5s Mechanical Workshop

Increase Efficiency Profitability With The 5s Methodology

Represents

70 5s Ideas In 21 Lean Manufacturing Visual Management Lean Six Sigma

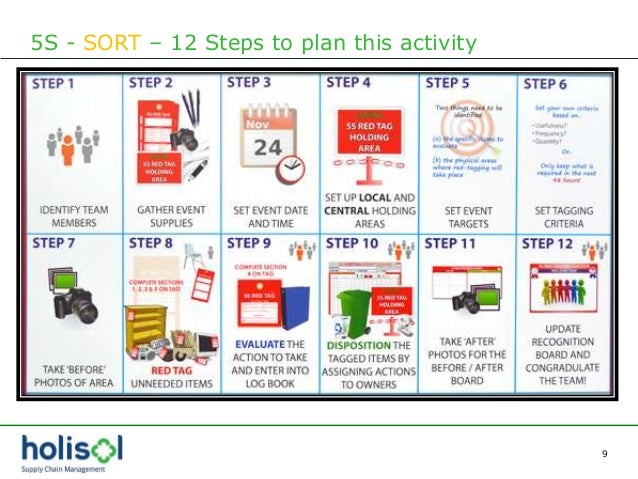

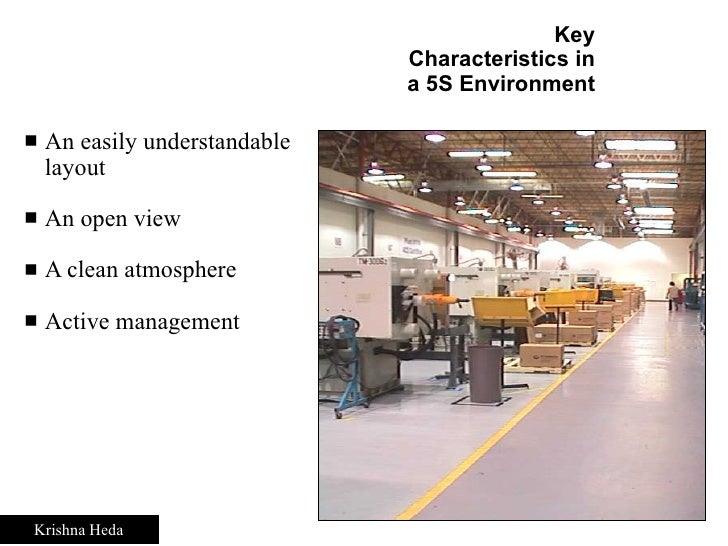

5s Workshop Visual Management Krishna Heda

Home Shop Machinist Hall Of Fame

5s Office To 5s Manufacturing Results Lean Production Youtube

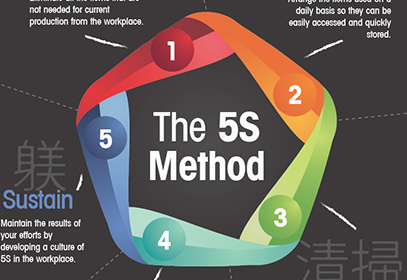

Defining 5S 5S is a formulaic method you can use to straighten and organize a work area Using 5S reduces waste (a fundamental goal in lean manufacturing), improves safety (see our article on Lean 6S Safety ), and otherwise improves your production process and work environment 5S is called 5S because their are 5 steps and each step begins with the letter “S” (and/or the sound “s”).

