Atex Zone 1 Vs Class 1 Div 1

Atex Overview

Comparing Atex And Ex Proof Classifications Hanningfield

Http Www Iecex Com Assets Uploads D1s4a Implementation Ei Installation In Haz Area Classification Phe Onwj Pdf

Nec Iec Atex A Guide To Intrinsically Safe Handhelds

Atex Explained Lgm Products

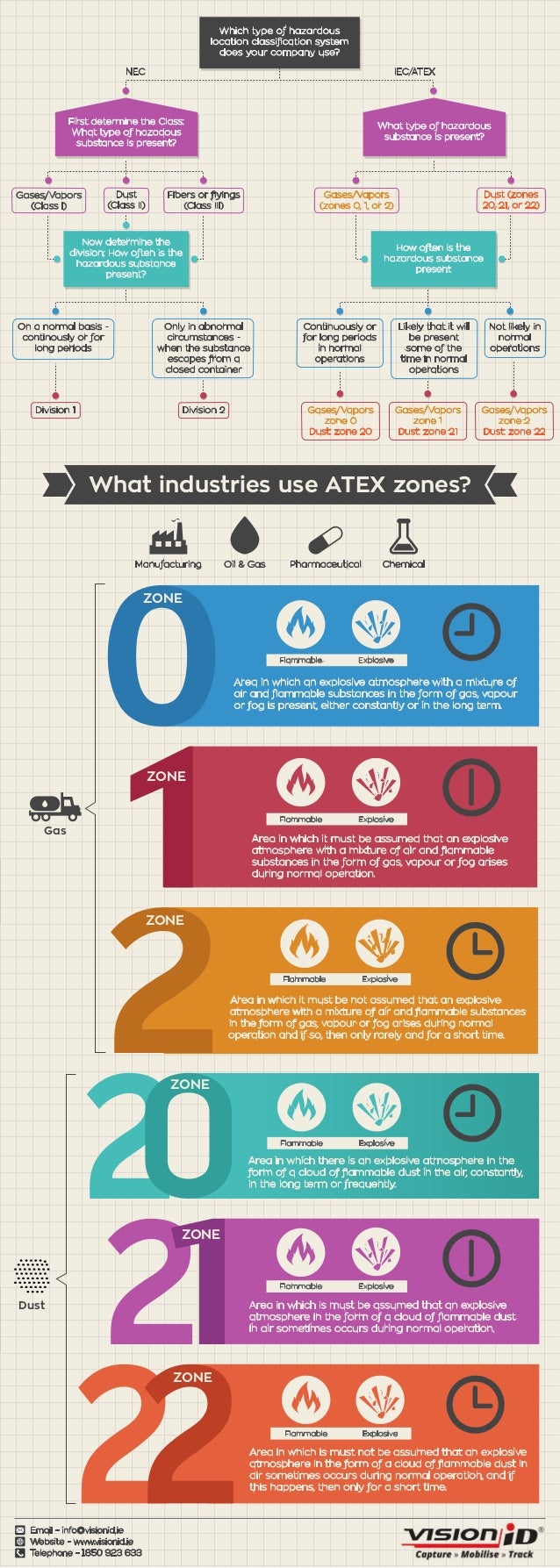

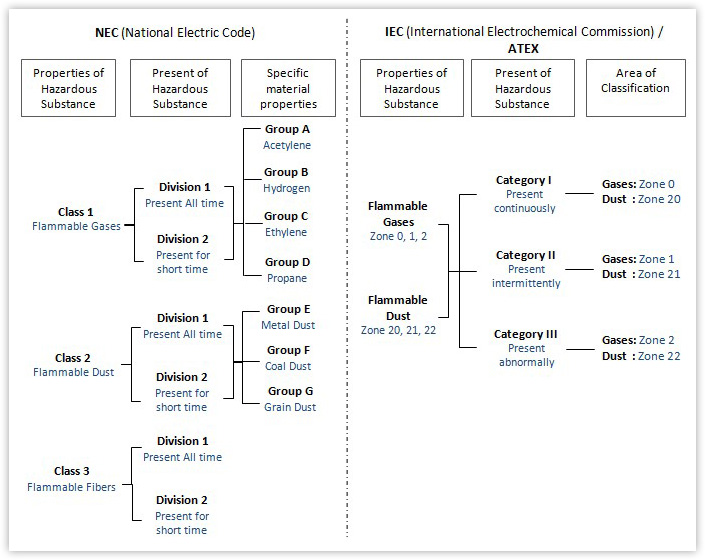

Hazardous Location Classification Guide Nec Vs Iec

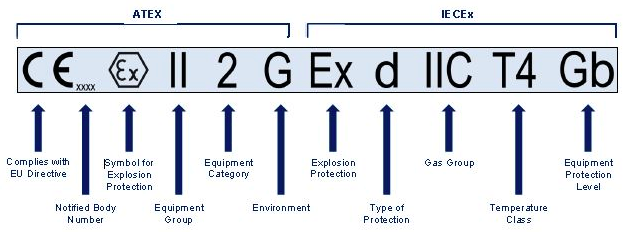

