Atex Zone 1 Vs Zone 2

Standards And Regulations Ex Zones Atex Iecex

Atex Catalog Peli

Hazardous

Is 655 2 Atex Atex Instrinically Safe Zone Tablet Cctv Computer Camera Certified Hazardous What Is Atex

M25 Conduit Atex Flameproof Exd Barrier Glands Zone 1 Zone 2 Haza

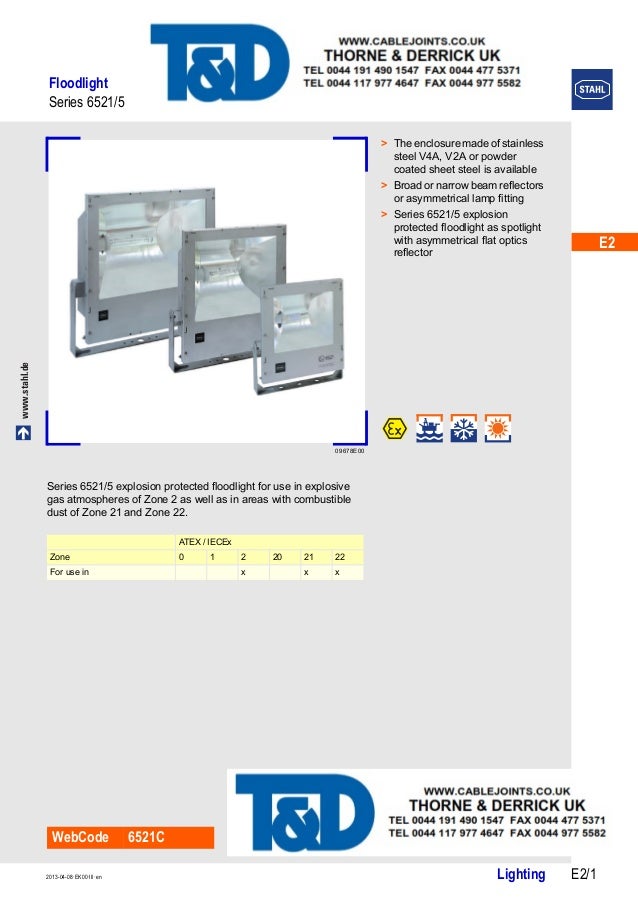

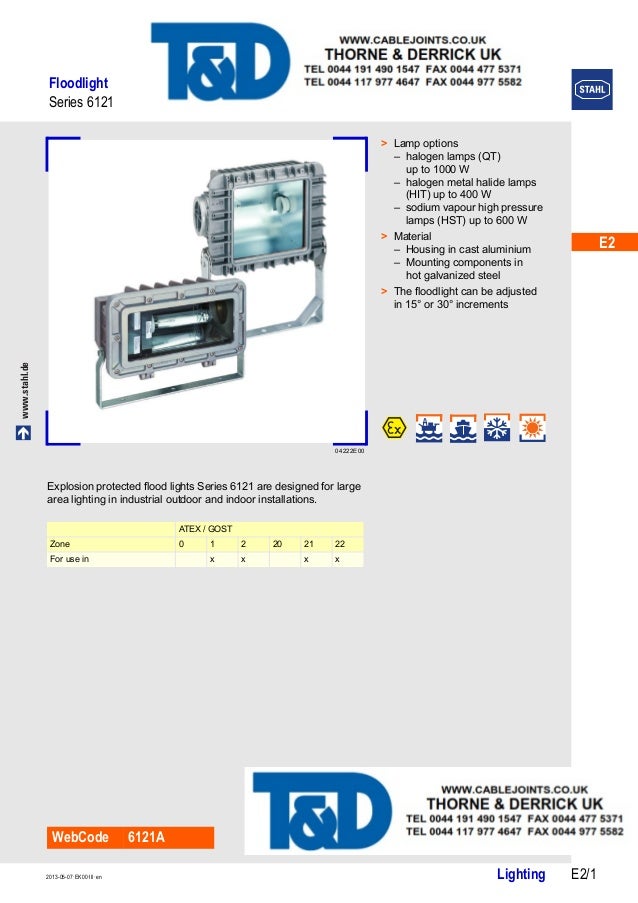

Stahl 6521 5 Floodlight Atex Zone 1 Zone 2 Hazardous Area Lighting

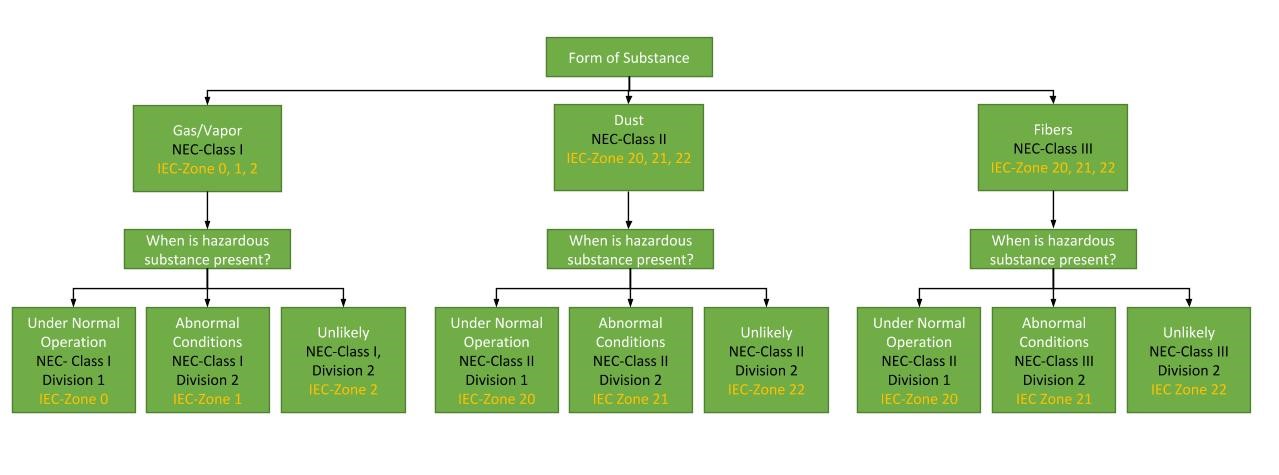

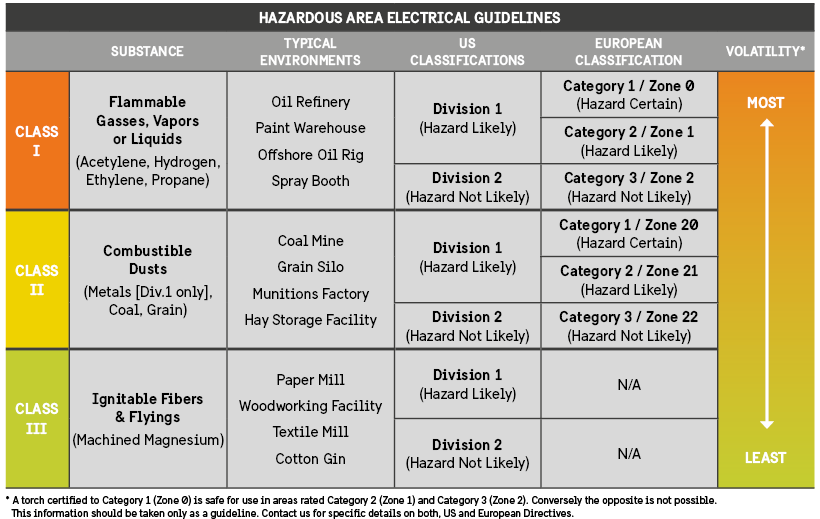

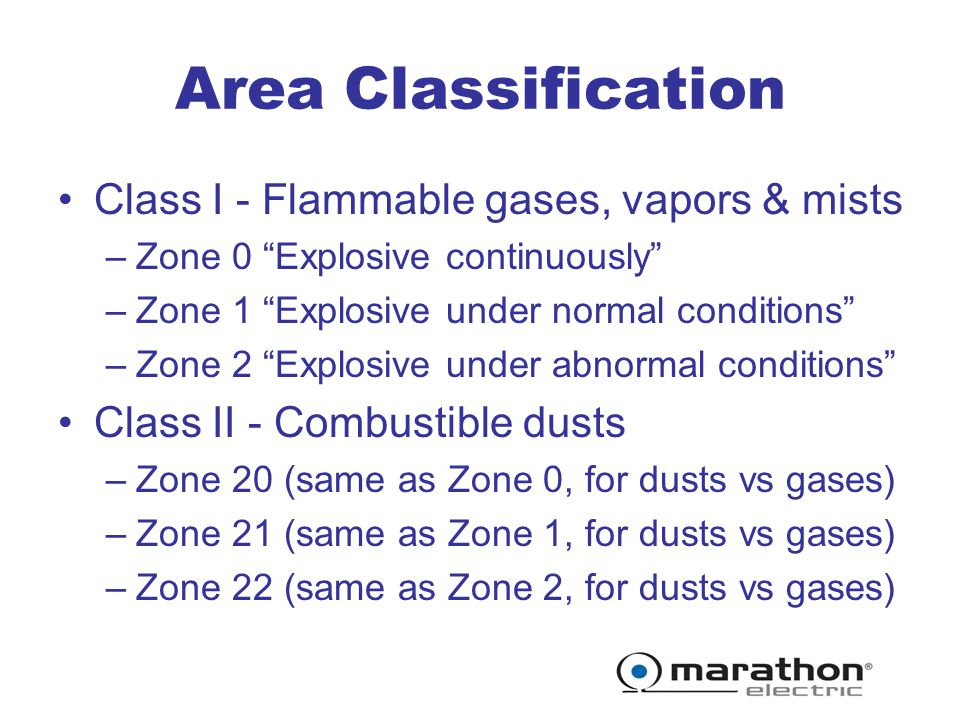

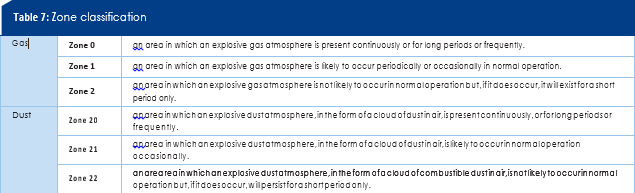

I A location made hazardous by the presence of flammable gas or vapour that may be present in the air in quantities sufficient to produce an explosive or ignitable mixture II A location made hazardous by the presence of combustible or electrically conductive dust.

