Hygienic Design Of Food Processing Facilities

Handbook Of Hygienic Design In Dairy Industry Guide For Food Processing Plants Zeytinci Ceren Amazon Com Books

2 5 Establishing Production Facilities

Food Processing Plants Brucha Spezial Und Kuhlraumbau

Hygienic Pumps For Food Processing And Beverage Plants Sanitary Positive Displacement Pumps Eccentric Screw Pumps Sps

Q Tbn And9gcriwc3buodtzfpmpfckemuu3je425blpbhdgex1khkcsvobrouo Usqp Cau

The Importance Of Flooring In Food Processing Plants By David Ryan Issuu

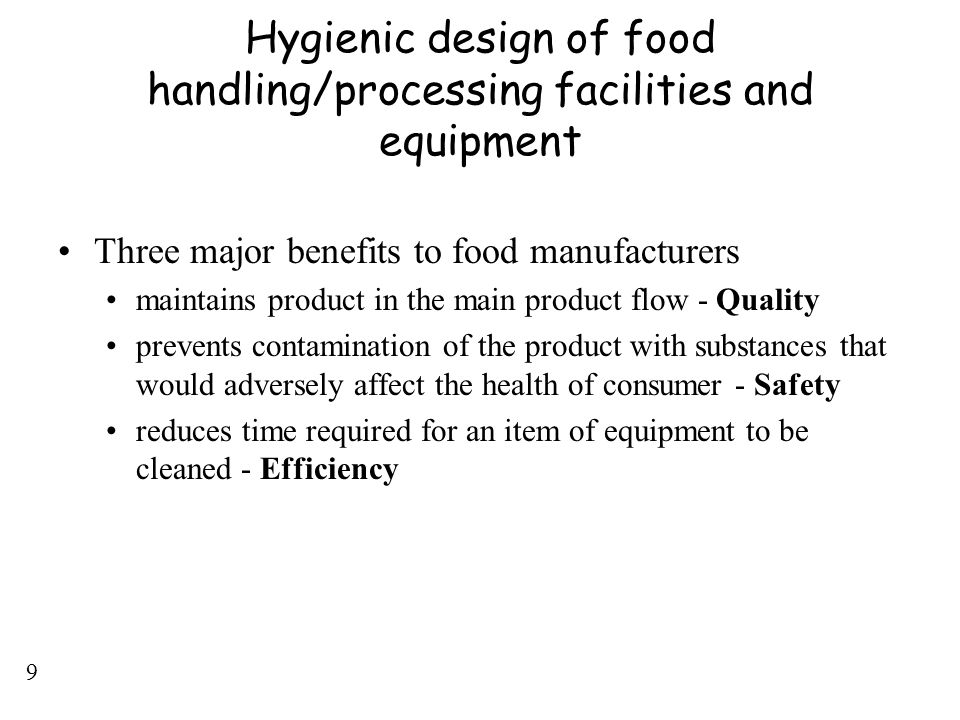

Hygienic design of food factories provides an essential overview of hygiene control in the design, construction and renovation of food processing factories Opening chapters consider the business case for hygienic facilities design Hygienic Design of Food Factories Woodhead Publishing Hygienic design of food factories provides an authoritative.

Hygienic design of food processing facilities. Principle 3 Water accumulations controlled inside the facility Water is an essential part of products, process and sanitation But it is also one of the greatest threats to food safety From the walls to the floors and ceilings, the design must prevent accumulation of water and, in fact, facilitate positive drainage and water removal. We need to evolve to meet the increasing demands Please note Remax will be closed from the 24th of December to the 11th of January. 5 Ways to A Hygienic Processing Facility Design Food safety is the greatest challenge for manufacturers;.

