Atex Zone 0 1 2

Identifying Zone 0 Zone 1 And Zone 2 Hazardous Areas Raytec Led Blog

Nightsearcher Ex Ht2 Atex Led Head Torch

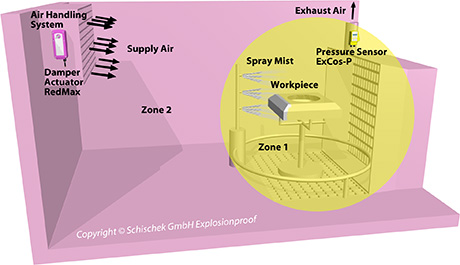

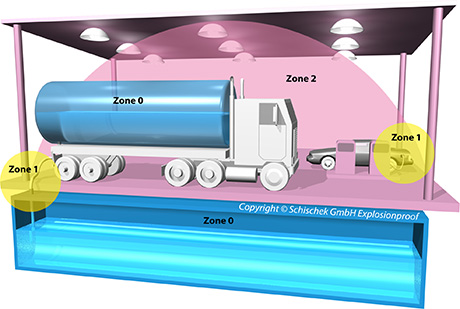

Explosion Proof Classification Divisions Zones Of A Spray Room And A Filling Station Explosion Groups Temperature Classes Fire Protection

Explosive Atmospheres Atex Sertec S R L

Atex Catalog Peli

Atex Iecex Markings Explained

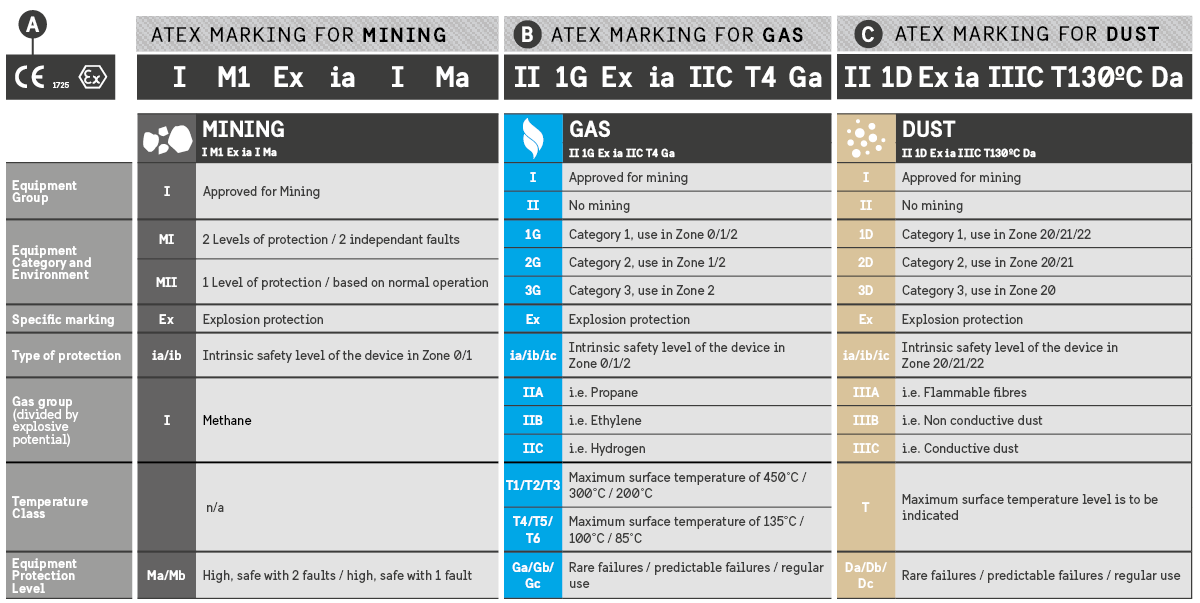

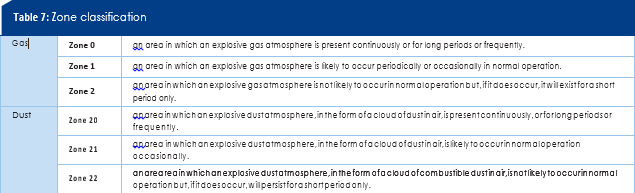

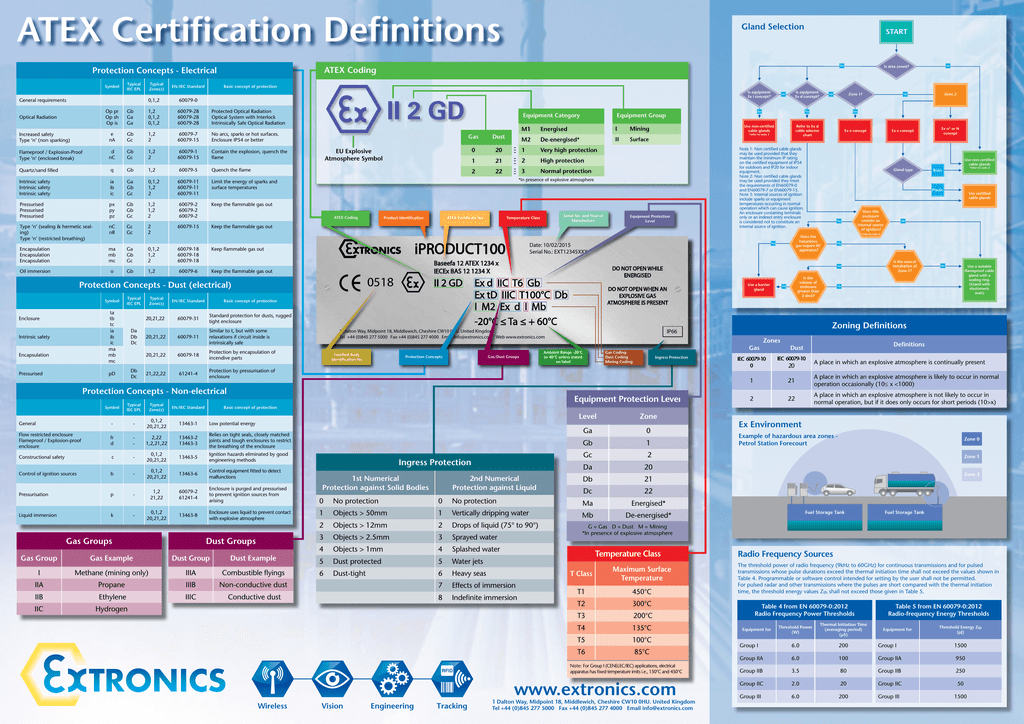

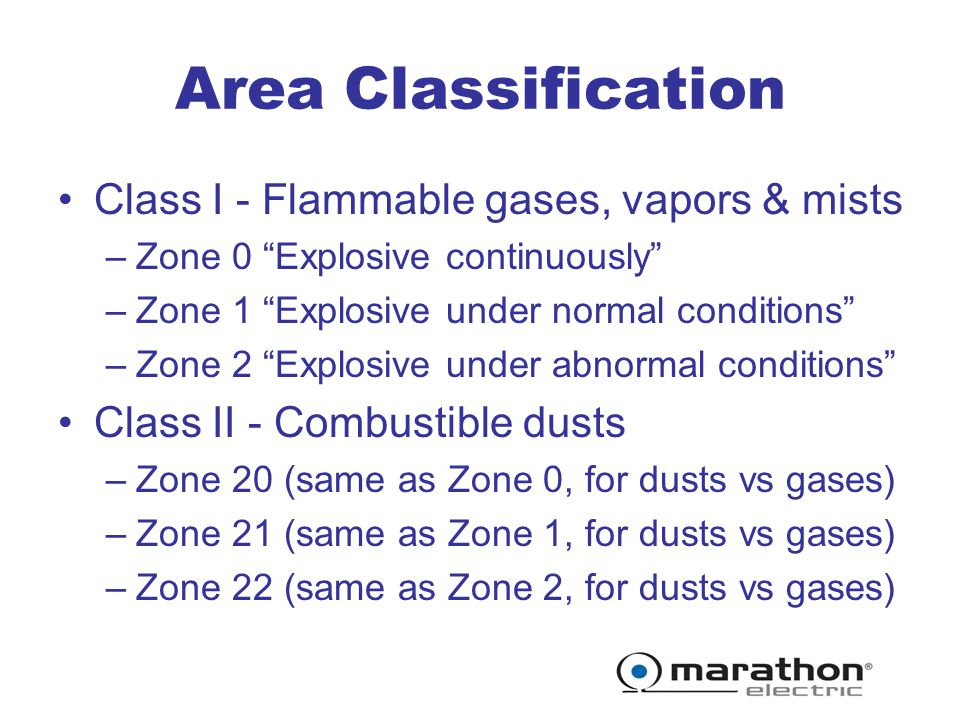

Definitions ATEX Category Equipment Protection Levels Typical Zone Suitability 0A place in which an explosive atmosphere is continually present 1 G GaEquip suitable for Zones 0,1,2 1 D DaEquip suitable for Zones ,21,22.