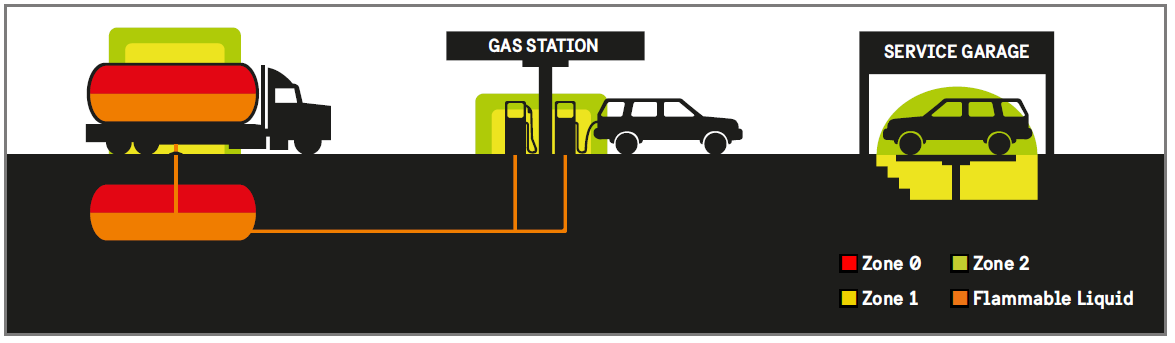

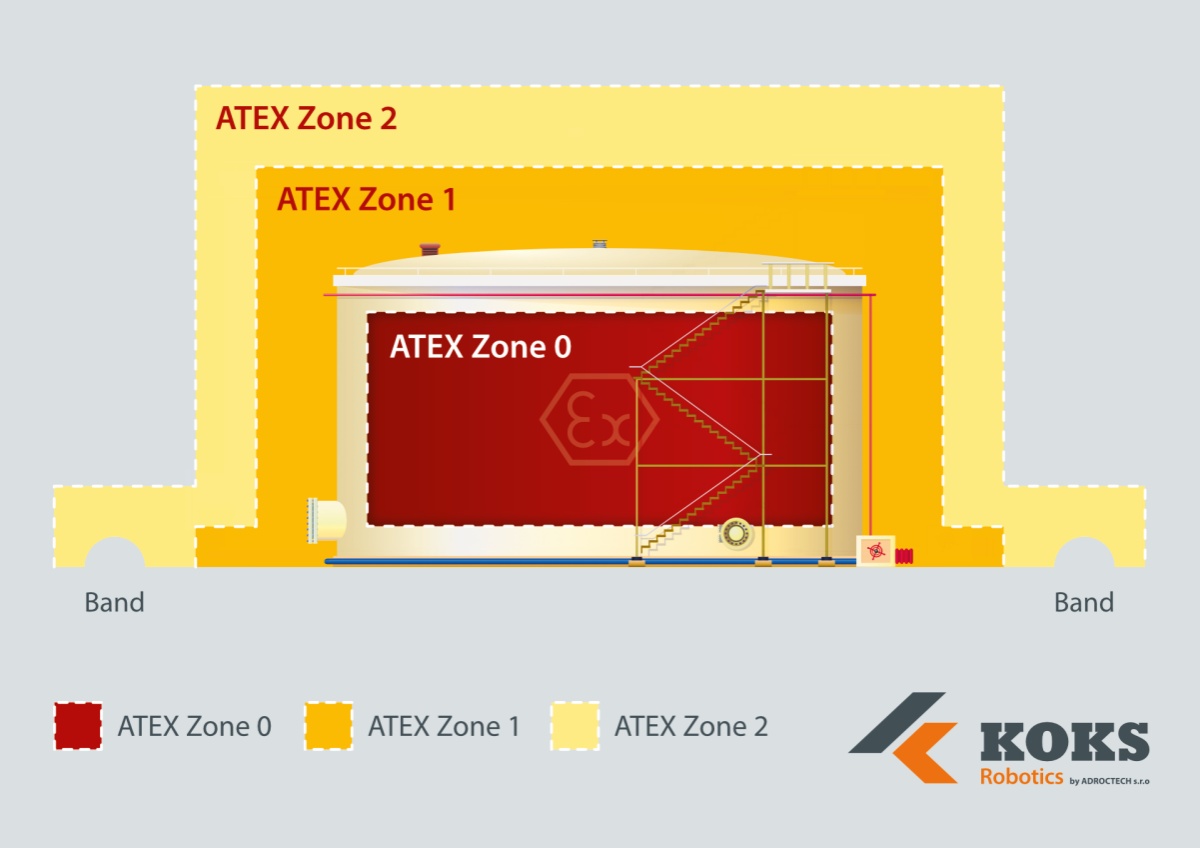

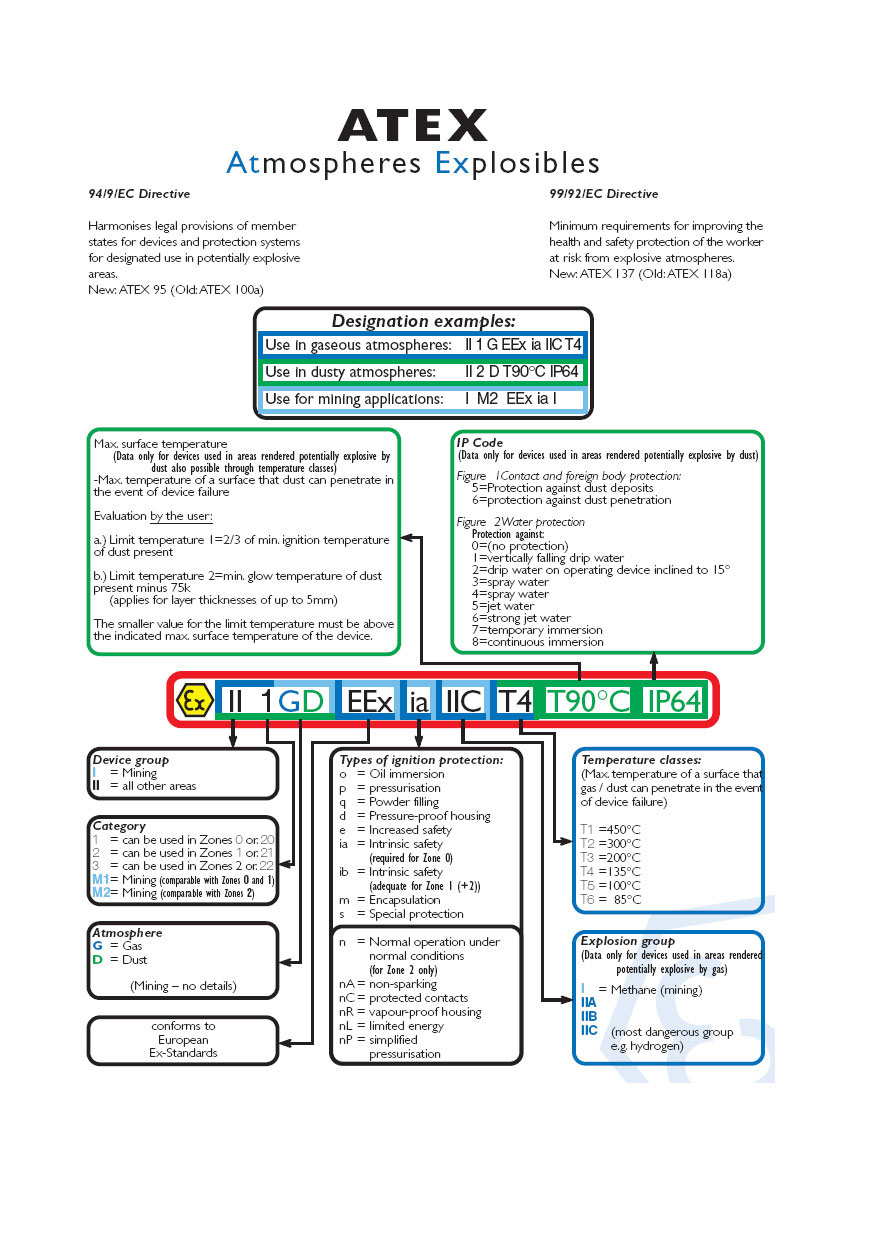

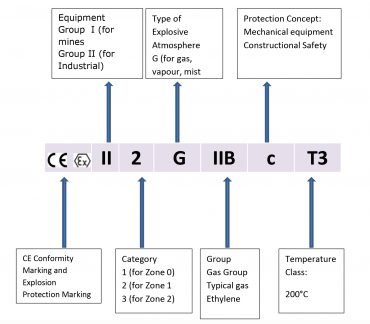

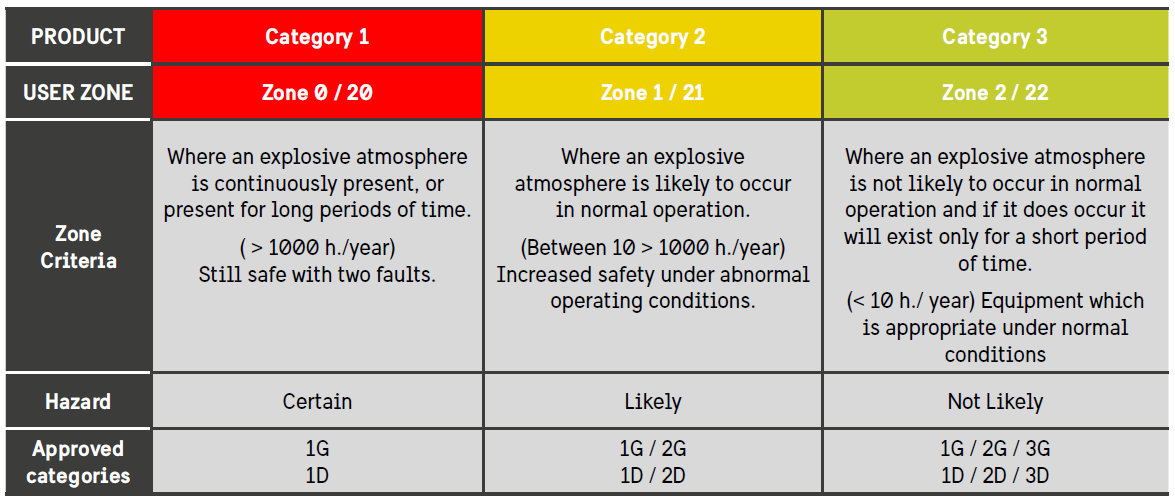

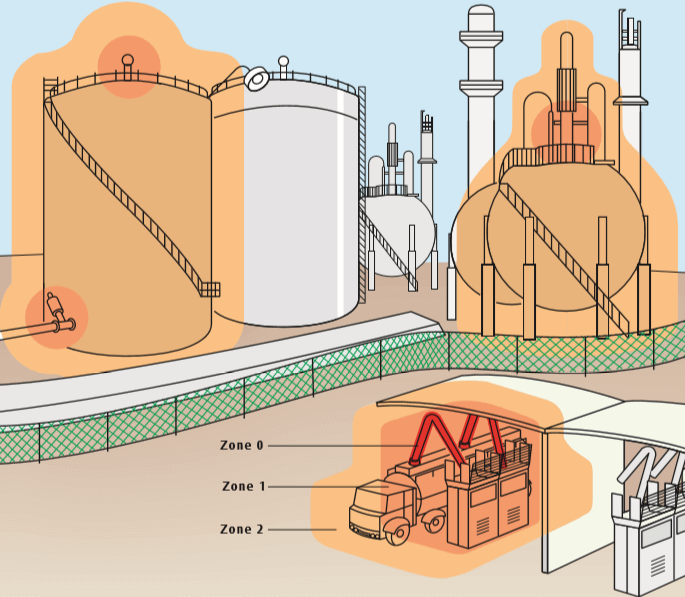

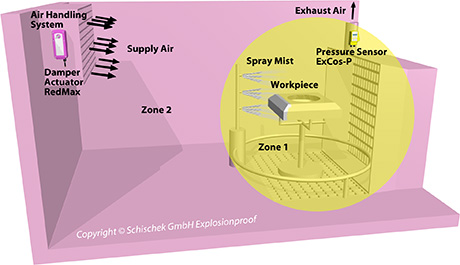

Atex zone 1 vs zone 2. Can be installed in conditions ranging from °C to 40°C;. The ATEX directive divides risk levels into zones 0/22, 1/21 & 2/22 ATEX equipment marking is based on these ATEX zones The following infographic will explain which industries deal with ATEX, how ATEX zones are specified, what they look like in practice and how they relate to ATEX marking. Hoist UK offer a range of electric chain hoists, wire rope hoists, trolleys, winches and pneumatic lifting and handling equipment that is rated as safe to use within ATEX Zones 1 and 2 ATEX Zone 1 is an area that is classified ‘as a place in which an explosive atmosphere consisting of a mixture with air or flammable substances in the form of.

Hoist UK offer a range of electric chain hoists, wire rope hoists, trolleys, winches and pneumatic lifting and handling equipment that is rated as safe to use within ATEX Zones 1 and 2 ATEX Zone 1 is an area that is classified ‘as a place in which an explosive atmosphere consisting of a mixture with air or flammable substances in the form of. Home / Hazardous Locations Motors / Zone 2 ATEX & IECEx Motors ATEX & IECEx Zone 2 Increased Safety, and nonsparking electric motors The environments are classified as Zone 2, groups IIA, IIB and IIC, and as Zone 22, groups IIA, IIB and IIC. 1, G Zone Område, hvor der vedvarende, hyppigt eller i længere tid kan være en eksplosiv atmosfære bestående af en sky af brændbart støv og luft 1, D Zone 1 Område, hvor der under normal drift lejlighedsvis kan forekomme eksplosiv blanding af luft og brandfarlig gas, damp eller tåge 1 eller 2, G Zone 21.