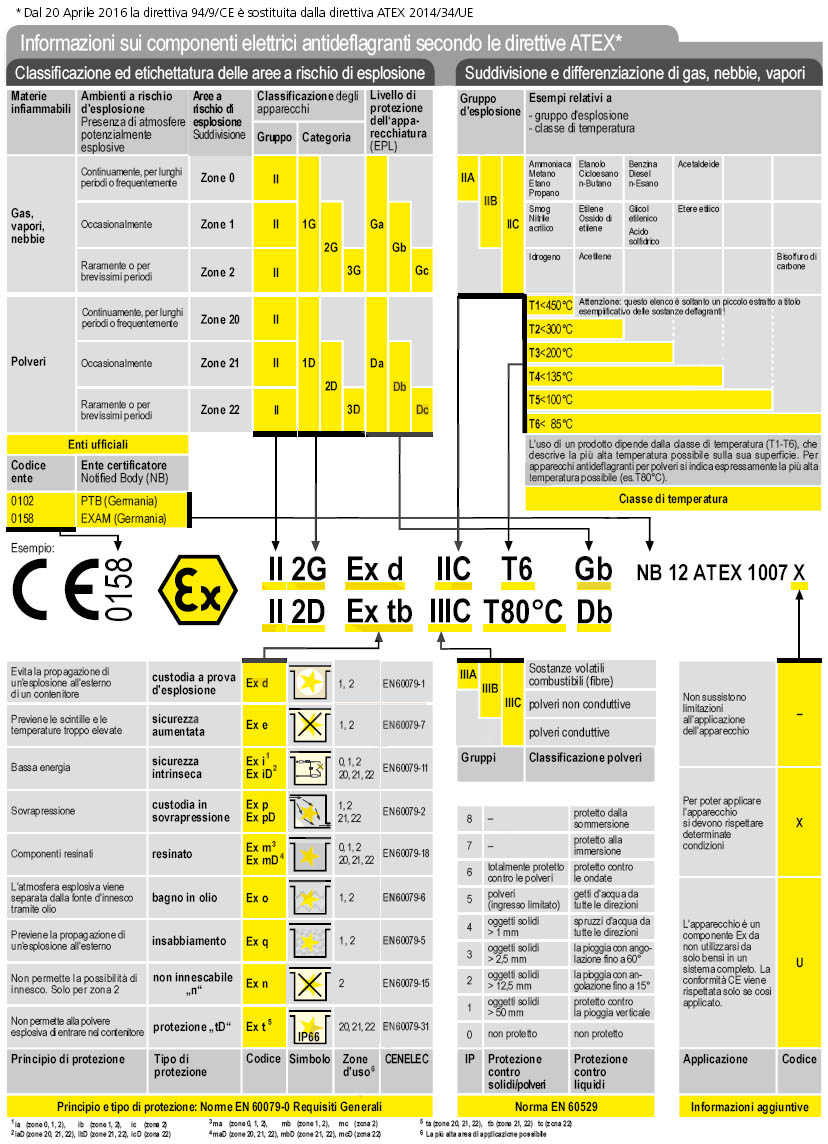

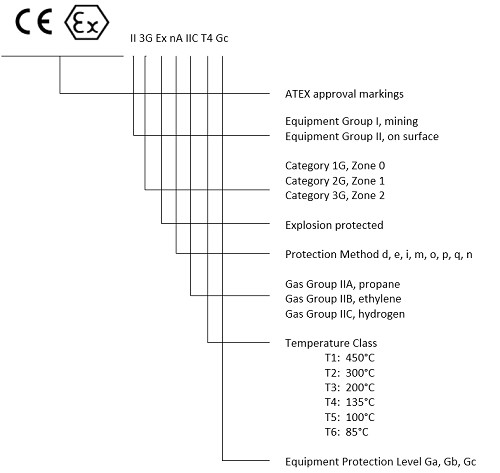

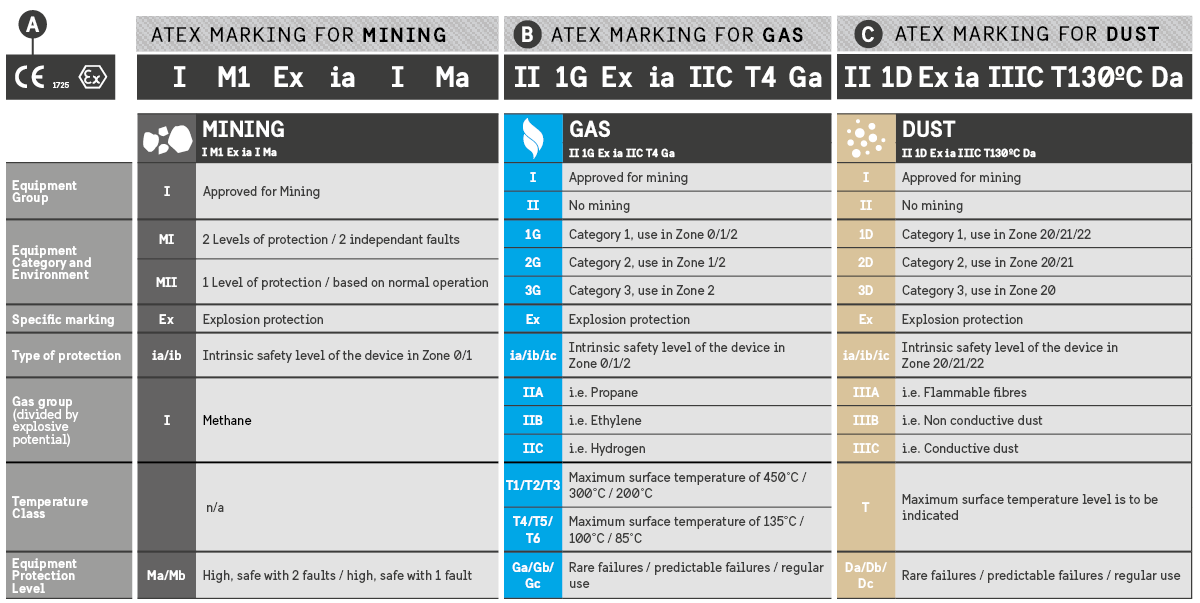

1 G Ga Equip suitable for Zones 0,1,2 1 D Da Equip suitable for Zones ,21,22 1 A place in which an explosive atmosphere is likely to occur in normal operation occasionally 2 G Gb Equip suitable for Zones 1,2 21 2 D Db Equip suitable for Zones 21,22 2 A place in which an explosive atmosphere is not likely to occur in normal operation,.

