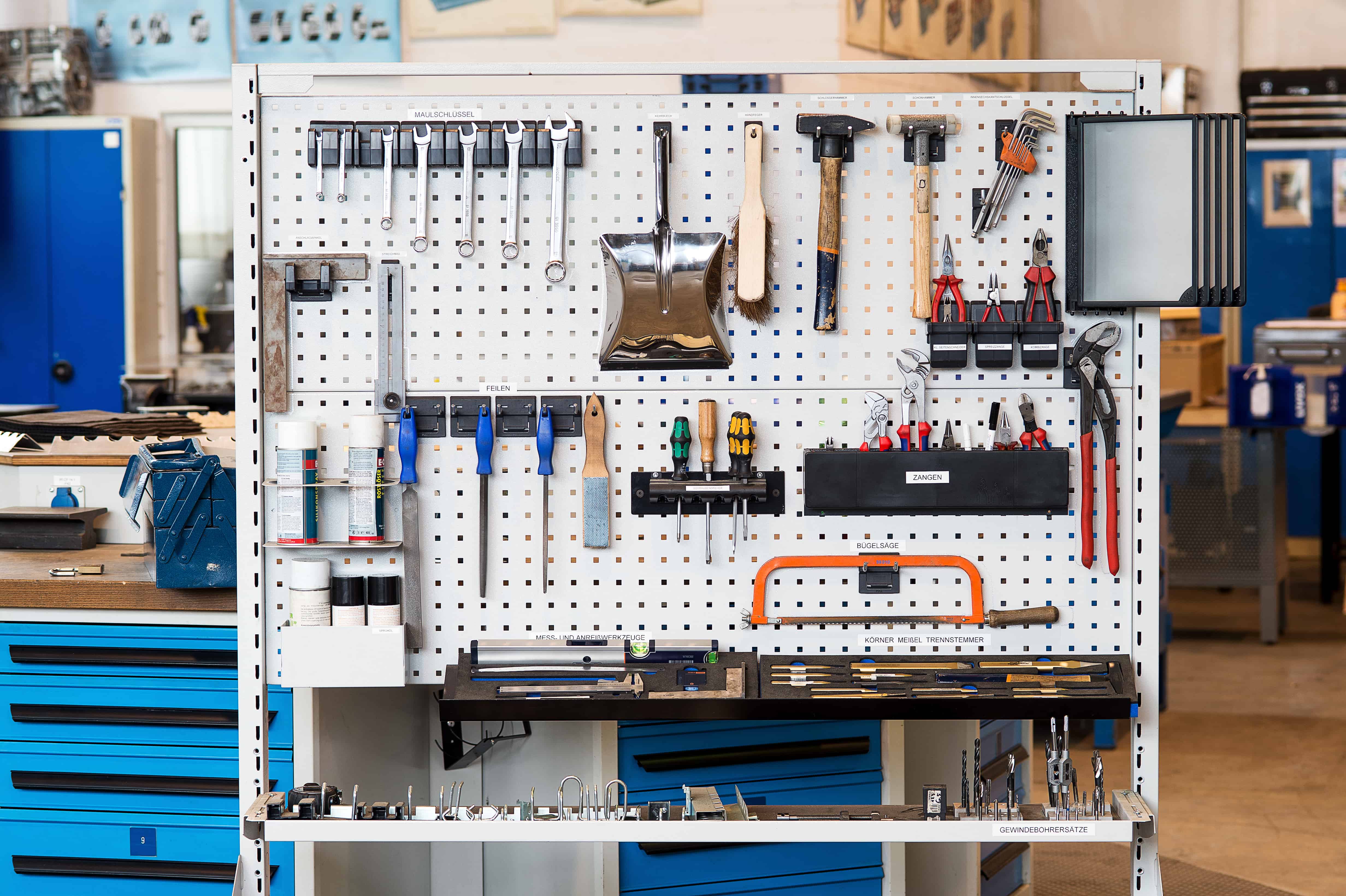

5S is amongst the first and fundamental steps implemented by an enterprise towards the path of implementing Total Quality Management and continuous improvement at the operation level 5S is a process designed to organize the workplace, keep it clean,. Because 5S is just one of several elements that make up the Lean Methodology, it is usually done as part of the Lean Belt Certification Training Our focus is to educate our customers and deliver on their unique needs, so if the 5S training is the only interest of your organization, our program will be customized to do exactly that. That’s why the second practice in 5S methodology is “set in order,” although some people also call it “straighten” Set in order gives a home to every item so it is never lost and the workplce remains efficient Source 5S Training Tool foam, hooks, labels, signs, floor tape, holsters, and more are all used to give every item a home.