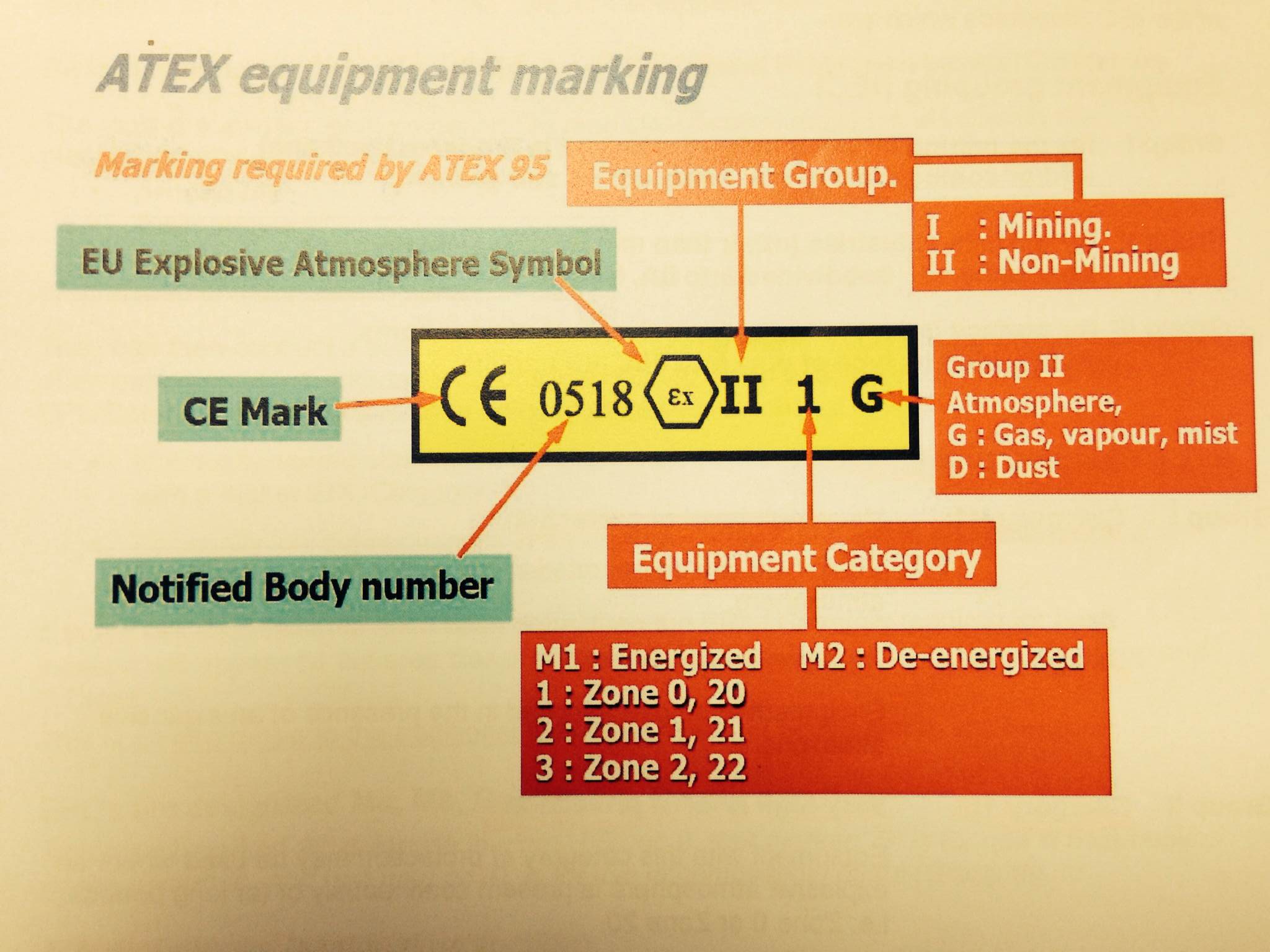

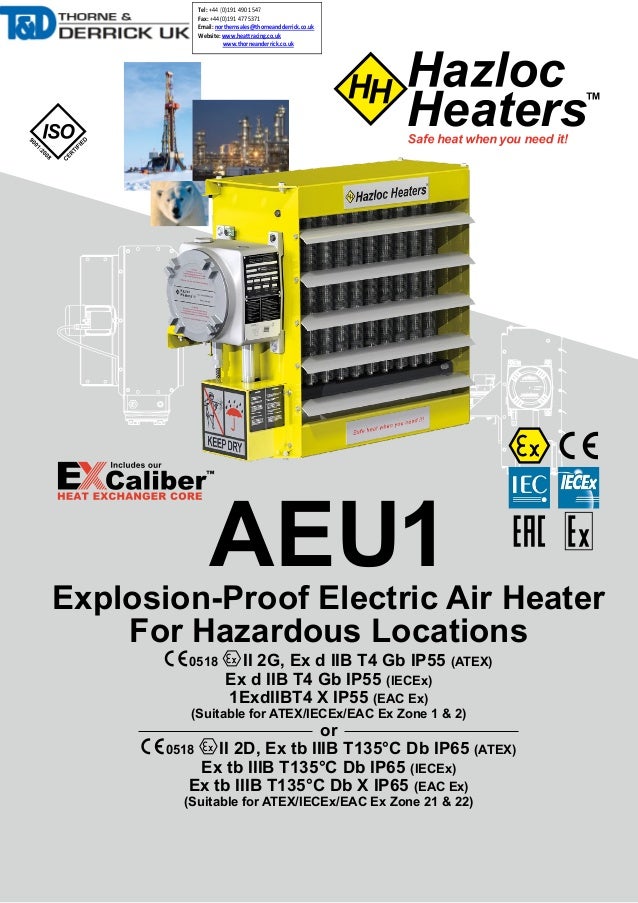

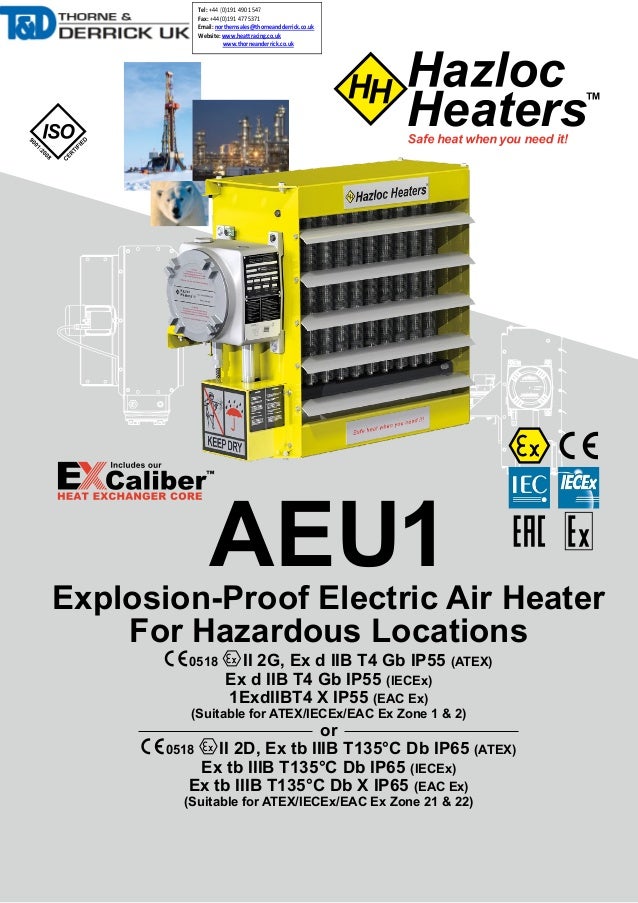

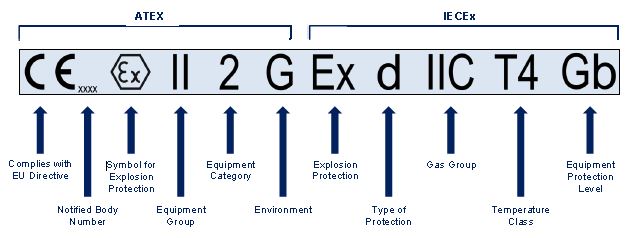

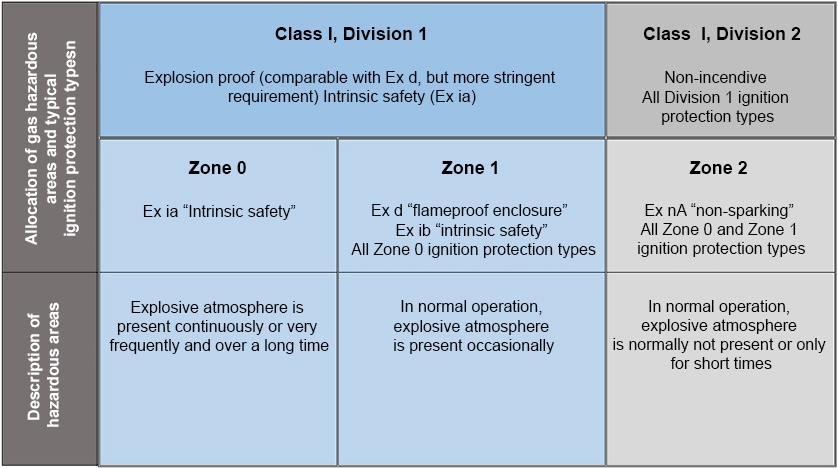

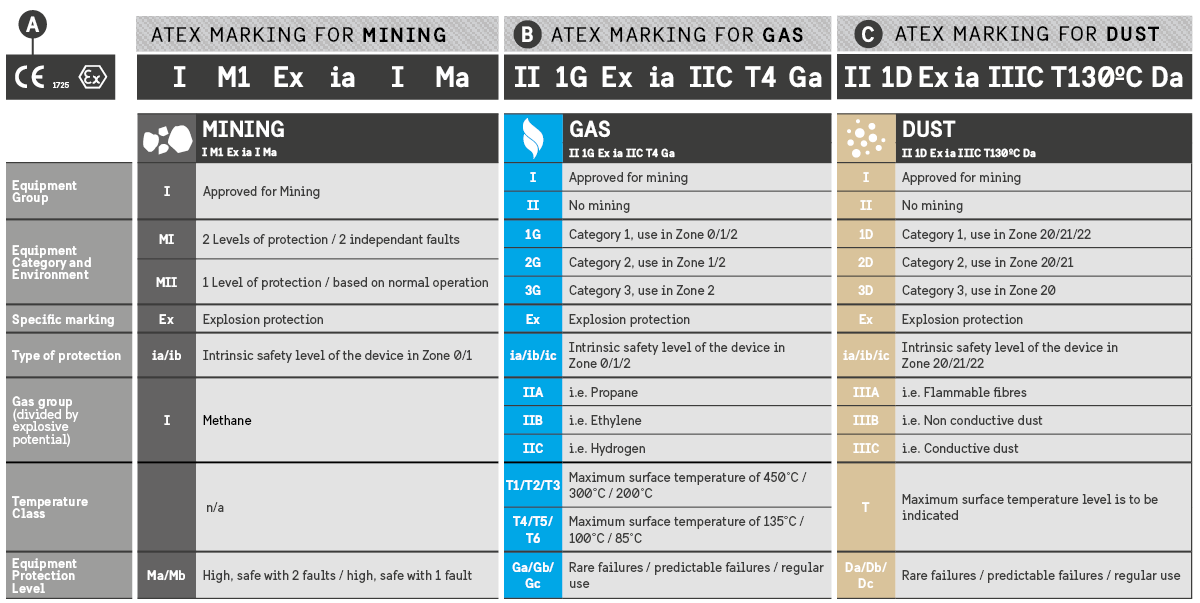

This classification is for an EC (ATEX) compliant system for surface equipment that has an equipment category of 2 (Zone 1) and is for gasses as opposed to dusts The protection concept is "d" which is flameproof, the gas group is IIC and the maximum allowable temperature is 0°C. Continuously for long periods or frequently Zone 0 II 1 G II Ga very high Occasional occurrence Zone 1 II 2 G II Gb high Not likely, but if it occurs only rarely and for a short period Zone 2 II 3 G II Gc enhanced Dust Continuously for long periods or frequently Zone II 1 D III Da very high Occasional occurrence Zone 21 II 2 D III Db high. Suitable for both Zones 1 & Zone 2 hazardous areas;.