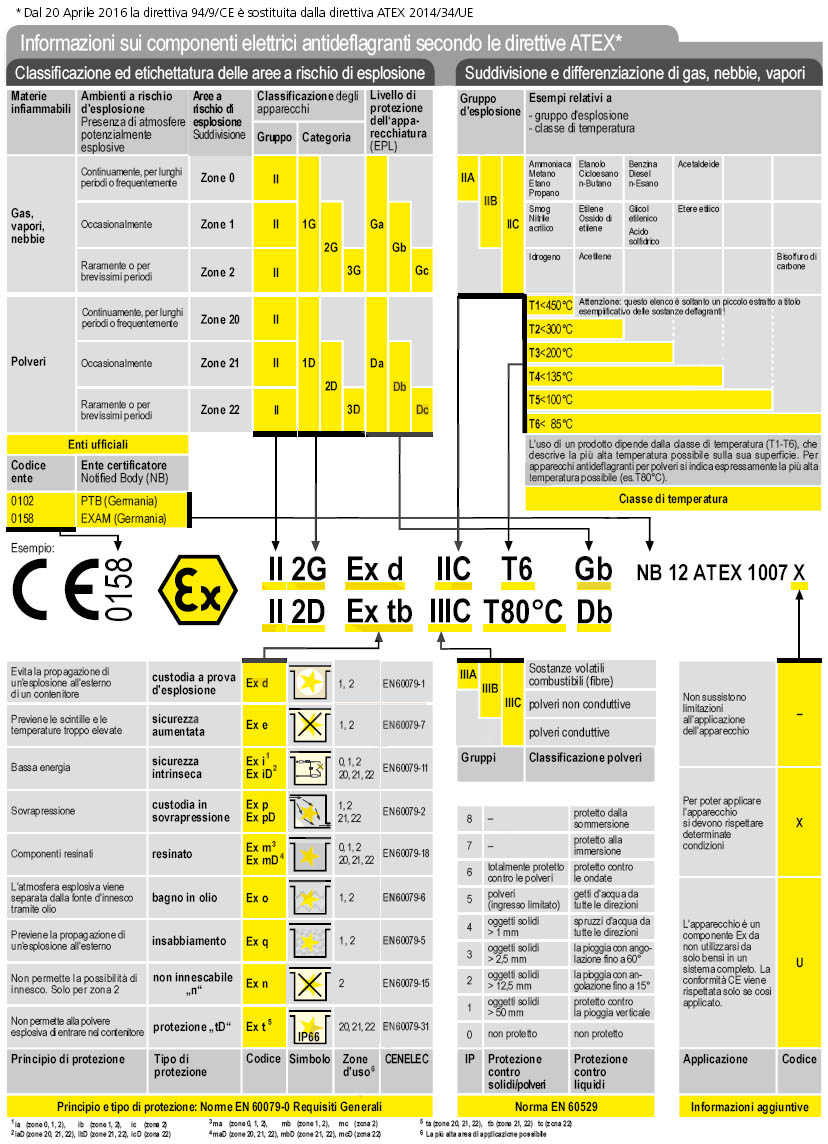

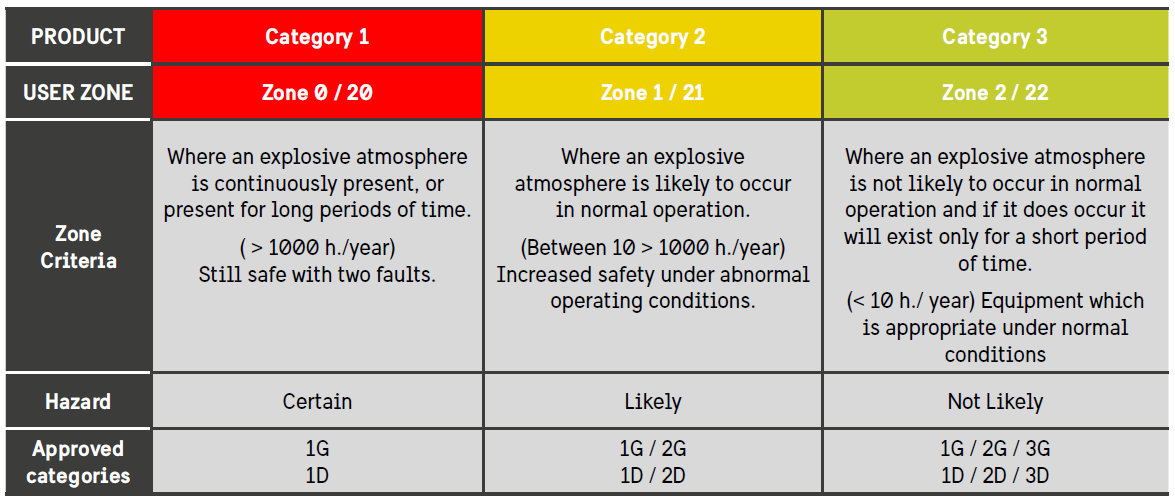

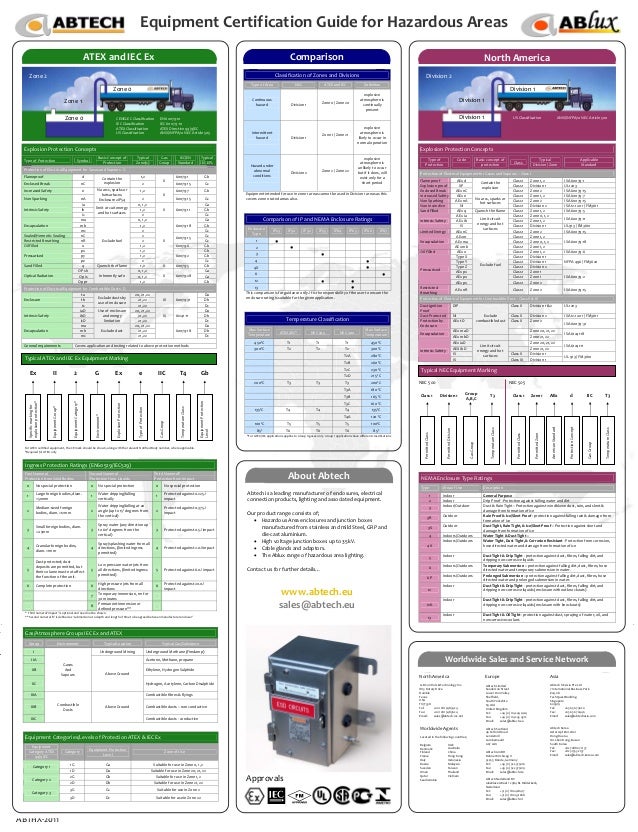

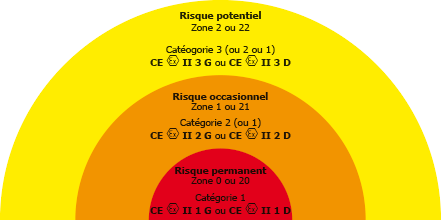

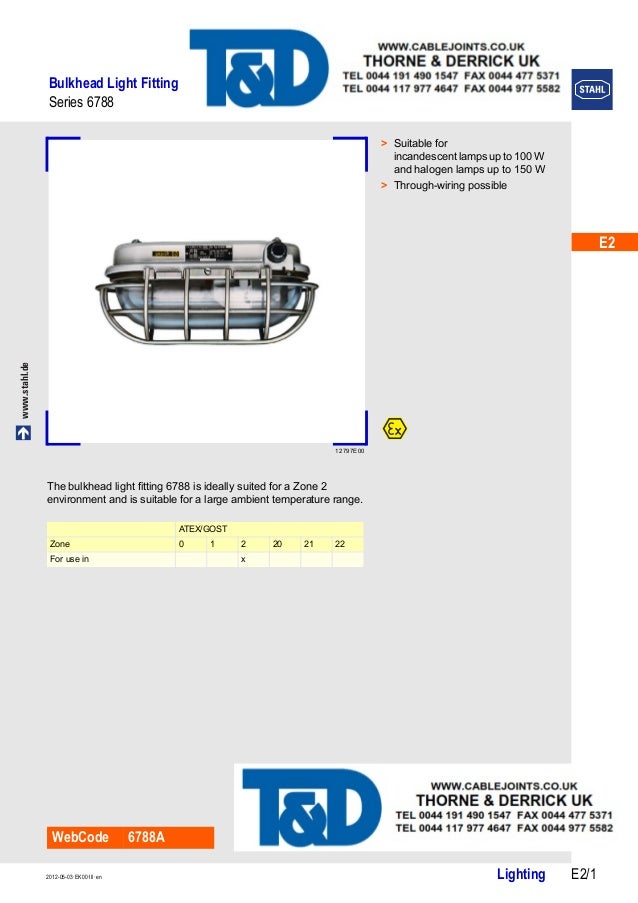

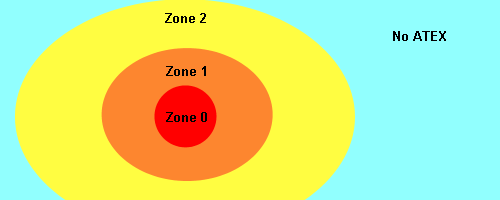

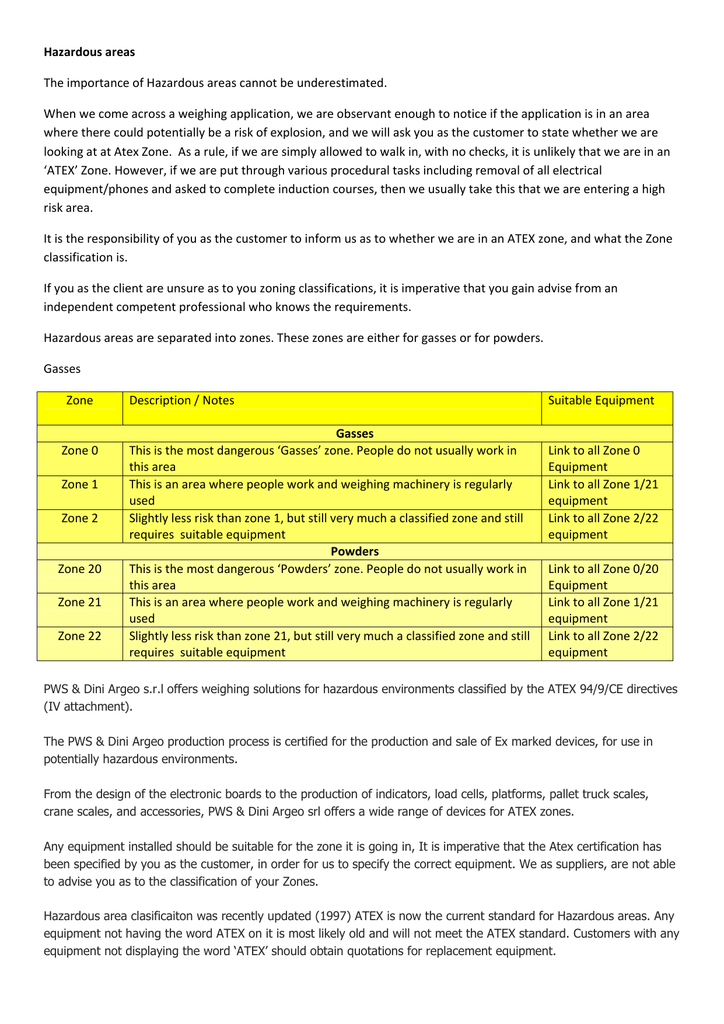

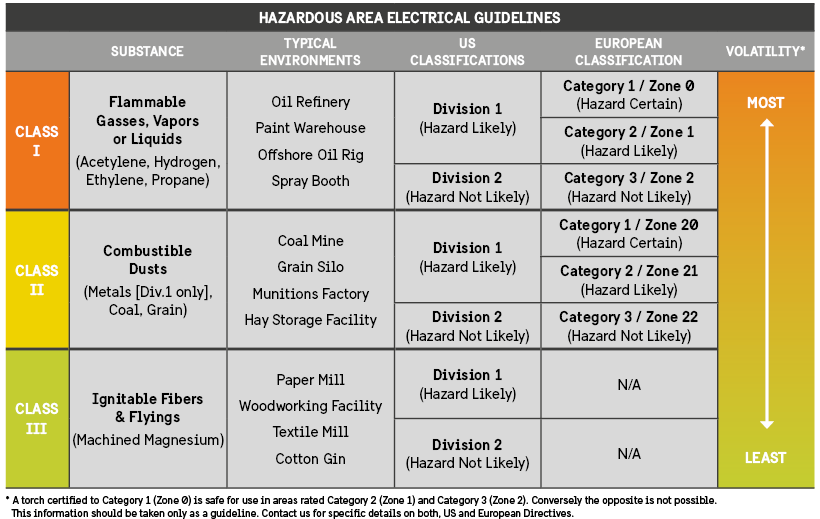

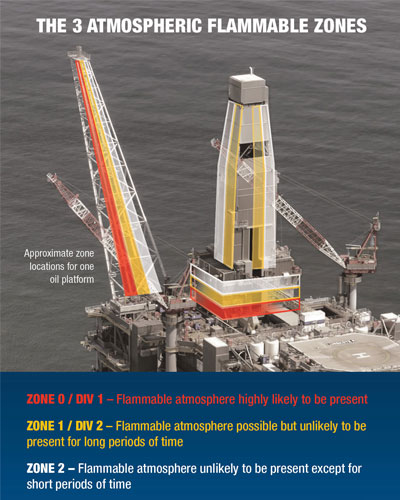

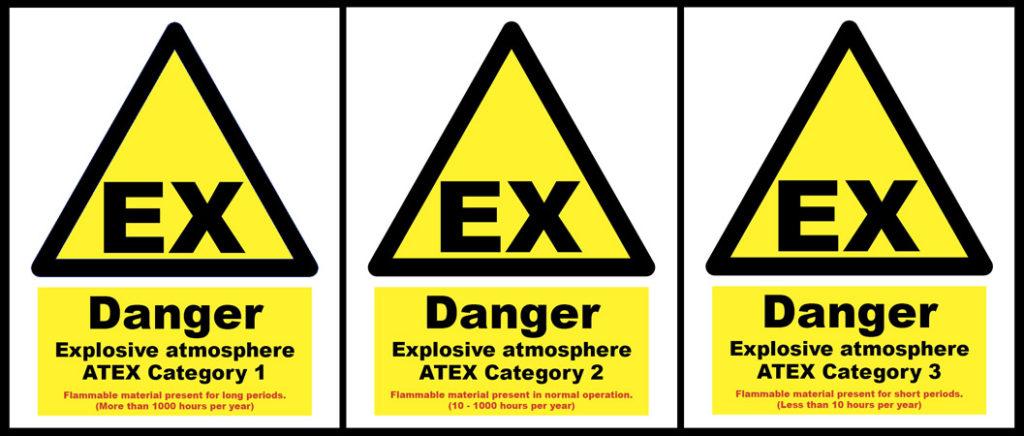

Atex zone 0 1 2. The three categories of equipment match the three different levels of risk identified by ATEX More details on ATEX Zones can be found on our Zone 0 and Zone pages In these ATEX Zones This Category of equipment must be used Zone 0 and Category 1 Zone 1 and 21 Category 2 or 1 Zone 2 and 22. Zone 0 zone 1 zone 2 zone zone 21 zone 22 mines mines Equipment protection level Equipment group Category group II II II II II II I I 1G 2G 1G 3G 2G 1G 1D 2D 1D 3D 2D 1D M1 M2 M1 Ga Gb Ga Gc Gb Ga Da Db Da Dc Db Da Ma Mb Ma Apparatus may be used in The measurement function according to ATEX (DIN EN ) guarantees highest. Zone 2 Gases & Vapours Category 1 Category 2 Category 3 Note Category 2 certification also covers the lower category 3 Table 2 ATEX Category There are three area category types, with Category 1 requiring a very high level of protection and defined as an area having a permanent or prolonged risk of explosions (Zone 0), Category 2 which.

