5s Workshop Activities

5 S Process Improvement 5s Video Elearning Training Certification

Lean 5s Challenge Game

What Is The 5s System Definitions Core Concepts Principles Graphic Products

Implementing 5s Methodology The First Step Toward Workplace Efficiency Updated

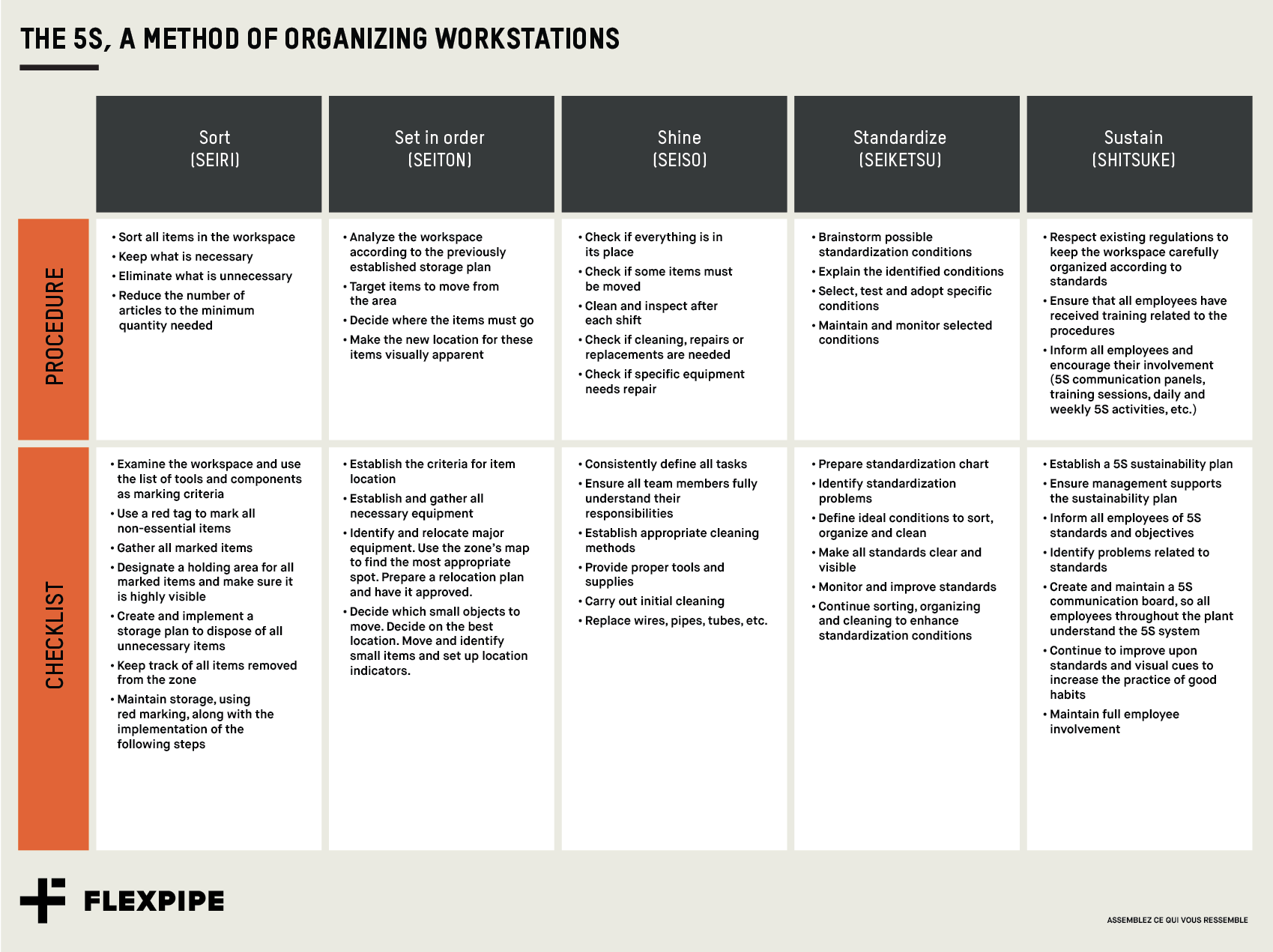

The 5s System Lean Manufacturing Methodology

The 5s System Lean Manufacturing Methodology

The 5S Alphabet Game Online A webbased 5S game Lean Lingo Bingo A bingo game to use while you're presenting The Multitasking Test Prove how great at multitasking you are with this quick, online game The Name Game Write down names to prove that multitasking doesn't work The 5S Shapes Game A Japanese lean guy teaches 5S using geometric shapes.

5s workshop activities. Mar 2, 17 Explore Vipul Vikas Singh's board "5S Ideas" on See more ideas about lean manufacturing, visual management, kaizen. A Japanese trainer eloquently presents a lean 5S game in the following video Lean 5S games differ a little from typical lean push vs pull games, since 5S focuses on organization, visual controls and standardization In many of these 5S games, a team sorts through a large group of items, trying to find specific things. This final step helps to maintain the progress built through the first four steps, and eliminates waste by ensuring the wastesaving practices of 5S are adhered to.

5S is amongst the first and fundamental steps implemented by an enterprise towards the path of implementing Total Quality Management and continuous improvement at the operation level 5S is a process designed to organize the workplace, keep it clean,. An experiential learning activity for 5S training session Song Yume no naka e Artist Inoue Yosui wwwfacebookcom/fauzantribe. But I really want to make this training handson, and am looking for exercises to demonstrate 6S, standard work, takt time, value stream mapping etc Thanks!.