This classification is for an EC (ATEX) compliant system for surface equipment that has an equipment category of 2 (Zone 1) and is for gasses as opposed to dusts The protection concept is "d" which is flameproof, the gas group is IIC and the maximum allowable temperature is 0°C. 1, 2 3 G 2 D is added after G in the certification class number D = dust (ie GD) if device is dust category approved also 1 D , 21, 22 2 D 21, 22 BACK TO TOP 3 D 22 Explanation of the categories 1 Very high safety = device safety must be guaranteed even in case of rare device failures, eg simultaneous failure of. Zone 1 (21) and Zone 2 (22) hazardous area enclosures for instrumentation, small power or lighting applications – stainless steel, mild steel, glass reinforced polyester, aluminium and polycarbonate certified according to ATEX and IECEx Also high voltage junction boxes for jointing, terminating and connecting 33kV, 66kV, 11kV and 33kV power cables in Zone 2 hazardous area.

1, 2 3 G 2 D is added after G in the certification class number D = dust (ie GD) if device is dust category approved also 1 D , 21, 22 2 D 21, 22 BACK TO TOP 3 D 22 Explanation of the categories 1 Very high safety = device safety must be guaranteed even in case of rare device failures, eg simultaneous failure of. Zone 2 An area in which an explosive gas atmosphere is not likely to occur in normal operation and, if. ปรับปรุงวันที่ กค 59 ATEX เป็นการเล่นคำย่อจากชื่อเต็มว่า "ATmosphere EXplosive" ซึ่งเป็นหนึ่งในมาตรฐานแนวทางการปฏิบัติของสหภาพยุโรป ประกอบไปด้วย 2 หัวข้อ.

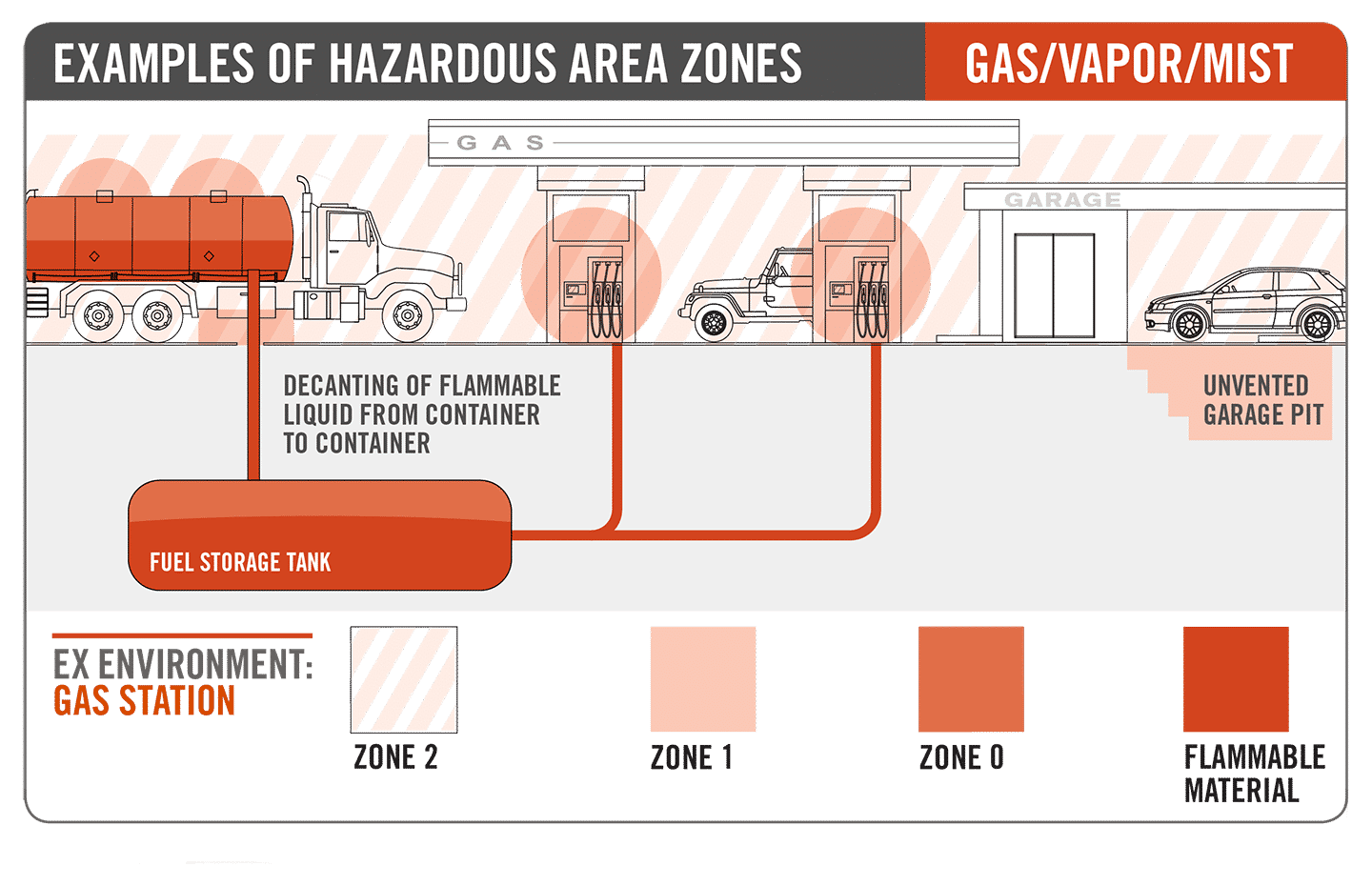

HAZARDOUS AREA CLASSIFICATION Ex d or Ex de IIB or IIC T1 to T6 T6 Maximum Surface Temp. Hazardous areas declared by the employer or facility owner are classified in Zones The classification given to each Zone, its size and location are dependent on the likelihood of the environment being explosive and the persistence or length of time if it is ATEX 14/34/EC (ATEX 95 / Equipment Directive). Mostly green (ATEX zone 2) and purple (ATEX zone 1) ATEX zones, equipment groups and categories When the ATEX zone is clear, the table helps you to find the accessory equipment ATEX equipment is classified into equipmentgroups.

A atex zone 1 is similar to a zone 0 However, a zone 1 is a place in which an explosive atmosphere is likely to occur in normal operation occasionally, instead of a continuously presence of a hazardous atmosphere Atex zone 2 In a atex zone 2, a explosive atmosphere is not likely to occur in normal operation. 1 – Can be used in zones 0 or 2 – Can be used in zones 1 or 21 3 – can be used in zones 2 or 22 M1 – mining (in case of firedamp, continuation of operation is possible) M2 – mining (must be switched off in case of firedamp This table shows the type of zones European & IEC Classification. Zone 1 – ATEX 2G conversions;.

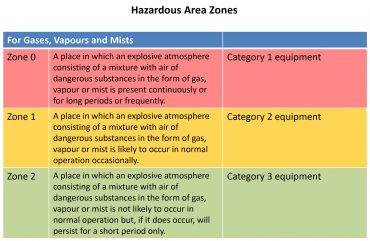

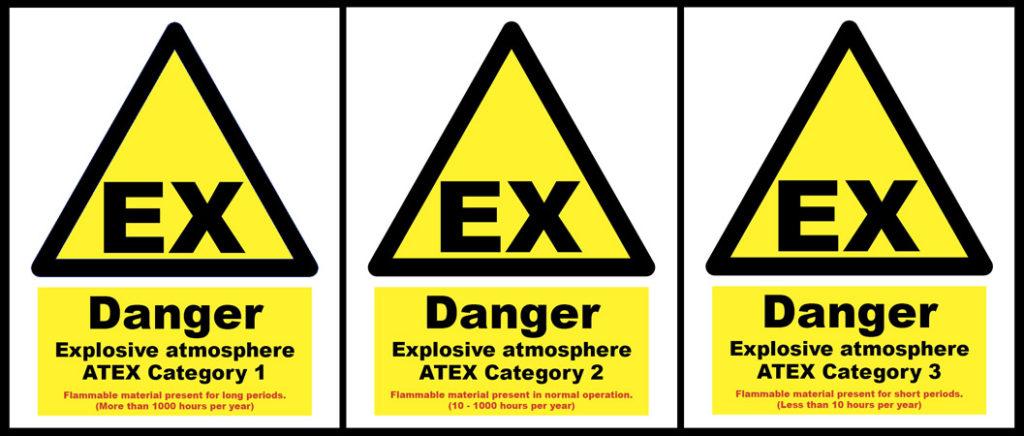

ATEX provides the requirements and procedures to establish the conformity of products placed on the EU market for the first time Category 1 – Equipment in this category is intended for use in areas in which explosive atmospheres caused by mixtures of air and gases, vapors or mists or by air/dust mixtures are present continuously, for. There are three area category types, with Category 1 requiring a very high level of protection and defined as an area having a permanent or prolonged risk of explosions (Zone 0), Category 2 which requires a high level of protection and has a frequent risk of an explosive mix being present in the air (Zone 1), and Category 3, specified as requiring a normal level of protection with a small chance of an explosive mix forming (Zone 2). Zone 1 Zone 1 is an area in which an explosive atmosphere is likely to occur occasionally in normal operation It may exist because of repair, maintenance operations, or leakage Zone 2 Zone 2 is a place in which an explosive atmosphere is not likely to occur in normal operation but, if it does occur, will persist for a short period only.