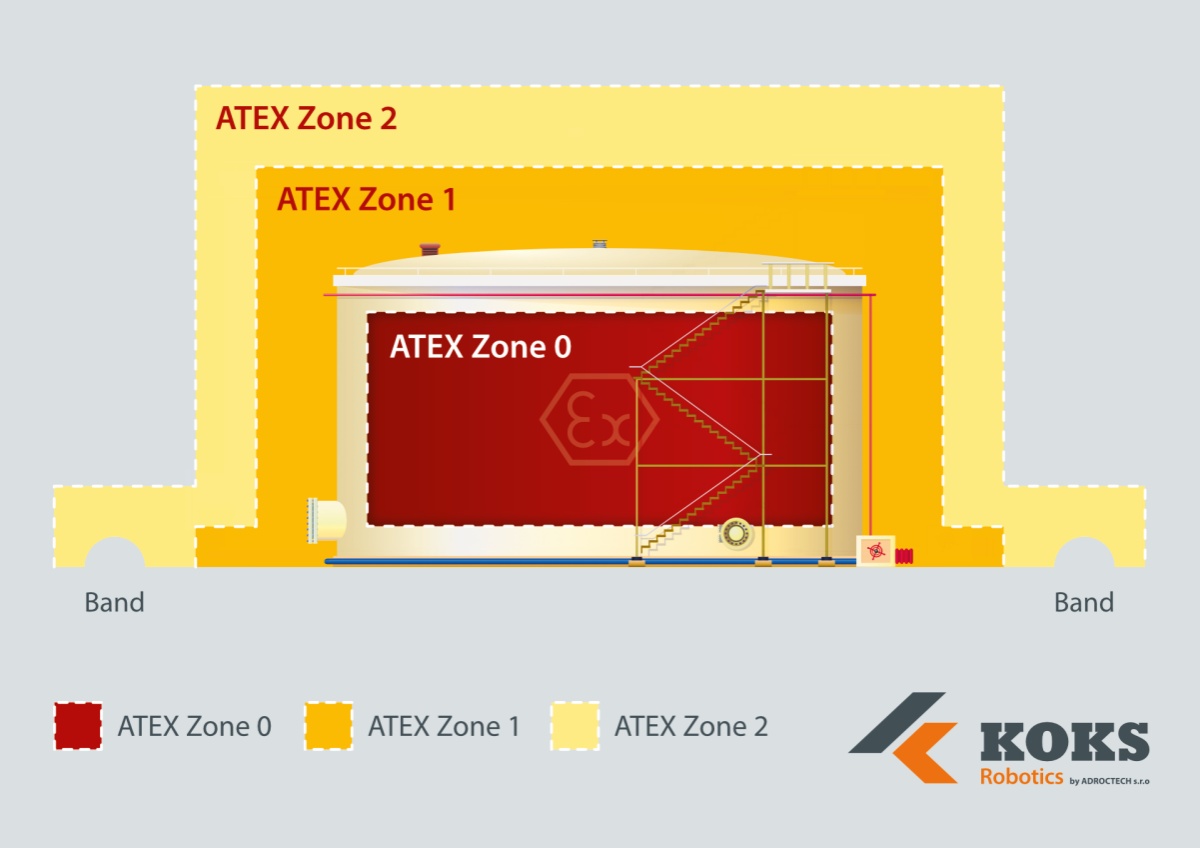

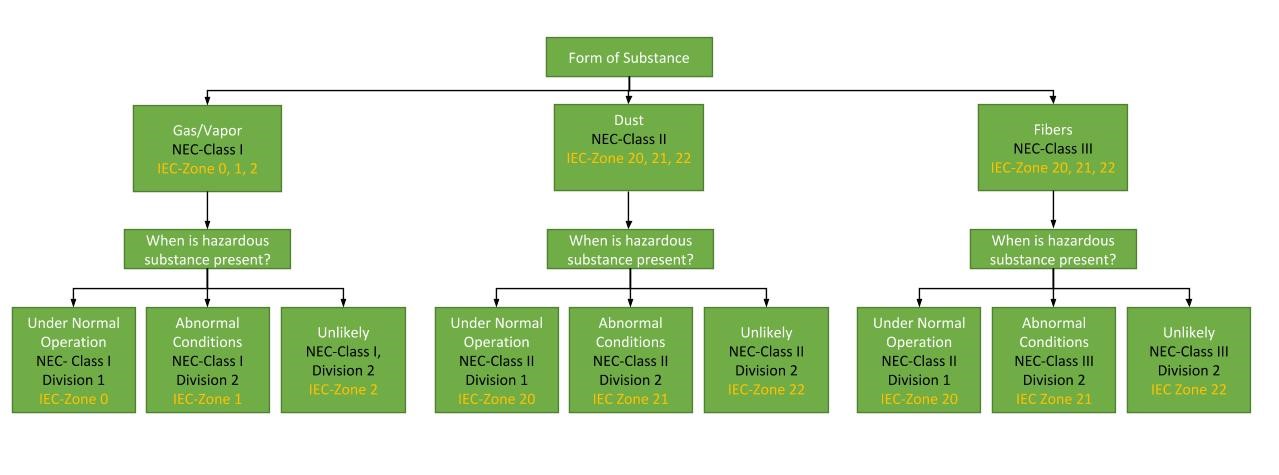

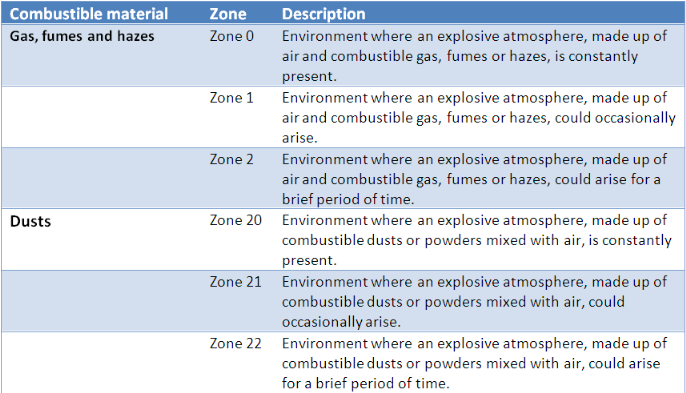

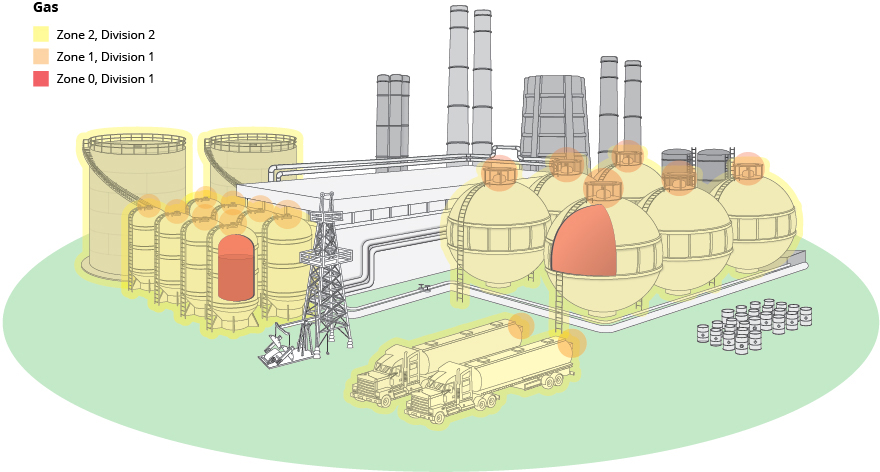

1 – Can be used in zones 0 or 2 – Can be used in zones 1 or 21 3 – can be used in zones 2 or 22 M1 – mining (in case of firedamp, continuation of operation is possible) M2 – mining (must be switched off in case of firedamp This table shows the type of zones European & IEC Classification. Areas within these two kinds of explosive atmospheres are each divided into three subzones Although the zones characteristics are identical for both gas and dust, their numbering is different Zone 0, 1 and 2 refer to gas and Zone , 21 and 22 refer to dust Permanent presence of explosive gasses or combustive dust. We have experienced situations where ATEX zone 0 has been reduced back to ATEX zone 2 – just with the help of ventilation In general, we see that 80% of all ATEX zones are set as a zone 2 or 22 In practice ATEX zone reduction The extent of the impact of explosionreducing measures is shown in the example below.

0,1,2 1,2 2 IEC The ignition is contained, quenched and does not ignite the surrounding atmosphere Pressurised Zone I to NonHazardous Zone I to Zone II Zone II to NonHazardous px py pz Gb Gb Gc 1,2 1,2 2 IEC Keep the flammable gas out Powder Filled q Gb 1,2 IEC Quench the ignition source Oil Immersion ob oc Gb Gc. This classification is for an EC (ATEX) compliant system for surface equipment that has an equipment category of 2 (Zone 1) and is for gasses as opposed to dusts The protection concept is "d" which is flameproof, the gas group is IIC and the maximum allowable temperature is 0°C. The three categories of equipment match the three different levels of risk identified by ATEX More details on ATEX Zones can be found on our Zone 0 and Zone pages In these ATEX Zones This Category of equipment must be used Zone 0 and Category 1 Zone 1 and 21 Category 2 or 1 Zone 2 and 22.

ATEX Zone 0, 1, 2, , 21 & 22 Lighting ATEX Zone 0, 1, 2, , 21 & 22 Lighting The Atex zone classification system took effect in 03 as a method of identifying products suited for use in areas with explosive atmosphere It is a European classification system used primarily by the nations of the European Union. Equipment (fans) of category 2 is suitable for use in zone 1 and 21 (also 2 and 22) Group II, Category 3 Equipment (fans) of Category 3 is intended for use in areas in which explosive atmospheres caused by gases, vapors, mists or air/dust are unlikely to occur, or, if they do occur, are likely to do so infrequently and for a short period only. Ex pressure sensors and transmitters for ATEX Zone 0, Zone 1 or Zone 2 – markings of pressure instruments for use in a hazardous area The field of application or the suitability of a pressure sensor for a hazardous area is designated by the marking on the device As a matter of principle, intrinsically safe pressure sensors marked Ex ia can be used in zone 0 (the “most dangerous” area), whereby a number of additional conditions have to be taken into account.