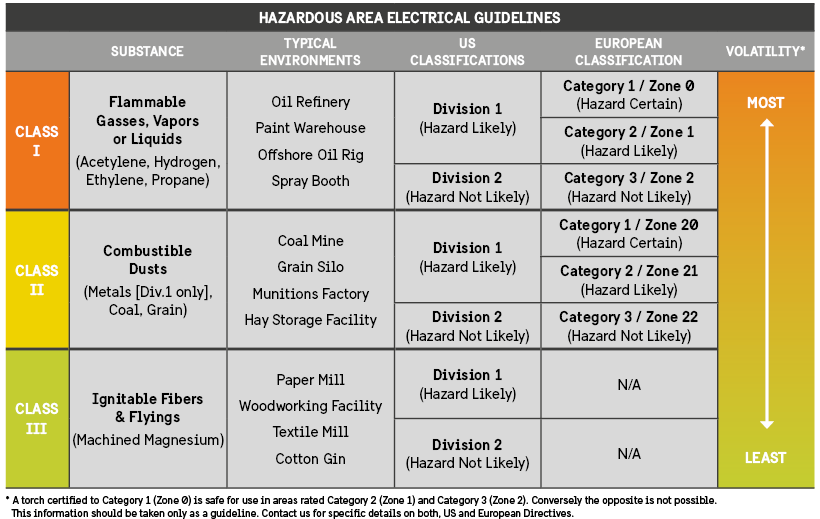

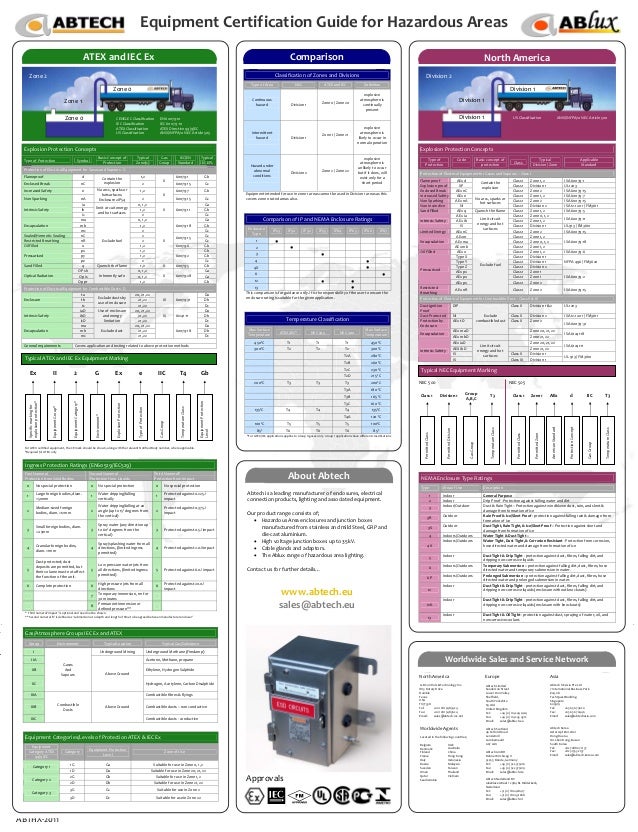

Atex zone 1 vs class 1 div 1. Running the widely used Windows operating system and certified under the highest standards of safety for some of the most explosive conditions, ATEX/IECEx Zone 1 and UL913 Class 1 Division 1, this tablet is designed to be part of a fully integrated platform that is the preferred solution for mobilizing the world’s most hazardous industries. ATEX Zone ATEX Zone 1/21 & M2 Mining CSA Class 1, Division 1 Android 60 BETA / 4G LTE & WLAN. Zone (dusts) Class II Division 1 (dusts) Zone 1 (gases) An area in which an explosive mixture is likely to occur in normal operation Class I Division 1 (gases) Zone 21 (dusts) Class II Division 1 (dusts) Zone 2 (gases) An area in which an explosive mixture is not likely to occur in normal operation and if it occurs it will exist only for a.

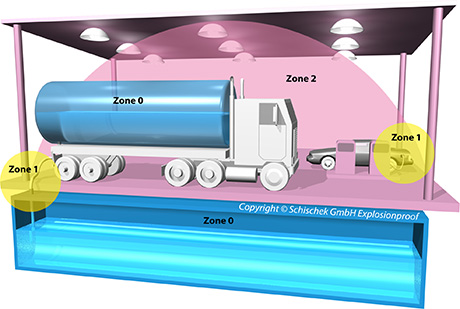

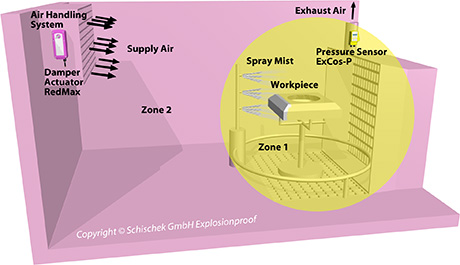

A good example of an ATEX Zone 1 or ATEX Zone 2 classified operation would be a chemical or petrochemical plant, where there is a heightened risk for explosion during the course of normal day to day operations Within a hazardous gas environment an explosion can take place if a flammable substance, an oxidiser and a source of ignition are found. Our SmartEx® 01 is an intrinsically safe smartphone with LTE, WiFi and Android 51 that is approved for use in Zone 1 (ATEX/IECEx) and Div 1 (NEC) You can order a demo kit or get in contact with our support to request an individual quote. Regarding ATEX 99/92/EC Directive, the requirement is that Employers must classify areas where potentially explosive atmospheres may occur, into zones The classification given to a particular zone, and its size and location, depends on the likelihood of an explosive atmosphere occurring and its persistence if it does.

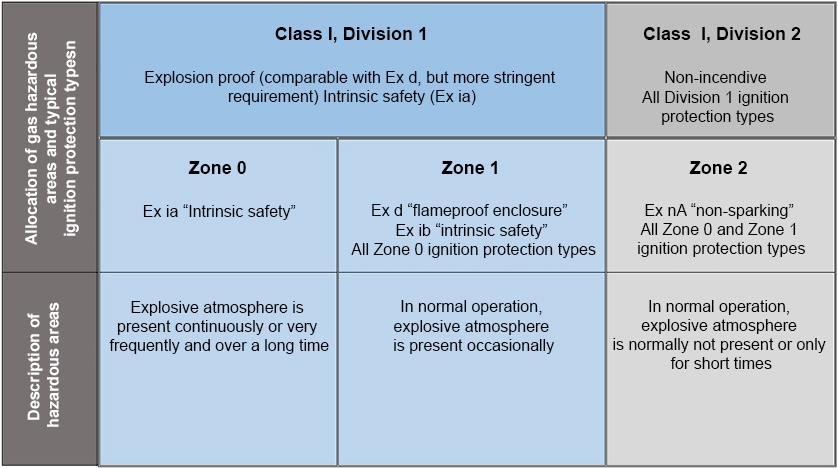

Location is considered lower The Division system tends to be less specific in its consideration of Division 1 The Division system treats all areas where a hazard is expected to occur in normal operation the same The following chart illustrates the differences between the various Zones Class I, Division 1 Risk Risk Division 1 Duration of. Hazardous area working has never been easier The IS9101 with Qualcomm 2GHz Snapdragon 625 processor, 4G LTE and WLAN enables greater efficiency and mobile working across your remote and industrial engineering baseIncreases productivity, and allows companies to utilise the latest mobile applications across the business, connecting the field to the office. Use any wireless technology Choose the latest AC access points from market leaders like Cisco, Aruba, Siemens and more – make the most of their MIMO functionality for high performance WiFi, even in metallic process environments.