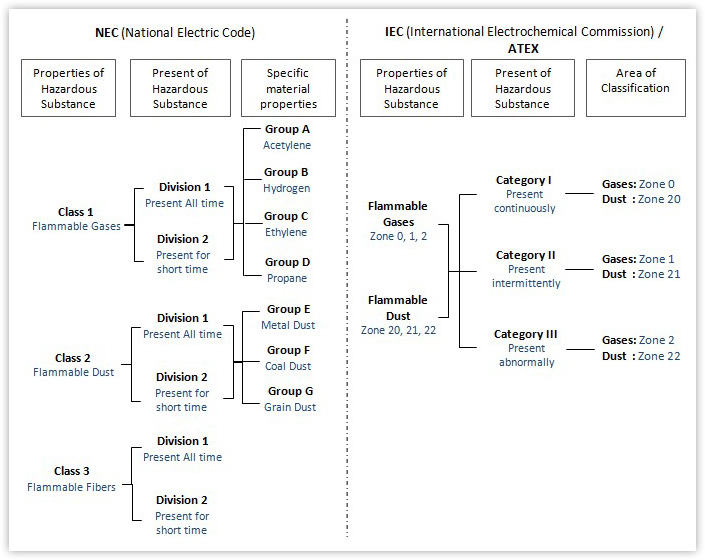

Class 1 / Division 1 ATEX Zone 1 Orange Zone Class 1 / Division 2 ATEX Zone 2 Yellow Zone Industrial Computing for Class 1 / Division 2 and ATEX Zone 2 Where embedded electrical products are concerned, the requirement for harsh environment industries such as oil and gas will usually be certification to Class 1 / Division 2 and/or ATEX Zone 2. ATEX approved control systems II 2 G;. Equipment of category 1 is intended for use in areas in which explosive atmospheres caused by gases, vapors, mists or air/dust mixtures are likely to occur Category 2 comprises equipment designed to be capable of functioning in conformity with the operational parameters established by the manufacturer and of ensuring a high level of protection.

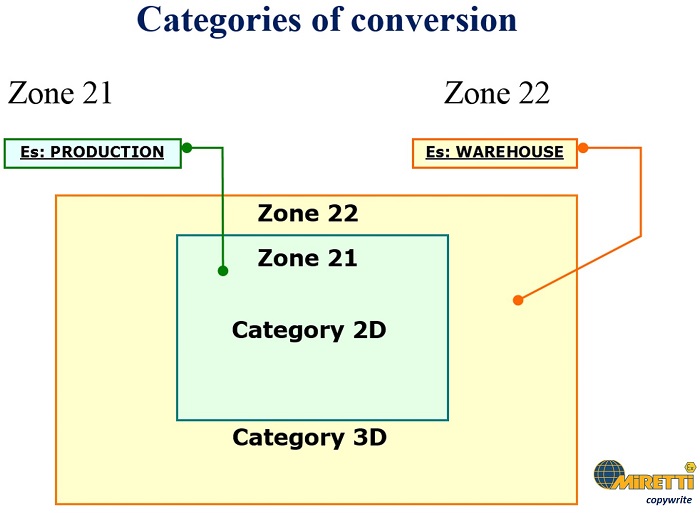

Equipment of category 1 is intended for use in areas in which explosive atmospheres caused by gases, vapors, mists or air/dust mixtures are likely to occur Category 2 comprises equipment designed to be capable of functioning in conformity with the operational parameters established by the manufacturer and of ensuring a high level of protection. 1 Equipment must be safe under normal operation, expected and rare malfunction Zone 1 Class 1 Division 1 Zone 21 Class 2 Division 1 Explosive atmosphere is likely to occur occasionally under normal operation ( hours per year) 2 Equipment must be safe under normal operation, expected malfunction Zone 2 Class 1 Division 2 Zone 22 Class 2 Division 2. We also provide lift truck conversion solutions for other hazardous areas, including Zone 2 – ATEX 3G conversions with Gas detection (system6000), Zone 2 – ATEX 3G conversions without Gas detection, Zone 21 – ATEX 2D conversions, Zone 22 – ATEX 3D conversions and added safety systems.

Zone 0 zone 1 zone 2 zone zone 21 zone 22 mines mines Equipment protection level Equipment group Category group II II II II II II I I 1G 2G 1G 3G 2G 1G 1D 2D 1D 3D 2D 1D M1 M2 M1 Ga Gb Ga Gc Gb Ga Da Db Da Dc Db Da Ma Mb Ma Apparatus may be used in The measurement function according to ATEX (DIN EN ) guarantees highest. There are three area category types, with Category 1 requiring a very high level of protection and defined as an area having a permanent or prolonged risk of explosions (Zone 0), Category 2 which requires a high level of protection and has a frequent risk of an explosive mix being present in the air (Zone 1), and Category 3, specified as requiring a normal level of protection with a small chance of an explosive mix forming (Zone 2). Zone 1 is an area that is classified ‘as a place in which an explosive atmosphere consisting of a mixture with air or flammable substances in the form of gas, vapours and mists is likely to occur occasionally during normal operation’, whereas Zone 2 is an area that is classified ‘as a place in which an explosive atmosphere consisting of a mixture with air or flammable substances in the form of gas, vapours and mists is not likely to occur in normal operation but if it does occur, it.

Outside of North America, ATEX (Appareils destinés à être utilisés en ATmosphères EXplosives) and IEC (International Electrotechnical Commission) provide standards that are recognised internationally * A torch certified to Category 1 (Zone 0) is safe for use in areas rated Category 2 (Zone 1) and Category 3 (Zone 2). Zone dust cloud likely to be present continuously or for long periods Zone 21. The ATEX directive divides risk levels into zones 0/22, 1/21 & 2/22 ATEX equipment marking is based on these ATEX zones The following infographic will explain which industries deal with ATEX, how ATEX zones are specified, what they look like in practice and how they relate to ATEX marking.

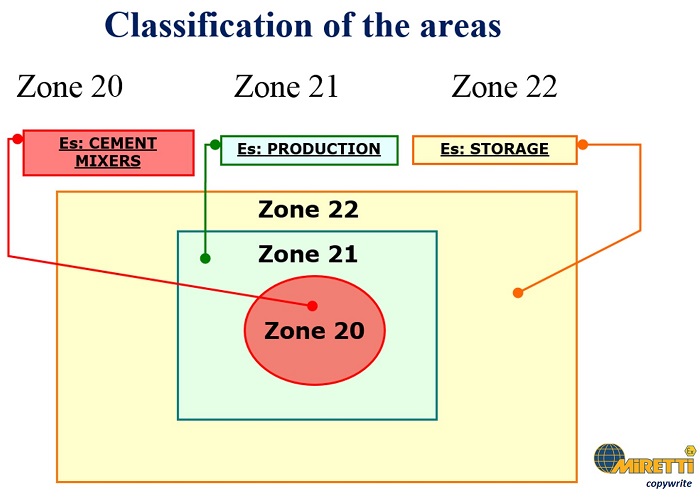

Regarding ATEX 99/92/EC Directive, the requirement is that Employers must classify areas where potentially explosive atmospheres may occur, into zones The classification given to a particular zone, and its size and location, depends on the likelihood of an explosive atmosphere occurring and its persistence if it does. Classify the workplaces into hazardous area Zones depending on the frequency and time that an explosive atmosphere is present in the form of gas, vapour, powder or dust For example ATEX Zone 1 (high risk gas/vapour) ATEX Zone 2 (medium risk gas/vapour) ATEX Zone 21 (high risk powder/dust) ATEX Zone 22 (medium risk powder/dust). Ex d or Ex de IIB or IIC T1 to T6;.

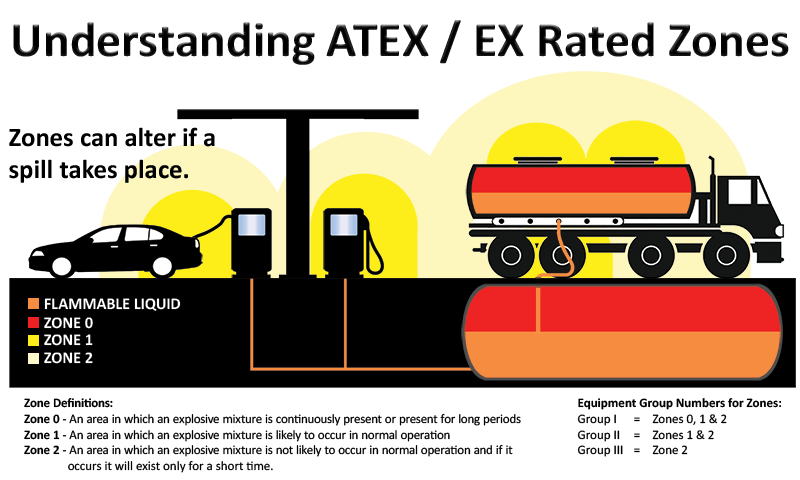

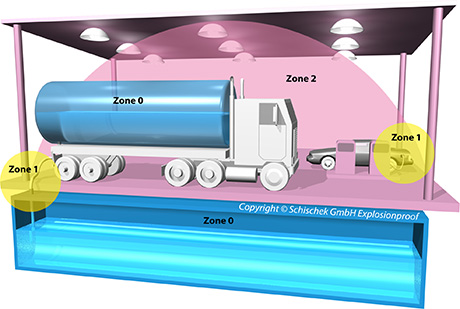

Zone 0 An area where an explosive atmosphere is present continuously or for long periods Zone 1 An area where an explosive atmosphere is likely to to occur in normal operation Zone 2 An area where an explosive atmosphere is not likely to occur in normal operation. See the following chart which shows the zones under both IECEx / ATEX and the North American system of Classes & Divisions Areas where potentially explosive liquids, gases or dust are being produced, refined or where some repeated contact is likely are generally classified as Zone 1 Conversely, examples of Zone 2 areas are storage areas, maintenance workshops and other ancilliary areas adjacent to the main production areas Temperature Classifications. ATEX Directive 14/34/EU is a «new approach» directive that applies to protective systems against explosions as well as all equipment used in or related to explosive atmospheres, such as electrical and nonelectrical equipment, components and safety devices, control and adjustments necessary for the safe operation of this equipment and protective systems.