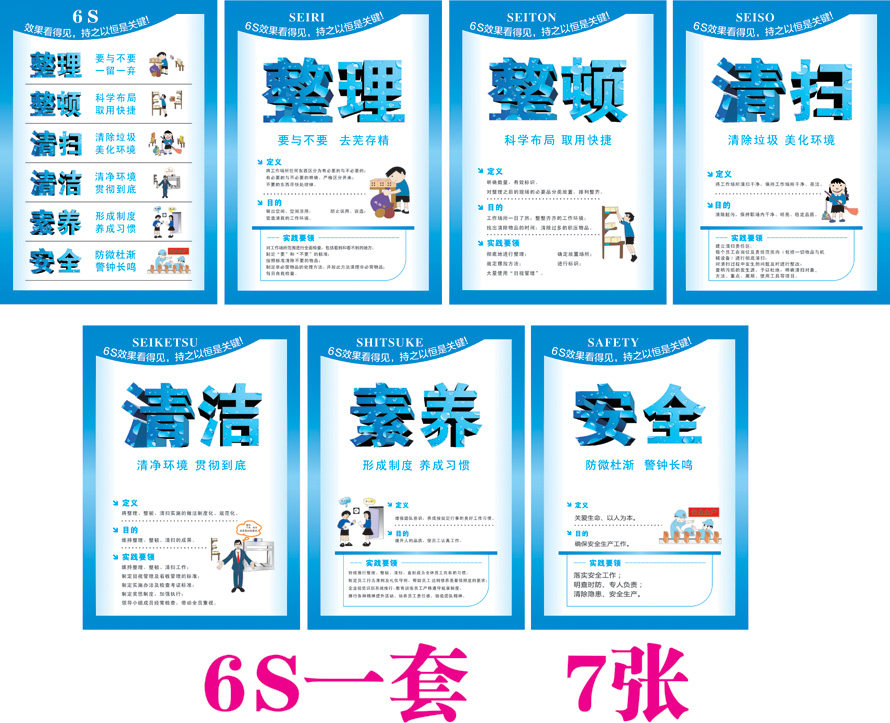

5s mechanical workshop. Purpose To show the 5th S, sustain or self discipline Main Points Begins with training so people understand the meaning and importance of 5 S Workers buyin and agree to support 5S activities Once 5S is implemented and people continue to do it, it becomes a habit like brushing your teeth every morning Management supports people who are. Even though 5S comes with “builtin” safety benefits, that’s not the end of the story Over time, people have modified 5S by adding a new “S” to create 6S systems One of the most common of the 6S systems results from adding Safety to 5S This is sometimes called 5S, 6S, lean 6S, 6S safety, or lean 6S safety. 5S is amongst the first and fundamental steps implemented by an enterprise towards the path of implementing Total Quality Management and continuous improvement at the operation level 5S is a process designed to organize the workplace, keep it clean, maintain effective and standard conditions.

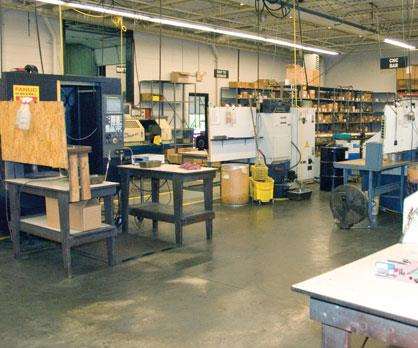

Jan 10, 21 Explore janisleilands's board "5S" on See more ideas about lean manufacturing, visual management, lean six sigma. The implementation of 5S at the department of mechanical and industrial engineering firstly took place at workshop G308 This is a mechanical worksh op clustered with heavy machines, equipment, tools and materials It is divided in two parts, where the first part is a machine (manual and cnc lathe and milling machines) keeper and the other part is. As well as general 5S or equipment marking Durable PVC material and superior adhesive make our SafetyTac Alignment Markers highly resistant to forklifts, pallet jacks, and other industrial floor hazards Smart Stripe Tape is a cost effective, durable solution for your floor marking needs and.

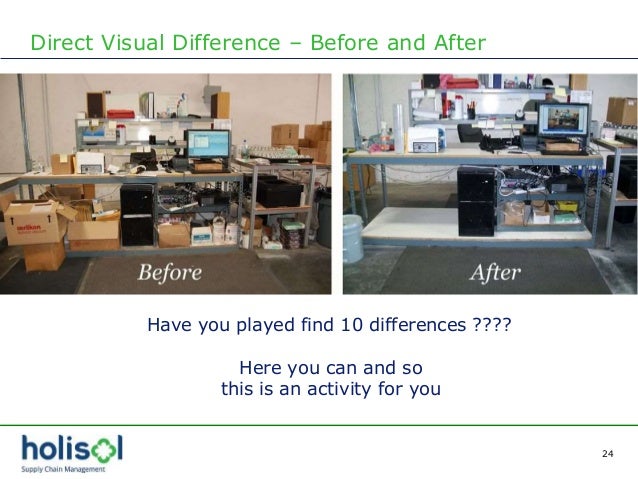

Started 5S’ing and colorcoding your facility Each kit contains an assortment of our most popular floor and workbench marking supplies Kits that include a Brady portable label printer are also available Kits Contain Floor marking (1 roll each of yellow, red, blue, green). That makes the workshop an important strategic asset Take for example the following workshops This is what can be achieved by application of 5S Lean Techniques. QualityOne International 1333 Anderson Road Clawson, MI Ph Fx.

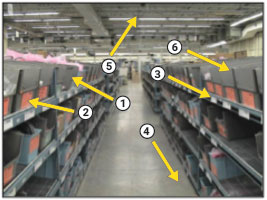

Use of Mechanical Equipment §(a) Where mechanical handling equipment is used, sufficient safe clearances shall be allowed for aisles, at loading docks, through doorways and wherever turns or passage must be made Aisles and passageways shall be kept clear and in good repair, with no obstruction across or in aisles that could create a hazard. The Origins of 5S – 5S & Lean Manufacturing 5S began as part of the Toyota Production System (TPS), the manufacturing method begun by leaders at the Toyota Motor Company in the early and midth century This system, often referred to as Lean manufacturing in the West, aims to increase the value of products or services for customers. 5S is based on the CANDO system developed by Henry Ford in the early th century Watch this video, which explains the steps, and provides video time lapse of how a healthcare organization performed their 5S event Here is a breakdown of each ‘S’.