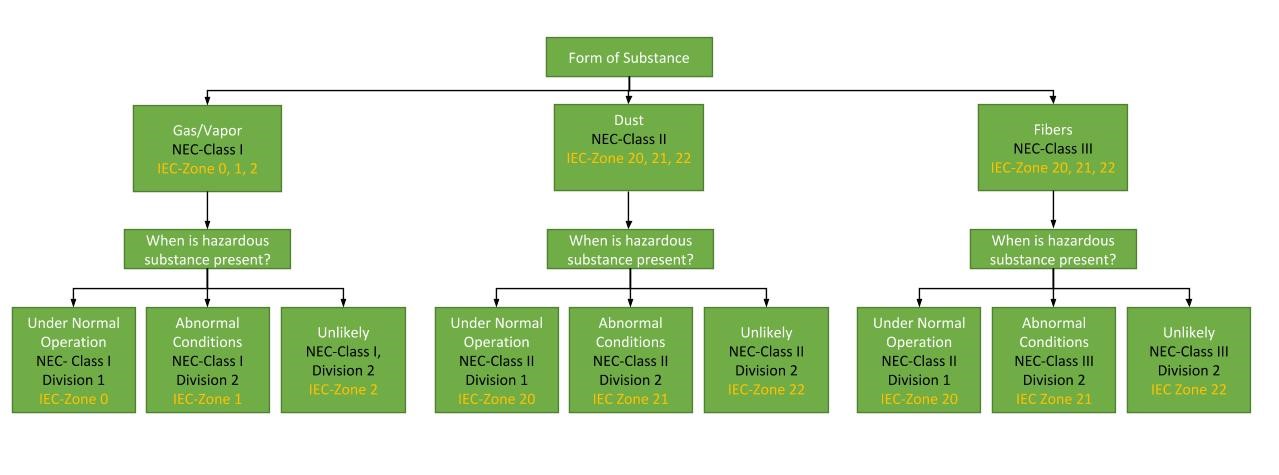

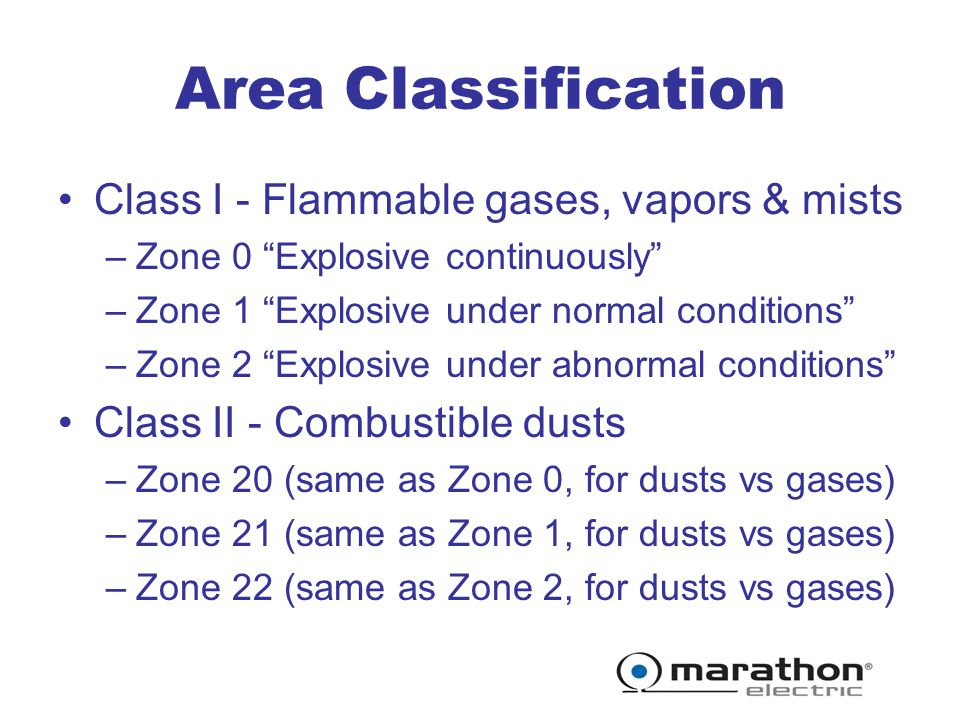

Zone 0, 1 & 2 Locations that would be considered to be Class I include Petroleum Refineries, Gasoline Storage Areas, Dry Cleaning Plants, Spray Finishing. In Canada, all new installations must use the 3 Zone system Existing installations may continue to use the 2 Division system or opt to reclassify using the 3 Zone system In the US, all installations (both new and existing) can either continue using the 2 Division system or reclassify using the 3 Zone system. Explosive gases, vapors and mists of Class I are subdivided into the gas groups A, B, C and D;.

Group IIC, IIB, IIA, I The “Ex Hexagon” mark United Kingdom and Europe Safety Standards Intrinsically safe devices covered by the ATEX Directive can be separated into two distinct options notably “Ex ia” and “Ex ib” devices Devices with the former designation are designed to be safe even after a second order failure. Explosive gases, vapors and mists of Class I are subdivided into the gas groups A, B, C and D;. Class I locations consist of areas where gases, vapors or liquids may exist that have the potential to become flammable or ignitable There are two different divisions that exist in Class I, Division 1 and Division 2, along with three Zones;.

So is it going to Class 1 Div 2, ATEX or IECEx for the next project?. “The product is suitable for use in Zone 1, as well as for use in Class 1, Div 1” This statement is heard or read again and again in the descriptions for products for use in hazardous areas (ATEX) directive, describes, among other things, the ignition protection types for electrical equipment as well as the evaluation or. 1, 2 3 G 2 D is added after G in the certification class number D = dust (ie GD) if device is dust category approved also 1 D , 21, 22 2 D 21, 22 BACK TO TOP 3 D 22 Explanation of the categories 1 Very high safety = device safety must be guaranteed even in case of rare device failures, eg simultaneous failure of.

And if they are in hazardous areas then they need to be Class 1 Division 1 or 2 rated ATEX 1 or 2 rated but for more information and product updates, this will be a very hot item and it’s transforming the way maybe facility inspections and hazards will be identified using maybe AI machine learning. Class I Div 1 or 2 – Combustible Dusts Class II Div 1 or 2 – Fiber & Flyings Class III Div 1 & 2 Zone System – Gases, Mists & Vapors Only – Zone 0, 1 or 2 Note The majority of Areas Classified in North America are Class and Division. General Requirements US Class I, Division 1 & 2 FM 3600 CA Class I, Division 1 & 2 CSA C222 No 0 AEx US Class I, Zone 0, 1 & 2 ANSI/UL Ex CA Zone 0, 1, & 2 CSA C222 No Ex EU Category 1G, 2G, & 3G EN IEC Ex IEC EPL Ga, Gb, Gc IEC Increased Safety AEx eb (or AEx e) US Class I, Zone 1 ANSI/UL No arcs,.