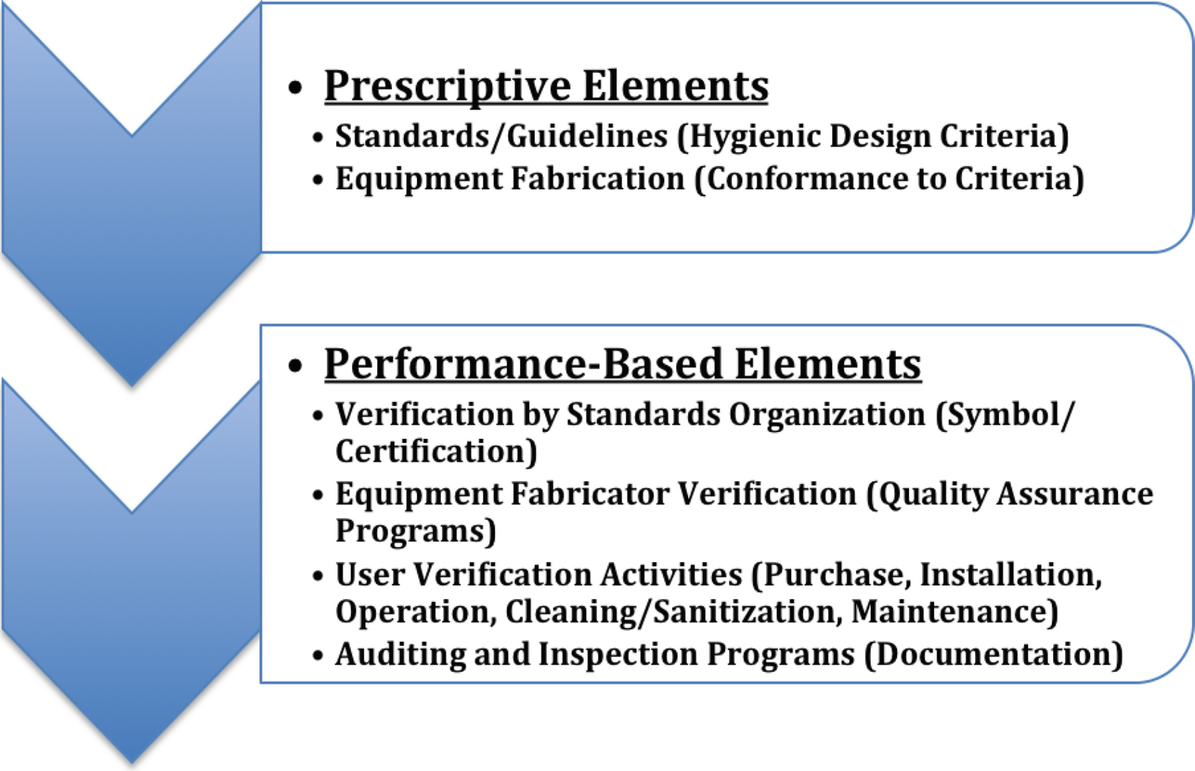

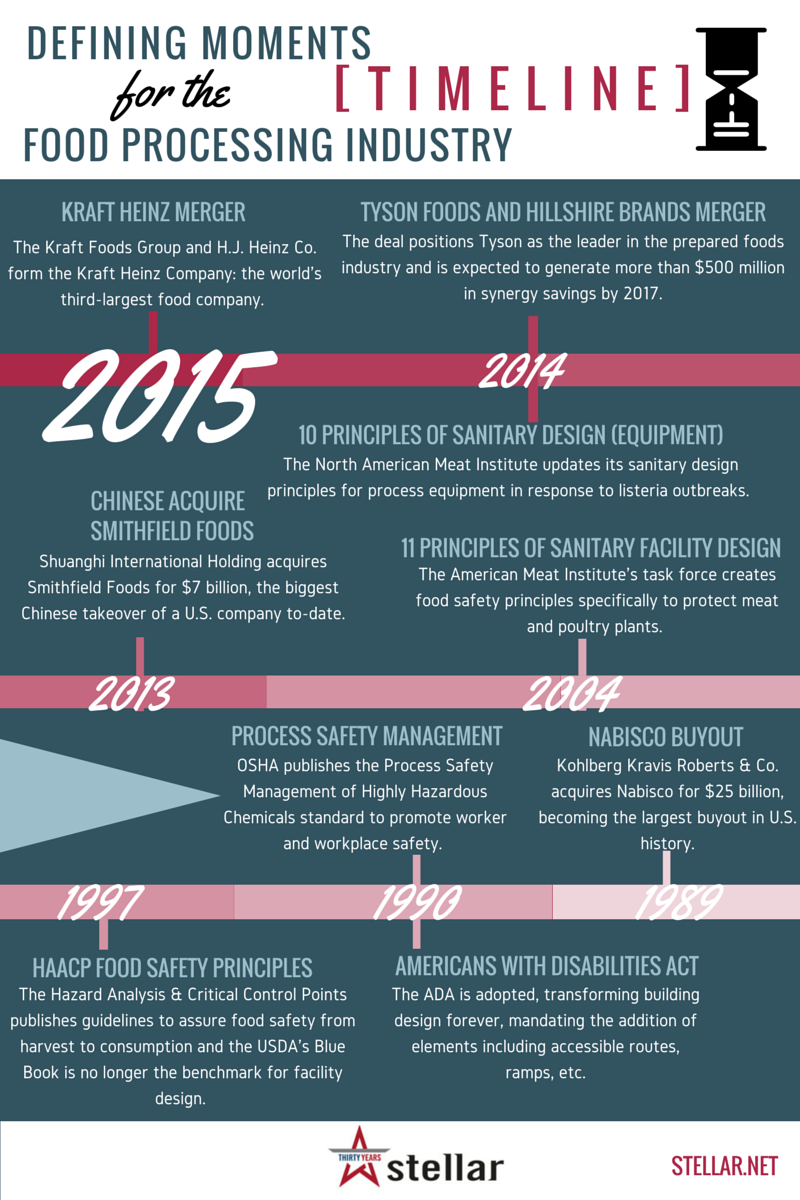

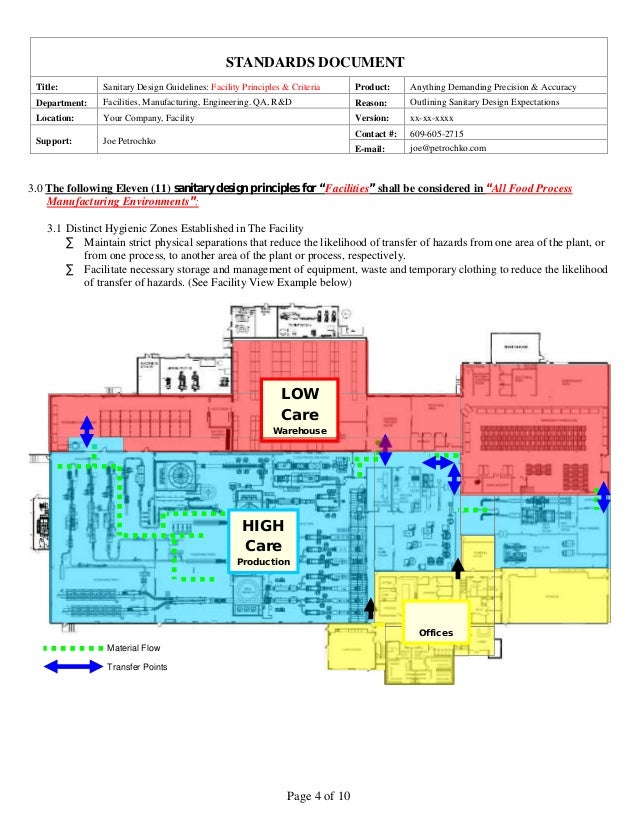

We need to evolve to meet the increasing demands Please note Remax will be closed from the 24th of December to the 11th of January. Optimizing the design and performance criteria for equipment and related systems as well as establishing industrywide specifications benefit the entire industry by promoting one standard design that will help reduce contamination and associated recalls These principles are applicable to equipment for all food uses Importance of Design Principles. Sanitary Facility Design Best Practices The previously mentioned AMI principles are commonly the point of reference for new construction, remodeling, and renovation of food processing plants, and not just those in the meat and poultry industries The principles are as follows Distinct hygienic zones are established in the facility.

Food safety is vital for consumer confidence, and the hygienic design of food processing facilities is central to the manufacture of safe products Hygienic design of food factories provides an. Its purpose is to help food safety professionals discover the unique characteristics of the cultures in which their companies operate around the world by exploring five distinct regions Europe, Australia, Asia, North America, and Latin America. Hygienic Design Training This training uniquely incorporates handson and theoretical learning on hygienic design of equipment and facilities Sessions are taught by industry recognized subject matter experts of the Food Sanitation Institute and participants are tested to help ensure proficient competency in offered training topics.