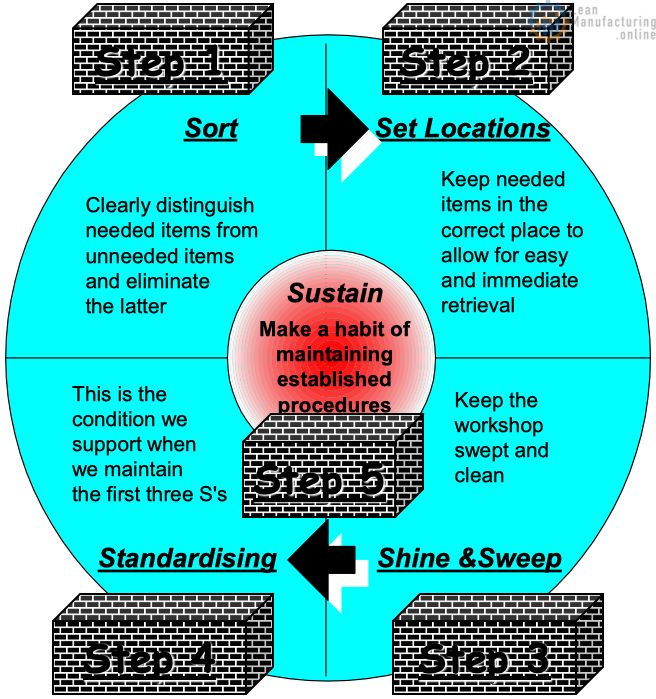

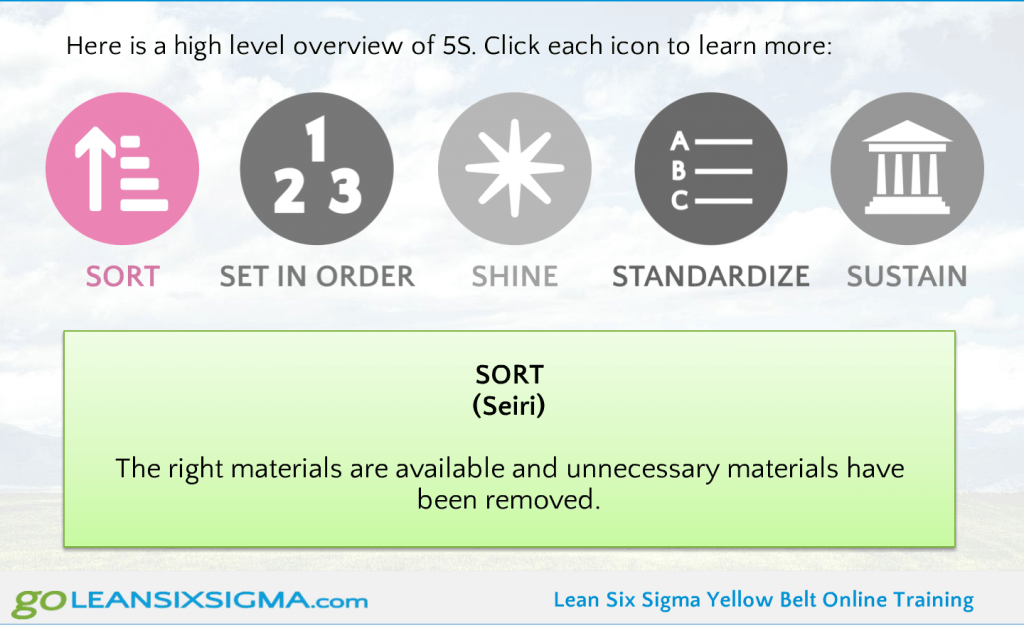

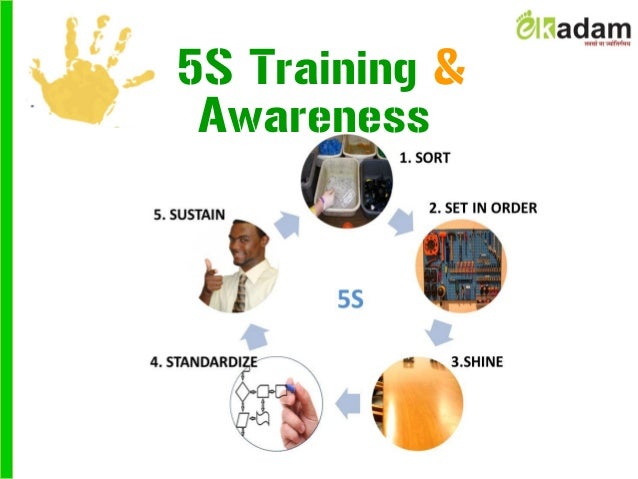

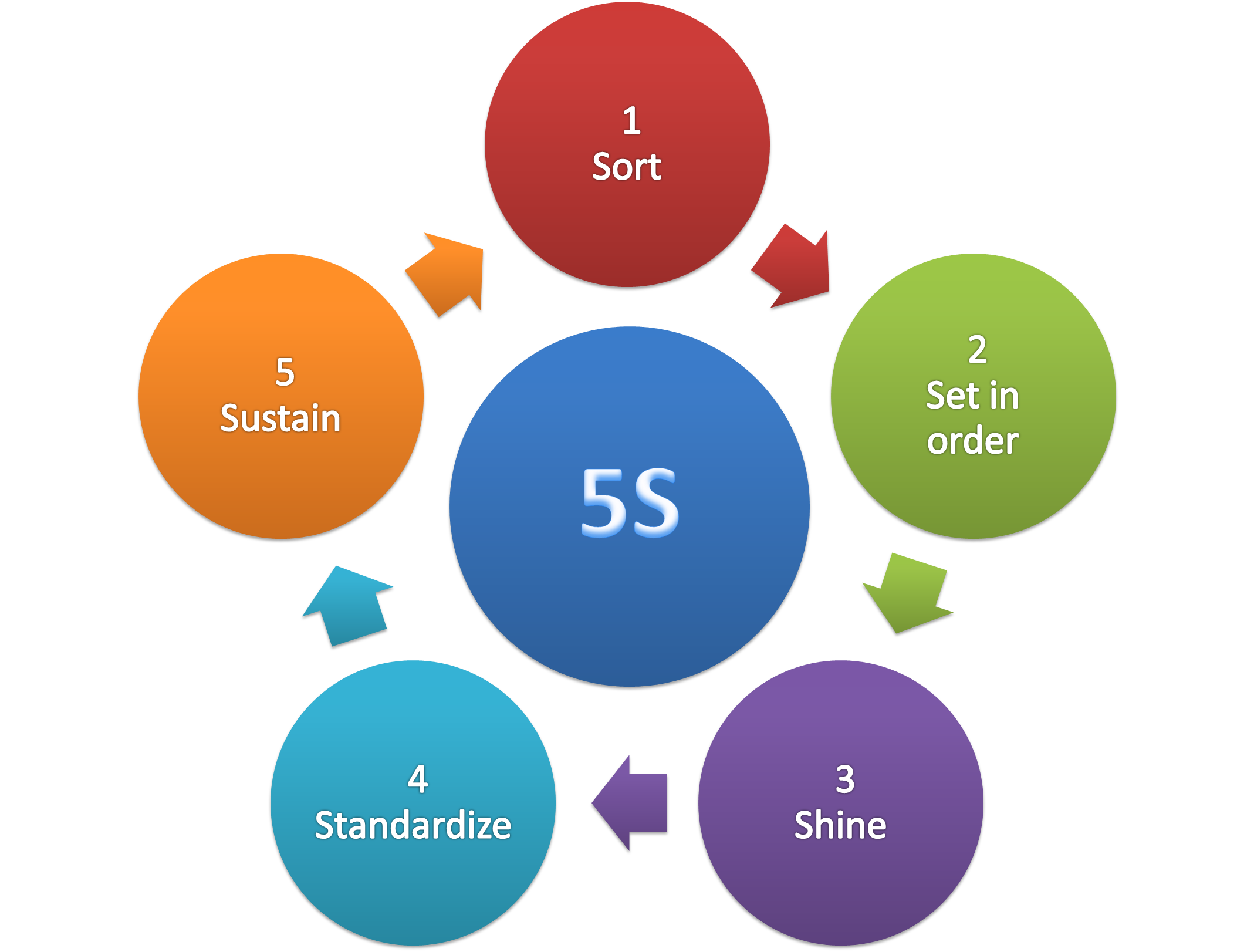

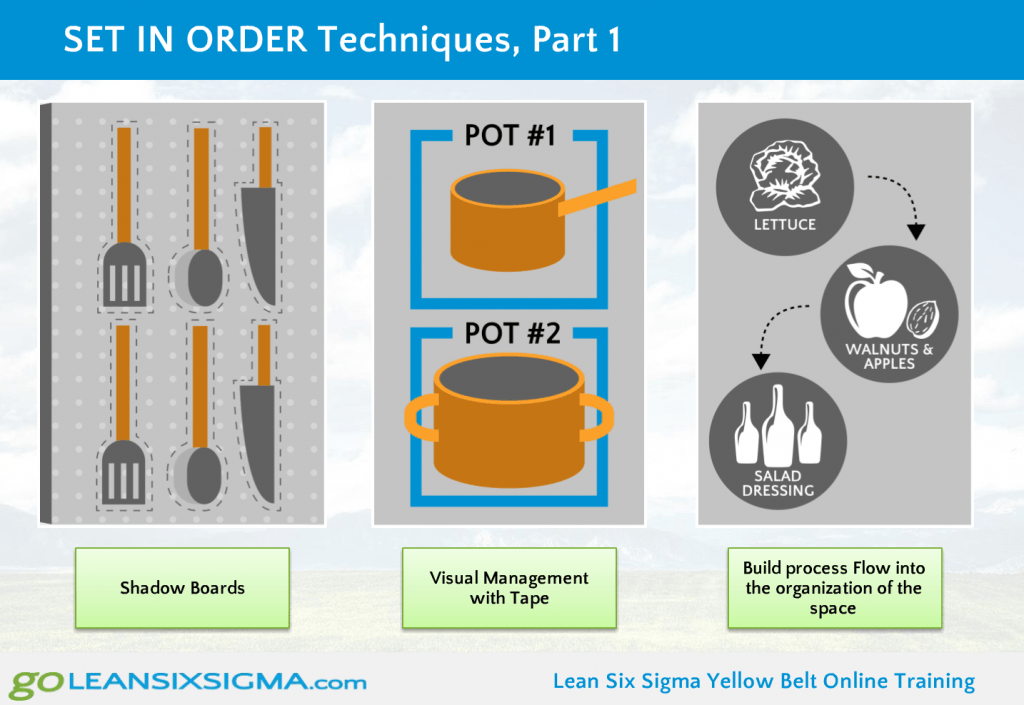

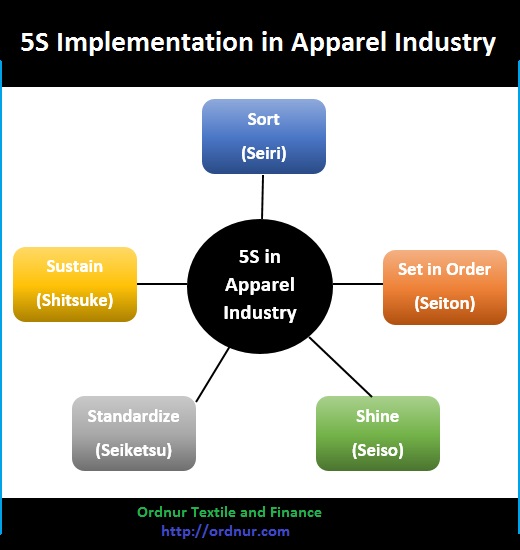

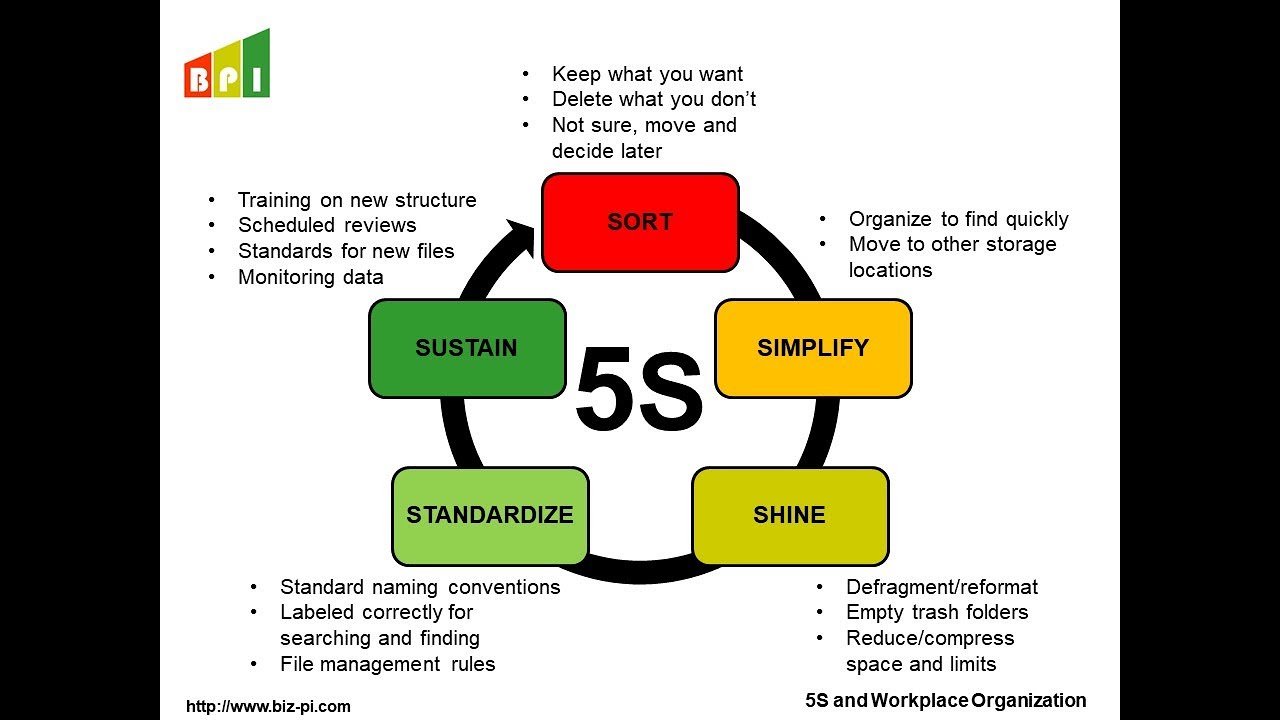

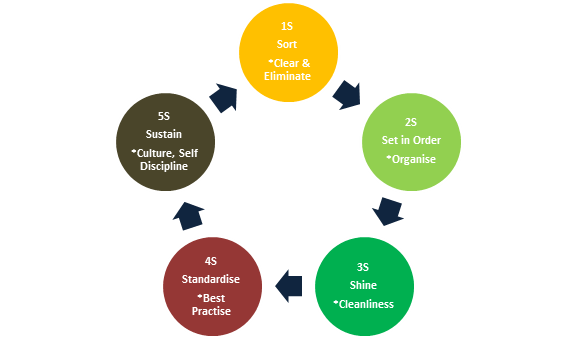

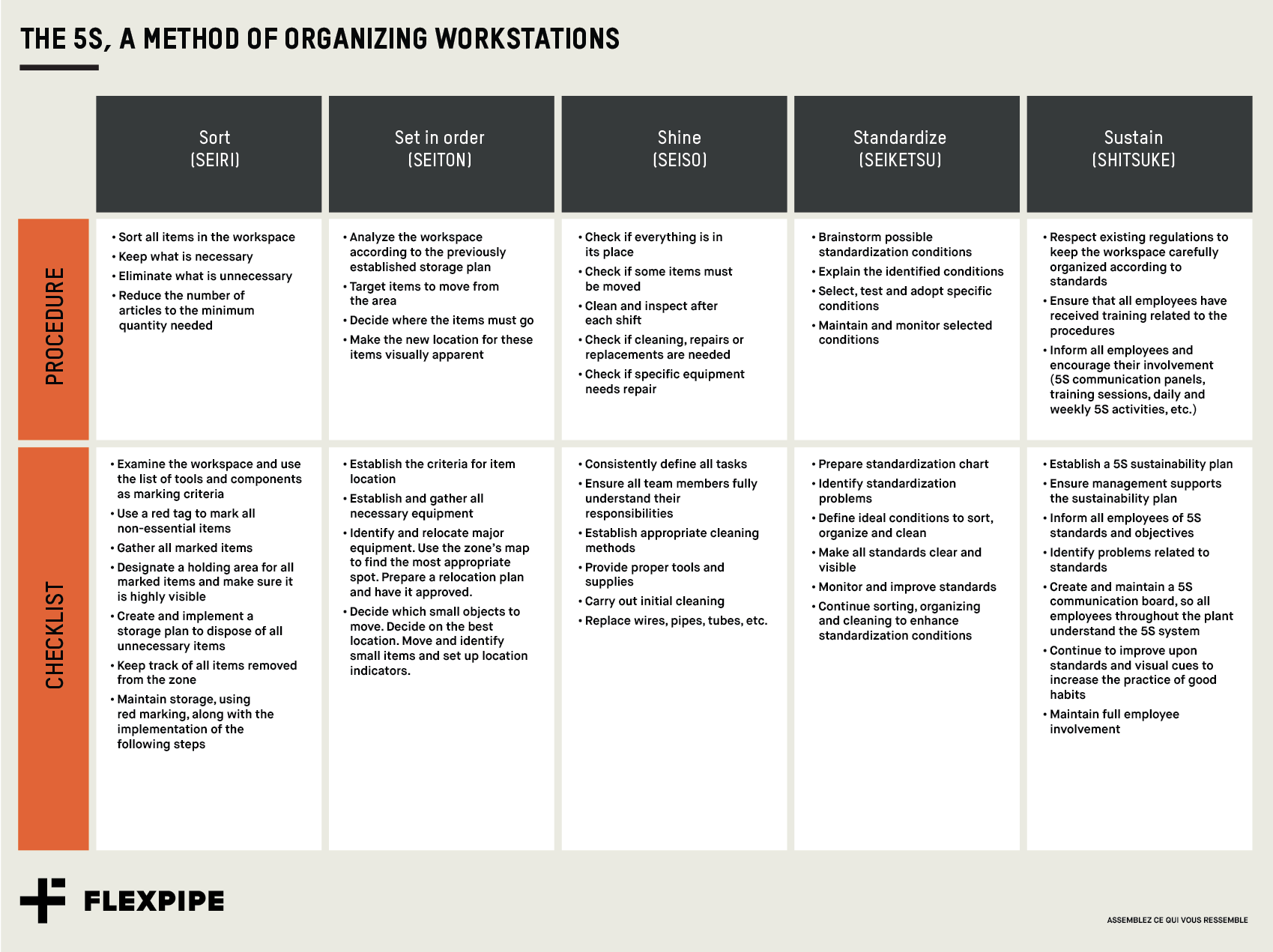

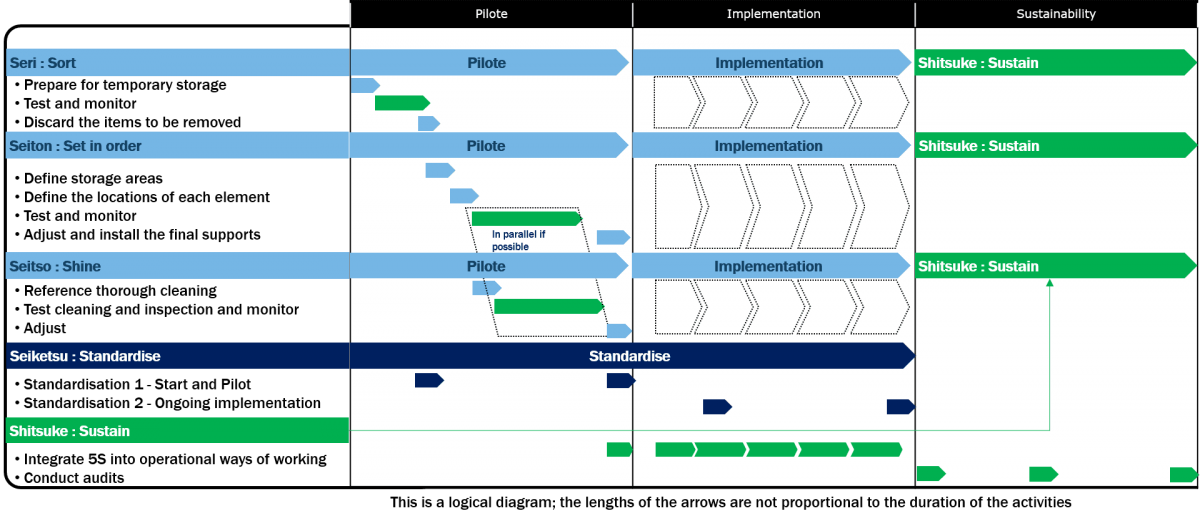

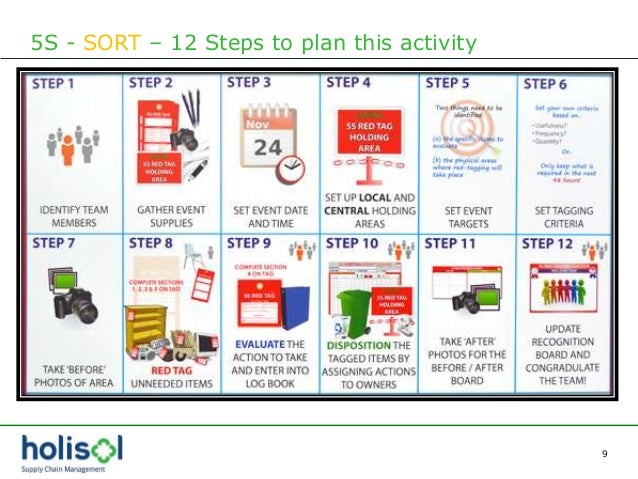

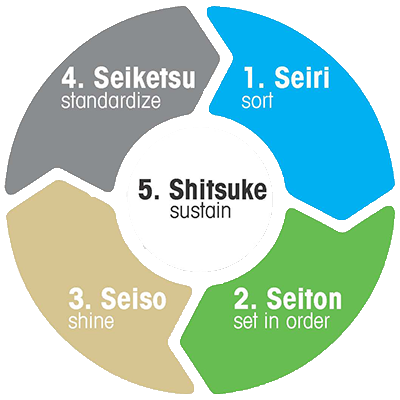

The PDCA (plan, do, check, act), or “Deming cycle,” of implementing 5S is effective This is a neverending process and has to follow a process approach Step 1 Seiri, or Sort Seiri is sorting through the contents of the workplace and removing unnecessary items. Include 5S in the organisation skills matrix and implement 5S training as part of the induction programme Ensure all managers are included in the application of 5S to show how important it is to the organisation Management must define responsibilities and ensure time is allocated for initial and ongoing 5S activities. 