Implementation of Shitsuke for Sustaining with 5S Culture in a Mechanical Workshop Valentine Khumalo Department of Quality and Operations Management University of Johannesburg Johannesburg, 28, South Africa valentinekhumalo@ymailcom Kapil Gupta* Department of Mechanical and Industrial Engineering Technology University of. Lean Implementation in Higher Education – University of Agriculture Faisalabad (UAF) Lean kaizen Workshop Lean kaizen in Folding 5S Implementation in Mechanical Workshop Process Optimization – Printing & Finishing Production Planning and Control – Arshad Corporation Ltd Total Productive Maintenance Training – (CTM & CBL) Read More. 5S is the Foundation of any Lean Program This infographic outlines what 5S does and how to implement it without headaches or hassles Stop the Spread of Germs This infographic describes best practices established by the CDC for restricting the spread of respiratory illness.

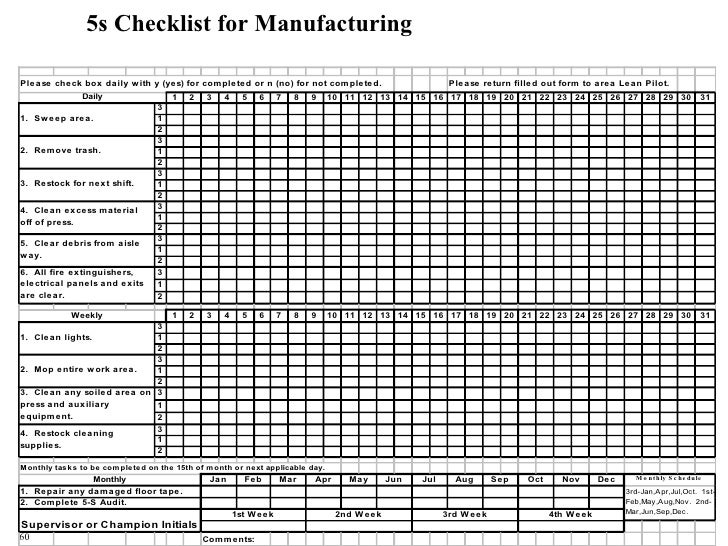

Mechanical Engineering at (11) ‘Defects and improvement of 5S implementation in the workshop Findings SEM of 5S various parameters has established that attributes like top management. 5S is a Lean technique that involves activities designed to create and maintain a disciplined workplace It helps create a better working environment and can be implemented to eliminate waste and improve the flow of work 5S audits are often used to evaluate the performance of 5S implementation in any workplace This 5S audit checklist will help ensuring that 5S standards and workplace. Course5Sdocx 18 June 10 Page 1 of 3 Introduction to 5S Training Workshop Welcome to the oneday 5S training course by Lifetime Reliability Solutions Introduction to 5S 5S is workplace management where the work area and workplace are organised and ritualised to minimise the loss of time and the use of movement.

