Hygienic Design Of Food Processing Equipment Ppt

Workplace Sanitation Food Safety Sanitation And Personal Hygiene

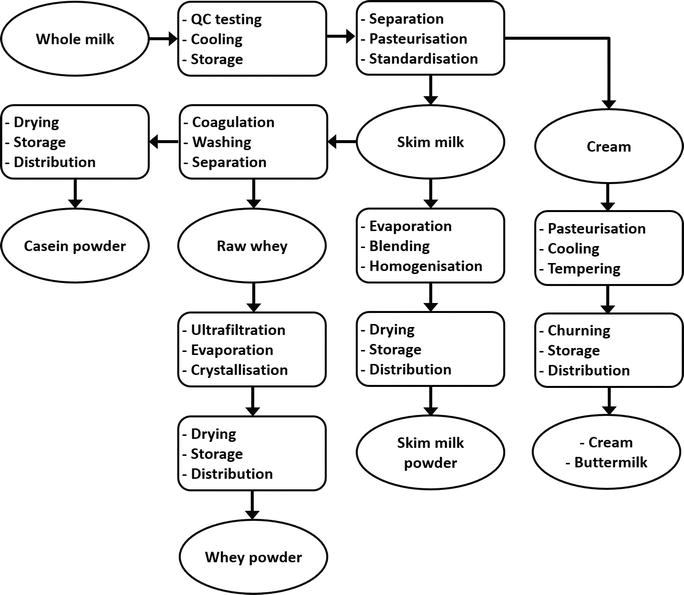

The Dairy Industry Process Monitoring Standards And Quality Intechopen

Food Processing Wikipedia

Food Safety Resume Samples Velvet Jobs

Sanitary Design An Introduction To Standards Of Design Excellence Nov

The Basics Of Cleaning And Sanitation In Food Plants 01 15 Food Engineering

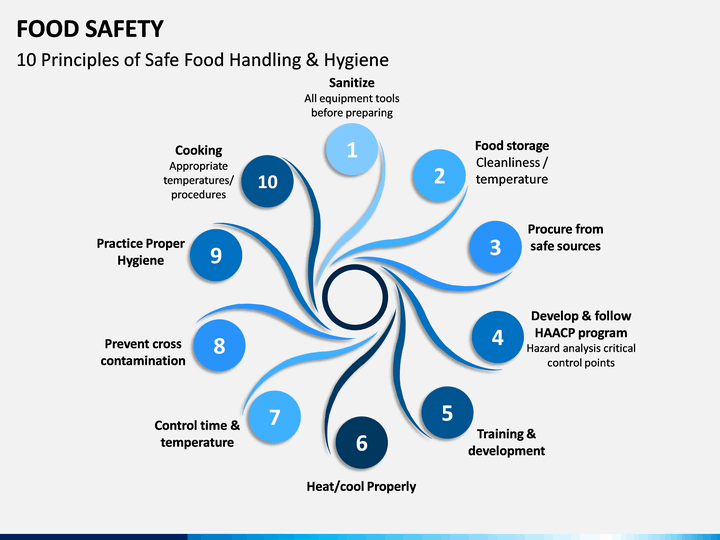

Proper processing methods ;.

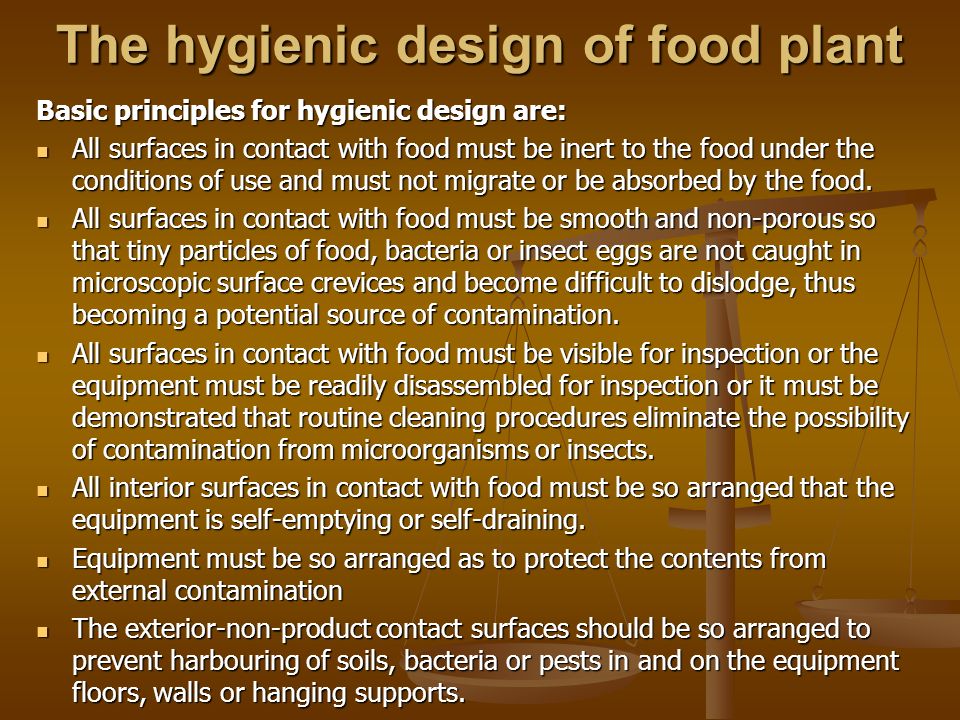

Hygienic design of food processing equipment ppt. The overall requirement for design of equipment for foodprocessing and handling operations is that it be cleanable and maintained in such a manner as to prevent contamination Foodcontact surface equipment standardsof varying thoroughness have been developed for segments of the food industry Some of these standards are listed here. 10 Hygienic design of closed equipment for the processing of liqui d food (07) 11 Hygienic packing of food products (1993) 12 The continuous or semicontinuous flow thermal treatment of part iculate foods (1994). The ECODHYBAT project aims to demonstrate that the hygienic ecodesign of equipment and facilities of food industry can significantly reduce the environmenta.