5S stands for the 5 steps of this methodology Sort, Set in Order, Shine, Standardize, Sustain These steps involve going through everything in a space, deciding what's necessary and what isn't, putting things in order, cleaning, and setting up procedures for performing these tasks on a regular basis.

5S visual cues (eg, signs, placards, scoreboards, laminated procedures in workstations) can be used to raise employee understanding of proper waste handling and management procedures, as well as workplace hazards and appropriate emergency response procedures 5S techniques can be used to improve labeling of hazardous materials and wastes. Preview our hilarious Introduction to 5S video from our 5S Productivity training series!. The offsite 5S Training option is generally most popular with organizations having five or less associates that require a thorough working knowledge of 5S Our training centers provide the participants an environment free from the distractions and interruptions of daily work activities.

A 5S basics, interesting, fun 1day Introduce to 5S Workplace Management for Shopfloor People, Supervision and Managers You get 5S training workshop material containing a 5S PPT PowerPoint Presentation of foundational 5S knowledge, and a 5S game people play that puts them into a 5S Simulation where they continually improve and learn the value of 5S. The 5S Workshop can be taught in either the office or shop floor environment In keeping with Pinnacle's Lean QMS ® approach, the 5S program is sustained within the context and culture of your quality management system (QMS) or business operating system (BOS). 5S is a Lean technique that involves activities designed to create and maintain a disciplined workplace It helps create a better working environment and can be implemented to eliminate waste and improve the flow of work 5S audits are often used to evaluate the performance of 5S implementation in any workplace This 5S audit checklist will help ensuring that 5S standards and workplace.