Group IIC, IIB, IIA, I The “Ex Hexagon” mark United Kingdom and Europe Safety Standards Intrinsically safe devices covered by the ATEX Directive can be separated into two distinct options notably “Ex ia” and “Ex ib” devices Devices with the former designation are designed to be safe even after a second order failure. E2x nonsparking devices now for Class I & II Division 2 and Zone 2, 22 applications;. Browse all Zone 1 Division 1 Hazardous Area Products The Zone 1 hazardous rating is used in Canada, Europe and by the international community as a standard to describe the type of hazardous environment that the electrical equipment can operate safely and properly within It is equivalent to the Division 1 classification for North America.

Zone 0, 1, 2;. A (propane), B (ethylene) and C (Acetylene and Hydrogen), are used to define Group II hazardous area characteristics For a particular zone and group a specific equipment category and protection concept are required. Zone (dusts) Class II Division 1 (dusts) Zone 1 (gases) An area in which an explosive mixture is likely to occur in normal operation Class I Division 1 (gases) Zone 21 (dusts) Class II Division 1 (dusts) Zone 2 (gases) An area in which an explosive mixture is not likely to occur in normal operation and if it occurs it will exist only for a.

DIVISION 1 The danger may be present during normal plant operation DIVISION 2 The danger may be present only in case of failure The most obvious difference between the European and American practice is the lack of presence of a division equivalent to Zone 0 This comes from a more pragmatic and less philosophizing view of Americans. Class I, Division 1 is further subdivided into Zone 0 and Zone 1 under the Zone classification system Zone 0 defines those locations in which an explosive gasair mixture is present continuously or for long periods during normal operation An example of this would be the vapor space of a closed, but vented, process vessel or storage tank. Hazardous Location Hole Seals are designed to be used on Increased Safety (Ex e) enclosures in ATEX or IECEx Zone 1 or 2 hazardous areas Certified to be used on metallic, nonpainted enclosures, these hole seals are made with a robust Type 316 stainless steel formed outer plate and a silicone rubber gasket to ensure a dust, oil and water.

Explosion Proof Gauges, Class 1, Div 1, ATEX Certificate Maximum Working Pressure Complete Enclosure with Sensor 1/4" NPT standard, 1/2" NPT optional Replacement Sensor Only Performance Specifications Catalog Page $1404 $1309 $1309 $1416 $1416 $1416 $1135 $1034. Whereas the rest of the world generally uses the Zone system However, the United States and Canada are trending more towards the Zone System Class/Division System Hazardous locations per the Class/Division system are classified according to the Class, Division, and Group 1 Class—The Class defines the general nature (or properties) of the. 1) MESG (Maximum Experimental Safe Gap) The maximum clearance between two parallel metal surfaces that has been found under specified test conditions to prevent an explosion in a test chamber from being propagated to a secondary chamber containing the same gas or vapor at the same concentration 2) MIC (Minimum Igniting Current) Ratio The ratio of the minimum current required from an.

D1xB2 range Class I & II Division 1 , Zone 1 & 21 Xenon strobes and LED beacons. Working Safely in ATEX Zone 1 and Class I, Div 1 With ExHandy 08 Read full article February 4, 14, 600 AM. Since the changes to the code, hazardous locations with gases or vapors (Class I) present can be reclassified as Zone 0, 1 or 2 When comparing Divisions and Zones, Division 2 is equivalent to Zone 2, but Division 1 is equivalent to either Zone 0 or 1 The key difference between Divisions and Zones relate to terminations.

US & Canada Class I Div 1 / Zone 1 and 21 certified;. Similar to divisions, “zones” (0, 1 or 2) and gas groups;. Zone 0, 1 & 2 Locations that would be considered to be Class I include Petroleum Refineries, Gasoline Storage Areas, Dry Cleaning Plants, Spray Finishing.

Class 1/Div 2 ATEX Zone 2 Panel PCs;. Understanding the NEC Hazardous Location Option Class 1, Div 2, Groups A, B, C, and D, for Enclosure Cooling Systems Posted on August , September 17, by Barry Slotnick When you are working with hazardous materials, it is important to know exactly how the materials and compounds are classified. Digital Signage We specialize in providing computing solutions for hazardous locations including phones and tablets which are rated for ATEX Zone 1/21 & DIV 1 areas See How We Can Help RUGGED.

1, 2 3 G 2 D is added after G in the certification class number D = dust (ie GD) if device is dust category approved also 1 D , 21, 22 2 D 21, 22 BACK TO TOP 3 D 22 Explanation of the categories 1 Very high safety = device safety must be guaranteed even in case of rare device failures, eg simultaneous failure of. Class III hazardous because ignitable fibers or flying's are present, but not likely to be in suspension in sufficient quantities to produce ignitable mixtures Division (probability of material being present) Division 1 the substance referred to by class is present during normal conditions Division 2. E2x nonsparking devices now for Class I & II Division 2 and Zone 2, 22 applications;.

D1x range Class I and II Div 1,Zone 1 explosion proof signals;. Enclosures & Junction Boxes Zone 1 (21) and Zone 2 (22) hazardous area enclosures for instrumentation, small power or lighting applications – stainless steel, mild steel, glass reinforced polyester, aluminium and polycarbonate certified according to ATEX and IECEx Also high voltage junction boxes for jointing, terminating and connecting 33kV, 66kV, 11kV and 33kV power cables in Zone 2. The Zones are decided by the site based on a risk assessment of the likelihood of a potentially explosive atmosphere being present Zone 0 for gas, for dust or a Category 1 rating means that the risk is continually present and a very high Protection Level is required.

Personnel in multiple zones of hazardous locations, helping them harness the power of their data to optimize efficiency, safety and productivity 101” WUXGA Display Powered by Intel Atom Quad Core Windows 10 Intel Security Suite ATEX IECEx Zone 1 UL913 Class I, II, III Div 1 aegexcom y t aegex10 Intrinsically Safe Tablet AEGMDS. Class III – Contains easily ignitable fibres or flyings in the air However, the quantities of fibres and flyings suspended in the air are not likely to be large enough to cause an explosion Group designations further define the types of gases, and dusts Example of an American certification would be Class 1, Div I A, B and C Div II E, F and G. Class I locations consist of areas where gases, vapors or liquids may exist that have the potential to become flammable or ignitable There are two different divisions that exist in Class I, Division 1 and Division 2, along with three Zones;.