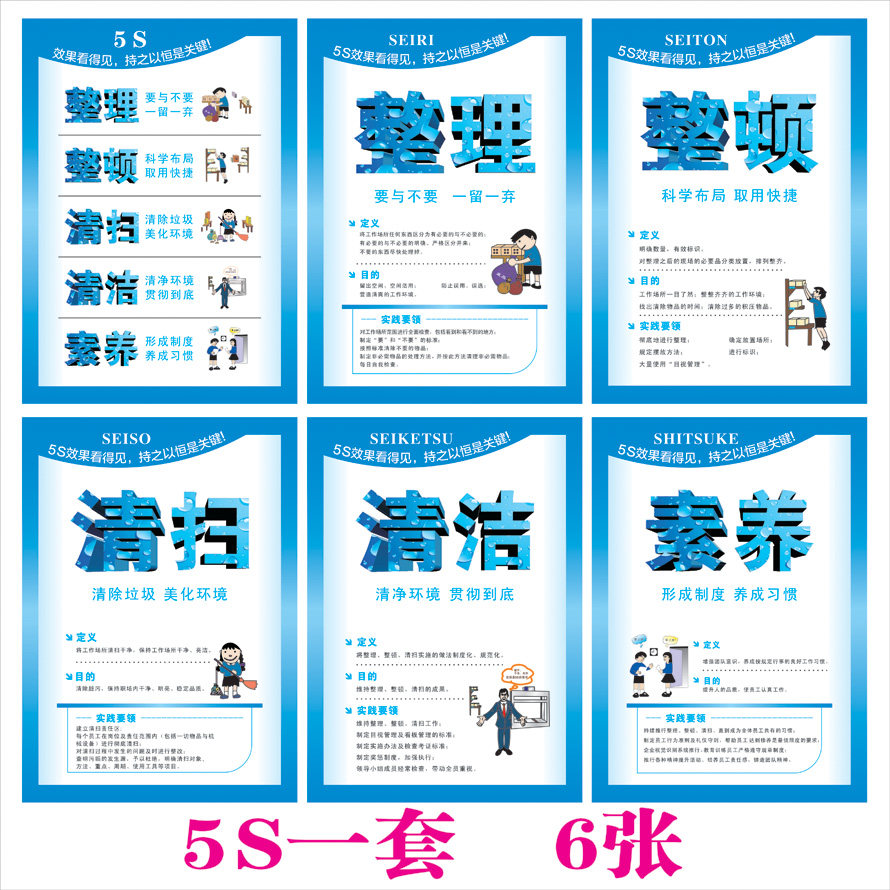

THE FIVE STEPS OF GOOD MAINTENANCE– 5S In Japanese, 5S is the short form of five words which present the concept of good maintenance Fig 2 KAIZEN – 5S The definitions and significance of the five words Fig 2 are given below • SEIRI – Sorting – making the difference between necessary and useless things in GEMBA, giving up. What are the Five S's (5S) of Lean Quality Glossary Definition Five S’s (5S) 5S is defined as a methodology that results in a workplace that is clean, uncluttered, safe, and well organized to help reduce waste and optimize productivity It's designed to help build a quality work environment, both physically and mentally. 5S for your Warehouse Lean warehousing is the way of the future In its April 14 report, the Council of Supply Management Professionals identified Lean as a projected characteristic of the 25 India supply chainAccording to the report “The pressure to do more with less will not subside.

The greatest benefit from using 5S is realized when it is part of a larger initiative and the entire organization has adopted its principles 5S is more than a system;. As well as general 5S or equipment marking Durable PVC material and superior adhesive make our SafetyTac Alignment Markers highly resistant to forklifts, pallet jacks, and other industrial floor hazards Smart Stripe Tape is a cost effective, durable solution for your floor marking needs and. Previously our workshop was ‘pigsty’ We could not find tools, materials were scattered all over the place We adopted a 5S approach (part of Certificate 2 in Engineering VETiS) to what we do and have seen the improvements We are still improving but some of the comments by the students have been ‘it is much easier to work on our bikes’.

Versatility Professional Tool Storage Industrial Tool Storage Solutions Press Brake Tooling Storage Cabinet Automotive, aircraft and diesel mechanics now have the flexibility to create the tool storage center which best fits their needs. 5S AS A TOOL AND STRATEGY FOR IMPROVISING THE WORK PLACE Harsha Lingareddy, GSahitya Reddy, KJagadeshwar Address for Correspondence Mechanical Engineering Department, K L University, Guntur, Andhra Pradesh, India ABSTRACT We provided some vast literature on the implementation of 5S in any industry This strategy involves the study and change. Toyota 5S–FE Engine Repair Manual (RM547E) PDF The 5S–FE engine is an in–line, 4–cylinder engine with the cylinders numbered 1–2–3–4 from the front The crankshaft is integrated with eight weights for balance Oil holes are placed in the center of t.

Previously our workshop was ‘pigsty’ We could not find tools, materials were scattered all over the place We adopted a 5S approach (part of Certificate 2 in Engineering VETiS) to what we do and have seen the improvements We are still improving but some of the comments by the students have been ‘it is much easier to work on our bikes’. Started 5S’ing and colorcoding your facility Each kit contains an assortment of our most popular floor and workbench marking supplies Kits that include a Brady portable label printer are also available Kits Contain Floor marking (1 roll each of yellow, red, blue, green). THE FIVE STEPS OF GOOD MAINTENANCE– 5S In Japanese, 5S is the short form of five words which present the concept of good maintenance Fig 2 KAIZEN – 5S The definitions and significance of the five words Fig 2 are given below • SEIRI – Sorting – making the difference between necessary and useless things in GEMBA, giving up.

This allows the use of hand or mechanical means of launch, plus the benefit of using a crane if available, in addition to keeping the operation to a safe standard and using a minimum of labour A concrete apron from the workshop with a winch and deadmen is also a very useful requisite. 5S is a fivestep organization technique to create and maintain an intuitive workspace Sort – Remove unnecessary items from the workplace Keep only what is essential Set in Order – Arrange items so they are easily accessible “A place for everything, and everything in its place”. This study focuses on the application of 5S in welding workshop, to simplify wasteful activities Performance m easures are used as a reference in m easuring the success of 5S implementation is the.

11 What Is ‘5S’?. The implementation of 5S at the department of mechanical and industrial engineering firstly took place at workshop G308 This is a mechanical worksh op clustered with heavy machines, equipment, tools and materials It is divided in two parts, where the first part is a machine (manual and cnc lathe and milling machines) keeper and the other part is. License Free for personal and commercial use, No attribution requiredBut we would appreciate if you could place a link refer to Hippopx.

5S is a system and way of organizing and managing workspaces to improve efficiency by eliminating waste, improving flow and reducing the number of processes where possible 5S systems are common in manufacturing, warehouses, offices and hospitals but 5S principles can be applied to any workplace. 5S is the Foundation of any Lean Program This infographic outlines what 5S does and how to implement it without headaches or hassles Stop the Spread of Germs This infographic describes best practices established by the CDC for restricting the spread of respiratory illness. A set of slides from a workshop to launch 5S in an office Slideshare uses cookies to improve functionality and performance, and to provide you with relevant advertising If you continue browsing the site, you agree to the use of cookies on this website.