The offsite 5S Training option is generally most popular with organizations having five or less associates that require a thorough working knowledge of 5S Our training centers provide the participants an environment free from the distractions and interruptions of daily work activities. 5S is the foundation of a successful Lean implementation, making possible the use of other Lean techniques and tools Standardized work cannot be achieved without good 5S, Just in Time becomes deficient if 5S is done poorly, and the whole Lean culture cannot be absorbed without the 5S mentality This workshop has been designed to introduce you. Ken T 0 January 12, 06 at 505 pm #.

5S implementation responsibilities are to be distributed throughout the organisation Every member must know their own 5S responsibilities and perform accordingly It is the duty of the Chairman to administer accountability for each of the responsibilities, as outlined below 5S Council (See page & 21) comprises the following 5S Training. Receive a FREE Helpful 5S Training Document by submitting your email below Email Sign Up Sign Up More 5s Quick Contacts The 5S Store 16 Lomar Park, Unit 8 Pepperell MA Tel Fax. Ken T 0 January 12, 06 at 505 pm #.

5S Workshop Format Because Pinnacle customizes all training and consulting service, this workshop is presented onsite to groups of up to 12 individuals All discussions and examples are relevant to your organization The delivery style is interactive and participants are required to actively participate Contact Pinnacle to schedule your 5S. An experiential learning activity for 5S training session Song Yume no naka e Artist Inoue Yosui wwwfacebookcom/fauzantribe. • Plan/Prepare 5S Kaizen Blitz Workshop Exercises • 5S Experiment #1 – Sort, Straighten, Shine • 5S Experiment #2 – Refine the Layout • 5S Experiment #3 – Fastest Process • 5S Experiment #4 to #7 – Standardise and Sustain.