5S Defined 5S is one of the cornerstone practices of lean manufacturingIt is a systematic framework for workspace organization based on the idea that a better work environment results in better operations, which in turn leads to better products. While some Lean Six Sigma (LSS) practitioners consider 5S a tool, it is more than that 5S, abbreviated from the Japanese words seiri, seito, seiso, seiketsu, shitsuke, is not just a methodology, it is a culture that has to be built in to any organization which aims for spontaneous and continuous improvement of working environment and working conditions. This workshop consists of two modules Module 1 covers the origins of 5S and its roots in Toyota This presentation shows through various media formats, such as photos, videos, examples and interviews how 5S is applied in several of the Toyota facilities around the world.

A 5S basics, interesting, fun 1day Introduce to 5S Workplace Management for Shopfloor People, Supervision and Managers You get 5S training workshop material containing a 5S PPT PowerPoint Presentation of foundational 5S knowledge, and a 5S game people play that puts them into a 5S Simulation where they continually improve and learn the value of 5S. Phil Mickelson will use his coach on his bag this week as his brother is ready to become a new dad To say the Diamond Resorts Tournament of Champions is unlike any other event on the LPGA Tour is. 5S is amongst the first and fundamental steps implemented by an enterprise towards the path of implementing Total Quality Management and continuous improvement at the operation level 5S is a process designed to organize the workplace, keep it clean,.

Set In Order – Arrange items so they are easily accessible;. Sustain 5S is a habit and is continually improved 5S is a simple concept with powerful results You will get additional information on 5S so that you will be well equipped Our experience is that the more we do 5S the better the work environment becomes cleaner, safer, more organized, the work is easier, less confusion and less stress. The workshop is designed to provide theoretical knowledge about 5S along with the handson experience when done on the shop floor In the two days of the workshop, a model area will be chosen and steps 1, 2, and 3 of 5S will be demonstrated in the designated area.

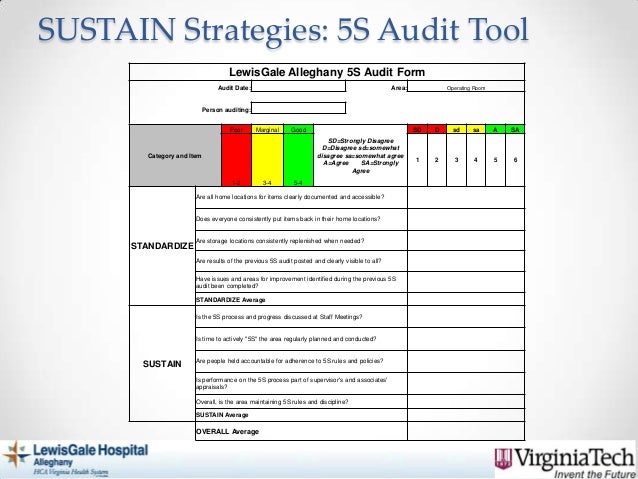

5S Audit Checklist This 5S Audit Checklist is a tool used by area supervisors or plant managers to perform monthly or quarterly audits As a 5S audit form, this checklist can help ensure that 5S principles and set standards are being followed and implemented by workers. Shine – Clean the work area so it is neat and tidy;. Standardize – Set standards for a consistently organized workplace;.

Sustain – Maintain and review standards. Phil Mickelson will use his coach on his bag this week as his brother is ready to become a new dad To say the Diamond Resorts Tournament of Champions is unlike any other event on the LPGA Tour is. Defining 5S 5S is a formulaic method you can use to straighten and organize a work area Using 5S reduces waste (a fundamental goal in lean manufacturing), improves safety (see our article on Lean 6S Safety), and otherwise improves your production process and work environment 5S is called 5S because their are 5 steps and each step begins with the letter “S” (and/or the sound “s”).

5S is a fivestep organization technique to create and maintain an intuitive workspace The five steps are Sort – Remove unnecessary items from the workplace;. The PD Training 5S Introduction course is a great place to start on your continuous improvement initiative, because it promotes an action oriented approach to change and allows everyone in the organisation to get involved and provide input on improving their workplace. While some Lean Six Sigma (LSS) practitioners consider 5S a tool, it is more than that 5S, abbreviated from the Japanese words seiri, seito, seiso, seiketsu, shitsuke, is not just a methodology, it is a culture that has to be built in to any organization which aims for spontaneous and continuous improvement of working environment and working conditions.

