Hygienic Design

Hygienic Design Of Equipment A Central Point For Food Safety Dairy Industry

Food Safety Hygienic Design Takes The Cake Worldbakers

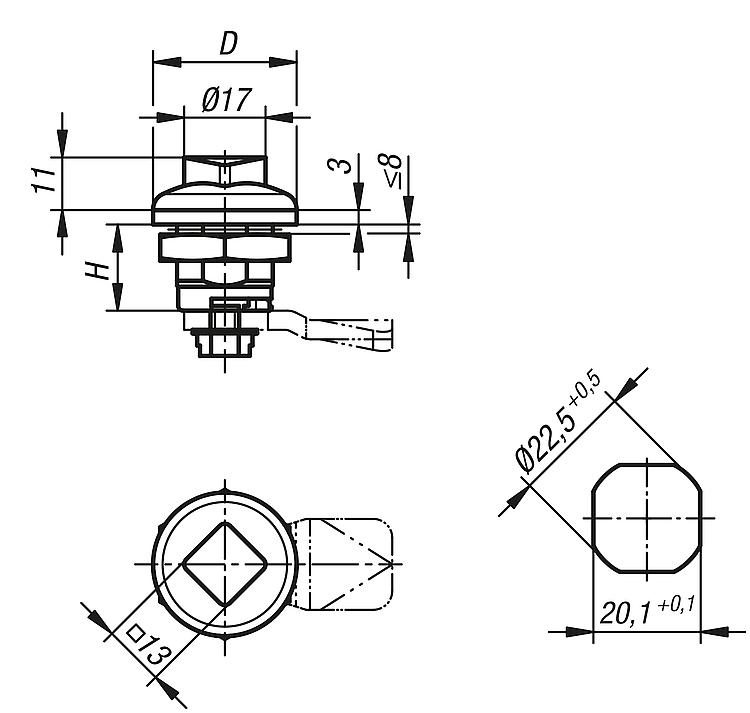

Gn 5445 Stainless Steel Three Lobed Knobs Hygienic Design With Tapped Blind Bore Jw Winco Standard Parts