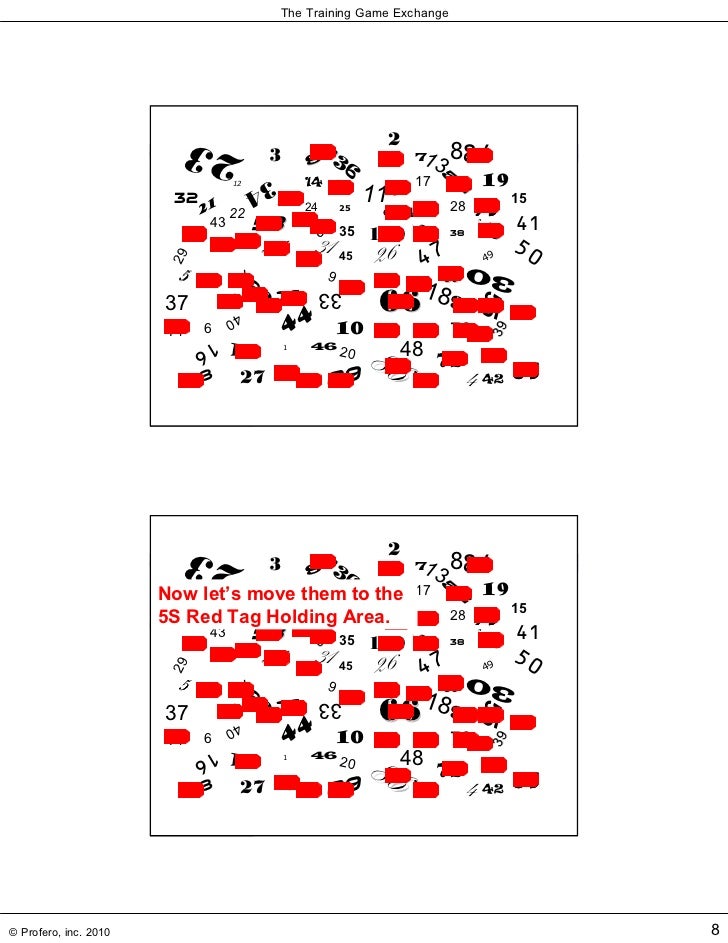

Dec 10, 17 5S AUDIT WORKSHEET 5S Audit Sheet (for workshops) Workshop name Completed by Score Previous Score Date 1S No Check item Description Score 0 1 2 3. But I really want to make this training handson, and am looking for exercises to demonstrate 6S, standard work, takt time, value stream mapping etc Thanks!. I normally use this game to explain the benefits of the 5S This game is very easy and engaging In less than 10 minutes you can explain why 5S is important and with incredible benefits in terms of efficiency and quality See this video and stay tuned for a 5S Numbers’ Game I am going to produce To stay tuned subscribe the newsletter in the box on the right.

Implement regular communications about 5S activities in the company and reward those who are spearheading 5S initiatives Develop 5S manuals and perform regular reviews with your teams Company leaders can hold regular genba walks to stay attuned with their processes Make sure new hires are onboard the 5S program from day one. 5S Training DVDs Whether you need 5S training in Spanish or 5S training for healthcare, we carry the top 5S instructional DVDs Lean Manufacturing Guide Learn about all the benefits that Lean manufacturing has to offer your facility. The 5S methodology is a way to cut waste, boost efficiency, and just generally improve the way everything is done within a facility 5S gets its name from the five Japanese words, Seiri, Seiton, Seiso, Seiketsu, and Shitsuke, which translate in English to Sort, Set in Order, Shine, Standardize, and Sustain.

The 5S Alphabet Game Online A webbased 5S game Lean Lingo Bingo A bingo game to use while you're presenting The Multitasking Test Prove how great at multitasking you are with this quick, online game The Name Game Write down names to prove that multitasking doesn't work The 5S Shapes Game A Japanese lean guy teaches 5S using geometric shapes. 5S visual cues (eg, signs, placards, scoreboards, laminated procedures in workstations) can be used to raise employee understanding of proper waste handling and management procedures, as well as workplace hazards and appropriate emergency response procedures 5S techniques can be used to improve labeling of hazardous materials and wastes. Mar 2, 17 Explore Vipul Vikas Singh's board "5S Ideas" on See more ideas about lean manufacturing, visual management, kaizen.