Flammable dusts of Class II into the groups E, F and G Depending on the frequency or duration of occurrence of these materials, the hazardous locations are divided into socalled divisions Division 1 corresponds to Zones 0 and 1 and Division 2 to. T Class Ratings Hazardous Areas Temperature Classifications are given to hazardous area Temperature Class Ratings (also known as Tratings or TClass) and are applied to hazardous area zones and electrical equipment – T Class Ratings are utilised for all hazardous areas and explosion protection methods This helps the user to quantify the level of thermal energy allowed in the hazardous. Intrinsically Safe Mobile Computing;.

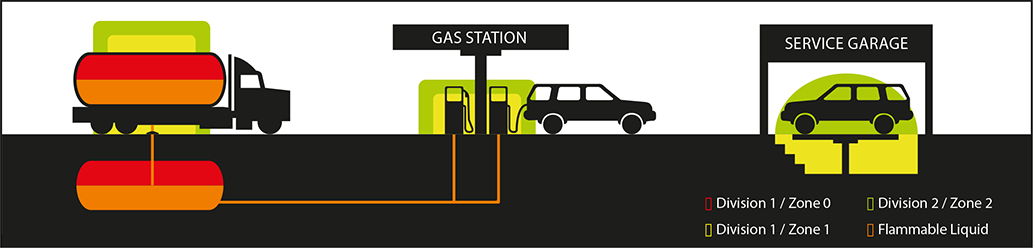

A good example of an ATEX Zone 1 or ATEX Zone 2 classified operation would be a chemical or petrochemical plant, where there is a heightened risk for explosion during the course of normal day to day operations Within a hazardous gas environment an explosion can take place if a flammable substance, an oxidiser and a source of ignition are found. Div 1 Zone 1 Div 1 Zone 0 Flammable Liquid or Dust Div 2 Zone 2 mexico Hoffman Enclosures Mexico, S de R L de C V Arquimedes No 33 Piso 1 Col Palmas Polanco Mexico, DF CP Tel (55) Fax (55) / COMPARING DIVISIONS, ZONES, & CATEGORIES Frequency of Occurrence CEC, NEC Editions Division System Zone System. Regarding ATEX 99/92/EC Directive, the requirement is that Employers must classify areas where potentially explosive atmospheres may occur, into zones The classification given to a particular zone, and its size and location, depends on the likelihood of an explosive atmosphere occurring and its persistence if it does.

Additionally, we can provide a specialized selection of custom electric motors suitable for operation in Division 1, Class A or B hydrogenrich or equivalent hazardous environments These custom electric motors are available in all NEMA frame sizes, from ¼to100 horsepower, and in foot and flange mountings. D1xB2 range Class I & II Division 1 , Zone 1 & 21 Xenon strobes and LED beacons. Zone 21 – Ignitable concentrations of combustible dust or ignitable fibers/flyings are likely to exist occasionally under normal operating conditions Zone 22 – Ignitable concentrations of combustible dust or ignitable fibers/flyings are not likely to occur under normal operating conditions Groups – Class I, Zone 0, 1 and 2.

Zone 0, 1, 2;. Don’t worry as PULS’s CPS241 and QS are. Zone 21 – Ignitable concentrations of combustible dust or ignitable fibers/flyings are likely to exist occasionally under normal operating conditions Zone 22 – Ignitable concentrations of combustible dust or ignitable fibers/flyings are not likely to occur under normal operating conditions Groups – Class I, Zone 0, 1 and 2.

Class 1/Div 2 ATEX Zone 2 Monitors;. Zone Definition Equipment Category Protection Method Zone 0 Class 1 Division 1 Zone Class 2 Division 1 Explosive atmosphere is present continuously, for long periods or frequently ( hours per year) 1 Equipment must be safe under normal operation, expected and rare malfunction Zone 1 Class 1 Division 1 Zone 21 Class 2. Working Safely in ATEX Zone 1 and Class I, Div 1 With ExHandy 08 Read full article February 4, 14, 600 AM.

D1x range Class I and II Div 1,Zone 1 explosion proof signals;. Zone 1 classified location An area where ignitable concentrations of flammable gases, vapors or liquids are likely to exist under normal operating conditions As a guide for Zone 1, this can be defined as 10–1000 hours/year or 01–10% of the time Class I, Division 2 or Zone 2 classified locations. Class 1 / Division 1 ATEX Zone 1 Orange Zone Class 1 / Division 2 ATEX Zone 2 Yellow Zone Industrial Computing for Class 1 / Division 2 and ATEX Zone 2 Where embedded electrical products are concerned, the requirement for harsh environment industries such as oil and gas will usually be certification to Class 1 / Division 2 and/or ATEX Zone 2.

1 G Ga Equip suitable for Zones 0,1,2 1 D Da Equip suitable for Zones ,21,22 1 A place in which an explosive atmosphere is likely to occur in normal operation occasionally 2 G Gb Equip suitable for Zones 1,2 21 2 D Db Equip suitable for Zones 21,22 2 A place in which an explosive atmosphere is not likely to occur in normal operation,. Class I, Zone 1 Class I, Zone 1 Zone 1 Druckfeste Kapselung AEx d Ex d Ex d XP XP USA Kanada IEC USA Zone 21 Class II, Div 1 Class II, Div 2 Explosionsgeschützte elektrische Kennzeichnung nach ATEX Einsatzbereich/Zone ExKennzeichnung nach Richtline 94/9/EG Kennnummer der benannten Stelle E n d r e ss H a u s e r. ATEX Zone ATEX Zone 1/21 & M2 Mining CSA Class 1, Division 1 Android 60 BETA / 4G LTE & WLAN.

ATEX & IECEx Zone 1 and 21 certified;. A When comparing Divisions and Zones, Division 2 is equivalent to Zone 2, but Division 1 is equivalent to either Zone 0 or 1 Sources 29 CFR – Hazardous (classified) Locations. D2x range A truly global product range for hazardous locations;.

Now I have an instrument that is designated just as "CSA approved for Class II, Div 1 & 2, Groups E,F, and G" (no refernce to ATEX) So I understand that this instrument can be used in a "Class II Div 1&2" zone, but it does not say anything about the "Protection Method", so I don't know if I need to use a Barrier to feed the instrument. Classification in “Zone” similar to ATEX;. Our CSA Class 1 Division 2 (ATEX Class 1 Zone 2) meters, gauges and controllers are approved for use in environments where ignitable gases are present The inherently low power consumption of Alicat instruments allows for monitoring of flow and pressure in hazardous environments without losing critical features like our multiparameter display.