Hygienic Design A Food Industry Essential

Hygienic Design Werma Signaltechnik Gmbh

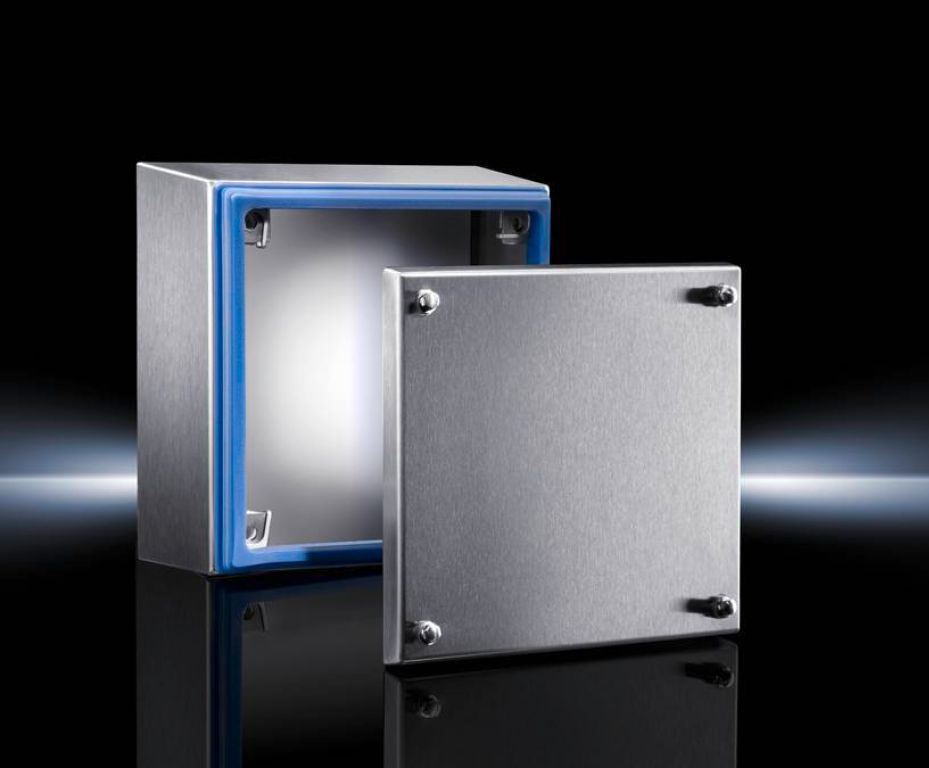

Hygienic Design Compact Enclosure Hd

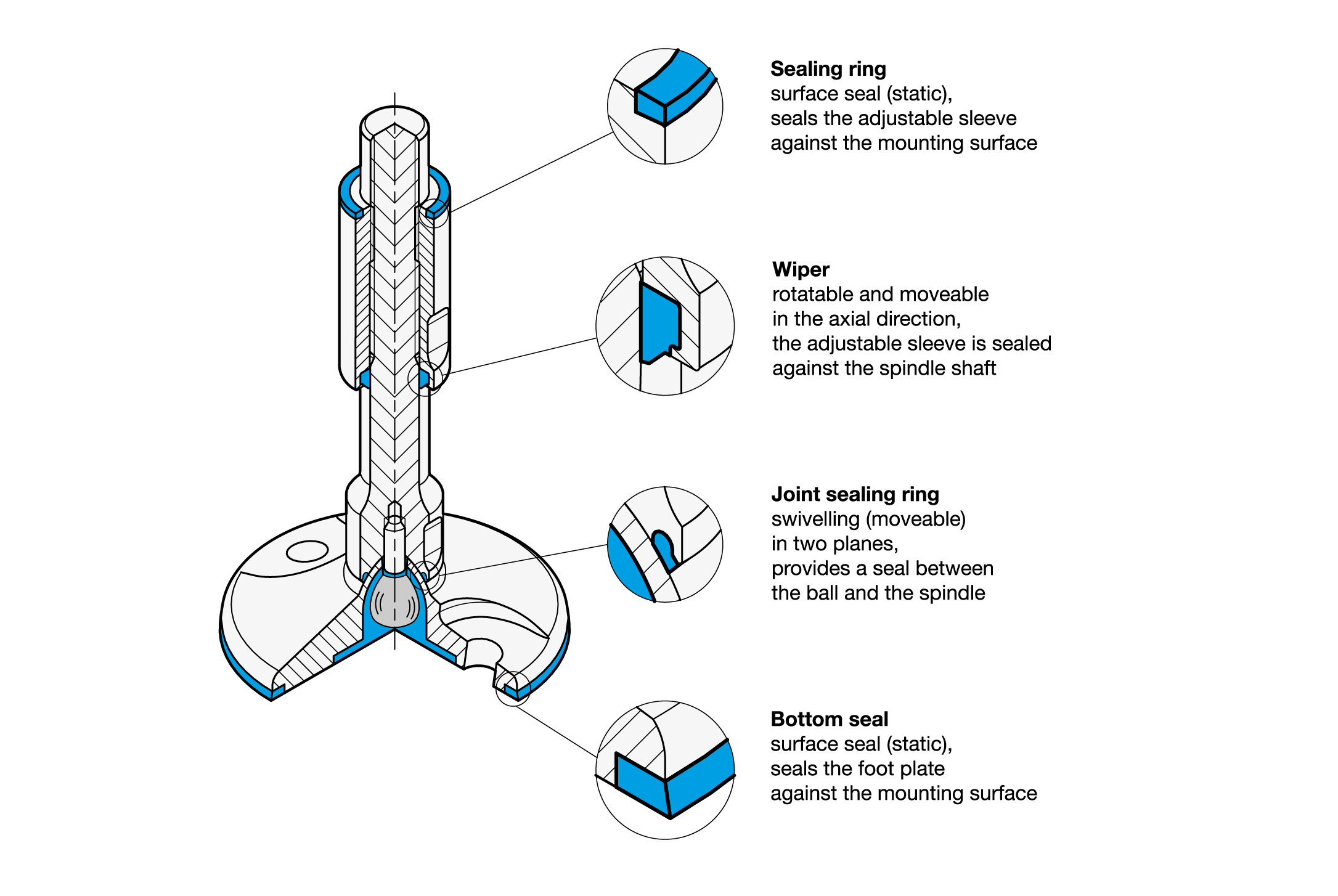

Hygienic Design A must for Hygienic Sealing For the food and beverage industry, identifying seals that meet Hygienic Design standards is one of the most important challenges In food and beverage applications where seals are in direct contact with the end product, Hygienic Design is the key way to make sure that foods and beverages are.

Hygienic design. Design, materials and surface treatments at the service of hygiene Components studied in the geometries, choice of materials and surface finishes to meet the requirements of sectors subject to hygienic regulations, such as food and beverage, pharmaceutical and chemical industries. New Public Consultation Open Hygienic Design in Version 8 Thursday 31 October 19 As part of our development of Version 8 of the GFSI Benchmarking Requirements, GFSI is very pleased to submit our proposed additions addressing hygienic design for a public stakeholder consultation. Hygienic design costs more In the short run this is often true for some equipment The materials of construction, often stainless steel, and the design details increase the initial, upfront cost The longterm benefits of hygienic design over the life of the equipment will reduce the overall operating costs.