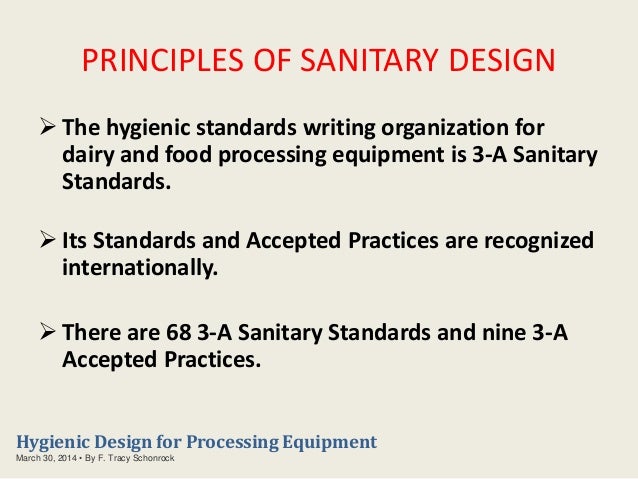

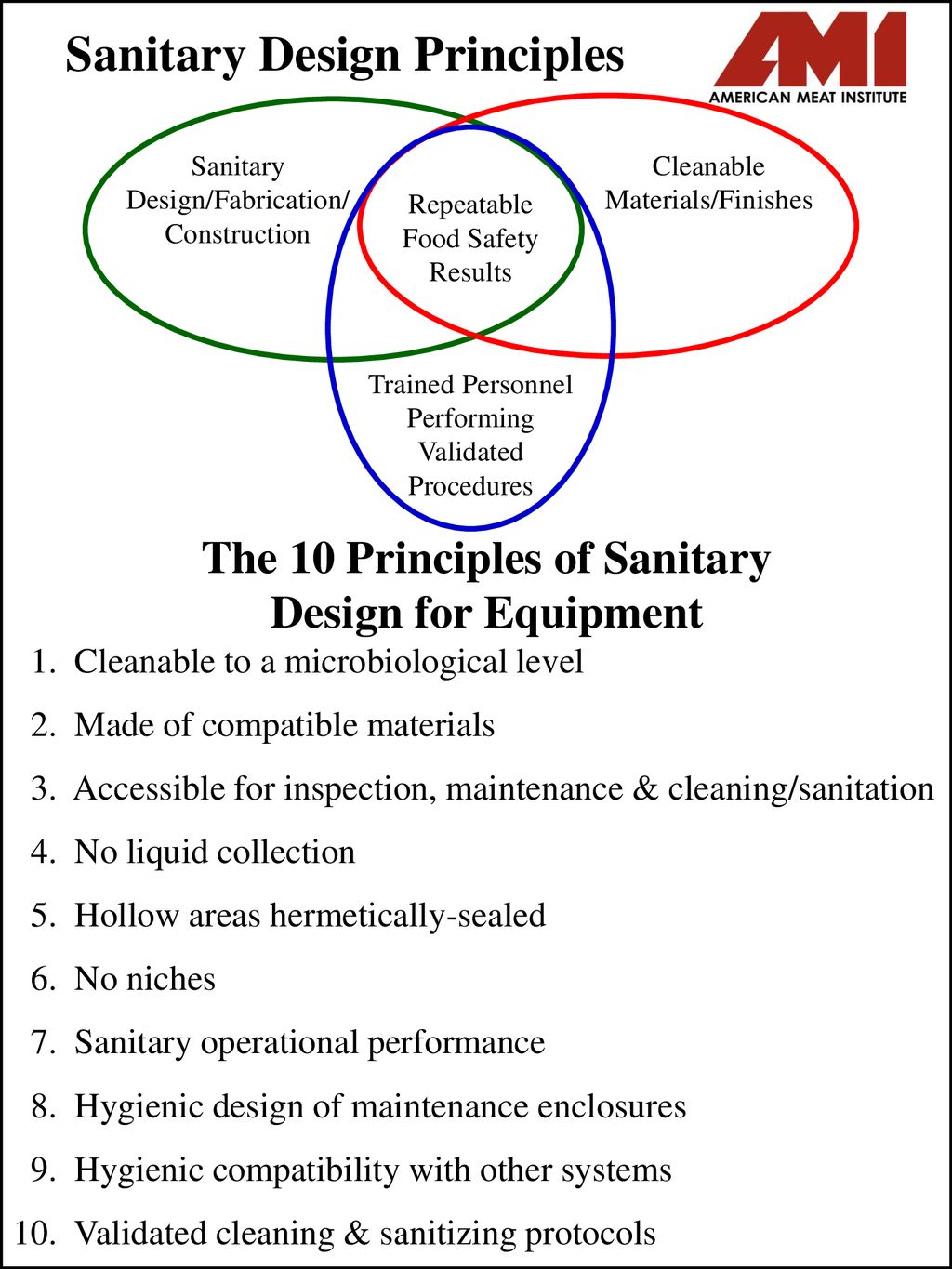

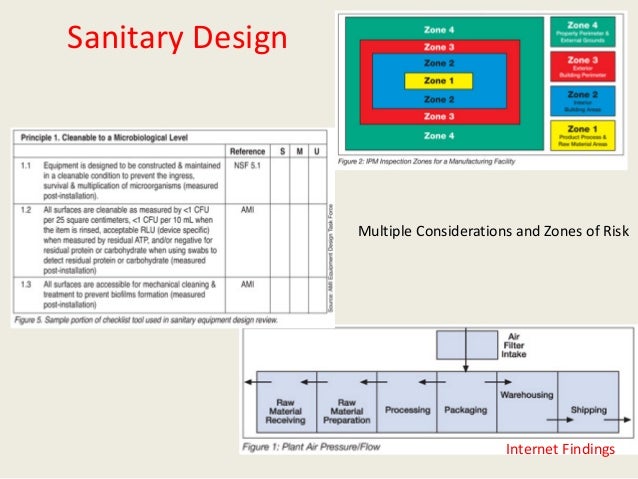

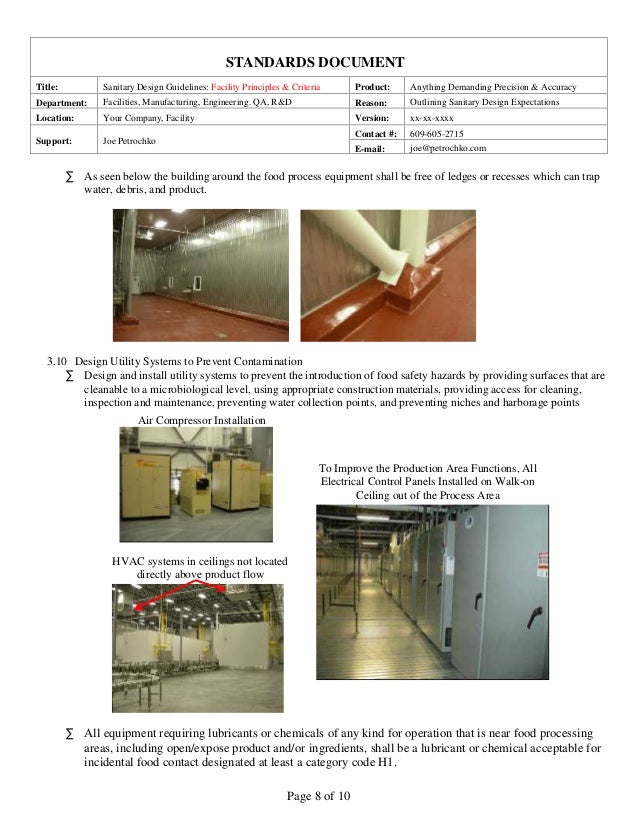

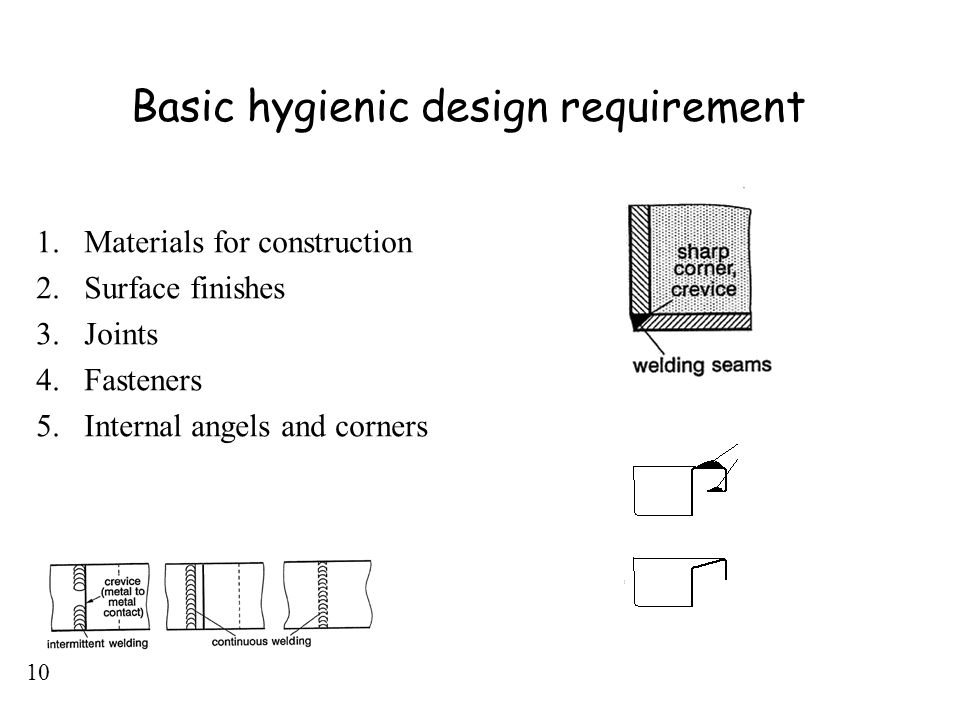

Hygienic Equipment Design In Hygiene in Food Processing Eds HLM Lelieveld, MA Mostert, J Holah and B White Cambridge, UK Woodhead Publishing, 151 6 Schmidt, RH and PD Pierce 15 The Use of Standard Operating Procedures (SOPs) In Handbook of Hygiene Control in the Food Industry, 2nd ed, Cambridge, UK Woodhead Publishing, in press. FSHN0408 Sanitary Design and Construction of Food Processing and Handling Facilities 1 Ronald H Schmidt and Daniel J Erickson 2 1 This document is FSHN0408, one of a series of the Food Science and Human Nutrition Department, UF/IFAS Extension. Hygienic