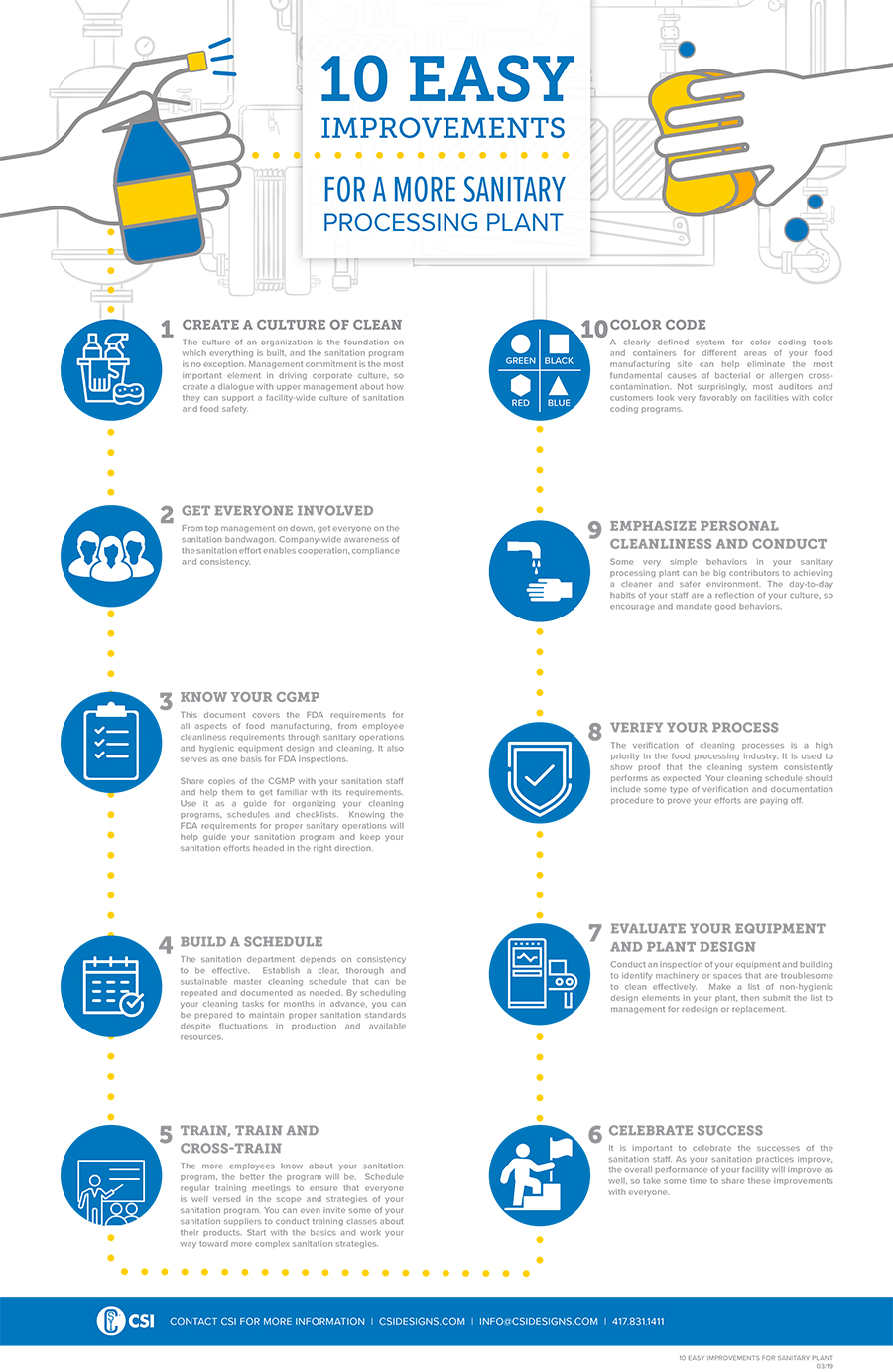

Mark Morgan of the University of Tennessee discuses hygienic design in his presentation at PROCESS EXPO 15 Skip navigation Hygienic Design of Food Processing Equipment PROCESS EXPO. Basic Elements of a Sanitation Program for Food Processing and Food Handling 3 Buildings and Facilities The two most important overall elements of any foodprocessing and handling facility is that it should be cleanable, and so designed and constructed that it prevents entrance or harborage of pests or other sources of contamination. Evaluating Equipment and Buildings for Hygienic Design The principles of hygienic design can be readily applied to any piece of equipment or building The accompanying checklist has been developed specifically for farmbased produce handling equipment and buildings It is based on other, more extensive guides from the processing industry.

Maintaining high standards of hygiene has always been important in any facilities, such as food and pharmaceutical processing plants, that are involved in the manufacturing and/or processing of anything—food, drinks, or drugs—that will ultimately be ingested by human beings or injected or inserted into them. The food processing industry is a subset of the manufacturing sector with unique challenges Among these, ensuring food hygiene and preventing contamination are two issues of prime importance Hence, designers have to overcome such challenges when designing facilities suitable for food processing The paper formulates a model that simplifies the layout planning process for the food processing. Sanitary Facility Design Best Practices The previously mentioned AMI principles are commonly the point of reference for new construction, remodeling, and renovation of food processing plants, and not just those in the meat and poultry industries The principles are as follows Distinct hygienic zones are established in the facility.

Hygienic design costs more In the short run this is often true for some equipment The materials of construction, often stainless steel, and the design details increase the initial, upfront cost The longterm benefits of hygienic design over the life of the equipment will reduce the overall operating costs. To ensure safe food and adequate sanitation programs, the facility and surroundings in which food processing and handling operations are conducted must be designed and constructed with sanitary design principles in mind Many existing facilities do not have optimum sanitary design and construction. Food product operations Depending on the operation, a facility may be divided into one, two, or three processing areas in addition to nonprocessing areas The layouts may be used to demonstrate how Salmonella may enter and spread throughout a facility if hygiene practices and controls are not in place.

Hygienic design costs more In the short run this is often true for some equipment The materials of construction, often stainless steel, and the design details increase the initial, upfront cost The longterm benefits of hygienic design over the life of the equipment will reduce the overall operating costs. GUIDELINE FOR THE DESIGN, CONSTRUCTION AND RECONSTRUCTION OF A FOOD PROCESSING ESTABLISHMENT This guideline provides general information to anyone proposing to construct a new food processing establishment, extensively remodel an existing food processing establishment or convert an existing building into a food processing establishment. Zone M (Medium Hygiene) To control or reduce the creation of hazard ous sources that can affect a higher zone classification Zone H (High Hygiene) To control all product contamination hazards a nd to protect the interior of food processing equipment from exposure to the room atmosphere Hygienic Air Quality for the Food Industry.