Category 1 G (GAS) Zone 0 Category 2 G (GAS) Zone 1 Category 3 G (GAS) Zone 2 Devices that provide a very high protection Device Group II for device or protection system in areas with risk of explosion Group II (explosive gases or dusts) Devices that provide normal protection Devices that provide high protection D (Dust) Zone. The new TR65 (Zones 0, 1, 2, 21 & 22) and TR60 (1, 2, 21 & 22) are compact, lightweight, right angle ATEX torches for use in the most demanding hazardous area workplaces A flat back increases stability TR65 ATEX Compact Safety LED Torch The TR65 has an intense spot beam, with a wide angle flood of fringe light. ATEX Zone 0 The ATEX 137 Workplace Directive (Directive 99/92/EC) defines safety standards that apply to different levels of dangerous working environments The more dangerous the environment, the more stringent the requirements ATEX Zone 0 is one of the two most dangerous zoning classifications IPU’s ATEXApproved Starter Motors and Packages.

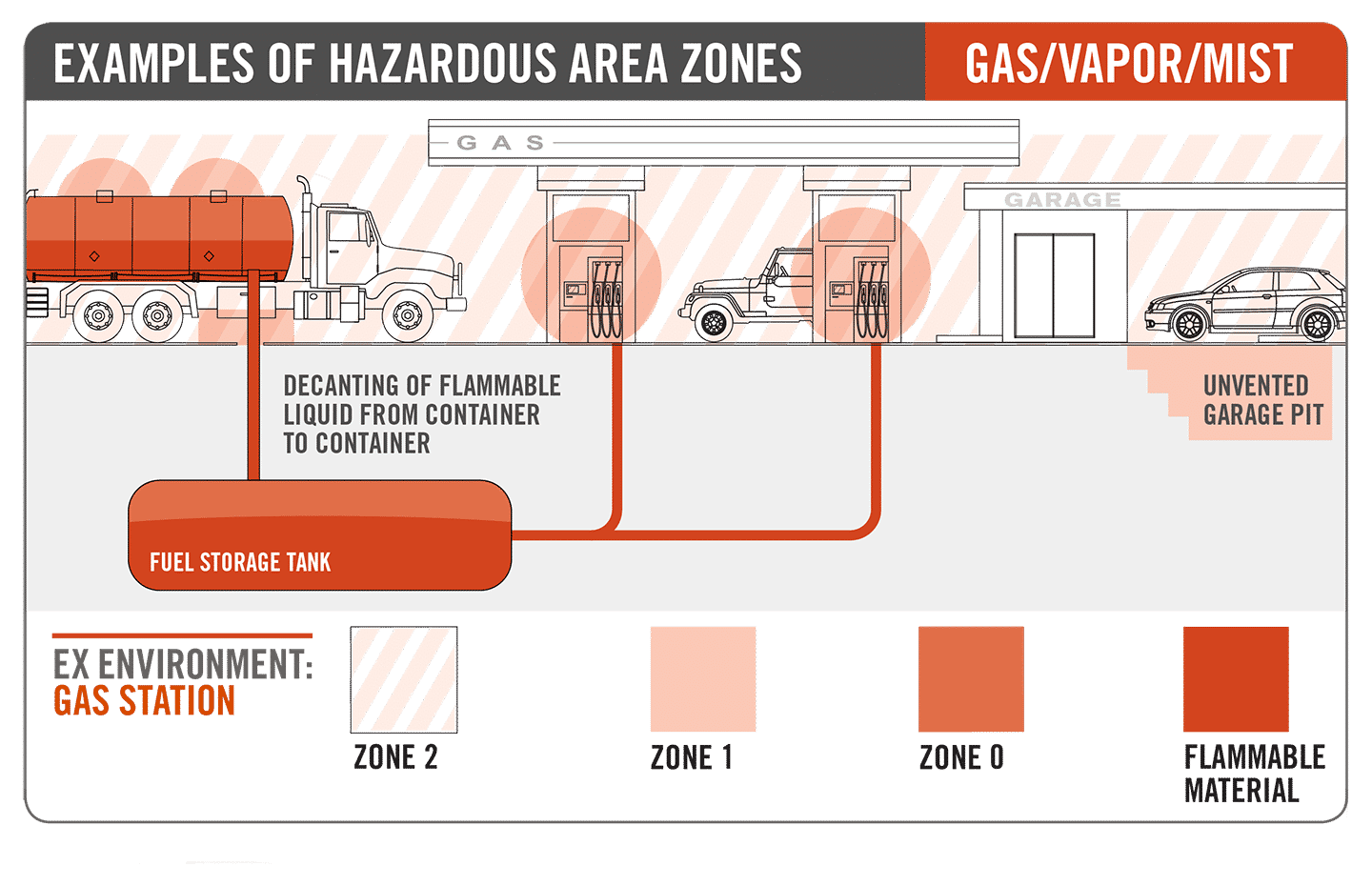

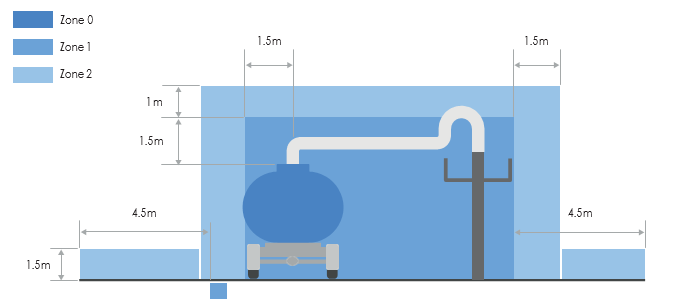

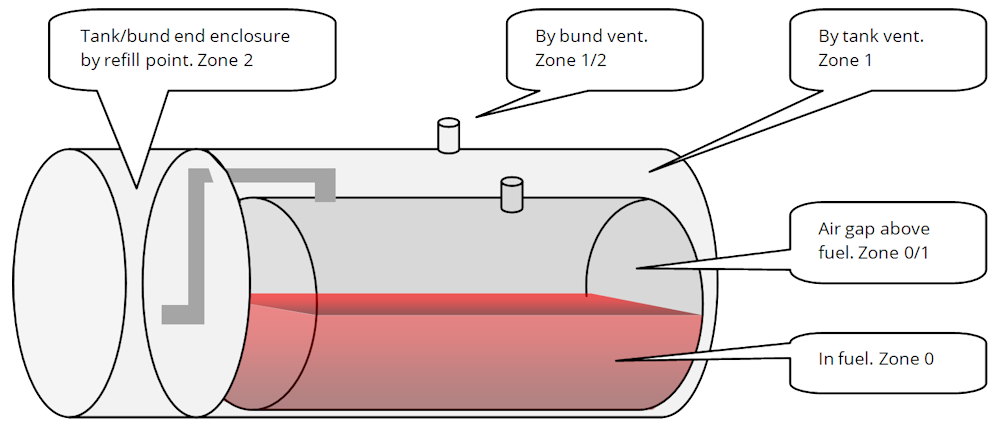

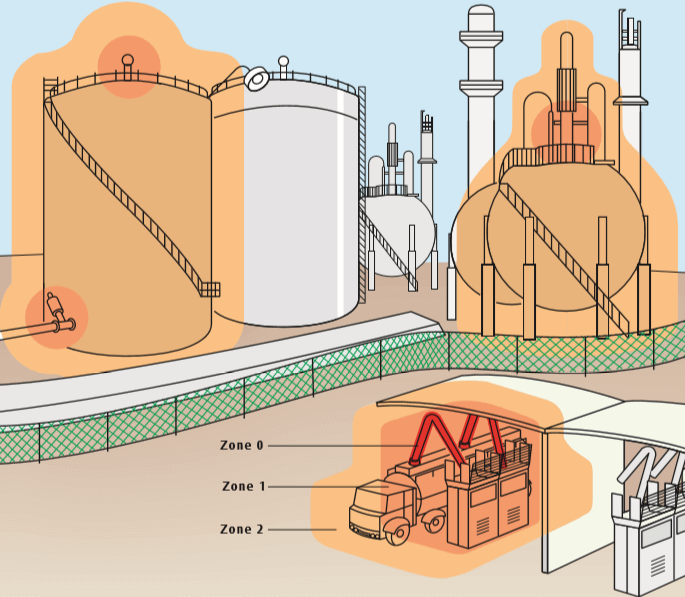

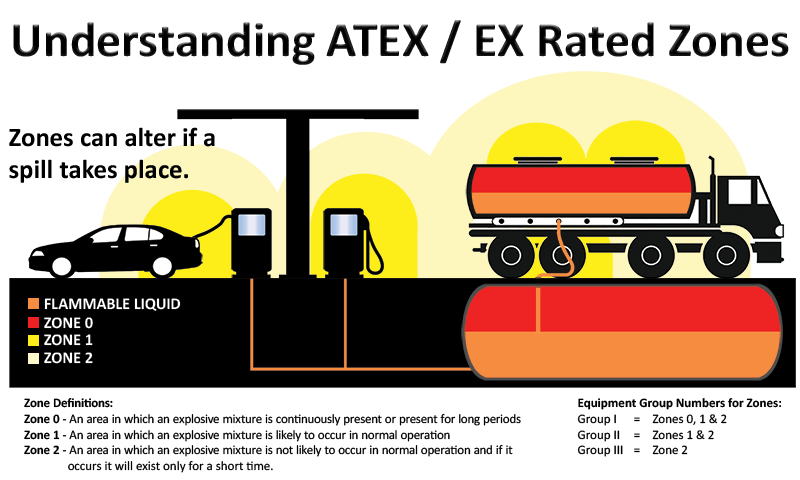

ATEX Zone 0, , 1, 21 A hazardous area is defined by the likelihood and concentration of an explosive atmosphere being present in a specific area, and is split into zones depending on the type of atmosphere present. ATEX The ATEX directive uses zones to classify potentially explosive gas and dust atmospheres Classifications range from an ignitable condition being an unlikely occurrence (Zones 2 and 22) to continuously present (Zones 0 and ) > Gas / Vapour / Mist Zone 0, Zone 1, Zone 2. The ATEX zones for gas or mist explosive risk are indicated with ATEX zone 0, 1 or 2 The ATEX zones for dust explosive risk are indicated with zone ATEX , 21, 22 In order to define the ATEX zones the following aspects need to be considered Hazardous sources, all points where gas, damp or dust could possible break out need to be documented.

1 In which an explosive gas/air mixture is likely to occur in normal operation Exd Exe, Exib, Exp, Exia, Exs 2 In which an explosive gas/air mixture is not likely to occur in normal operation All concepts suitable for Zone 0 & 1, ExN, ExO and Exq. 13 Schedule 14 TYPE EXAMINATION CERTIFICATE No DEMKO 11 ATEX X Rev 1 Report 12NK 00ICF0060 – Issue 60 This certificate may only be reproduced in its entirety and without any change, schedule included Page 2 of 3 15 Description of Equipment The Passive SONAR Flow Monitoring System is a clampon, nonwetted, flow measurement system used to measure certain properties of. Zone 0, 1, 2 – These are zones specifically for atmospheres with hazardous gases, vapors, and mist Zone 0 – Explosive mixtures are present continuously Category 1 equipment required Zone 1 – Explosive mixtures are present intermittently Category 2 or 1 equipment required Zone 2 – Explosive mixtures are present abnormally or infrequently Category 3, 2, or 1 equipment required.

EX Camera for use in Zone 0,1 and 2 Hazardous Areas Options for Tank Cleaning, Manhole inspection and other hazardous area camera applications The camera is ATEX certified for use in Zone 0 hazardous areas It can be permanently installed tanks , r. 1, G Zone Område, hvor der vedvarende, hyppigt eller i længere tid kan være en eksplosiv atmosfære bestående af en sky af brændbart støv og luft 1, D Zone 1 Område, hvor der under normal drift lejlighedsvis kan forekomme eksplosiv blanding af luft og brandfarlig gas, damp eller tåge 1 eller 2, G Zone 21. Zone 1 Zone 1 is an area in which an explosive atmosphere is likely to occur occasionally in normal operation It may exist because of repair, maintenance operations, or leakage Zone 2 Zone 2 is a place in which an explosive atmosphere is not likely to occur in normal operation but, if it does occur, will persist for a short period only.

Within the European Union, these are defined by IEC/EN standards (IEC/EN or 2) as directed by ATEX There are three zones for gas Zone 0, Zone 1 and Zone 2 And there are three corresponding zones for dust Zone , Zone 21 and Zone 22 Put simply, the 0zones (0 and ) are highest risk probability, and 2zones lowest (2 and 22) How the risks are classified is a bit more complex One Hazardous Area can have several different zones. The are 6 Atex Categories, designated ' 1 ', ' 2 ' and ' 3 ' representing levels of Risk ' High ' ' Medium ' and ' Low ' respectively each with either ' G ' and ' D ' for Gas and Dust Equipment is allocated a protection Level (EPL) of ' G ' and ' D ' then ' a ', ' b ' and ' c ' representing the degree of protection dependant on a number of factors, particularly 'fault conditions. Explosion proof LED Output 1 lumen Beam distance 80m IP67 Gas zone 0, 1 & 2 Dust zone , 21 & 22 art ce700ebdwz.