Design for Processing Equipment March 30, 14 • By F Tracy Schonrock 12 PRINCIPLES OF SANITARY DESIGN Equipment Surfaces Food Product Contact Surfacesdefined as in “direct contact with food residue, or where food can drip, drain, diffuse or be drawn” NonFood Contact Surfacesdefined as part of the equipment that does.

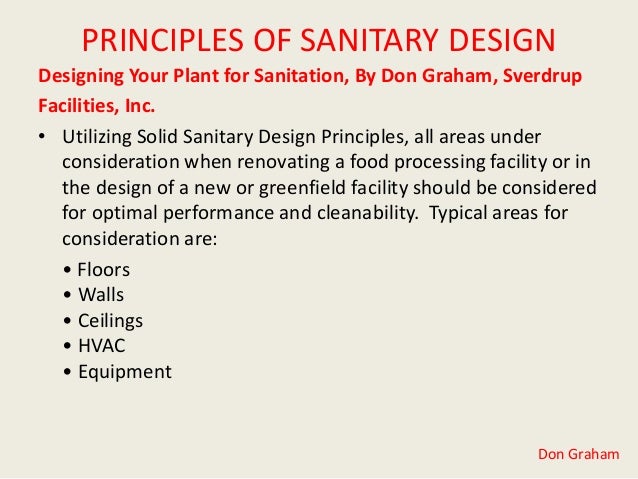

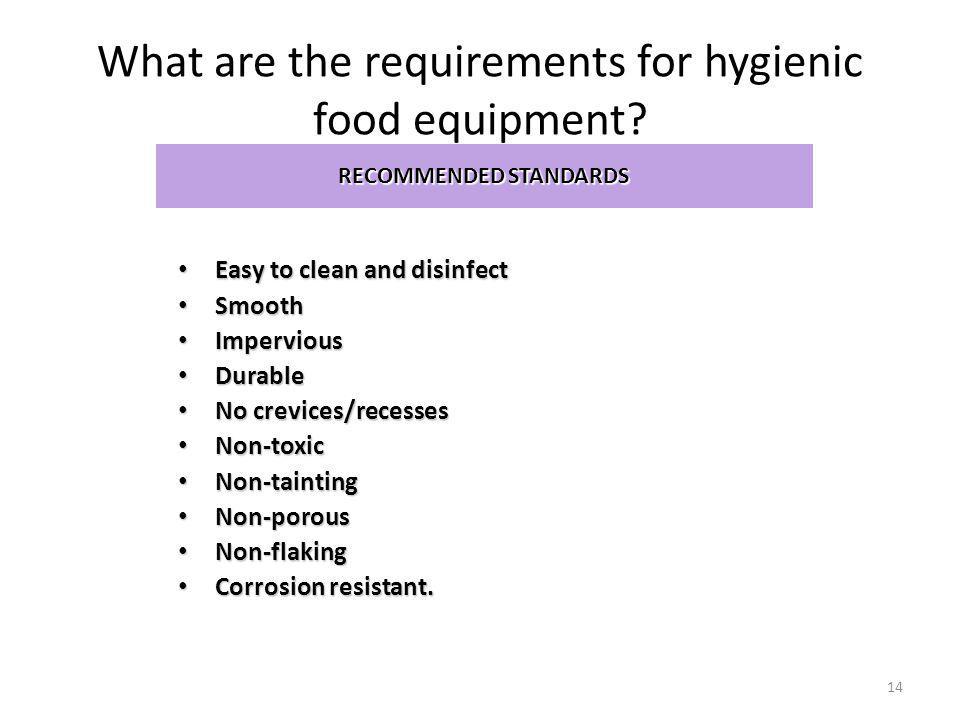

Furthermore, equipment that is designed and constructed to meet hygienic principles is easier to maintain and reduces the risks of physical hazards (eg, metal fragments from food equipment) in food processing Surfaces of food equipment and related ancillary equipment are divided into food contact and nonfood product contact surfaces. Of materials designed for food use;. Hygienic processing facilities ;.

(PDF) Hygienic design of food processing equipment and Hygienic design. Wouters (EHEDG) “In recent years, hygienic design guidelines have been widely adopted and applied by food processing companies and their equipment suppliers, which contributed to improved cleanability of food processing lines and environments But not all food industry stakeholders are sufficiently aware of the necessity of hygienic design yet. Life Cycle for Equipment in a Plant Sanitary Design Opportunities •Produce 2 billion meals •Train 250 employees on how to clean •Introduce and train 80 production supervisors •Spend up to 33,000 hours cleaning it •Spend 2500 hours doing preop inspections •Not produce up to 295 Million lbs of food •Generate 15 million gallons of effluent BOD.