Purpose To show the 5th S, sustain or self discipline Main Points Begins with training so people understand the meaning and importance of 5 S Workers buyin and agree to support 5S activities Once 5S is implemented and people continue to do it, it becomes a habit like brushing your teeth every morning Management supports people who are. Use of Mechanical Equipment §(a) Where mechanical handling equipment is used, sufficient safe clearances shall be allowed for aisles, at loading docks, through doorways and wherever turns or passage must be made Aisles and passageways shall be kept clear and in good repair, with no obstruction across or in aisles that could create a hazard. „5S‟ is one of the Japanese techniques which was introduced by Takashi Osada in the early 1980s 2 It is basically a workplace management methodology which helps for improving working environment, human capabilities and thereby productivity 6 The word „5S‟ represents.

5S is the name given to the Lean Manufacturing method for the clearing out of all unnecessary items to allow room for the acquisition of tools and parts in the fastest and easiest manner A comparison of 5S methodology with an evaluation and optimization of a PM program at a plant quickly shows how similar these processes are. Toyota 5S–FE Engine Repair Manual (RM547E) PDF The 5S–FE engine is an in–line, 4–cylinder engine with the cylinders numbered 1–2–3–4 from the front The crankshaft is integrated with eight weights for balance Oil holes are placed in the center of t. A set of slides from a workshop to launch 5S in an office Slideshare uses cookies to improve functionality and performance, and to provide you with relevant advertising If you continue browsing the site, you agree to the use of cookies on this website.

5S Implementation in Mechanical Workshop Corporate Trainings Lean Implementation in Higher Education – University of Agriculture Faisalabad (UAF) Lean kaizen Workshop Lean kaizen in Folding 5S Implementation in Mechanical Workshop Process Optimization – Printing & Finishing Production Planning and Control – Arshad Corporation Ltd Total. 5S for your Warehouse Lean warehousing is the way of the future In its April 14 report, the Council of Supply Management Professionals identified Lean as a projected characteristic of the 25 India supply chainAccording to the report “The pressure to do more with less will not subside. 5S is one of the most widely adopted techniques from the lean manufacturing toolbox Along with Standard Work and Total Productive Maintenance, 5S is considered a "foundational" lean concept, as it establishes the operational stability required for making and sustaining continuous improvements The primary objective of 5S is to create a clean, orderly environment an environment where there is a place for everything and everything is in its place.

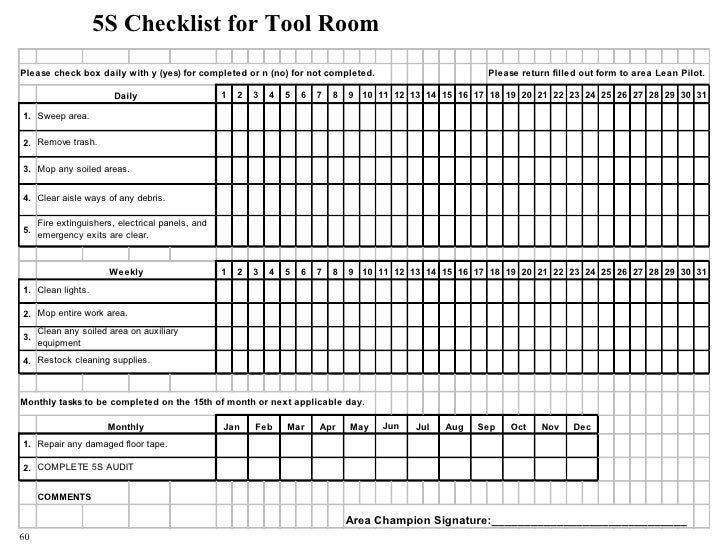

5S is a Japanese visual management tool that is a structured methodology to continuously practice a clean, organized and efficient working environment The 5S methodology assists in eliminating the frustration, confusion, stress that is found due to the space limitations and poor inventory management at any workplace. 5S AS A TOOL AND STRATEGY FOR IMPROVISING THE WORK PLACE Harsha Lingareddy, GSahitya Reddy, KJagadeshwar Address for Correspondence Mechanical Engineering Department, K L University, Guntur, Andhra Pradesh, India ABSTRACT We provided some vast literature on the implementation of 5S in any industry This strategy involves the study and change. 5S CHECKLIST FOR ENGINEERING WORKSHOPS Mechanical engineering is a discipline of engineering that applies the principles of engineering, physics and materials science for analysis, design, manufacturing, and maintenance of mechanical systems.