Using machinery designed with hygienic design principles in mind helps food manufacturers limit the risk of toxins or other microbiological organisms coming into contact with food supplies The good news is that sanitary and hygienic design doesn’t necessarily cost more than the same equipment would cost without these principles in mind That said, there is sometimes a higher upfront cost due to certain material choices, but the benefits of these choices reduce operating costs in the long. BASIC RULES OF HYGIENE, SANITATION AND SAFETY IN FOOD PROCESSING Facilities required in the processing room A changing room where clothing and shoes that are not worn for work can be stored. The hygienic processing of food concerns both potential hazards in food products and the regulation, design, and management of food processing facilities This second edition of Hygiene in Food Processing gives a revised overview of the practices for safe processing and incorporates additional chapters concerning pest control, microbiological.

– To make users aware of the importance of hygienic design, location and construction of food processing facilities for the prevention of food safety hazards and to enable them to identify hazardous design and layout and lack of adequate facilities and equipment in food production premises. Incorporation of hygienic design into your food processing facility can prevent development of pests and microbiological niches;. Sanitary Design and Construction of Food Processing and Handling Facilities 2 and limitation of pest entry into buildings are all part of a successful pest management program Location As with real estate, an important feature of a sanitary food facility is “location, location, location” Ideally, a facility.

Even though sanitary design, also known as hygienic design, is important throughout a food processing facility, the subject of this chapter is the first design step in preventing microorganisms, insects, rodents and any other type of contaminate that originates outside the facility from entering in or on the product. Whether you’re revamping an old facility or building a new one from scratch, what can you do to design a food processing facility that is hygienic as humanly possible?. With such history, of which these examples are just a snippet, it’d be natural to think that sanitary design would be a fundamental aspect of every food processing facility But while many facilities do focus on at least some aspects of sanitary design, just as many others are unsure of what, exactly, sanitary design is and how to apply it in.

Hygienic design guidelines take into account how to design, construct, and install the equipment, and associated infrastructure needed for the food storage processing and distribution In general, hygienic design aims to enhance control of potential external and internal hazards. These key principles of hygienic design guide all CMP's food processing equipment designs to ensure the products handled retain their quality during the processing phase If you're considering any type of material handling, or food processing equipment for your facility, speak with one of our Hygienic Design Specialists. Food safety is vital for consumer confidence, and the hygienic design of food processing facilities is central to the manufacture of safe products Hygienic design of food factories provides an authoritative overview of hygiene control in the design, construction and renovation of food factories.

Guidelines for dairy food manufacturing premises 7 Contaminants Std 323 Div 2 Clause 3 The design and construction must, to the extent that is practicable, exclude dirt, dust, fumes, smoke and other contaminants The exclusion of contaminants such as microorganisms, chemicals and foreign matter from the food processing. Principles of Hygienic Design for Food Processing Facilities 08 July, 19 The American Meat Institute has come up with the following principles of hygienic design for food processing facilities These design principles have been created to reduce food safety hazards, keeping food safe Whether you're building a new facility, updating your existing one or onboarding new employees, take these principles of hygienic design into consideration to prevent food borne illness and product recalls. Food Safety Content on Hygienic Equipment Design The Global Food Safety Series meets you where you live!.

Avoid product contamination with chemicals (eg, cleaning agents, lubricants, peeling paint, etc) and particles (eg, glass, dust, iron, etc);. Facility Construction The first step to creating a hygienic facility is to look at the construction of the facility itself. Avoid product contamination with chemicals eg, cleaning agents, lubricants, peeling paint, etc and particles eg, glass, dust, iron, etc;.

Its purpose is to help food safety professionals discover the unique characteristics of the cultures in which their companies operate around the world by exploring five distinct regions Europe, Australia, Asia, North America, and Latin America. BASIC RULES OF HYGIENE, SANITATION AND SAFETY IN FOOD PROCESSING Facilities required in the processing room A changing room where clothing and shoes that are not worn for work can be stored. Even though sanitary design, also known as hygienic design, is important throughout a food processing facility, the subject of this chapter is the first design step in preventing microorganisms, insects, rodents and any other type of contaminate that originates outside the facility from entering in or on the product.

Hygienic design of food processing buildings and equipment has a major effect on global food safety, across many sectors from farmtofork Poor hygienic design has led to many major food safety challenges from crosscontamination of food products by biological, chemical and physical hazards Well thoughtout hygienic design enables food safety. Whether you’re revamping an old facility or building a new one from scratch, what can you do to design a food processing facility that is hygienic as humanly possible?. Hygienic Design of Food Processing Equipment Perry Johnson Registrars Food Safety, Inc Hygienic conveyor design in the food factory Duration 224 FlexLink 7,860 views 224.