(PDF) Hygienic design of food processing equipment and Hygienic design. Clean, sanitary equipment and utensils and again, proper personal worker hygiene!. Hygienic design of food factories provides an authoritative overview of hygiene control in the design, construction and renovation of food factories The business case for a new or refurbished food factory, its equipment needs and the impacts on factory design and construction are considered in two introductory chapters.

The European Hygienic Design Group (EHEDG) – Oversees the approval of food processing equipment in Europe They’ve published guidelines for designing and constructing any machinery used in food processing plants American companies looking to sell their food processing equipment there need to ensure their products pass the testing guidelines established by this body How Does Oversight Work?. Hygienic design of food factories provides an authoritative overview of hygiene control in the design, construction and renovation of food factories The business case for a new or refurbished food factory, its equipment needs and the impacts on factory design and construction are considered in two introductory chapters. The hygienic design of food processing equipment is a critical factor in determining the quality and safety of foods produced It involves the selection of suitable materials of construction, their fabrication into a functional piece of equipment, the ability of constructed equipment to produce food hygienically and the maintenance of hygienic conditions throughout the equipment’s working.

17 Proper personal worker hygiene Very high standards of personal hygiene for food handlers are. Equipment and Utensils Incorporating hygienic design is thus a requirement of GMP’s in food production While the food regulatory agencies in the United States do not regulate food processing equipment, they do regulate its sanitary use As a key element of the Food Safety. Hygienic design in food processing plays an important role in controlling the microbiological safety and quality of the products made This will prevent products from having undesirably high microbial counts, containing toxins or chemical residues, or from contamination from other nonfood substances.

The European Hygienic Design Group (EHEDG) is the primary organization for food equipment approval in Europe While EHEDG has published a series of guidelines for the construction and design of food processing equipment, they have chosen not to issue standards. Be impermeable and rust or corrosionfree;. Principles of Hygienic Design for Food Processing Facilities 08 July, 19 The American Meat Institute has come up with the following principles of hygienic design for food processing facilities These design principles have been created to reduce food safety hazards, keeping food safe Whether you're building a new facility, updating your existing one or onboarding new employees, take these principles of hygienic design into consideration to prevent food borne illness and product recalls.

Stress equipment hygienic design standards In this article, I will describe the importance and general principles of hygienic design, examine current regulatory and thirdparty auditing programs with regard to their emphasis on food equipment and stress the importance of effective and appropriate hygienic design standards. With the publication of two new hygienic design benchmarking requirements, the Global Food Safety Initiative (GFSI) paves the way to incorporate hygienic design in food safety management programs, according to 3A Sanitary Standards Inc (3A SSI) and the European Hygienic Engineering and Design Group (EHEDG) What practical implications can be expected for food processing companies and. Hygienic design is a process of continual improvement This guide and the checklist are meant to aid in evaluating equipment and buildings as a “snapshot” of one point in time The act of reviewing the equipment or building should motivate a plan for improving certain areas of design.

Why Food Processing Companies Need To Abide by Hygienic Design in 19 14 November, 18 The importance of hygienic design in food processing equipment is more apparent today than it was a decade ago. Hygienic Design of Food Processing Equipment Perry Johnson Registrars Food Safety, Inc Hygienic conveyor design in the food factory Duration 224 FlexLink 7,860 views. NOTE If the equipment is also intended for use in the processing or packaging of meat and poultry products, review may also be necessary according to the criteria in the standard ANSI/NSF/3A , Hygiene requirements for the design of meat and poultry processing equipment You may contact our meat and poultry equipment.