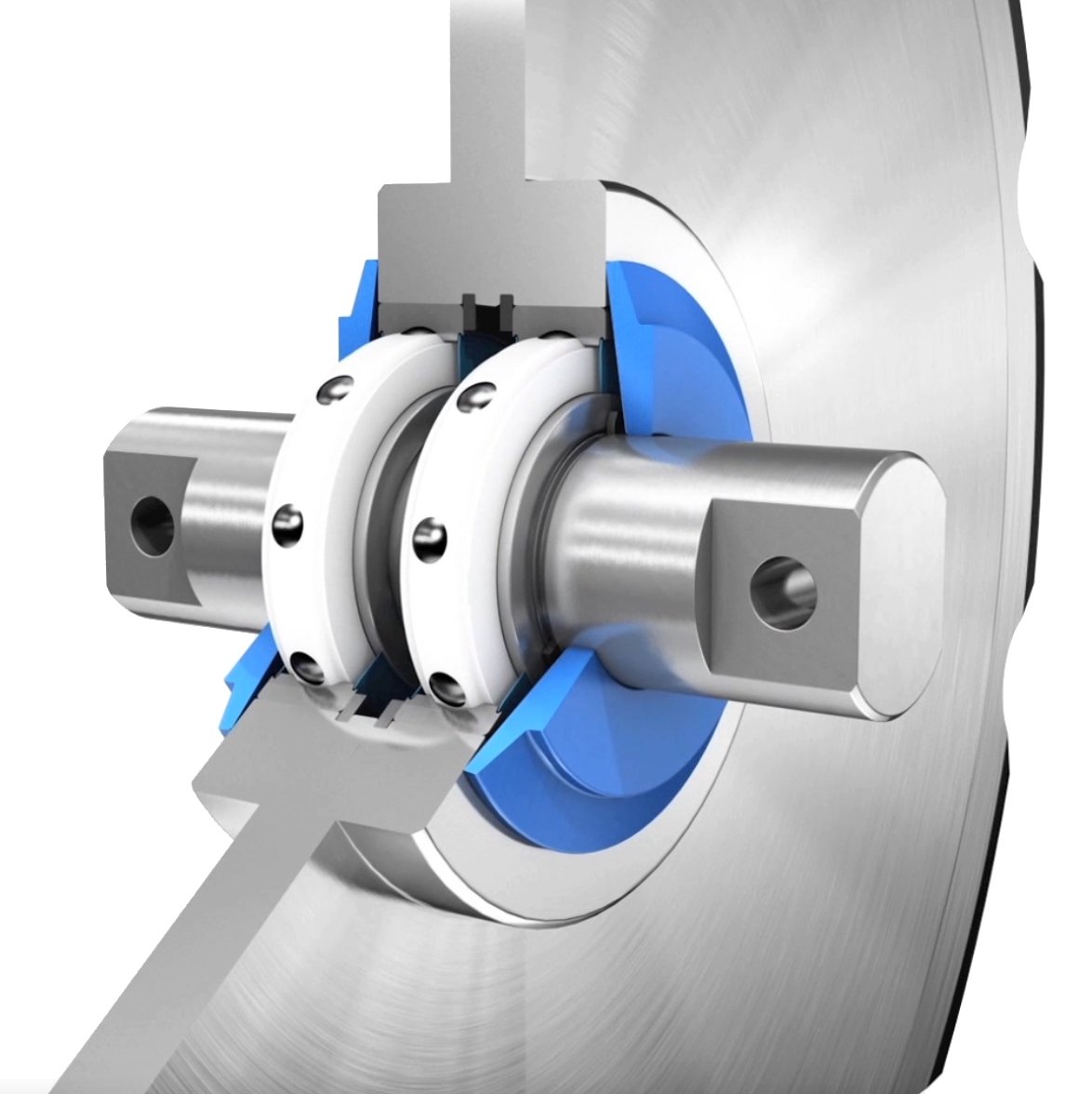

Hygienic design in stainless steel (AISI 304) simplifies cleaning procedures and guarantees food safety with protection category IP 56/59 if correctly fitted – suitable for highpressure and steamjet cleaning. Hygienic Design DESIGN, MATERIALS AND SURFACE TREATMENTS AT THE SERVICE OF HYGIENE Geometry, choice of material, and surface finish have all been considered to meet to meet hygienic regulations in the food and beverage, pharmaceutical,. The Hygienic Design planetary gearbox HDV is the world‘s first planetary gearbox to be certified by the EHEDG Safe, direct integration in the process is now a reality In addition to Hygienic Design gearbox HDV with output shaft we now offer the gearbox HDP with output flange Find The RightSized Solution.

Hygienic Design DESIGN, MATERIALS AND SURFACE TREATMENTS AT THE SERVICE OF HYGIENE Geometry, choice of material, and surface finish have all been considered to meet to meet hygienic regulations in the food and beverage, pharmaceutical,. Hygienic Design DESIGN, MATERIALS AND SURFACE TREATMENTS AT THE SERVICE OF HYGIENE Geometry, choice of material, and surface finish have all been considered to meet to meet hygienic regulations in the food and beverage, pharmaceutical,. Hygienic Design A must for Hygienic Sealing For the food and beverage industry, identifying seals that meet Hygienic Design standards is one of the most important challenges In food and beverage applications where seals are in direct contact with the end product, Hygienic Design is the key way to make sure that foods and beverages are.