Set In Order – Arrange items so they are easily accessible;. Best Lean Video Collection https//wwwleanvlogcomLean Video Course in PDFs https//gumco/yVgzTelegram Channel https//tme/leanvlog5S Methodology with. Phase 0 5S Basic Training When a management team of a health facility considers installing 5S activities, top management (eg District Health Officer) and a focal person for QA in the facility shall attend “5S Basic Training” designated by Zonal Health Office or DHMT (for Health Centres) supported by MOH.

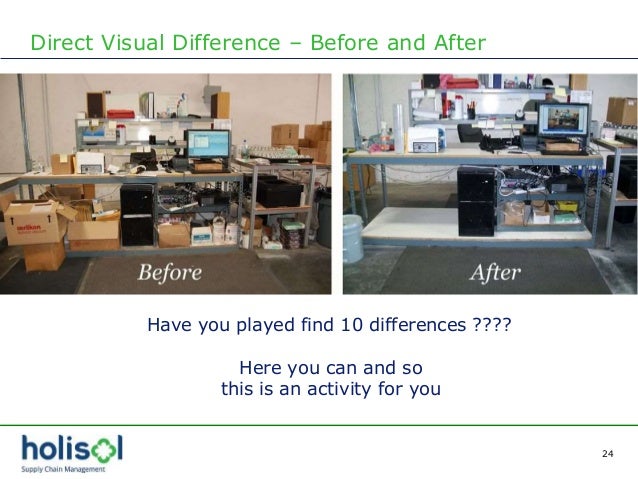

Make everyone happy 1) Form a comfortable workshop 2) Be aware that 5S benefits the worker, and that is its purpose 3) Involve all members Do not rush when performing 5S Take the initiative, do not wait for the next person to start Provide learning opportunities 1) Let everyone participate in problem identification and brainstorming. Visual Workplace and 5S go hand in hand One of the main purposes of 5S is to prepare the work environment to hold visual information From that perspective, 5S is a method, while creating a visual workplace is the goal “A visual workplace is a work environment that is selfordering, selfexplaining,. Make everyone happy 1) Form a comfortable workshop 2) Be aware that 5S benefits the worker, and that is its purpose 3) Involve all members Do not rush when performing 5S Take the initiative, do not wait for the next person to start Provide learning opportunities 1) Let everyone participate in problem identification and brainstorming.

5S is a Lean technique that involves activities designed to create and maintain a disciplined workplace It helps create a better working environment and can be implemented to eliminate waste and improve the flow of work 5S audits are often used to evaluate the performance of 5S implementation in any workplace This 5S audit checklist will help ensuring that 5S standards and workplace. Simply stated, a 5S is the structured method to organize the work place As evidenced by its name, there are 5 steps in a 5S. 5S The application of 5S in welding workshop requires a storage device in the form of a rack equipment by naming information or information items saved in it With the implementation of 5s and the procurement of storage rack able to minimize the search activity of 1875% and the use of space 11% 1 Introduction.

Receive a FREE Helpful 5S Training Document by submitting your email below Email Sign Up Sign Up More 5s Quick Contacts The 5S Store 16 Lomar Park, Unit 8 Pepperell MA Tel Fax. 5S is a system to reduce waste and optimize productivity through maintaining an orderly workplace and using visual cues to achieve more consistent operational results Implementation of this method "cleans up" and organizes the workplace basically in its existing configuration, and it is typically the first lean method which organizations. 5S Training DVDs Whether you need 5S training in Spanish or 5S training for healthcare, we carry the top 5S instructional DVDs Lean Manufacturing Guide Learn about all the benefits that Lean manufacturing has to offer your facility.

5S is defined as a methodology that results in a workplace that is clean, uncluttered, safe, and well organized to help reduce waste and optimize productivity It's designed to help build a quality work environment, both physically and mentally The 5S philosophy applies in any work area suited for visual control and lean production. The PD Training 5S Introduction course is a great place to start on your continuous improvement initiative, because it promotes an action oriented approach to change and allows everyone in the organisation to get involved and provide input on improving their workplace. The offsite 5S Training option is generally most popular with organizations having five or less associates that require a thorough working knowledge of 5S Our training centers provide the participants an environment free from the distractions and interruptions of daily work activities The participants are allowed to concentrate on the.