Zones 1 & 2 EExo EN Zones 1 & 2 Exo IEC Class 1 Division 2 UL698 Powder Filling – Equipment is surrounded with a fine powder, such as quartz, which does not allow the surrounding atmosphere to come into contact with any sparks or hot surfaces Zones 1 & 2 EExq EN Zones 1 & 2 Exq IEC. Class 1/Div 2 ATEX Zone 2 Computers;. Standards IEC xx (harmonized standards) 24V/A and 24V/40A Single Phase Input Power Supply that conform to Class 1 Div 2, ATEX and IECEx Hazardous Location approvals!.

Enclosures & Junction Boxes Zone 1 (21) and Zone 2 (22) hazardous area enclosures for instrumentation, small power or lighting applications – stainless steel, mild steel, glass reinforced polyester, aluminium and polycarbonate certified according to ATEX and IECEx Also high voltage junction boxes for jointing, terminating and connecting 33kV, 66kV, 11kV and 33kV power cables in Zone 2. Flammable dusts of Class II into the groups E, F and G Depending on the frequency or duration of occurrence of these materials, the hazardous locations are divided into socalled divisions Division 1 corresponds to Zones 0 and 1 and Division 2 to. • IECEx Ex 1a IIC, T4, Class 1 DIV 1&2, Zone 0/1/2 • Cree XPG2 LED, 133 Lumens • Mining flashlight (ATEX / IECEx approved) • Air free heat sink to enhance LED heat dissipation • Stainless belt/pocket clip • Valve design for hydrogen gas release • Battery carriage with a foolproof mechanism • IP67, Flameproof accessories available.

Atex Catalog Peli

Ul Class 1 Division 2 Atex Zone 2 Industrial Monitor Display Ais

Electrical Equipment In Hazardous Areas Wikipedia

Intrinsically Safe Samsung Galaxy S10 Case Atex Zone 1

Hazardous Location Areas And Explosion Proof Vehicles Certifications

Standards And Regulations Ex Zones Atex Iecex

Explosion Proof Classification Divisions Zones Of A Spray Room And A Filling Station Explosion Groups Temperature Classes Fire Protection

Nec Vs Atex Iecex In 5 Rounds From A Cost Perspective

6 79 211 210 March15presentation

Hazardous Areas Hazardous Area Zones Guide Explanation Definitions

What Is Atex Zone 1 2 21 And 22 Hoist Uk

We Offer Pad Ex 01 With Atex Iecex Zone 2 22 And Nec Cec Division 2 To Enter The Market As Quickly As Possible Product Launch Dec 16 We Offer First Nec Cec Certification This Division 2 Variant Unmodified From Durabook Comes With A

Electrical Equipment In Hazardous Areas Wikipedia

Atex Enclosures Index Hazardous Area Information

China Class I Division 1 Zone 1 100w Atex Led Explosion Proof Flood Light China Atex Led Flood Light 100w Explosion Proof Flood Light

Caution With Zone 1 Ratings The United States Certifigroup

Explosion Proof Anti Static Vacuums Hafcovac

Making Sense Of Intrinsic Safety And Intrinsically Safe Tools Pdf Free Download

Ul And C Ul Hazardous Areas Certification For North America Ul

Ul And C Ul Hazardous Areas Certification For North America Ul

Ul Class 1 Division 2 Atex Zone 2 Industrial Monitor Display Ais

Hazardous Location Classification

Atex Zone 2 Hazardous Duty Motors Ppt Video Online Download

Intrinsically Safe Knowledge Base Intrinsically Safe Store

Led Lighting Fixtures For Use In Hazardous Areas Airfal

Lightweight Zone 1 Pc And Ddu Drillers Display Unit 470 Z1 Pc Is Small Tough Smart

Unilite Atex Ra2 Led Atex Zone 0 Right Angle Torch 350 Lumen 4 X Discount Home Lighting

Atex Ipad 9 7 Atexxo Manufacturing

Atex Hazloc Headlamps Petzl Other Professional

Zone1 Division1 Tablets Airacom Push To Talk Unified Communications

Hazardous Areas Hazardous Area Zones Guide Explanation Definitions

6 79 211 210 March15presentation

Identifying Zone 0 Zone 1 And Zone 2 Hazardous Areas Raytec Led Blog

Explosion Proof Classification Divisions Zones Of A Spray Room And A Filling Station Explosion Groups Temperature Classes Fire Protection

Hazardous Areas Hazardous Area Zones Guide Explanation Definitions

Overview Of Hazardous Areas Expo Technologies

Understanding Atex Technical Specifications

Intrinsically Safe Iphone 8 Case Class 1 Division 2 Atex Zone 2 Youtube

Class 1 Division 2 And Atex Zone 2 Explained

What Does Hazloc Mean Free Hazloc Area Classification Diagram Get Rugged

Http Www Iecex Com Assets Uploads D1s4a Implementation Ei Installation In Haz Area Classification Phe Onwj Pdf

Zone2 Division2 Smartphones Airacom Push To Talk Unified Communications

Zone 2 Definition What Is Zone 2 Hazardous Area Atex 1999 92 Ec

Frequently Asked Questions Atex Ecoquip Blasting Equipment Graco

Standards And Regulations Ex Zones Atex Iecex

Literature Rockwellautomation Com Idc Groups Literature Documents Wp 800 Wp003 En P Pdf

Classificazione Zone Aree Atex

Q Tbn And9gct4twrojxudqbpsrtcglcpohwinfglw Tkly28gq A Usqp Cau

Atex Zone 0 Classification

Http Www Iecex Com Assets Uploads D1s4a Implementation Ei Installation In Haz Area Classification Phe Onwj Pdf

Ex80 Getac

.jpg)

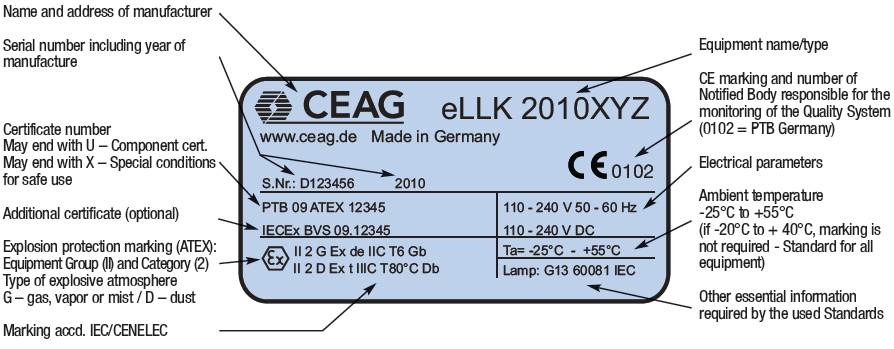

Atex And Iecex Markings How To Decode And Understand Them

Unilite Atex H2 Led Atex Zone 0 Headlight Torch 225 Lumen 3 X a Discount Home Lighting