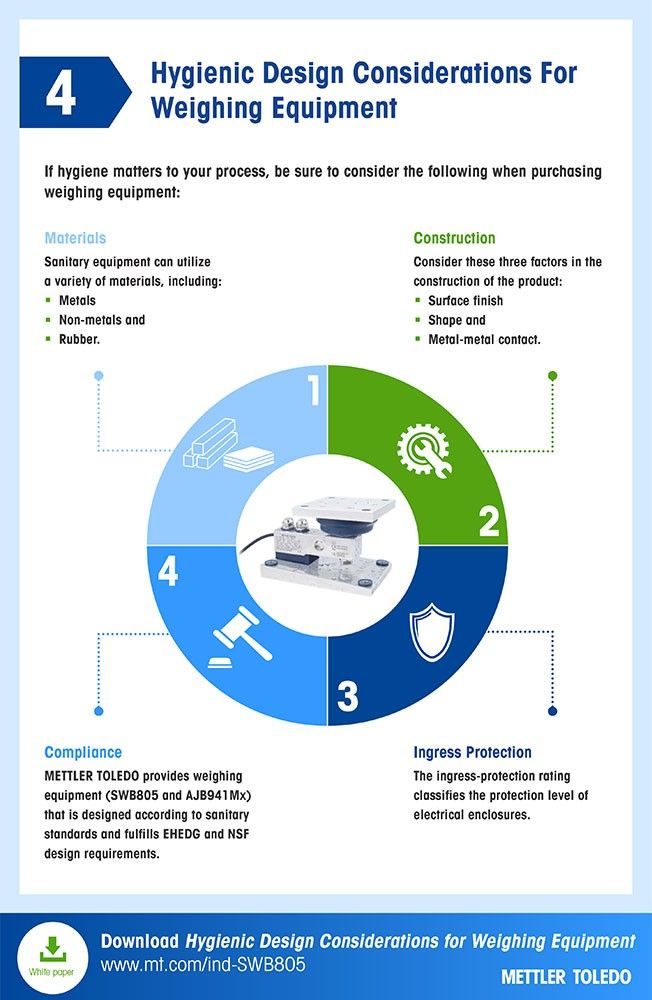

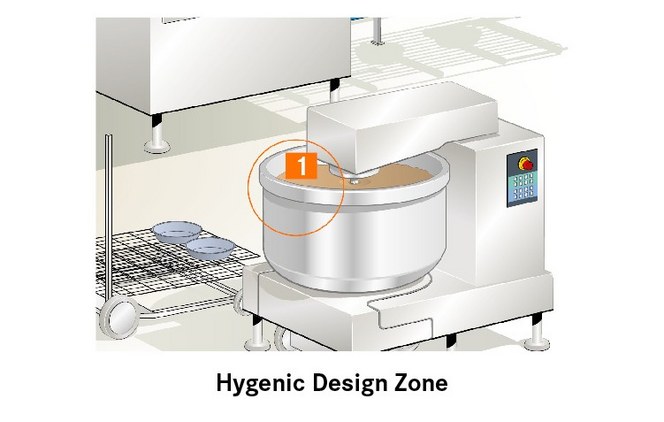

Hygienic design impacts all elements of the food manufacturing infrastructure, including equipment, the facility, buildings and grounds This section outlines key principles of hygienic equipment and facility design with illustrative examples frozen food companies can implement to best address Listeria monocytogenes (Lm) risks. The course provides knowledge of and insight into the hygienic design of equipment and processes for the food, feed and pharmaceutical industry, to better fulfil the wishes of purchasers and retailers These include minimising down time, maintenance, cleaning costs and environmental impact, but also efficient cleaning, optimal product safety and constant product quality. In the EU, EHEDG (European Hygienic Engineering and Design Group) works continuously to improve guidelines for the industry in collaboration with retail, food producers and equipment manufacturers so that the future standard for production, logistics and other product handling is optimised with regard to hygiene.

Hygienic design is an element of sustainable production Hygienic design can be a component of more sustainable production, both ensuring that products are of high, uniform quality with long shelf lives and optimising the consumption of water, energy, and cleaning chemicals through the design of a facility, as well as its production and cleaning procedures. The course provides knowledge of and insight into the hygienic design of equipment and processes for the food, feed and pharmaceutical industry, to better fulfil the wishes of purchasers and retailers These include minimising down time, maintenance, cleaning costs and environmental impact, but also efficient cleaning, optimal product safety and constant product quality. Sanitary and hygienic design take into account all the machinery and related infrastructure involved in processing food for public consumption Different places use different methods depending on the type of product produced or served.

The hygienic design of plants, machines and components is an important part to implement these specifications Further, hygienic design is becoming increasingly important for the production of cosmetic products, at the biotechnology and the chemical industry It makes high demands on the construction, the material and the surface of all plant. Hygienic Equipment Design Basics of Hygienic Equipment Design The purpose of this training module is to provide basic principles of hygienic equipment design for equipment that will be used to produce or process a wide variety of products for human consumption, as well as pet foods. Optimal hygienic design Compliance with high hygiene requirements extends the devices' service life and reduces maintenance effort considerably The result Production costs decline and efficiency increases.

Hygienic by design, COTI delivers a safe and clean solution for OCS COTI reduces customer touchpoints with a 21” touchscreen and premixed beverages, all while reliably delivering the perfect. Sanitary design guarantees easy cleaning because of fewer areas that can trap food and cause contamination In addition, the hygienic machine design allows food manufacturers to minimize downtime and product waste, ensure consistently high product quality and focus on developing and delivering fresh and safe products to consumers. In the EU, EHEDG (European Hygienic Engineering and Design Group) works continuously to improve guidelines for the industry in collaboration with retail, food producers and equipment manufacturers so that the future standard for production, logistics and other product handling is optimised with regard to hygiene.

Hygienic Design Hygienic design impacts all elements of the food manufacturing infrastructure, including equipment, the facility, buildings and grounds This section outlines key principles of hygienic equipment and facility design with illustrative examples frozen food companies can implement to best address Listeria monocytogenes (Lm) risks. Hygienic Design DESIGN, MATERIALS AND SURFACE TREATMENTS AT THE SERVICE OF HYGIENE Geometry, choice of material, and surface finish have all been considered to meet to meet hygienic regulations in the food and beverage, pharmaceutical,. A hygienic design refers to the design of machinery, plant and components that are easy to clean and maintain in a hygienic condition for use in areas where hygiene is a priority, such as in the production of foodstuffs and pharmaceutical, cosmetic or biotechnical products Hygienic design also includes design principles for preventing design.