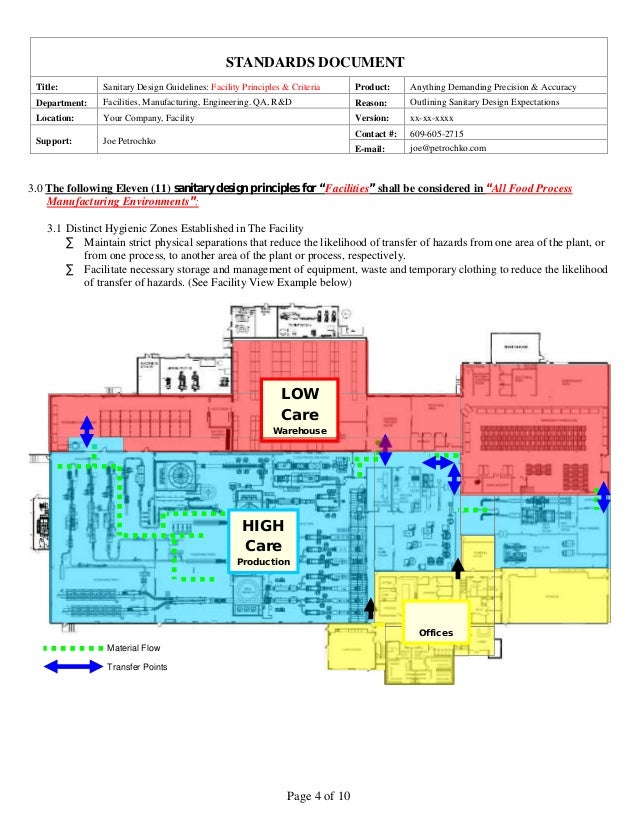

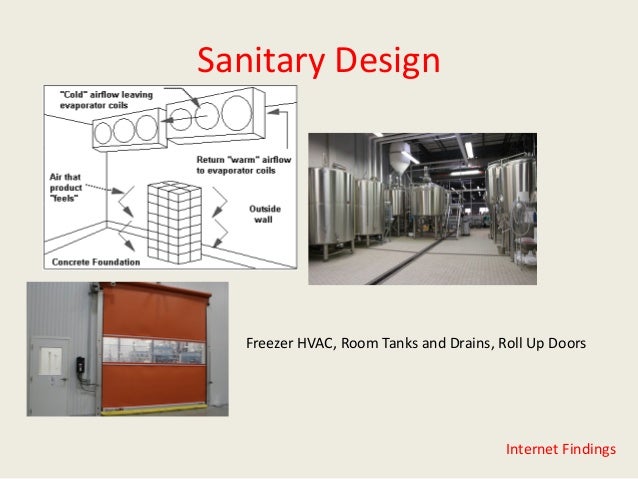

The design and construction of food premises must be appropriate for the activities for which the premises are used Dairy processing activities generally occur in discrete manufacturing areas Ensuring a oneway flow from unprocessed (eg raw) product receipt through the various processing operations to final storage and dispatch. The European Hygienic Design Group (EHEDG) is the primary organization for food equipment approval in Europe While EHEDG has published a series of guidelines for the construction and design of food processing equipment, they have chosen not to issue standards. !!93/94 on the hygiene of food stuff 1993 !!1990 Food safety Act (UK) Its good business 9 Universal Emphasis on Hygienic Design and Cleanability of Food Processing Equipment What is Cleaning and Sanitation ?.

Manufacturers of machinery for processing of fish and milk that also (requirement) possess hygienic design certification may be involved in the project by putting their equipment to the disposal of the test phase, serving directly as a basis for the proposed improvements More info. With the publication of two new hygienic design benchmarking requirements, the Global Food Safety Initiative (GFSI) paves the way to incorporate hygienic design in food safety management programs, according to 3A Sanitary Standards Inc (3A SSI) and the European Hygienic Engineering and Design Group (EHEDG) What practical implications can be expected for food processing companies and. PRINCIPLES OF SANITARY DESIGN The hygienic standards writing organization for dairy and food processing equipment is 3A Sanitary Standards Its Standards and Accepted Practices are recognized internationally There are 68 3A Sanitary Standards and nine 3A Accepted Practices.

The above text deals with only a fraction of hygienic equipment for processing of food products For a description of the requirements for hygienic design of equipment, see EHEDG guideline no81 and for meeting these requirements, see Hygiene in food processing Principles and practice2 Hygienic design of factory buildings. The hygienic design of food processing equipment is a critical factor in determining the quality and safety of foods produced It involves the selection of suitable materials of construction, their fabrication into a functional piece of equipment, the ability of constructed equipment to produce food hygienically and the maintenance of hygienic conditions throughout the equipment’s working life. NOTE If the equipment is also intended for use in the processing or packaging of meat and poultry products, review may also be necessary according to the criteria in the standard ANSI/NSF/3A , Hygiene requirements for the design of meat and poultry processing equipment You may contact our meat and poultry equipment.

Food safety is vital for consumer confidence, and the hygienic design of food processing facilities is central to the manufacture of safe products. Part two discusses the hygienic design of food factory infrastructure, encompassing the design and materials for the factory itself, as well as food processing equipment. 16 At the farm This is where food quality and safety start or get compromised!.

Food Safety Farm to Fork!. The overall requirement for design of equipment for foodprocessing and handling operations is that it be cleanable and maintained in such a manner as to prevent contamination Foodcontact surface equipment standards of varying thoroughness have been developed for segments of the food industry Some of these standards are listed here. Therefore valves for hygienic or aseptic use should conform to EHEDG guidelines as follows Doc 8 Hygienic Equipment Design Criteria Doc 9 Welding Stainless Steel to meet Hygienic Requirements Doc10 Hygienic Design of closed Equipment for the Processing of Liquid Food Doc13 Hygienic Design of Equipment for Open Processing.

Abstract Until comparatively recently manufacturers have concerned themselves almost exclusively with the mechanical design and operational requirements of food processing equipment and have tended to neglect hygiene considerations Equipment should be designed and constructed so that cleaning, maintenance and inspection are facilitated. Hygienic design and practices are thus two of the key factors in producing safe and wholesome foods Food processing equipment that is designed hygienically has three key advantages• Food quality Good hygienic design maintains product in the main product flow This ensures that product is not 'heldup' within the equipment where it could. The location, design, layout and construction of food premises and the choice of fixtures, fittings and equipment are crucial to ensure that food businesses can operate under hygienic conditions and produce food safely Poorly designed and constructed buildings and equipment are potential sources of physical, chemical and microbiological hazards.