The volume of regulation on the hygienic design and construction of food processing plants is comparatively small These regulations largely provide general and performance oriented requirements This permits greater freedom of innovation, but it also requires greater expertise Third party certifying organizations simplify the process. Sanitary Facility Design Best Practices The previously mentioned AMI principles are commonly the point of reference for new construction, remodeling, and renovation of food processing plants, and not just those in the meat and poultry industries The principles are as follows Distinct hygienic zones are established in the facility. These best practices fall into three major buckets of hygienic design—zones of control, temperature and moisture control and ability to clean and maintain the facility Zones of control To prevent cross contamination, the design and construction of any food processing facility should incorporate a complete separation of production areas that house uncooked (raw) from cooked, readytoeat.

To create a sanitary process, hygienic duct design and fabrication, duct being the air delivery system, is often required For the “food safe design” of your facility, consider the following regulatory and safety considerations, as well as related ductwork design elements to help you make informed decisions. Designing Your Plant for Sanitation, By Don Graham, Sverdrup Facilities, Inc Ceilings • Ceilings are always a point of discussion when designing or renovating a food processing facility For good sanitary design criteria the solid walkon type is the best especially in a wet process. GUIDELINE FOR THE DESIGN, CONSTRUCTION AND RECONSTRUCTION OF A FOOD PROCESSING ESTABLISHMENT This guideline provides general information to anyone proposing to construct a new food processing establishment, extensively remodel an existing food processing establishment or convert an existing building into a food processing establishment.

Hygienic design in food processing plays an important role in controlling the microbiological safety and quality of the products made This will prevent products from having undesirably high microbial counts, containing toxins or chemical residues, or from contamination from other nonfood substances. Facility Construction The first step to creating a hygienic facility is to look at the construction of the facility itself. 5 Ways to A Hygienic Processing Facility Design Food safety is the greatest challenge for manufacturers;.

Design The Guide to Food Safety is based upon the Recommended International Code of Practice General Principles of Food Hygiene adopted by the Codex Alimentarius Commission (Codex) in 03 It is consistent with Codex's recommendations to enhance food safety by applying a systematic preventive approach. Although never mutually exclusive, the health of the food processing staff and hygienic design are now even more intertwined and interdependent As we look to a sustainable future, we must use Industry 40 methodologies and marry hygienic design with enablers of business continuity such as heating, ventilation, and air conditioning (HVAC. Basic Elements of a Sanitation Program for Food Processing and Food Handling 3 Buildings and Facilities The two most important overall elements of any foodprocessing and handling facility is that it should be cleanable, and so designed and constructed that it prevents entrance or harborage of pests or other sources of contamination.

These key principles of hygienic design guide all CMP's food processing equipment designs to ensure the products handled retain their quality during the processing phase If you're considering any type of material handling, or food processing equipment for your facility, speak with one of our Hygienic Design Specialists. With such history, of which these examples are just a snippet, it’d be natural to think that sanitary design would be a fundamental aspect of every food processing facility But while many facilities do focus on at least some aspects of sanitary design, just as many others are unsure of what, exactly, sanitary design is and how to apply it in. Maintaining high standards of hygiene has always been important in any facilities, such as food and pharmaceutical processing plants, that are involved in the manufacturing and/or processing of anything—food, drinks, or drugs—that will ultimately be ingested by human beings or injected or inserted into them.

2 In existing facilities a risk based action plan will include addressing the “gimmies” or “low hanging fruit” as well as any major redesign needs 3 This process provides the platform to engage all of the key players in a facility to focus on the “Food Safety” aspect of facility design and maintenance. Non food production areas Factory barrier (2) Basic hygiene area Soiled raw materials, packed ingredients/finished products Medium hygiene area Ingredient preparation General processing High hygiene barrier (3) High hygiene area M icrobiologically decontaminated products, design risk assessed. Sanitary Design and Construction of Food Processing and Handling Facilities 2 and limitation of pest entry into buildings are all part of a successful pest management program Location As with real estate, an important feature of a sanitary food facility is “location, location, location” Ideally, a facility.

Facilitate cleaning and sanitation and preserve hygienic conditions both during and after maintenance. 2 In existing facilities a risk based action plan will include addressing the “gimmies” or “low hanging fruit” as well as any major redesign needs 3 This process provides the platform to engage all of the key players in a facility to focus on the “Food Safety” aspect of facility design and maintenance. Hygienic design of food factories provides an essential overview of hygiene control in the design, construction and renovation of food processing factories Opening chapters consider the business case for hygienic facilities design Hygienic Design of Food Factories Woodhead Publishing Hygienic design of food factories provides an authoritative.

NOTE If the equipment is also intended for use in the processing or packaging of meat and poultry products, review may also be necessary according to the criteria in the standard ANSI/NSF/3A , Hygiene requirements for the design of meat and poultry processing equipment You may contact our meat and poultry equipment. Food safety is vital for consumer confidence and the sanitary design of food processing facilities is central to the manufacture of safe products This book provides an essential overview of hygiene control in the design, construction and renovation of food processing factories Hygienic Design of Food Factories by John Holah. Incorporation of hygienic design into your food processing facility can prevent development of pests and microbiological niches;.