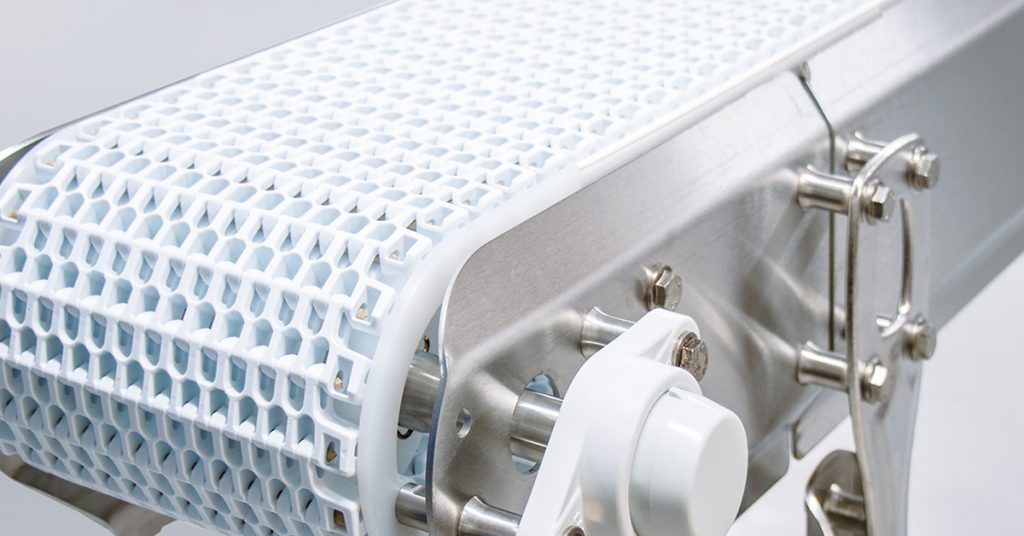

The Hygienic Design product family All Standard Parts of the “Hygienic Design” product family are labeled with the HD icon They combine high surface quality, freedom from dead spaces, nonscooped outer surfaces, and sealed bolting areas A sealing concept based on FEM calculations ensures reliable contact pressure after installation. Hygienic Design HD system enclosure The HD system enclosure is a flexible, bayable large enclosure solution for hygienically sensitive areas that are subjected to regular cleaning With its standard TS mounting plate and fitting components within the sealed area, and when equipped with the appropriate HD and TS 8 accessories, the enclosure is. Hygienic design is a set of processes and principles to manage potential hazards and reduce food safety risks as it relates to equipment, processes and facilities These processes and principles include Specification of safe and durable materials, stainless steel being the most common choice Managing the potential for foreign objects and substances including physical, chemical and.

EHEDG (European Hygienic Engineering and Design Group) has been supporting sanitary and hygienic design efforts in food production and packaging since 19 With its network of research institutes, it provides scientific grounds on which standards could be built or improved upon The EHEDG certificate is recognized primarily in Europe. 17 Hygienic design of pumps, homogenizers and dampening devices (13) 18 Chemical Treatment of Stainless Steel Surfaces (14) 19 A method for assessing the bacterial impermeability of hydrophobi c membrane filters (12) Hygienic design and safe use of doubleseat mixproof valves ( 00). Hygienic food factory design provides Defence against external factory hazards Defence against internal factory hazards no harbourage sites and ease of cleaning Internal flows of people, product, packaging, air and wastes to prevent crosscontamination Security against deliberate contamination.

The Hygienic Design product family All Standard Parts of the “Hygienic Design” product family are labeled with the HD icon They combine high surface quality, freedom from dead spaces, nonscooped outer surfaces, and sealed bolting areas A sealing concept based on FEM calculations ensures reliable contact pressure after installation. Whether referencing the European Hygienic Engineering Design Group Hygienic Design Principles, Codex Alimentarius, CFR Title 21 Part 110, or the North American Meat Institute’s fact sheets on hygienic design of equipment, we cannot lose sight of the overriding principles and goals of hygienic design. AVENTICS has expertise in designing hygienic devices that ensure that the foodstuffs currently produced are not contaminated, even with adhering food residue or microorganisms.

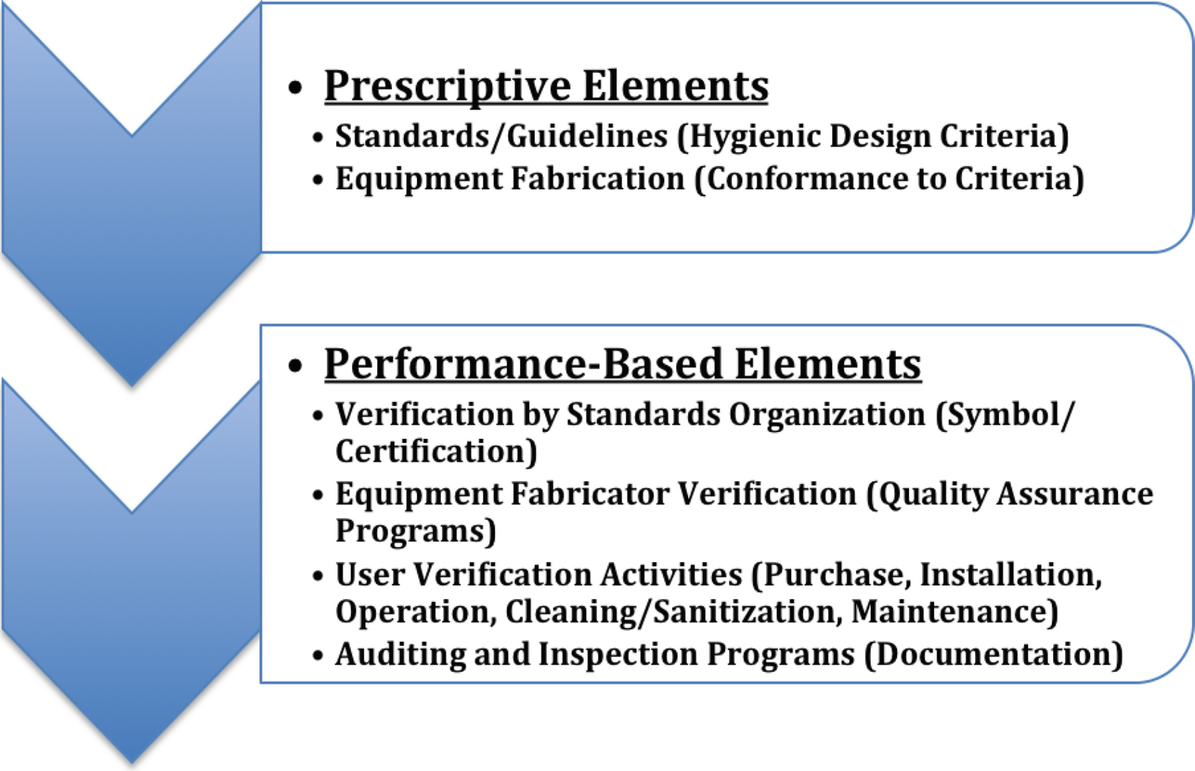

Hygienic design in food processing plays an important role in controlling the microbiological safety and quality of the products made This will prevent products from having undesirably high microbial counts, containing toxins or chemical residues, or from contamination from other nonfood substances. The hygienic design elements included in the standard are based on the PMMI B155 TR3 technical report facilitated by PMMI and its OpX Leadership Network The report defines a fourstep process, beginning with risk assessment, which allows hygienic and machinery hazards to be collectively assessed and mitigated. Hygienic design — whether implemented during facility construction and equipment purchase or through later renovations, modifications, or additions — will help to protect your products, customers, and brand A thorough assessment of your facility and equipment can reveal inadequacies and needed improvements and ensure you are fully.