Even though 5S comes with “builtin” safety benefits, that’s not the end of the story Over time, people have modified 5S by adding a new “S” to create 6S systems One of the most common of the 6S systems results from adding Safety to 5S This is sometimes called 5S, 6S, lean 6S, 6S safety, or lean 6S safety. The 5S methodology was born at Toyota in the 60s under an industrial environment to achieve better organized, tidier, and cleaner workplaces to increase productivity and to obtain a better working environment The 5S methodology has been widely spread, and many companies and organizations are implementing it worldwide Although it is conceptually simple and does not require a complex training. This study focuses on the application of 5S in welding workshop, to simplify wasteful activities Performance m easures are used as a reference in m easuring the success of 5S implementation is the.

It is a business philosophy and should be integrated into the organization’s culture. Responsible for the implementation of 5S and other HSEQ standard within the workshop area Deputise for the Fabrication and Painting Supervisor whilst they are on Field Break Test and approve operators for truck, excavator, loaders, cranes, grader, backhoe, etc. The 5S methodology was born at Toyota in the 60s under an industrial environment to achieve better organized, tidier, and cleaner workplaces to increase productivity and to obtain a better working environment The 5S methodology has been widely spread, and many companies and organizations are implementing it worldwide Although it is conceptually simple and does not require a complex training.

5S was developed in Japan and was identified as one of the techniques that enabled Just in Time manufacturing Two major frameworks for understanding and applying 5S to business environments have arisen, one proposed by Osada, the other by Hiroyuki Hirano. Versatility Professional Tool Storage Industrial Tool Storage Solutions Press Brake Tooling Storage Cabinet Automotive, aircraft and diesel mechanics now have the flexibility to create the tool storage center which best fits their needs. Collect this idea Atelier Mecanic (Mechanical Workshop) is the name given to an interesting Romanian bar located in Bucharest With an appealing exterior, based on the connection between the artistic expression of the past and modern entertainment, the Mechanical Workshop bar was designed by a young and dynamic Romanian architect, Corvin Cristian.

Lean Training Easier, Better, Faster, and CheaperSee My Lean Video Collection Here https//wwwleanvlogcom/greatestleanvideocollectionlanding/You ca. Presented by David Potty What this presentation is all about Explain the 5S process Go through each “S” Show tools that can be used for each “S” Talk about my experiences putting the 5S system in place. QualityOne International 1333 Anderson Road Clawson, MI Ph Fx.

The 5S Housekeeping Standards First Step towards Continuos Improvement The aim of 5S is to create an atmosphere to keep a clean, organized, safe and efficient workplace for everyone The foundation for the practice of 5S, comes from a Japanese program derived from these words, seiri, seiton, seiso, seiketsu and shitsuke The.

5s Kaizen Buscar Con Google Visual Management Kaizen Lean Manufacturing

Here S How To Optimize And Automate Your Equipment With 5s

Teaching Lean Workshop Shs Asq Poole Hinton Kraebber 10 02 25

The 5s System Lean Manufacturing Methodology

The 5s System Lean Manufacturing Methodology

Plant Engineering Safety Is It The Sixth S In A 5s System

Usd 4 96 Chinese And English 5s Slogan 6s Slogan 7s8s Wall Chart Corporate Culture Quality Factory Workshop Safety Logo Slogan Wholesale From China Online Shopping Buy Asian Products Online From

Here S How To Optimize And Automate Your Equipment With 5s

5s Examples In Action The Good The Bad Graphic Products

5s Safety Lean 6s Safety Convergence Training

Ovako Imatra Steelworks All Workstations In The Spirit Of 5s Treston

Pdf Implementation Of 5s Methodology In A Metalworking Company

Ai Powered 5s Board

Roadmap To Qe 5s Implementation See Online Version For Colours Download Scientific Diagram