The FSSC (eg, ISO 200/PAS 2) scheme has, perhaps, the most specific verbiage with regard to equipment and provides that food contact equipment be designed and constructed to facilitate appropriate cleaning;. Both food processing equipment and food processing layout saving money and time Legislation do not contain any detailed instructions for hygienic design There are guidelines and standards available eg by European Hygienic Engineering &. 0pm Edyta Margas, Food Safety & Hygienic Design Expert, Bühler, CH Hygienic Design of Food Processing Equipment 840pm Deb Smith, Global Hygiene Specialist, Vikan, UK Hygienic Design of Food Industry Brushware 900pm Deb Smith, Global Hygiene Specialist, Vikan, UK Workshop Hygienic Design of Brushware Monday, July 10th.

There is a generally position that it is impossible to provide hygienic design guidelines for all individual food processing equipment The approach of the European Committee for Standardization CEN/TC 153 was, therefore, to define the basic hygienic design requirements and these can be presented under two headings. In all stages of design, construction, installation and maintenance of food processing equipment, hygienic design aims to reduce the buildup of food material or microorganisms in individual items of equipment and the complete line, and to ensure that all detectable soil is removed after cleaning (and disinfection) According to European. Hygienic Design Training The Food Sanitation Institute, an initiative of Commercial Food Sanitation, is committed our Hygienic Design Training to professionals in the food industry that have the desire to learn critical details about hygienic design of equipment and facilities This course challenges for food processing plants across.

Hygienic design of equipment Microbes multiply given the right conditions, ie temperature, moisture, nutrients and time In food processing, the practical options for reducing the temperature and moisture are limited and by nature, nutrients generally are in abundance Hence, to keep the number of microbes in the product under control,. An illustration of a complete automated food processing system for jam production Image Credit Dukesn/com Food processing equipment is an umbrella term referring to the components, processing machines, and systems used to handle, prepare, cook, store, and package food and food productsAlthough this equipment is primarily aimed toward the transformation—ie, increasing the. Food hygiene and control 1 Food hygiene and control SITHARA V P II nd semester Msc microbiology 2 Food hygiene • Food is a potential source of infection and is liable to contamination by microbes, at any point during its journey from the producer to the consumer.

!!Cleaning Removal of all soil, food product residue, dirt, grease or other objectionable matter Vasavada IAFP Webinar 97. Hygienic Design of Food Processing Equipment Perry Johnson Registrars Food Safety, Inc Hygienic conveyor design in the food factory Duration 224 FlexLink 7,860 views. And meet established principles of hygienic design Summary and Conclusions Food equipment hygienic design is more important than ever before and is addressed in a general manner in.

Manufacturers of machinery for processing of fish and milk that also (requirement) possess hygienic design certification may be involved in the project by putting their equipment to the disposal of the test phase, serving directly as a basis for the proposed improvements More info. On one hand, the 3A Standards establish design criteria regarding materials, surface finish, radii and other aspects of food processing equipment that can be cleaned and inspected On the other hand, EHEDG standards utilize performance requirements and design guidelines rather than fabrication specifications. 10 Hygienic design of closed equipment for the processing of liqui d food (07) 11 Hygienic packing of food products (1993) 12 The continuous or semicontinuous flow thermal treatment of part iculate foods (1994).

It provides a comprehensive, yet concise and practical reference source for food plant managers, suppliers of food processing equipment, building contractors, and food inspectors looking for an authoritative introduction to hygiene regulation, hygienic design, and sanitation.

Clean In Place Wikipedia

Ppt Gmp Good Manufacturing Practices For Food Manufacturers Powerpoint Presentation Free To Download Id 66a9ef N2u5y

Food Safety For Hotels And Restaurants Rentokil

The 10 Principles Of Sanitary Design For Equipment Ppt Download

Sanitary Facility Design Guidelines Part 2 Of 2

Sanitary Design An Introduction To Standards Of Design Excellence Nov

Food Beverage Processing Industry Angst Pfister

Sanitary Design An Introduction To Standards Of Design Excellence Nov

Pilot Plant Design Build For Food Processing Systems Formulation

Overview Of Food Processing Equipment Types Applications And Important Attributes

Sanitary And Hygienic Design Guide For Food Equipment Mpc

Pilot Plant Design Build For Food Processing Systems Formulation

Designing Your Hygienic Zoning Quality Assurance Food Safety

Sanitary Equipment Design Principles Checklist Glossary American Me

Sanitary And Hygienic Design Guide For Food Equipment Mpc

Sanitary Facility Design Guidelines Part 2 Of 2

Food Beverage Processing Industry Angst Pfister

Sanitary And Hygienic Design Guide For Food Equipment Mpc

Lesson 9 Design Construction Of Food Premises Equipment Ppt Video Online Download

Equipment Food Safety Quality Assurance Food Safety

Design Elements Of Listeria Environmental Monitoring Programs In Food Processing Facilities A Scoping Review Of Research And Guidance Materials Zoellner 18 Comprehensive Reviews In Food Science And Food Safety Wiley Online Library

Hygienic Zoning For Sanitation Preventive Control Food Science Technology Extension

What All You Need To Know About Good Hygiene Practices

Division Of Plant Products And Beverages Ppt Download

Development Of A Layout Model Suitable For The Food Processing Industry

Hygienic System Design For Food Processing Facilities Panorama Consulting Engineers India