Design, materials and surface treatments at the service of hygiene Components studied in the geometries, choice of materials and surface finishes to meet the requirements of sectors subject to hygienic regulations, such as food and beverage, pharmaceutical and chemical industries. Hygienic design — whether implemented during facility construction and equipment purchase or through later renovations, modifications, or additions — will help to protect your products, customers, and brand A thorough assessment of your facility and equipment can reveal inadequacies and needed improvements and ensure you are fully. Optimal hygienic design Compliance with high hygiene requirements extends the devices' service life and reduces maintenance effort considerably The result Production costs decline and efficiency increases.

Hygienic design of food factories This book provides an authoritative overview of hygiene control in the design, construction and renovation of food factories The business case for a new or refurbished food factory, its equipment needs and the impacts on factory design and construction are considered in two introductory chapters. Hygienic food factory design provides Defence against external factory hazards Defence against internal factory hazards no harbourage sites and ease of cleaning Internal flows of people, product, packaging, air and wastes to prevent crosscontamination Security against deliberate contamination. The design of our hygienic load cells is based on the strict hygienic guidelines for the production areas of the food and pharmaceutical industry Their unique design features easy and secure inspection and cleaning and thus reduces any contamination risk The materials used provide solid corrosion protection, even when cleaned frequently with aggressive agents.

Hygienic design is a set of processes and principles to manage potential hazards and reduce food safety risks as it relates to equipment, processes and facilities These processes and principles include Specification of safe and durable materials, stainless steel being the most common choice Managing the potential for foreign objects and substances including physical, chemical and. Geniox air handling units are #HygienicByDesign and set new industry standard with Eurovent Hygiene Certification as an additional option In view of modern society’s growing awareness on the importance of indoor air quality (IAQ), Systemair believes that all air handling units (AHUs) should be #HygienicByDesign. Hygienic design is an element of sustainable production Hygienic design can be a component of more sustainable production, both ensuring that products are of high, uniform quality with long shelf lives and optimising the consumption of water, energy, and cleaning chemicals through the design of a facility, as well as its production and cleaning procedures.

The hygienic design elements included in the standard are based on the PMMI B155 TR3 technical report facilitated by PMMI and its OpX Leadership Network The report defines a fourstep process, beginning with risk assessment, which allows hygienic and machinery hazards to be collectively assessed and mitigated. Hygienic design costs more In the short run this is often true for some equipment The materials of construction, often stainless steel, and the design details increase the initial, upfront cost The longterm benefits of hygienic design over the life of the equipment will reduce the overall operating costs. The hygienic cable entry plates KELDPZHD with metric threads from M32 to M63 have been developed for installation in food processing and packaging machinery During the development according to the Hygienic Design guidelines, care was taken to ensure that the visible sides of the cable entry plate are free of dirtcollecting recesses.