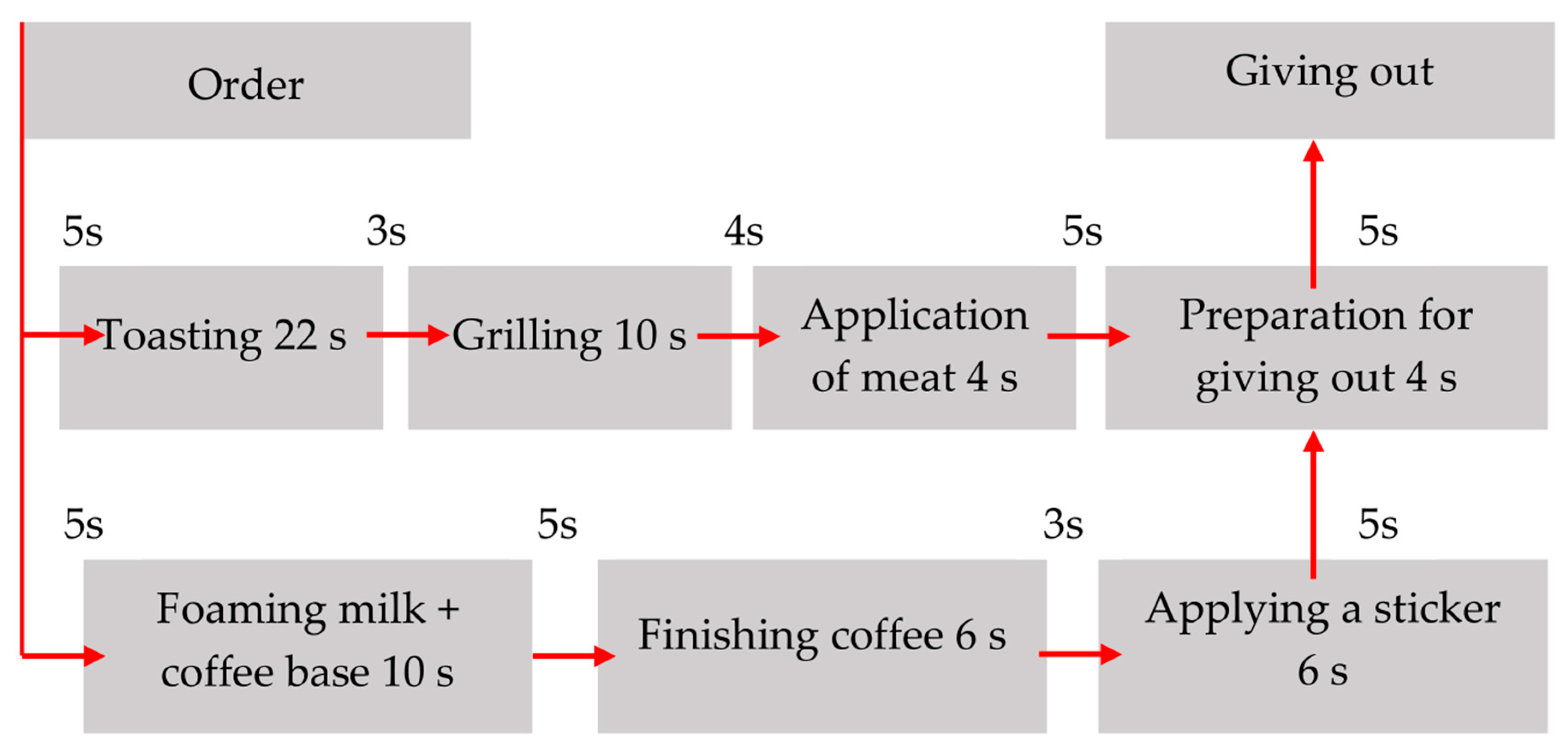

Energies Free Full Text Implementation Of Lean Management As A Tool For Decrease Of Energy Consumption And Co2 Emissions In The Fast Food Restaurant Html