Classify the workplaces into hazardous area Zones depending on the frequency and time that an explosive atmosphere is present in the form of gas, vapour, powder or dust For example ATEX Zone 1 (high risk gas/vapour) ATEX Zone 2 (medium risk gas/vapour) ATEX Zone 21 (high risk powder/dust) ATEX Zone 22 (medium risk powder/dust). ATEX Zone 12 Item Number Thermatex, ATEX capillary tube thermostat Capillary tube thermostat with concealed knob for ATEX zones 1 and 2. Our host Michael explains the ins and outs of ATEX zones in his whiteboard explainer video So summarizing, ATEX Zones indicate how dangerous a potentially explosive atmosphere is.

ATEX Zones – Zones are defined in the ATEX Workplace Directive 1999/92/EC, as follows Gas, Vapor, or Mist Zone 0 – a place in which an explosive atmosphere consisting of a mixture with air of flammable substances in form of gas, vapor or mist is present continuously or for long periods or frequently. Definitions ATEX Category Equipment Protection Levels Typical Zone Suitability 0A place in which an explosive atmosphere is continually present 1 G GaEquip suitable for Zones 0,1,2 1 D DaEquip suitable for Zones ,21,22. ATEX Continuous Zone 0, Category 1 Intermittent Periodically Class I, Division 1 Class II, Division 1 Zone 1, 21 Category 2 Abnormal Condition Class I, Division 2 Class II, Division 2 Zone 2, 22 Category 3 Created Date 10/29/07 AM.

CLASSIFYING HAZARDOUS AREAS INTO ZONES MAINTENANCE EQUIPMENT IN HAZARDOUS AREAS MARKING OF EQUIPMENT SELECTION OF EQUIPMENT HAZARDOUS AREA ZONES AND EQUIPMENT CATEGORIES Overview Gases, vapours, mists and dusts can all form explosive atmospheres with air Hazardous area classification is used to identify places where, because of the. Suitable for zone 0, 1 and 2 Ingress protection IP65 / IEC529 Ambient temp range 45°C80°C, this can be limited depending on the materials applied such as cables, connection heads, junction boxes and transmitters. ATEX Approved Tablets We offer a range of rugged Windows 10 and Android Tablet PCs with ATEX Zone 0/, Zone 1/21 or Zone 2/22 approvals Designed from the inside out to be safe and durable for use in explosive atmospheres Ranging from 7” to 116” capacitive or digitiser, high brightness, displays All with drop resistance, MILSTD801G approvals, Ingress Protection rating for dust and water.

Torches approved for usage in these zones are divided in Categories (1, 2, 3) An accidental explosion in a hazardous location could mean serious injury for an employee Only an authorised supervisor should decide the Lighting ATEX Category for each Zone after strict evaluation. EX Camera for use in Zone 0,1 and 2 Hazardous Areas Options for Tank Cleaning, Manhole inspection and other hazardous area camera applications The camera is ATEX certified for use in Zone 0 hazardous areas It can be permanently installed tanks, reactors, production, sump pits and anywhere that permanent monitoring through a camera is necessary. Gb or Db “High” protection level, for zones 1 and 21;.

ATEX The ATEX directive uses zones to classify potentially explosive gas and dust atmospheres Classifications range from an ignitable condition being an unlikely occurrence (Zones 2 and 22) to continuously present (Zones 0 and ) > Gas / Vapour / Mist Zone 0, Zone 1, Zone 2 > Powder / Dust Zone , Zone 21, Zone 22 ExProof. However it is ideal for large areas such as container skids in a zone 1 or 2 hazardous location (see table 10) and where several different types of EX protection may be required, the Ex p solution will negate the need for other Ex requirements as the internal equipment does not need additional apparatus approvals or accreditation. ATEX Zones – Zones are defined in the ATEX Workplace Directive 1999/92/EC, as follows Gas, Vapor, or Mist Zone 0 – a place in which an explosive atmosphere consisting of a mixture with air of flammable substances in form of gas, vapor or mist is present continuously or for long periods or frequently.

Zone 2 Gases & Vapours Category 1 Category 2 Category 3 Note Category 2 certification also covers the lower category 3 Table 2 ATEX Category There are three area category types, with Category 1 requiring a very high level of protection and defined as an area having a permanent or prolonged risk of explosions (Zone 0), Category 2 which. 2 G Gb Equip suitable for Zones 1,2 21 2 D Db Equip suitable for Zones 21,22 2 A place in which an explosive atmosphere is not likely to occur in normal operation, but if it does only occurs for short periods 3 G Gc Equip suitable for Zone 2 22 3 D Dc Equip suitable for Zone 22 Protection Concepts (ATEX and IECEx) Type of Protection Symbol. IEC Dust IEC Definitions ATEX Category Equipment Protection Levels Typical Zone Suitability 0 A place in which an explosive atmosphere Zone 0,1,2 Zone 1, 2 Ex ia Ex ib Limit the spark energy and temperatures Pressurized (Purged) Encapsulation Oil Immersion Division 1,2 NA Division 2 Zone 1, 2.