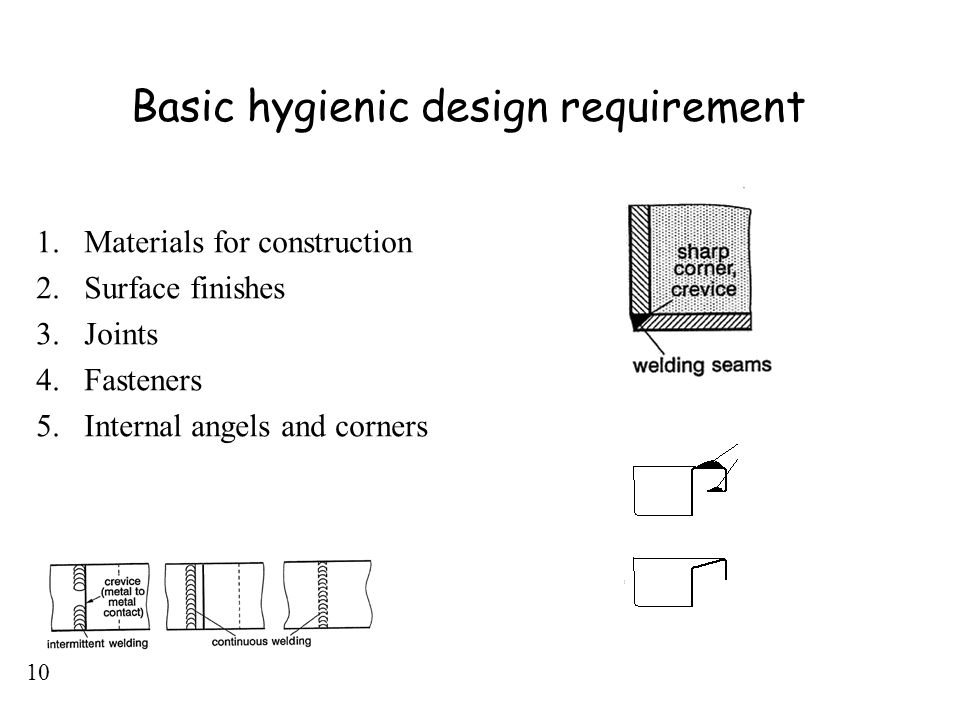

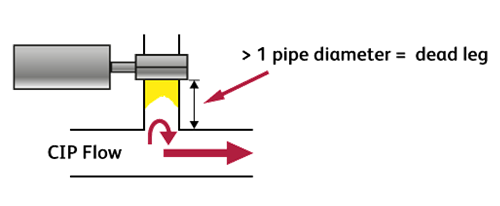

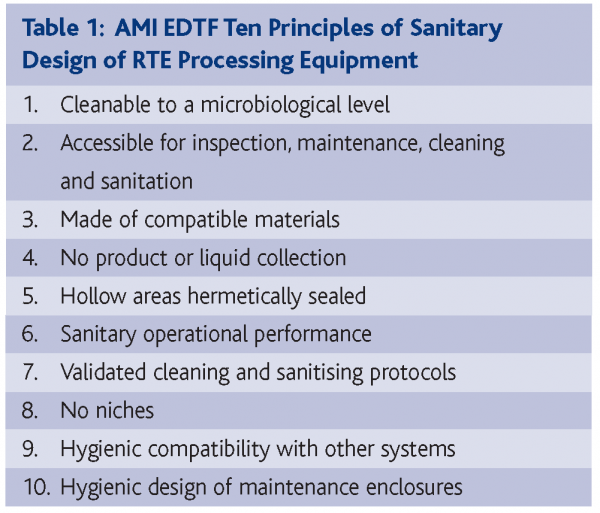

The American Meat Institute has come up with the following principles of hygienic design for food processing facilities These design principles have been created to reduce food safety hazards, keeping food safe Whether you're building a new facility, updating your existing one or onboarding new employees, take these principles of hygienic design into consideration to prevent food borne. The hygienic design elements included in the standard are based on the PMMI B155 TR3 technical report facilitated by PMMI and its OpX Leadership Network The report defines a fourstep process, beginning with risk assessment, which allows hygienic and machinery hazards to be collectively assessed and mitigated. Basic principles of hygienic design The most common design faults which cause poor cleanability are poor accessibility, inadequately rounded corners, sharp angles and dead ends It must be recognised that there are degrees of sanitary design generally related to the permitted tolerance of microbial infection in the final product.

Hygienic Design and Controls April 29, Established in 18, the Food Safety Modernization Act (FSMA) demands that food processors comply with advanced hygienic design standards FSMA represented a major shift in the industry, transferring priority from treating foodborne illness to preventing it entirely. The hygienic design of plants, machines and components is an important part to implement these specifications Further, hygienic design is becoming increasingly important for the production of cosmetic products, at the biotechnology and the chemical industry It makes high demands on the construction, the material and the surface of all plant. Hygienic design in stainless steel (AISI 304) simplifies cleaning procedures and guarantees food safety with protection category IP 56/59 if correctly fitted – suitable for highpressure and steamjet cleaning.

Hygienic design of food factories provides an authoritative overview of hygiene control in the design, construction and renovation of food factories The business case for a new or refurbished food factory, its equipment needs and the impacts on factory design and construction are considered in two introductory chapters. Hygienic Design DESIGN, MATERIALS AND SURFACE TREATMENTS AT THE SERVICE OF HYGIENE Geometry, choice of material, and surface finish have all been considered to meet to meet hygienic regulations in the food and beverage, pharmaceutical,. With stainless steel open frame designs, clean surfaces and clutterfree work areas, innovative packaging machinery solutions will help you to achieve the highest hygiene standards, preventing bacterial contamination, and enabling you to meet regulatory requirements Retain your key customers.

Hygienic design means designing systems like checkweighers or Xray inspection equipment, which are used in hygienerelevant areas such as those in the food industry, so that cleaning is effortless The aim is to prevent design flaws that could promote hygienerelated hazards The ability to clean materials, surfaces and structural elements. Hygienic Design Sarah Polo 0402T Hygienic Design Our experts have extensive hygienic equipment and facility design experience and can help verify regulatory compliance as well as provide recommendations to your cleaning and sanitization processes.

Www Designsociety Org Download Publication New Ways Of Hygienic Design E2 80 93 A Methodical Approach

Food Safety Considerations For Robot System Overall Hygienic Design Principles Sirris

Hygienic Design Of Food Processing Equipment Sciencedirect

Hdw Hygienic Design Wall Mounted Enclosures Eldon Global Website

Hygienic Design Considerations For Weighing Equipment Mettler Toledo

Hygienic Design How To Design Plants And Equipment

Standard Parts In Hygienic Design Elesa Ganter

Hygienic Design Is Mandatory Hbm

Q Tbn And9gcrejfzum4ltfmamxxxb7d5ldm369jrwnld9vxipb5i L7tbvvrv Usqp Cau

Kipp Quarter Turn Locks Stainless Steel In Hygienic Design

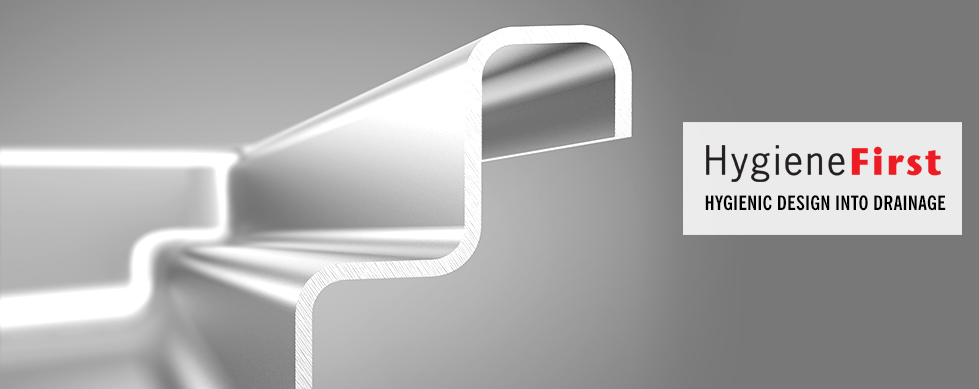

Hygiene First

Gn 429 Bridge Handles Hygienic Design Elesa

Standard Parts In Hygienic Design Ganter Norm

Jw Winco Now Offers Nuts With Hygienic Design

Wittenstein Hygienic Design Wittenstein Se

Hygienic Design Das Mussen Sie Unbedingt Wissen

Normelemente Im Hygienic Design

Dr C Hanser Ag Gn 1581 Stainless Steel Screws Hygienic Design Low Profile Head

Edepot Wur Nl 4570

Principles For Hygienic Design And Zoning Ppt Video Online Download

Skf Why Hygienic Design Of Bearings Is Key To Food Safety T Co Zml81t1dym Foodproduction Foodandbeverage Foodhygiene Ehedg T Co F8gznz4cko