Application Of Lean Manufacturing Tools In The Food And Beverage Industries

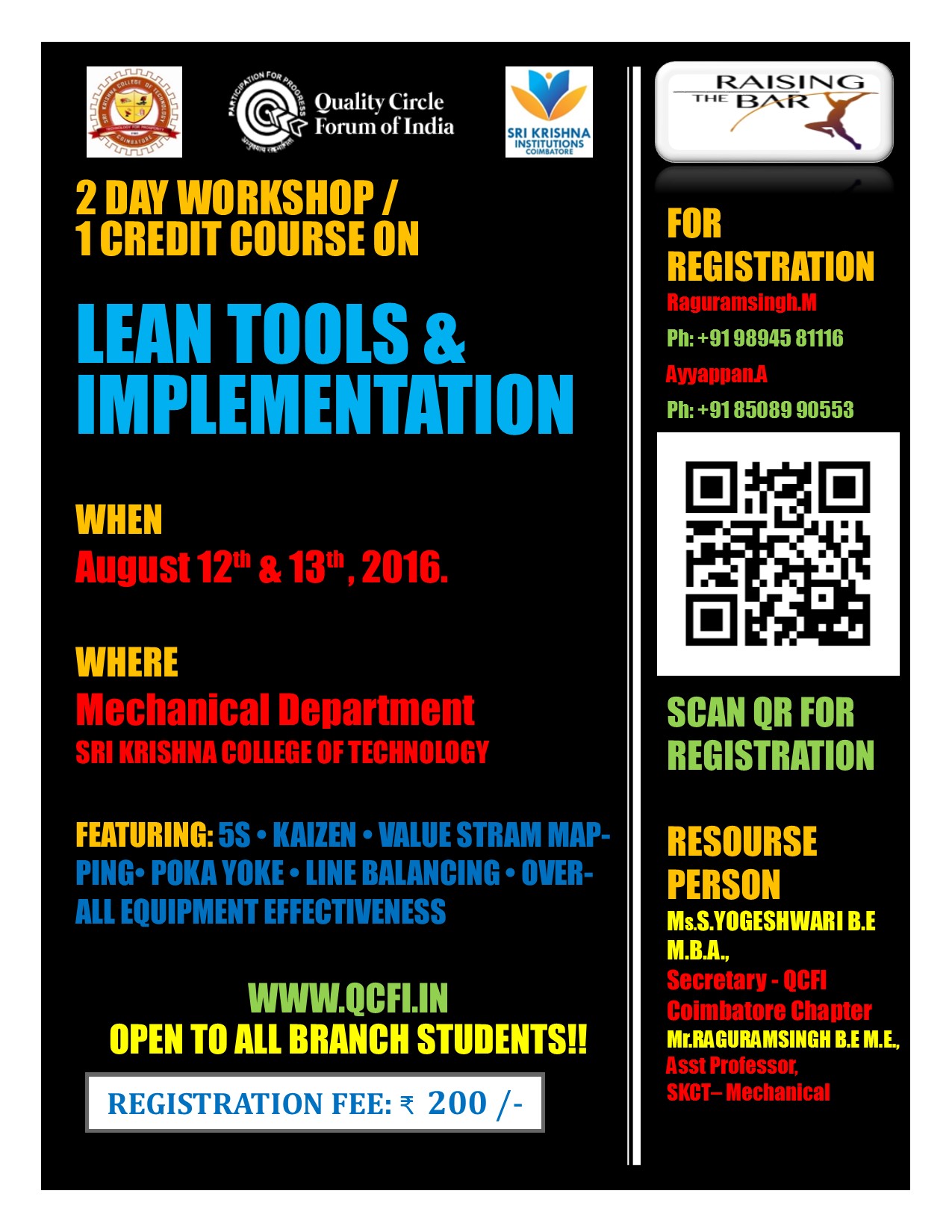

Two Days Workshop On Lean Tools Implementation Qcfi Quality Circle Lqc 5s Kaizen Total Quality Management Training Certifications

5s Implementation Workshop

About Sdlincin

5s Lean Manufacturing Training Video

5s Definition What Is 5s Six Sigma Free Training

Pdf Implementation Of 5s In A Mechanical Workshop At University Of Johannesburg A Case Study Semantic Scholar

The 5s System Standardize And Sustain Training Video

Safe Shops Not By Accident Construction Equipment

From Job Shop Chaos To Lean Order Modern Machine Shop

How The Integration Of 5s Improved Production Organization At Waterax Flexpipe

5s Workshop Visual Management Krishna Heda

The 5s System Lean Manufacturing Methodology

How To Apply 5s Method To Improve Shop Efficiency 18 12 06 Snips

What Is 5s Seiri Seiton Seiso Seiketsu Shitsuke

Detail Imbach Cie Ag

From Job Shop Chaos To Lean Order Modern Machine Shop

5s Basics Workplace Organization New Hampshire Manufacturing Extension Partnership Nh Mep

Extreme Makeover Storeroom Edition Life Cycle Engineering

5s Workshop Visual Management Krishna Heda

Pdf Implementation Of 5s In A Mechanical Workshop At University Of Johannesburg A Case Study Semantic Scholar

Westin Drives Refurbished Workshop And Facilities

The 5s System Lean Manufacturing Methodology

Workshop Excellence How We Apply Tools Like 5s Youtube

The 5s System Lean Manufacturing Methodology

A Practical Approach To The Successful Practice Of 5s

How The Integration Of 5s Improved Production Organization At Waterax Flexpipe

5s Methodology Wikipedia

5s Storyboard By Franknarciso

5s Methodology Wikipedia

Factory Workshop 5s 6s 7s 8s Management Placard Poster Quality Logo Wall Chart Enterprise Posters Exhibition

Westin Drives Refurbished Workshop And Facilities

Pdf Implementation Of 5s In A Mechanical Workshop At University Of Johannesburg A Case Study Semantic Scholar

5 Benefits Of Implementing 5s Audits At Your Plant Ease Inc

40 5s Ideas Lean Manufacturing Guide Book Visual Management

Clean Shop That Utilizes 5s Nordco Office Photo Glassdoor Co In

How The Integration Of 5s Improved Production Organization At Waterax Flexpipe

Nc Mechanical Engineering Glasgow Clyde College

5s Lean Manufacturing And Six Sigma Definitions

5s Methodology

Assembly Systems Fori Automation Inc

How The Integration Of 5s Improved Production Organization At Waterax Flexpipe

40 5s Ideas Lean Manufacturing Guide Book Visual Management

Keep People Away From Hazards Establish Safe Zones In Your Facility Our Floor Marking Infograp Visual Management Industrial Engineering Warehouse Management

Factory Workshop 5s 6s 7s 8s Management Placard Poster Quality Logo Wall Chart Enterprise Posters Exhibition Board

5s Lean Manufacturing And Six Sigma Definitions

Seiton Means Set In Oder In 5s Lean Methodology Click Here

5s Methodology Wikipedia

5s Implementation Workshop

6s Is Just Cleaning Up Isn T It Innoval Technology Innoval Technology

How The Integration Of 5s Improved Production Organization At Waterax Flexpipe

How To Do A 5s Audit With Your Iphone Flexpipe

Westin Drives Refurbished Workshop And Facilities

Keys And Tips To Implement The 5s Methodology