Intrinsically Safe Beacon Iot Class 1 Division 2 Atex Zone 2 Youtube

T Ex 1 0 Zone 1 Tablet For Windows 10

Explosive Atmospheres Atex Sertec S R L

Overview Of Hazardous Areas Expo Technologies

Hazardous Area Equipment Certification Atex Zone 1 Zone 2 Iec Ex

Aegex 10 Atex Zone 1 And 2 Windows 10 Rugged Tablet

Explosion Proof Classification Divisions Zones Of A Spray Room And A Filling Station Explosion Groups Temperature Classes Fire Protection

Q Tbn And9gct4twrojxudqbpsrtcglcpohwinfglw Tkly28gq A Usqp Cau

Class I Division 2 Atex Zone 2 Hazardous Locations Areas Hmi Ais

Comparison Table Peli Catalogue

Nec Vs Atex Iecex In 5 Rounds From A Cost Perspective

China Class 1 Div 2 Zone 1 Zone 2 Atex Led Explosion Proof Light 50w 0w China Explosion Proof Light Explosion Proof

Is 655 2 Atex Atex Instrinically Safe Zone Tablet Cctv Computer Camera Certified Hazardous Buy Hmt 1z1 Hands Free Head Mounted Tablet Atex Zone 1 21 Online

Q Tbn And9gcsgx8hdmfxqnypnehlarozqgrm2ql4bjbhyxizflcrpltv Usqp Cau

Prs Process Reliability Solutions Exloc Instruments

Expc 1519 Atex Zone 2 Panel Computer Moxa

6 79 211 210 March15presentation

Overview Of Hazardous Areas Expo Technologies

Atex Zone Classification

Ais Hazardous Area Hmis Drive Refinery Performance And Reliability While Reducing Maintenance And Regulatory Compliance Costs Business Wire

Zone1 Division1 Tablets Airacom Push To Talk Unified Communications

Www Festo Com Rep Ru Uk Ua Assets Pdf Ua Atex Pdf

Class 1 Division 2 And Atex Zone 2 Explained

Understanding Atex Zones

Atex Certification And Equivalent United States Designations Sensidyne

Cables For Use In Atex Or Iec Applications For Zone 1 And Zone 2 Cable Electrical Engineering

Unilite Atex H2 Zone 0 Led Head Torch 225 Lumen Ai Workwear

1

Explosion Proof Nema 4 Nema 4x Enclosures Class 1 Div 2 Enclosure Protection Nema Enclosures

Hazardous Zones Atex Peli

Hazardous Areas Iec And Nec Cec Comparison

Industrial Rf Antennas For Hazardous Areas

Intermec Solutions For Hazardous Environments Ck32is Ppt Download

Hazardous Locations Cable Glands Iecex Atex North American Glands

China Led Light Explosion Proof Light 40w 50w 080w 100w 150w With Atex Ul Certificates Class 1 Division 2 Explosion Proof Floodlight Npt3 4 Pipe Brackets Mounting China Led Flood Light Led Light

Prs Process Reliability Solutions Exloc Instruments Revised

Stac6 Q H Advanced Step Motor Drive For Hazardous Locations Applied Motion

Hazardous Locations How To Provide Explosion Protection And Create Intrinsically Safe Systems Ni

Intrinsically Safe Wearable Realwear Hmt Class 1 Division 1 Atex Zone 1 Youtube

Bartec Pixavi Zone 1 Vs Zone 2 Hazardous Areas

Class I Division 1 Products Hazardous Area Locations

Atex Guardian Telecom

The Difference Between The Zone And Division Model Wika Blog

Atex Catalog Peli

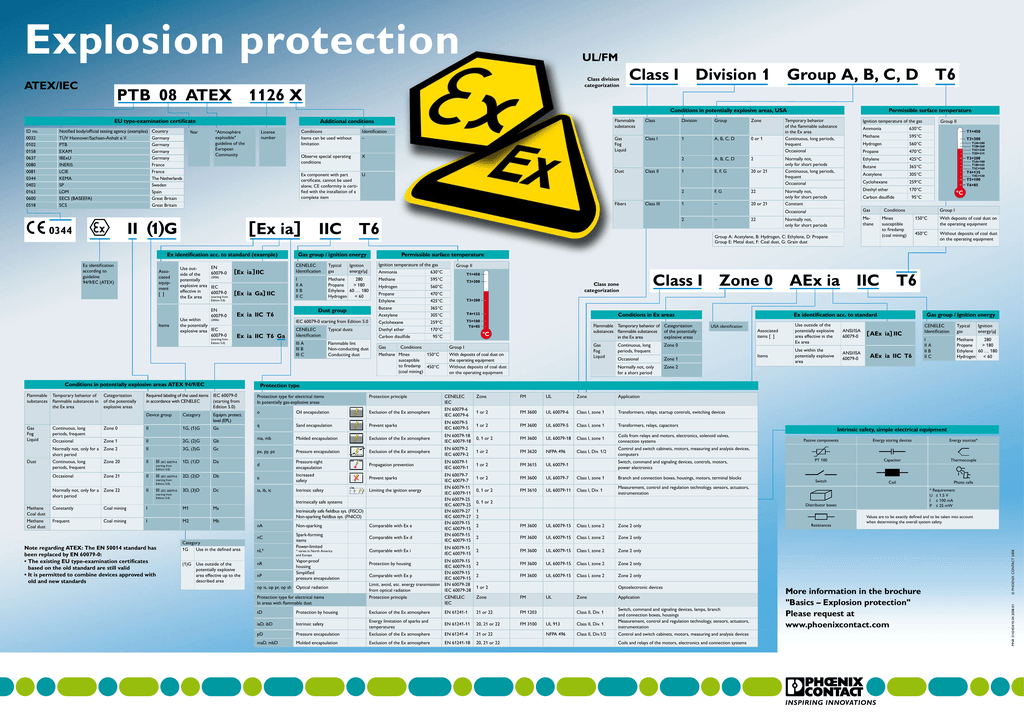

Ptb 08 Atex 1126 Xx Ii 1 G Class I Division 1