8 Hygienic Design of Maintenance Enclosures Maintenance enclosures and human machine interfaces (HMIs) such as pushbuttons, valve handles, switches and touchscreens must be designed to ensure that product residue or water doesn’t penetrate or accumulate in and on the enclosure or interface. Food Safety Content on Hygienic Equipment Design The Global Food Safety Series meets you where you live!.

Food Processors Must Be Proactive In Sanitary And Hygienic Design 19 10 14 Food Engineering

Hygienic Factory Design For Food Processing Sciencedirect

Hygiene Concepts For Food Factory Design Sciencedirect

Sanitary Facility Design Guidelines Part 2 Of 2

Division Of Plant Products And Beverages Ppt Download

The Hygienic Sanitary Design Of Food And Beverage Processing Equipment Springerlink

Hygienic System Design For Food Processing Facilities Panorama Consulting Engineers India

Cmp Equipment Hygienic Design Specialists Hygienic Design

Hygienic Design Werma Signaltechnik Gmbh

Health And Hygiene Drainage Products For The Food Industry Aco Food

Sanitary Design

Kimberly Clark Professional B L U E Food Processing

Food Processing Equipment Design And Cleanability Flair Flow Europe Technical Manual F Fe 377a 00 Pdf Free Download

How To Design A Hygienic Food Processing Facility

Innovations In Dry Bulk Food Processing And Handling Bulkinside

Sanitary And Hygienic Design Guide For Food Equipment Mpc

Poultry Processing Solutions Rezahygiene Your Partner In Hygiene

Http Link Springer Com Content Pdf 10 1007 2f0 387 9 14 Pdf

Handbook Of Hygienic Design In Dairy Industry 978 3 639 5 By Ceren Zeytinci

Guidelines For The Hygienic Design Construction And Layout Of Food Processing Factories Amazon Com Books

Factors To Consider In Designing Food Processing Equipment

Hygienic Design Of Food Processing Equipment Sciencedirect

Handbook Of Food Factory Design Christopher G J Baker Springer

The Importance Of Good Manufacturing Practices In The Food Industry Foodsafe Drains

Hygiene Design Powder Processing Plants Hvac Heat Exchanger

Pdf Hygienic Standards And Practices In Norwegian Salmon Processing Plants

Skedam Mwgp7wm

Development Of A Layout Model Suitable For The Food Processing Industry

Hygienic Design Of Centrifugal Pumps For The Beverage And Food Processing Industries

Choosing Hygienic Flooring For Your Food And Beverage Facility Food Quality Safety

Sanitary And Hygienic Design Guide For Food Equipment Mpc

Building A Foundation For Food Safety

Principles For Hygienic Design And Zoning Ppt Video Online Download

Combating Foodborne Bacteria With Hygienic Drainage Solutions Aco Food

Pdf Hygienic Design And Microbial Control Of Refrigeration And Air Conditioning Systems For Food Processing And Packaging Plants Alfredo Palop And Fulgencio Marin Iniesta Academia Edu

Modern Plant Design Leaves Room To Grow

Progress In The Hygienic Design Of Food Processing Equipment Food Safety Magazine

Food Processing 10 Ways To Ensure Food Safety Rentokil

Hygiene Concepts For Food Factory Design Sciencedirect

Sofht Focus October 18 By The Society Of Food Hygiene Technology Issuu

Hygienic Design Affi Food Safety Zone

Food And Beverage Webinar When Hygienic Design Matters Youtube

Pdf Many Food Manufacturers Do Not Fully Integrate Hygienic Design Into The Processing Environment