Gb 2G 1, 2 occasionally even with normal malfunctions Ga 1G 0, 1, 2 permanently or frequently even with rare malfunctions is uncommon for 1G or Ga electric motors Zone 0 is an area in which an explosive atmosphere consisting of a mixture of air and flammable gases, vapours or aerosols is present constantly, over long periods or frequently. Zone 1 (gases) An area in which an explosive mixture is likely to occur in normal operation Class I Division 1 (gases) Zone 21 (dusts) Class II Division 1 (dusts) Zone 2 (gases) An area in which an explosive mixture is not likely to occur in normal operation and if it occurs it will exist only for a short time Class I Division 2 (gases) Zone. We have experienced situations where ATEX zone 0 has been reduced back to ATEX zone 2 – just with the help of ventilation In general, we see that 80% of all ATEX zones are set as a zone 2 or 22 In practice ATEX zone reduction The extent of the impact of explosionreducing measures is shown in the example below.

Zones 0, 1 & 2 EExi EN500 Zones 1 & 2 Exi IEC Class 1 Divisions 1 & 2 UL913 Increased Safety – This equipment is so designed as to eliminate sparks and hot surfaces capable of igniting an explosive atmosphere Zones 1 & 2 EExe EN Zones 1 & 2 Exe IEC. Zone 1 and Zone 2 isolators (switch disconnectors) are ATEX certified to Ex d or Ex e for hazardous area installation – housed in heavy duty cast iron or cast aluminium enclosures with 1650A current ratings, 34 pole including fire resistant isolators for safety critical electrical circuits. This classification is for an EC (ATEX) compliant system for surface equipment that has an equipment category of 2 (Zone 1) and is for gasses as opposed to dusts The protection concept is "d" which is flameproof, the gas group is IIC and the maximum allowable temperature is 0°C.

Zone 1 is an area that is classified ‘as a place in which an explosive atmosphere consisting of a mixture with air or flammable substances in the form of gas, vapours and mists is likely to occur occasionally during normal operation’, whereas Zone 2 is an area that is classified ‘as a place in which an explosive atmosphere consisting of a mixture with air or flammable substances in the form of gas, vapours and mists is not likely to occur in normal operation but if it does occur, it. Gc or Dc “Normal” protection level, for zones 2 and 22. Abtech ZAG99 aluminium electrical enclosures are ATEX Certified for use in Zone 0, Zone 1 and Zone 2 hazardous areas – the terminal enclosures commonly used as junction boxes are manufactured from stainless steel and available in a full range of depths and sizes ATEX Ex ia (Zone 0) and Ex ta (Zone ).

It is important to note that equipment approved for use in a higher risk zone is automatically approved for use in lower risk zones too Category 1 equipment designed for use in Zone 0 and workplaces can also be used in Zone 1, 2, 21 and 22 workplaces ATEX Category 1 equipment is suitable for use in all ATEX Zones. Torches for Zone 0, 1, 2, Zone , 21, 22 Hazardous Area Lighting Wolf R50 & R55 Rechargeable Torches are ATEX certified torches for safe use in hazardous area Zone 0, 1 & 2 (Gas, Vapour & Mist Explosive Atmospheres) and Zone , 21 & 22 (Dust Explosive Atmospheres) – T&D are Approved Distributors for the Wolf Lighting including handlamps. What is the difference between ATEX Zone 2 and 22?.

Class 1 / Division 1 ATEX Zone 1 Orange Zone Class 1 / Division 2 ATEX Zone 2 Yellow Zone Industrial Computing for Class 1 / Division 2 and ATEX Zone 2 Where embedded electrical products are concerned, the requirement for harsh environment industries such as oil and gas will usually be certification to Class 1 / Division 2 and/or ATEX Zone 2. According to IEC, devices for use in explosive atmospheres that contain flammable gases (G) or dusts (D), are classified into three protection levels Ga or Da “Very High” protection level, for zones 0 and ;. Within the European Union, these are defined by IEC/EN standards (IEC/EN or 2) as directed by ATEX There are three zones for gas Zone 0, Zone 1 and Zone 2 And there are three corresponding zones for dust Zone , Zone 21 and Zone 22 Put simply, the 0zones (0 and ) are highest risk probability, and 2zones lowest (2 and 22) How the risks are classified is a bit more complex One Hazardous Area can have several different zones.

Peli ATEX Zone 1 & Zone 0 Lights Please select light model to see available shop items 1930Z0 L1 LED Zone 0 LED / 12 Lumen / 4 x LR44 Battery / ATEX Zone 0 1965Z0 MityLite LED Zone 0 LED / 87 Lumen / 2 x AAA Battery / ATEX Zone 0 1975Z0 Mitylite LED Pen Light ATEX Zone 0. ATEX Approved Tablets We offer a range of rugged Windows 10 and Android Tablet PCs with ATEX Zone 0/, Zone 1/21 or Zone 2/22 approvals Designed from the inside out to be safe and durable for use in explosive atmospheres Ranging from 7” to 116” capacitive or digitiser, high brightness, displays All with drop resistance, MILSTD801G approvals, Ingress Protection rating for dust and water. There are three area category types, with Category 1 requiring a very high level of protection and defined as an area having a permanent or prolonged risk of explosions (Zone 0), Category 2 which requires a high level of protection and has a frequent risk of an explosive mix being present in the air (Zone 1), and Category 3, specified as requiring a normal level of protection with a small chance of an explosive mix forming (Zone 2).

That is to say temperatures of − °C to 40 °C and pressures of 08 to 11 bar Zone classification The ATEX Directive covers explosions from flammable gas/vapours and combustible dust/fibres (which, contrary to common perception, can lead to hazardous explosions) Hazard – Gas/vapour/mist.

Gc060 Atex Ce Lsi 60k Load Cell Ce Atex Zone 0 1 For 1 1 8 To 1 1 2 Wire Rope Size Parts Supply Worldwide

Making Your Existing Equipment Atex Compliant

Process Industry Beckhoff Usa

What Are Atex Zones Koks Robotics

Standards And Regulations Ex Zones Atex Iecex

Classificazione Zone Aree Atex

Atex Enclosures Index Atex Zone 0 1 21

Atex Iecex Getac

Wolf Atex Hazard Lamp For Hazardous Area Zone 0 Zone 1 Zone 2

Peli Atex Zone 1 Zone 0 Lights Pelishop Com Peli Distributor Public Authorities Industry Retail Business Consumers Since 1999

Overview Of Hazardous Areas Expo Technologies

What Is Atex Knivesandtools Explains

How Sensors Work Atex Intrinsically Safe Sensors

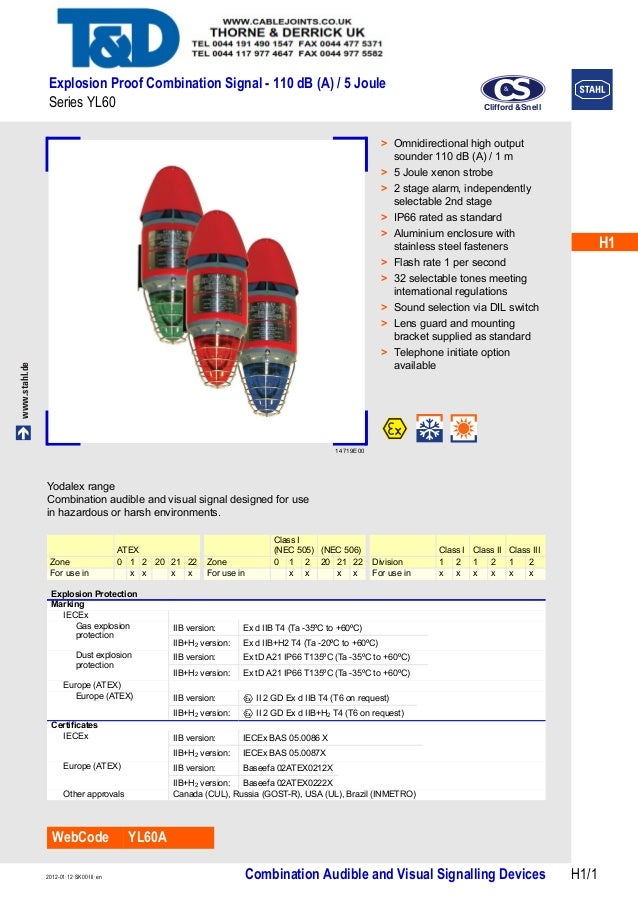

Stahl Yl60 Sounder Signalling Device Atex Zone 1 Zone 2 Hazardous A

Explosion Protection Technical Principles Atex Article Atexdb

Hazardous Areas Hazardous Area Zones Guide Explanation Definitions

Abtech Zag5 Atex Zone 0 1 2 Junction Box Electrical Enclosures

Atex Conveyor Belts Products Barbieri S P A

Hazardous Areas Hazardous Area Zones Guide Explanation Definitions

Epl Equipment Protection Level Cortem Group

Identifying Zone 0 Zone 1 And Zone 2 Hazardous Areas Raytec Led Blog

Hazardous Areas Hazardous Area Zones Guide Explanation Definitions

Atex Weighbridge Applications Kataskevastiki J Dimitriou Weighing Engineering

Q Tbn And9gcrvsqtxmrkekxaqf2wzppgi44j1iwzmianqtnmn3lm6dltsq05q Usqp Cau

Atex Equipment And Zones Explained Sciencedirect

Atex And Fuel Polishing

Working Group For Safety In Hazardous Areas Atex Zones And Categories Zoning For Working Areas As Defined In The Directive 99 92 Ec