Gmp In The Food Industry Haccp Mentor

Cleaning And Sanitation Maintenance Proposal Template Powerpoint Presentation Slides Powerpoint Presentation Designs Slide Ppt Graphics Presentation Template Designs

Principles For Hygienic Design And Zoning Ppt Video Online Download

Hygienic Design Of Dairy Equipment

The Evolution And Cultural Framing Of Food Safety Management Systems Where From And Where Next Manning 19 Comprehensive Reviews In Food Science And Food Safety Wiley Online Library

Sanitation In Emergencies Overview Sswm Find Tools For Sustainable Sanitation And Water Management

Many Food Manufacturers Do Not Fully Integrate Hygienic Design Into The Processing Environment

Hygiene In Food Processing 2nd Edition

Hygienic Design For Processing Equipment Food Quality Safety

Pilot Plant Design Build For Food Processing Systems Formulation

Color Coding As A Preventive Control In Food Processing

Hygienic Design Of Food Industry Equipment Pdf Design Sanitation

Food Safety Powerpoint Template Sketchbubble

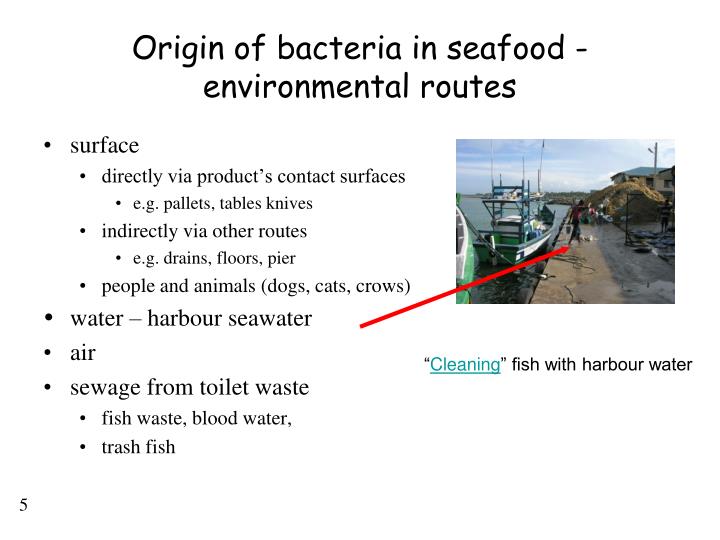

Assessment And Management Of Seafood Safety And Quality

Overview Of Food Processing Equipment Types Applications And Important Attributes

Food Safety Powerpoint Template Sketchbubble

Ppt ma Food Industry Ten Sanitary Design Principles Hygienic Restoration Powerpoint Presentation Free To View Id cab5 Zdc1z

Ppt Principles For Hygienic Design And Zoning Powerpoint Presentation Id

Risk Mitigation Policies For Smooth Operations In Theme Parks Feel Ppt Powerpoint Presentation Styles Aids Presentation Graphics Presentation Powerpoint Example Slide Templates

Ppt Principles For Hygienic Design And Zoning Powerpoint Presentation Id

Sanitary And Hygienic Design Guide For Food Equipment Mpc

Pilot Plant Design Build For Food Processing Systems Formulation

Lesson 9 Design Construction Of Food Premises Equipment Ppt Video Online Download

Sanitary Design An Introduction To Standards Of Design Excellence Nov

Sanitary Equipment Design 14 04 08 Food Engineering

Principles For Hygienic Design And Zoning Ppt Video Online Download

Sanitary Design An Introduction To Standards Of Design Excellence Nov

Ppt Sanitary Facilities And Equipment Powerpoint Presentation Free Download Id

Expert Advice On Sanitary Plant Design 17 08 16 Food Engineering

Sanitary Design An Introduction To Standards Of Design Excellence Nov

Overview Of Food Processing Equipment Types Applications And Important Attributes

Maintaining A Cleaning Schedule

Design And Facilities

Hygienic Design Of Food Processing Equipment Youtube

Ppt Industrial Food Processing Equipment Powerpoint Presentation Free Download Id

The Key To Successful Foreign Object Prevention Food Safety Experts

Ppt Clean And Maintain Kitchen Equipment And Utensils Powerpoint Presentation Id

Sanitary Design An Introduction To Standards Of Design Excellence Nov

Hygienic Design Of Food Processing Equipment Youtube

Food Hygiene Poster Food Safety Teacher Made

The Evolution And Cultural Framing Of Food Safety Management Systems Where From And Where Next Manning 19 Comprehensive Reviews In Food Science And Food Safety Wiley Online Library

Covid 19 Guidance For Gyms And Fitness Centers That Staff Ppt Powerpoint Presentation Portfolio Model Presentation Graphics Presentation Powerpoint Example Slide Templates

5s In The Food Industry Your Partners In Hygiene

Food Quality Control Plant Sanitation Fst 401 3units Ppt Download

Lesson 9 Design Construction Of Food Premises Equipment Ppt Video Online Download

Pdf Risk Management By Hygienic Design And Efficient Sanitation Programs

Design Elements Of Listeria Environmental Monitoring Programs In Food Processing Facilities A Scoping Review Of Research And Guidance Materials Zoellner 18 Comprehensive Reviews In Food Science And Food Safety Wiley Online Library

Equipment Tools Buildings New England Food Entrepreneurs

Equipment Food Safety Quality Assurance Food Safety