Outside of North America, ATEX (Appareils destinés à être utilisés en ATmosphères EXplosives) and IEC (International Electrotechnical Commission) provide standards that are recognised internationally * A torch certified to Category 1 (Zone 0) is safe for use in areas rated Category 2 (Zone 1) and Category 3 (Zone 2). 1 Gas a Zone 0—Ignitable concentrations of flammable gases or vapors which are present continuously or for long periods of time b Zone 1—Ignitable concentrations of flammable gases or vapors which are likely to occur under normal operating conditions c Zone 2—Ignitable concentrations of flammable. The next section of the coding refers to the Gas Group or Dust Type of the hazardous environment for which compliance has been certified I is solely for mining applications II covers all gas hazards and is shown as IIA, IIB or IIC which relates to the potential gases that may be present.

1, G Zone Område, hvor der vedvarende, hyppigt eller i længere tid kan være en eksplosiv atmosfære bestående af en sky af brændbart støv og luft 1, D Zone 1 Område, hvor der under normal drift lejlighedsvis kan forekomme eksplosiv blanding af luft og brandfarlig gas, damp eller tåge 1 eller 2, G Zone 21. ATEX Zones – Zones are defined in the ATEX Workplace Directive 1999/92/EC, as follows Gas, Vapor, or Mist Zone 0 – a place in which an explosive atmosphere consisting of a mixture with air of flammable substances in form of gas, vapor or mist is present continuously or for long periods or frequently. This classification is for an EC (ATEX) compliant system for surface equipment that has an equipment category of 2 (Zone 1) and is for gasses as opposed to dusts The protection concept is "d" which is flameproof, the gas group is IIC and the maximum allowable temperature is 0°C.

See the following chart which shows the zones under both IECEx / ATEX and the North American system of Classes & Divisions Areas where potentially explosive liquids, gases or dust are being produced, refined or where some repeated contact is likely are generally classified as Zone 1 Conversely, examples of Zone 2 areas are storage areas, maintenance workshops and other ancilliary areas adjacent to the main production areas Temperature Classifications. Zone 1 classified location An area where ignitable concentrations of flammable gases, vapors or liquids are likely to exist under normal operating conditions As a guide for Zone 1, this can be defined as 10–1000 hours/year or 01–10% of the time Class I, Division 2 or Zone 2 classified locations. Many people have heard terms like Class I, Division 2, Group E, or ATEX zone 21 but many of our customers only know what certification they require with little understanding of what they mean, so we thought it would be appropriate to write a blog post to help customers understand the broader implications of these terms.

Certified weatherproof to IP66;. Zone 1 (gases/vapours) an area in which an explosive mixture is likely to occur in normal operation Zone 2 (gases/vapours) an area in which an explosive mixture is not likely to occur in normal operation and if it occurs it will exist only for a short time ATEX zones for dust. Zones 1 & 2 EExd EN Zones 1 & 2 Exd IEC Class 1 Divisions 1 & 2 UL13 Intrinsic Safety – A technique whereby electrical energy is limited such that any sparks or heat generated by electrical equipment is sufficiently low as to not ignite an explosive atmosphere Zones 0, 1 & 2 EExi EN500 Zones 1 & 2 Exi IEC Class 1.

Zone 1 An area in which an explosive gas atmosphere is likely to occur in normal operation;. Classify the workplaces into hazardous area Zones depending on the frequency and time that an explosive atmosphere is present in the form of gas, vapour, powder or dust For example ATEX Zone 1 (high risk gas/vapour) ATEX Zone 2 (medium risk gas/vapour) ATEX Zone 21 (high risk powder/dust) ATEX Zone 22 (medium risk powder/dust). Home / Hazardous Locations Motors / Zone 2 ATEX & IECEx Motors ATEX & IECEx Zone 2 Increased Safety, and nonsparking electric motors The environments are classified as Zone 2, groups IIA, IIB and IIC, and as Zone 22, groups IIA, IIB and IIC.

Zone 0, 1, 2 – These are zones specifically for atmospheres with hazardous gases, vapors, and mist Zone 0 – Explosive mixtures are present continuously Category 1 equipment required Zone 1 – Explosive mixtures are present intermittently Category 2 or 1 equipment required Zone 2 – Explosive mixtures are present abnormally or infrequently Category 3, 2, or 1 equipment required. 0158 II 2 G Ex db IIC T6 NB 12 ATEX 1007 X II II II II II II T3< 0°C T4< 135°C T5< 100°C T6< 85°C Exd da db dc ta tb tc pxb pyb pzc ma mb mc nC nR ia ib ic eb ec ob oc qb Exe Exi Exp Exm Exo Exq Exn EN EN 1 EN EN EN EN 2 EN 2 – X U 2G 3G 2D 3D 1D IIA IIB IIC Zone 0 Zone 1 Zone 2. Zone 1 Group II Category 2G – the presence of explosive atmospheres is intermittent in normal operation (likely) Zone 2 Group II Category 3G — the presence of explosive atmospheres is occasional or for short periods (never in normal operation) Hazardous Area Zones.

Areas within these two kinds of explosive atmospheres are each divided into three subzones Although the zones characteristics are identical for both gas and dust, their numbering is different Zone 0, 1 and 2 refer to gas and Zone , 21 and 22 refer to dust Permanent presence of explosive gasses or combustive dust. Distance the zone classification is normally zone 2 or Safe Area This is one of the reasons why more than 85% of the Flame Detectors with EEx d housings, which are suitable for zone 1, are actually mounted in zone 2 Engineers design plants and installations with smaller ATEX zones 1 due to the high cost of operation of such hazardous areas That is why zones 2 in the Industry are getting larger. 0158 II 2 G Ex db IIC T6 NB 12 ATEX 1007 X II II II II II II T3< 0°C T4< 135°C T5< 100°C T6< 85°C Exd da db dc ta tb tc pxb pyb pzc ma mb mc nC nR ia ib ic eb ec ob oc qb Exe Exi Exp Exm Exo Exq Exn EN EN 1 EN EN EN EN 2 EN 2 – X U 2G 3G 2D 3D 1D IIA IIB IIC Zone 0 Zone 1 Zone 2.

Zone 1 (gases) An area in which an explosive mixture is likely to occur in normal operation Class I Division 1 (gases) Zone 21 (dusts) Class II Division 1 (dusts) Zone 2 (gases) An area in which an explosive mixture is not likely to occur in normal operation and if it occurs it will exist only for a short time Class I Division 2 (gases) Zone. NonHazardous Area Hazardous Area Zones 1, 2 Isolated coupling IS Barrier ZONE 1 ZONE 2 Figure 23 The installed SPD (here the ESP SL30X Series) provides protection for the instrumentation as well as providing protection for the IS Barrier The isolated screen version (ESP SL30X/I) should be used in Zone 1, 2. Zonex Enclosures are designed and certified to meet ATEX Directive 94/9/EC as well as IECEx and AEx standards for increased safety in housing electrical components in Zone 1 and Zone 2 applications Hoffman’s ATEX Ex e enclosures are not intended for use in explosionproof or flameproof applications.

Zone 1 (Zone 21) is likely to occur in normal operation occasional ly Zone 2 (Zone 22) is not likely to occur in normal operation but if it does occur, will persist for a short period only Zone Definitions. B Zone 1—Ignitable concentrations of flammable gases or vapors which are likely to occur under normal operating conditions c Zone 2—Ignitable concentrations of flammable gases or vapors which are not likely to occur under normal operating conditions and do so only for a short period of time 2 Dust a Zone —An area where combustible dusts or. Zone 1 (gases) An area in which an explosive mixture is likely to occur in normal operation Class I Division 1 (gases) Zone 21 (dusts) Class II Division 1 (dusts) Zone 2 (gases) An area in which an explosive mixture is not likely to occur in normal operation and if it occurs it will exist only for a short time Class I Division 2 (gases) Zone 22 (dusts) Class II Division 2 (dusts).