10 Ways Food Processors Can Ensure Food Safety Rentokil

Www Meatinstitute Org Index Php Ht A Getdocumentaction I

5 Key Questions To Answer During Hygienic Food Plant Design Stellar Food For Thought

Hygienic Factory Design For Food Processing Sciencedirect

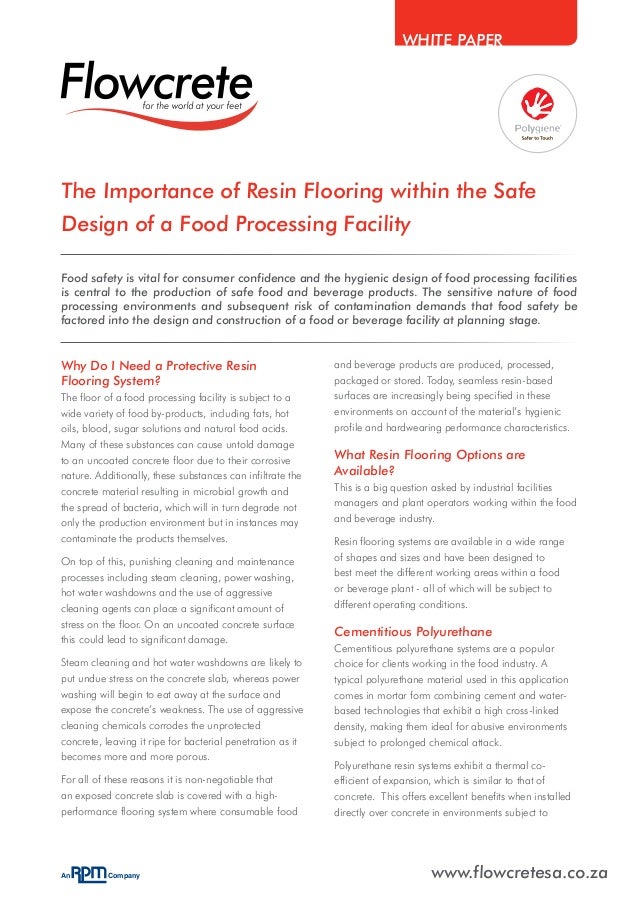

Flowcrete The Importance Of Resin Flooring Within A Food Processing

The Impact Of Factory Layout On Hygiene In Food Factories Sciencedirect

Q Tbn And9gcsetl Ffxs4sj6n68l4ddclvsvct5dv3jxydpxxksq4l 53 M1g Usqp Cau

Handbook Of Hygiene Control In The Food Industry 2nd Edition

Hygiene In Food Processing Principles And Practice Ed 2 Scholarvox International

Food Processors Must Be Proactive In Sanitary And Hygienic Design 19 10 14 Food Engineering

2

Hygienic Design Principles For Food And Beverage Plants Diversey Lithuania

Hygienic Drainage Design Promotes Food Safety Aco Food

Q Tbn And9gcsetl Ffxs4sj6n68l4ddclvsvct5dv3jxydpxxksq4l 53 M1g Usqp Cau

Hygienic Facility Structure Is A Fundamental Requirement For Food Saf

A Clean Slate Use It Wisely 14 12 02 Food Engineering

Food Processing Facility Design And Construction A M King

5 Factors That Matter The Most In Hygienic Equipment Design Profood World

Drainage Management For The Food Beverage Industry Food Beverage Aco Industrial Drainage

Multivac Hygienic Design August 17

Timeline 9 Defining Moments For The Food Processing Industry Stellar Food For Thought

Hygienic Design Of Food Processing Equipment Sciencedirect

Choosing Doors For Food Processing Facilities

Hygienic Design Archives Your Partners In Hygiene

Hygienic Design Of Food Processing Equipment Sciencedirect

Effect Of Hygienic Design And Operational Parameters On Frosting And Defrosting Of Evaporators In Refrigerated Food Processing And Storage Facilities Science Engineering Book Chapter Igi Global

Food Processing Facilities Archives Bakerpedia

Image Result For Food Processing Factory Layout How To Plan Factory Architecture Factory Design

Hygienic Stainless Gearmotor Designs Improve Fish Processing Plant

2

Sanitary And Hygienic Design Guide For Food Equipment Mpc

Equipment Food Safety Quality Assurance Food Safety

Hygienic Zoning For Sanitation Preventive Control Food Science Technology Extension

Www Ifst Org Sites Default Files J holah ifst hygiene 25th february Pdf

When To Use Hygienic Design Vs Washdown Machine Geeks

Food Plant Sanitation Choosing Flooring Walls Ceilings And Doors To Improve Food Safety Stellar Food For Thought

Overview Of Food Processing Equipment Types Applications And Important Attributes

Establishments And Production Demands For Freshwater Fish Processing

Pdf Food Safety From Farm To Fork Food Safety Issues Related To Processing

Food Processors Must Be Proactive In Sanitary And Hygienic Design 19 10 14 Food Engineering

Sanitary Design A Competitive Advantage Food Safety Magazine

Hygienic Design For Processing Equipment Food Quality Safety

Hygienic Design Affi Food Safety Zone

Pdf Hygienic Design Of Food Processing Equipment And Hygienic Practices During Maintenance Operations Marin G Academia Edu

The Importance Of Good Manufacturing Practices In The Food Industry Foodsafe Drains

Hygienic Design Considerations For Food Manufacturing

2

Q Tbn And9gcqttfwpcacdpf 8hbj5g94hzt96omngayn18xvzf5vpilgjjxrd Usqp Cau

Sanitary And Hygienic Design Guide For Food Equipment Mpc

The Hygienic Sanitary Design Of Food And Beverage Processing Equipment Springerlink

Sanitary Facility Design Guidelines Part 2 Of 2

10 Easy Improvements For A More Sanitary Processing Plant Impo

Hygienic Design Of Food Factories 1st Edition

Food Processors Must Be Proactive In Sanitary And Hygienic Design 19 10 14 Food Engineering

Hygienic Factory Design For Food Processing Sciencedirect