Visual Workplace and 5S go hand in hand One of the main purposes of 5S is to prepare the work environment to hold visual information From that perspective, 5S is a method, while creating a visual workplace is the goal “A visual workplace is a work environment that is selfordering, selfexplaining,. 5S is a system to reduce waste and optimize productivity through maintaining an orderly workplace and using visual cues to achieve more consistent operational results Implementation of this method "cleans up" and organizes the workplace basically in its existing configuration, and it is typically the first lean method which organizations. Phil Mickelson will use his coach on his bag this week as his brother is ready to become a new dad To say the Diamond Resorts Tournament of Champions is unlike any other event on the LPGA Tour is.

Introduction to 5S Training Workshop Welcome to the oneday 5S training course by Lifetime Reliability Solutions Introduction to 5S 5S is workplace management where the work area and workplace are organised and ritualised to minimise the loss of time and the use of movement. • Refresher training • Periodical evaluation of 5S activities with proper advices for continuation and further improvements • Appreciation, recognition and awarding on good 5S activities • Reminder using 5S corner, new letters, good practice sheet etc. Learn more about 5S workplace organization For more information, visit http//wwwimecorg/indexcfm.

23 5S checklists, schedules and routines are defined and being used 24 Everyone knows his responsibilities, when and how 25 Regular audits are carried out using checklists and measures S5 – Sustain SHITSUKE 26 5S seems to be the way of life rather than just a routine 27 Success stories are being displayed (ie before and after. Workshop Description 5S Visual Workplace Organization describes a systematic approach of how to organize a workspace or area for efficiency and effectiveness by identifying and storing the items used, maintaining the area and items, and sustaining the new order. The PD Training 5S Introduction course is a great place to start on your continuous improvement initiative, because it promotes an action oriented approach to change and allows everyone in the organisation to get involved and provide input on improving their workplace.

5S is a fundamental first step for any manufacturing company, wishing to call itself world class We will understand this with step by step approach of its deployment The 5S program mandates that resources be provided at the required location and be available to support work activities. 5S Course ID 5SASQ Format Webbased Gain an understanding in the purpose and benefits behind the 5S methodology Learn how to explain the 5S standard and how to use it to organize your workplace to create a clean, safe, orderly, highperformance work environment that promotes efficiency.

3 Top Ways A 5s Event Brought Order To Our Metal Fabrication Shop Wiley Metal

Keys And Tips To Implement The 5s Methodology

Introduction To 5s Youtube

Pdf Implementation Of 5s Methodology In A Metalworking Company

5s Methodology Wikipedia

Applying 5s Series Part I Introduction Reliable And Efficient

5s Implementation Workshop

Lean Management 5s Workshop 19 Tzu Chi Singapore

Factory Makeover 5s In 1 Day By Improvo Continuous Improvement Youtube

How Your Health Club Can Profit From The 5s Method Ihrsa

Introduction To The 5s Concept Uttana Com

Method 5s Explanations And Example Of The 5s Lean Sesa Systems

Workshop Tool And Equipment Organisation The 5s Superstore

5s Methodology

Usd 7 81 Factory Workshop 5s Slogan Safety Production Poster Wall Chart Company On Site Management Propaganda Column Quality Display Board Wall Paste Wholesale From China Online Shopping Buy Asian Products Online

Keys And Tips To Implement The 5s Methodology

Classic Kaizen Workshop Package 5s Supplies

Implementing 5s 1 6s To Make Workplace Hazards Easier To See

5s Implementation Workshop

Sunrise Shine 5s Optima

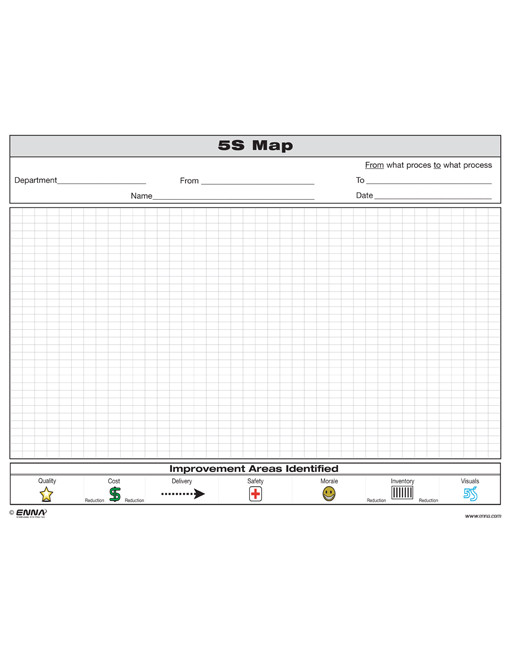

5s Map Form Used To Map Activities In A Workshop Enna Com

How To Apply 5s Method To Improve Shop Efficiency 18 12 06 Snips

Is 5s Really Just A Waste Of Time Txm Lean Solutions

Visual Management 5s In Lean T P S Workshop Slides Visual Management Management Visual