Explosion Protection Technical Principles Atex Article Atexdb

Atex Category 1 Equipment

Zone 0 1 2 Atex Explosion Proof Light Knowledge Shenzhen Cary Technology Co Ltd

Atex Enclosures Index Atex Zone 0 1 21

Pressure And Flow Catalogue 16 17 By Oem International Issuu

Overview Of Atex Zones And Equipment Ex Machinery Atex Blog

Atex Catalog Peli

Stahl 6600 Fluorescent Light Fitting Atex Zone 1 Zone 2 Hazardous Area Lighting Pdf Document

Overview Of Atex Zones And Equipment Ex Machinery Atex Blog

Hazardous Area Atex Zone 1 Zone 2 Flameproof Explosion Proof Intrinsically Safe Manualzz

Atex Zone 2 Hazardous Duty Motors Ppt Video Online Download

Q Tbn And9gctm Vig1iuruiviacx5yldx5uarjrds aslpomoax4otb Nka Usqp Cau

Langkamp Technology Ex I Zone 0 Gas Zone 0 1 Gas Zone Dust Zone 21 Dust Cable Sensors

Hazardous Location Classification Guide Nec Vs Iec

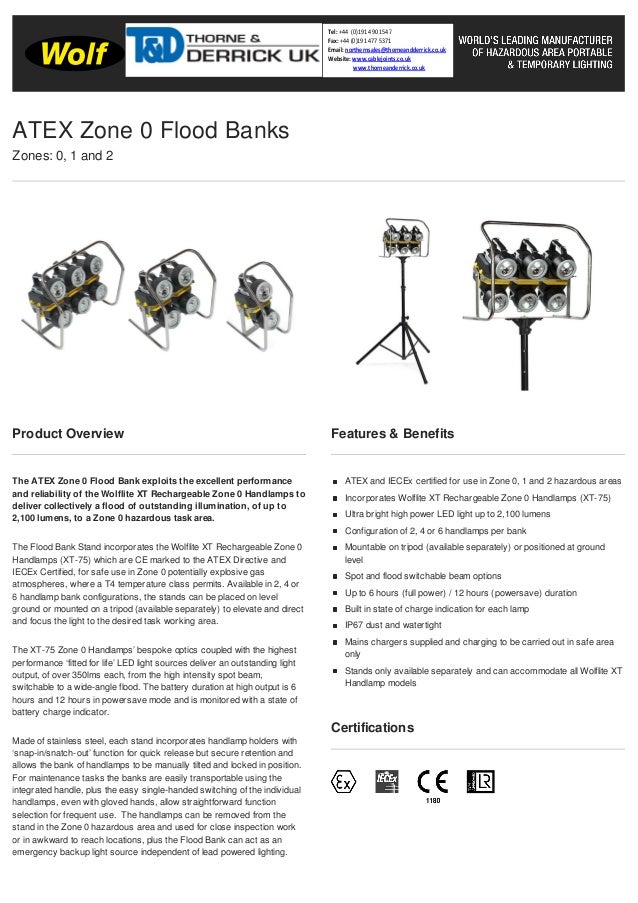

Wolf Atex Zone 0 Flood Banks Spec Sheet

What Are Atex Zones Koks Robotics

Gex Fz 1g High Precision Bench Balance For Atex Zone 0

Hazardous Area Equipment Certification Atex Zone 1 Zone 2 Iec Ex

Atex Directive

Valves Atex Certified Ro Bo Mechanical Workshop

Balluff Delivers More Intrinsically Safe Sensors From A Single Source Balluff

Zone 2 Definition What Is Zone 2 Hazardous Area Atex 1999 92 Ec

Ex Pressure Sensors And Transmitters For Atex Zone 0 Zone 1 Or Zone 2 Markings Of Pressure Instruments For Use In A Hazardous Area Wika Blog

Zone Atex Les Cles Pour Comprendre Et Bien Choisir Ses Equipements Sick

Stahl 67 Bulkhead Light Fitting Atex Zone 1 Zone 2 Hazardous Area

Hazardous Areas Hazardous Area Zones Guide Explanation Definitions

Is 655 2 Atex Atex Instrinically Safe Zone Tablet Cctv Computer Camera Certified Hazardous Buy Ex Camera For Use In Zone 0 1 And 2 Hazardous Areas Online

Atex Zone 0 Classification

Atex Explosive Atmospheres Gases Chemistry

Is 655 2 Atex Atex Instrinically Safe Zone Tablet Cctv Computer Camera Certified Hazardous What Is Atex

Atex Certification Definitions

Classification Of Atex Zones Petzl Other

Technetea Electrical Apparatus In Potentially Explosive Atmospheres

Atex Enclosures Index Hazardous Area Information

Zone Atex Les Cles Pour Comprendre Et Bien Choisir Ses Equipements Sick

What Is Atex Jenson Atex Depot

Explosive Atmospheres Atex Sertec S R L

Www Wasp Pfs Com Images Images Kallyas Brochures Wasp Pfs Atex Brochure Pdf

Identifying Zone 0 Zone 1 And Zone 2 Hazardous Areas Raytec Led Blog

Hazardous Areas The Importance Of Hazardous Areas Cannot Be

Http Www Iecex Com Assets Uploads D1s4a Implementation Ei Installation In Haz Area Classification Phe Onwj Pdf

Atex Catalog Peli

Industrial Iot In Hazardous Areas Microtronics Blog The World Of Iot And M2m

Ex Protection The Most Common Ignition Protection Types For Sensors In Gas Hazardous Areas Wika Blog

Understanding Atex Zones

Hazardous Area Sitech Gulf

Headlamp With Headsupe Lite Led Atex Zone 0 1 2

Atex Gas Explosiegevaarlijke Omgeving Rotor

The Use Of Protection Methods In Zone 0 Cortem Group

Peli 3415z0m Led Atex Zone 0 Flashlight Atex 15 Yellow Pelishop Com Peli Distributor Public Authorities Industry Retail Business Consumers Since 1999

Bartec Pixavi Zone 1 Vs Zone 2 Hazardous Areas

Atex Zone 2 Hazardous Duty Motors Ppt Video Online Download

Hazardous Area Atex Certfied Light Guide Led Work Lights Unilite

Overview Of Hazardous Areas Expo Technologies

Atex Explained Lgm Products

Http Www Iecex Com Assets Uploads D1s4a Implementation Ei Installation In Haz Area Classification Phe Onwj Pdf

Is 655 2 Atex Atex Instrinically Safe Zone Tablet Cctv Computer Camera Certified Hazardous What Is Atex

Explosion Proof Classification Divisions Zones Of A Spray Room And A Filling Station Explosion Groups Temperature Classes Fire Protection

Overview Of Atex Zones And Equipment Ex Machinery Atex Blog

Hazardous Zones Atex Peli

Straightpoint Atex Loadshackle Wireless Shackle Load Cell For Use In Zone 0 1 2 Coventry Scale Company

Q Tbn And9gctciypq 11rbrdjpd77r4vodsrlh8g Gaoeno28 Uifshglpo Usqp Cau

Explosion Proof Classification Divisions Zones Of A Spray Room And A Filling Station Explosion Groups Temperature Classes Fire Protection

Zone Atex Zonage Et Definition Nos Solutions s

Atex Zones Miretti Ex Atex Zone 1 2 21 22 Area Classification

Atex Zone 0 Helmet Light Peli 3315z0 Achetez Au Meilleur Prix Sur Proteclight

Ex Zone What Is An Ex Zone Atexor Knowledge Base

Exheat Hazardous Area Electric Process Heaters Control Systems

Atex Ex Zoned Equipment Ash Safety

Q Tbn And9gcqltmyan3aywhdm6dkhhjduqfl1d2bdon3i1s4pyps Usqp Cau

Hazardous Areas Hazardous Area Zones Guide Explanation Definitions