Hygienic Design System Solution For Hygienic Production Sick

Hygienic Design Cable Glands Hugro Armaturen Gmbh

Hygienic Design Is Mandatory Hbm

When To Use Hygienic Design Vs Washdown Automation Insights

Hygienic Design Groschopp Ag Drives More

Hygienic Design Dbi Control

Hygienic Design For Processing Equipment Food Quality Safety

Brand New Hygienic Design Wall Mounted Enclosures Now In The Market Eldon Global Website

Decanter In Hygienic Design Box Distributor Gea Video Portal

Standards Aco Gully

Ten Principles Of Hygienic And Sanitary Design Diversey South Africa

Hygienic Design And Installation Of Agitators In Closed Vessels Hygienic Design Of Permanently Installed Agitators Food Protection And Security Preventing And Mitigating Contamination During Food Processing And Pro

Screws And Nuts In Hygienic Design

Hygienic Design Zone

Hygienic Design Minebea Intec

Dr C Hanser Ag Gn 8170 Stainless Steel Indexing Plungers Knob And Pin Side Hygienic Design Full Hygiene

Prodec Introduces Hygienic Design Prodec

Food Equipment Cleaning Hygienic Design Inspection System Lifetime

Hygienic Design Elesa

Hygienic Design Of Food Factories 1st Edition

Konig Backereimaschinen Hersteller Fur Backereitechnik News Messen

Hygienic Design Autonox24 Com

Nt Hd Sst Screws And Nuts Hygienic Design Elesa

Why Hygienic Design Protects Food Production Flexlink Blog

Hygienic Design How Our Thinking Has Evolved Food Safety Magazine

Http Www Ifst Org Sites Default Files E partington ifst hygiene 25th february Pdf

Hygienic Design And Maintenance Of Equipment Sciencedirect

Hygienic Design Of Food Processing Equipment Sciencedirect

Hygienic Design Compact Enclosures Rittal Esi Building Services

Hygienic Design Of Food Processing Equipment Sciencedirect

Aco Food Standards Hygiene And Slip Resistance

Pdf Risk Management By Hygienic Design And Efficient Sanitation Programs

Standard Parts In Hygienic Design Ganter Norm

Sanitary Design An Introduction To Standards Of Design Excellence Nov

Cube67 Hygienic Design I O Extension Module Murrelektronik Shop

Why You Should Invest In Hygienic Design Profood World

Hygienic Design Enhances Food Safety Brand Protection Regulatory Compliance And The Bottom Line 16 10 25 Food Engineering

Sign Up For Our Newsletter And Receive Our Newest Leaflet On Hygienic Design And Sanitary Guidelines Graintec

Hygienic Design For Process Systems Ruland

Hdp Hygienic Design Planetary Gearbox Wittenstein Alpha Gmbh

Standard Parts In Hygienic Design Ganter Norm

Hygienic Design And Maintenance Of Equipment Sciencedirect

Sanitary And Hygienic Design Guide For Food Equipment Mpc

Hygienic Design How Our Thinking Has Evolved Food Safety Magazine

Hygienic Design Food Safety Aventics Expertise

Ilinox Pushbutton Box x142xmm 2x22mm Hole Ip66 Ip69k Ss304 Hygienic Design Hygienical Food Beverage Industry Product Solutions

Hygienic Design For Process Systems Ruland

Hygienic Design Affi Food Safety Zone

Hygienic Design Of Food Processing Equipment Sciencedirect

Hygienic Design Requirements For Components In Hygienic And Sterile Processes New Food Magazine

Hygienic Design Freudenberg Fst

Hygienic Design Reduces Cleaning Effort

Paperback Hygienic Design Of Food Factories By John Holah

Handbook Of Hygienic Design In Dairy Industry Guide For Food Processing Plants Zeytinci Ceren Amazon Com Books

Brandneue Wandschranke Im Hygienic Design I Magazin

Sanitary Design Principles For Meat Processing New Food Magazine

Hygienic Design Is Important In New Production Equipment

Plant Engineering 5 Key Questions To Answer During Hygienic Food Plant Design

Hygienic Design Screws Stainless Steel Gn1580 Ehedg Certified H Nbr Sealing Ring

Hygienic Design For Valve Clusters Scientist Live

Province Of Manitoba Agriculture Sanitary Design Of Equipment

Taking A Holistic Approach To Hygienic Design 16 05 17 Dairy Foods

Sanitary And Hygienic Design Guide For Food Equipment Mpc

The Hygienic Sanitary Design Of Food And Beverage Processing Equipment Springerlink

Hygienic Design Of Food Processing Equipment Sciencedirect

Ten Principles Of Hygienic And Sanitary Design Diversey Denmark

Hygienic Design Of Process And Utility Piping Drainable Process And Utility Lines Without Dead Ends Food Protection And Security Preventing And Mitigating Contamination During Food Processing And Pro

Hygienic Design The New Elesa Components Line To Guarantee Companies Hygiene And Maximum Machineries Cleanability Via Pompei 29 900 Monza Mb Italy Elesa

Home Ehedg

New Ways Of Hygienic Design A Methodical Approach Semantic Scholar

Hygienic Design Food Safety Buhler Group

Decanter In Hygienic Design Nozzles Gea Video Portal

Hygienic Design

The Growing Importance Of Hygienic Design Your Partners In Hygiene