5s Examples In Action The Good The Bad Graphic Products

Training 5s Workplace Management Training Consultants From Ahmedabad

Storage Cabinet For Perfect 5s Storage Sesa Systems

Japanese 5s Workshop With Dost Ncr For Smes Freelancers By Beam Team March 6 At Malingap Central Food Hall Beamstart Events

Lean 5s

5s Training Course Online 5s Training Video

5s Lean Manufacturing And Six Sigma Definitions

5s Workshop Storage Cabinet 5s Visual Cabinet Sesa Systems

Visual Management 5s In Lean T P S Workshop Slides

Lean 5s Visual Workplace Organization Workshop Request Synergy Resources

5s Implementation Workshop

Organizing Electronic Files 5s For Time Savings Workshop Business Performance Improvement Bpi

5s Standardized Workshop Management Mpmc Powertech Corp Facebook

How To Implement 5s In The Workplace Kanban Zone

5s Certification

Lean In To 5s 19 11 15 Quality Magazine

5s Maintenance Its International Thermal Systems

5s Kaizen Valueflo Consulting

5s In Wood Storage Area

Tps Lean Manufacturing Glossary 5s Visual Workplace Lean Manufacturing Visual Management Lean Sigma

5s In Hospitals Workshop

P1wohopqsgjm6m

How The Integration Of 5s Improved Production Organization At Waterax Flexpipe

5s Workshop Industrial Solutions

Ai Powered 5s Board

5s Kaizen Buscar Con Google Visual Management Kaizen Lean Manufacturing

The 5s System Lean Manufacturing Methodology

5s Program A Quality Tool Or Good Housekeeping

5s S Of The 5s Methodology Uttana Com

Tech Employee Lean Training 5s Workshop Michigan Tech Events Calendar

Ningbo Jieda Mold Workshop S Improvement In 5s Jieda Molding Machine

Three Keys To Sustainable 5s

3 Ways Your Organization Can Undertake A 5s Audit Izimage

Lambtoncollege Before The Holidays Our School Of Technology Participated In A 5s Workshop Considered A Foundational Lean Concept The 5s Sort Shine Set In Order Standardize Sustain Create A Clean

5s Visual Workplace Test Your Knowledge Trivia Quiz Proprofs Quiz

5s Work Flow Management In Enterprise Excellence Deployment Bpminstitute Org

5 S Workplace Organization

5s Lean Manufacturing And Six Sigma Definitions

5s Training By 25 Years Experienced Industry Experts In Delhi Ghaziabad Noida Sahibabad Gurgaon Lean For U

5s For Work Teams Seminar And Mini Kaizen Strategos

5s Visual Workplace Problems Identified Problems Solved Association For Manufacturing Excellence

Workshop Excellence How We Apply Tools Like 5s Youtube

Shadow Board Design In Uk By Lean 5s Products Uk Issuu

Zen Cart The Art Of E Commerce Lean Manufacturing Workstation Workshop Organization

Before And After Professional Garage Organization Using The 5s Japanese Organization Method Converted Garage Garage Organization Garage Renovation

5s Evaluation Board Of Production Workshop Page 1 Line 17qq Com

Why You Should Launch A 5s Program At Your Workplace Formaspace

Visual Management 5s In Lean T P S Workshop Slides Visual Management Management Visual

Success With The 5s Method Hoffmann Group

5s Online Workshop 1 Day For Workplace Organization Biztorming Training

5s Workplace Organization Ut Center For Industrial Services

5s Software Creative Safety Supply

Workshop On 5s

Opep 5s In Manufacturing

Plant Engineering Safety Is It The Sixth S In A 5s System

19 5s Ideas Lean Manufacturing Visual Management Kaizen

Projects Jamec Equipements Industriels Et Postes De Travail 5s

Storage Cabinet For Perfect 5s Storage Sesa Systems

Weifield S Success Through Lean 5s Weifieldweekly Com

3 Tips To Cross Functional 5s Projects Leancor A Transplace Company Leancor A Transplace Company

What Is The 5s Lean Manufacturing

Seiso Means Shine In 5s Lean Methodology Click Here

How The Integration Of 5s Improved Production Organization At Waterax Flexpipe

Zigma Consulting

5s Basics Workplace Organization New Hampshire Manufacturing Extension Partnership Nh Mep

Introduction To 5s Online Course Business Performance Improvement Bpi

5s On Technical Workshop Berezhlivoe Proizvodstvo Online Presentation