Hazardous Areas Hazardous Area Zones Guide Explanation Definitions

Avon Ex750 Rising Arm Barriers Atex Iecex Certified Vehicle Control

Hazardous Area Atex Certfied Light Guide Led Work Lights Unilite

Q Tbn And9gctm Vig1iuruiviacx5yldx5uarjrds aslpomoax4otb Nka Usqp Cau

Ex Pressure Sensors And Transmitters For Atex Zone 0 Zone 1 Or Zone 2 Markings Of Pressure Instruments For Use In A Hazardous Area Wika Blog

Is 655 2 Atex Atex Instrinically Safe Zone Tablet Cctv Computer Camera Certified Hazardous What Is Atex

Industrial Iot In Hazardous Areas Microtronics Blog The World Of Iot And M2m

China Led Explosion Proof High Bay Lights Atex Zone 1 Zone 2 China Led High Bay Light High Bay Light

Atex Enclosures Index Atex Zone 2 22

Overview Of Atex Zones And Equipment Ex Machinery Atex Blog

Hazloc Aeu1 Air Heater Hazardous Area Explosion Proof Atex Zone 1 C

Hazardous Location Classification Guide Nec Vs Iec

What Is Atex Jenson Atex Depot

Hazardous Area Atex Zone 1 Zone 2 Flameproof Explosion Proof Intrinsically Safe Manualzz

What Are Atex Zones Koks Robotics

How To Achieve Safe Motion Control In Atex Environments Parker Pneumatics

Ex Zones Divisions Learn More In Our Glossary Ecom Instruments

Classification Of Atex Zones Petzl Other

Identifying Zone 0 Zone 1 And Zone 2 Hazardous Areas Raytec Led Blog

Stahl 6600 Fluorescent Light Fitting Atex Zone 1 Zone 2 Hazardous Area Lighting Pdf Document

Atex Catalog Peli

Atex Zone 1 Zone 2 80w Led Flood Light For Hazardous Location Manufacturers And Suppliers China Factory Wholesale Cary Technology

Atex And Iecex Standards For Intrinsically Safe Load Cells For Hazardous Areas Explained Crosby Straightpoint Uk Europe Usa

Making Your Existing Equipment Atex Compliant

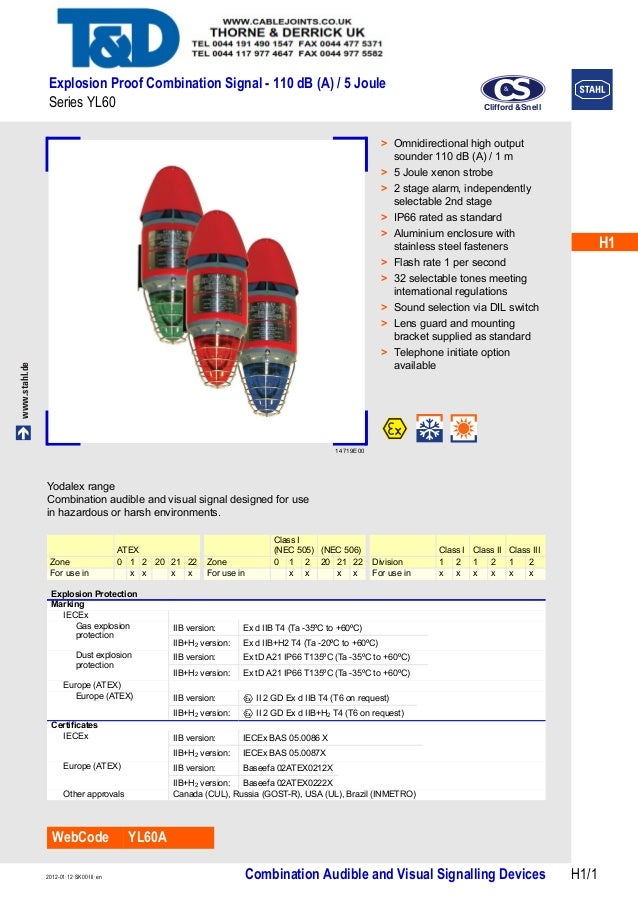

Stahl Yl60 Sounder Signalling Device Atex Zone 1 Zone 2 Hazardous A

Working Group For Safety In Hazardous Areas Atex Zones And Categories Zoning For Working Areas As Defined In The Directive 99 92 Ec

Atex Iecex Markings Explained

Atex Zone 2 Cat 3g Miretti Ex Zone 2 Equipment And Conversion Atex Zone 2 Definition

Stahl 6121 Floodlight Atex Zone 1 Zone 2 Hazardous Area Lighting

Ex D Isolators Hazardous Area Zone 1 Zone 2 Isolators Atex Certified

What Is Atex Zone 1 2 21 And 22 Hoist Uk

Atex From Our Newsletter Nr 1 Comecer

In General Atex Categories And Atex Zones Iwaki Nordic

Www Iecex Com Archive Gdansk Docs D2p2b r fraczek Pdf

Avon Ex750 Rising Arm Barriers Atex Iecex Certified Vehicle Control

Atex Category 1 Equipment

Standards And Regulations Ex Zones Atex Iecex

News Petzl Understanding Atex Markings Petzl Finland

Overview Of Atex Zones And Equipment Ex Machinery Atex Blog

Atex Iecex Getac

Identifying Zone 0 Zone 1 And Zone 2 Hazardous Areas Raytec Led Blog

Atex Zone 0 Classification

Atex Zone 2 Hazardous Duty Motors Ppt Video Online Download

Infographic Atex Zones And Equipment Categories Ex Machinery Atex Blog

Byrne Equipment Rental Atex Zone 1 And 2 Air Fan Kits By Byrnegroup Issuu

The Difference Between The Zone And Division Model Wika Blog

Ex Zone What Is An Ex Zone Atexor Knowledge Base

1

Atex Ex Zoned Equipment Ash Safety

Atex Guardian Telecom

How Sensors Work Atex Intrinsically Safe Sensors

Atex Equipment And Zones Explained Sciencedirect

Explosive Atmospheres Atex Sertec S R L

Q Tbn And9gcs1wplrs2nnxmga0yxqia3kpwv1z4oi6hc9xkcjyvhuxgkclomg Usqp Cau

Hazardex Explosion Proof Atex Zone 1 Ipad For Atex And Iecex

Zone 2 Definition What Is Zone 2 Hazardous Area Atex 1999 92 Ec

Explosion Proof Classification Divisions Zones Of A Spray Room And A Filling Station Explosion Groups Temperature Classes Fire Protection

Hazardous Location Areas And Explosion Proof Vehicles Certifications

Atex Cable Glands Atex Hazardous Area Zone 1 Zone 2 Cable Glands

Atex Catalog Peli

Atex Peli Katalog

Hazardous Area Equipment Certification Atex Zone 1 Zone 2 Iec Ex

Hazloc Products With Class 1 Division 2 Atex Certifications

Bartec Pixavi Zone 1 Vs Zone 2 Hazardous Areas

Useful Information On Atex

Standards And Regulations Ex Zones Atex Iecex

Hazardous Area Zone 1 Zone 2 Atex Flameproof Control Systems Atex

Hazardous Areas Hazardous Area Zones Guide Explanation Definitions

Overview Of Hazardous Areas Expo Technologies

Atex Explained Lgm Products

Control Panels Hazardous Areas Zone 2 Control Panels Atex Certifed

What Is Atex Knivesandtools Explains

Identifying Zone 0 Zone 1 And Zone 2 Hazardous Areas Raytec Led Blog

Overview Of Hazardous Areas Expo Technologies

Q Tbn And9gcrvsqtxmrkekxaqf2wzppgi44j1iwzmianqtnmn3lm6dltsq05q Usqp Cau

Www Interempresas Net Feriavirtual Catalogos Y Documentos Weg Weg Family Of Atex Motors Usaf1031 Brochure English Pdf

Classification Of Atex Zones Petzl Other

Explosion Protection Technical Principles Atex Article Atexdb

Www Galigrup Com Wp Content Uploads 15 10 Atex Protection 2 Pdf

Atex Zone 2 Cat 3g Miretti Ex Zone 2 Equipment And Conversion Atex Zone 2 Definition

Hazardous

Atex Zone 1 Zone 21 Zone 2 Zone 22 Explosion Proof Linear Led Lighting Fixture Manufacturers And Suppliers China Factory Wholesale Cary Technology

Everything About The Different Atex Zones Sensor Partners

What Is Atex Zone 1 2 21 And 22 Hoist Uk

Buy Weighing Indicators For Atex Zone 2 And 22 4 ma From Vetek Here

Led Lighting Fixtures For Use In Hazardous Areas Airfal

Zone 0 1 2 Atex Explosion Proof Light Knowledge Shenzhen Cary Technology Co Ltd

Hazardous Areas Hazardous Area Zones Guide Explanation Definitions

Explosive Atmospheres Atex Sertec S R L

Explosion Proof Classification Divisions Zones Of A Spray Room And A Filling Station Explosion Groups Temperature Classes Fire Protection

Poc5inch Ex Rug Ged Phone Suits For Atex Zone 1 21 Zone 2 22 Anti Explosion For Petroleum Petrochemical Industry Ex Ib Manufacturers And Suppliers In China

Atex Enclosures Index Hazardous Area Information

Explosion Proof Classification Divisions Zones Of A Spray Room And A Filling Station Explosion Groups Temperature Classes Fire Protection

Frequently Asked Questions Atex Ecoquip Blasting Equipment Graco

Hazardous Areas Hazardous Area Zones Guide Explanation Definitions

Overview Of Atex Zones And Equipment Ex Machinery Atex Blog

What Is Atex Zone 1 2 21 And 22 Hoist Uk

Understanding Atex Zones