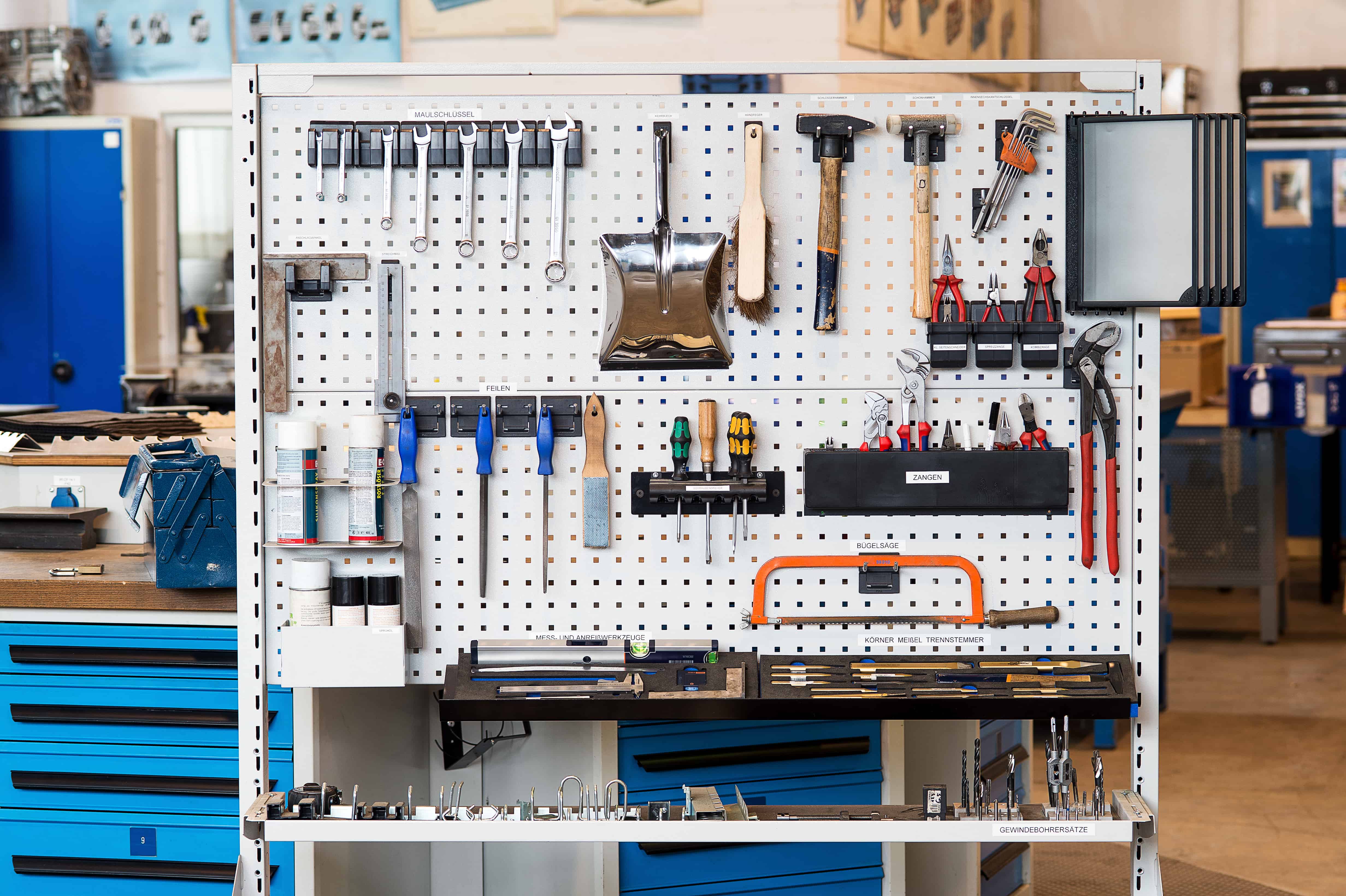

A 5S basics, interesting, fun 1day Introduce to 5S Workplace Management for Shopfloor People, Supervision and Managers You get 5S training workshop material containing a 5S PPT PowerPoint Presentation of foundational 5S knowledge, and a 5S game people play that puts them into a 5S Simulation where they continually improve and learn the value of 5S. Visual Workplace and 5S go hand in hand One of the main purposes of 5S is to prepare the work environment to hold visual information From that perspective, 5S is a method, while creating a visual workplace is the goal. 5S is a fundamental first step for any manufacturing company, wishing to call itself world class We will understand this with step by step approach of its deployment The 5S program mandates that resources be provided at the required location and be available to support work activities.

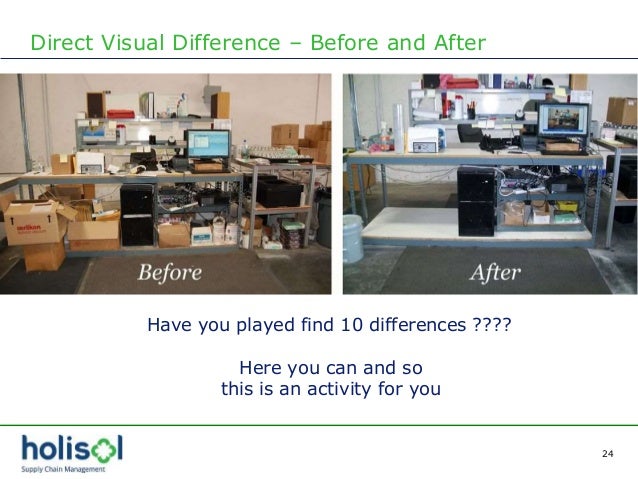

QualityOne provides Knowledge, Guidance and Direction in Quality and Reliability activities, tailored to your unique wants, needs and desires Let us help you Discover the Value of 5S Consulting, 5S Training or 5S Project Support. 5S Workshop Overview 5S, an acronym for “sort, setinorder, shine, standardize, sustain”, is a simple yet powerful method for transforming the physical workspace 5S is a simple but highly effective set of techniques that remove waste from your work environment through better workplace organization, visual communication and general cleanliness. Work This study focuses on the application of 5S in welding workshop, to simplify wasteful activities Performance measures are used as a reference in measuring the success of 5S implementation is the reduction of tool and goods search time and space usage efficiency 2 Methodology This paper uses a quantitative evaluation method.

5S Audit Checklist This 5S Audit Checklist is a tool used by area supervisors or plant managers to perform monthly or quarterly audits As a 5S audit form, this checklist can help ensure that 5S principles and set standards are being followed and implemented by workers. To become a Lean Office, office activities must fully support shopfloor manufacturing operations to eliminate waste The office, my any name, is a paperwork factory The adoption of 5S throughout all office functions is the first step to increase efficiency This oneday workshop provides a blueprint for building a Lean foundation for. 5S Workshop Overview 5S, an acronym for “sort, setinorder, shine, standardize, sustain”, is a simple yet powerful method for transforming the physical workspace 5S is a simple but highly effective set of techniques that remove waste from your work environment through better workplace organization, visual communication and general cleanliness.

Free Training activities, games,icebreakers, energizers and exercises There is no doubt that keeping your participants engaged is critical for you as a trainer in any class you deliver, not only because it’s more fun both for you and your participants to be in an engaging learning environment, but also to ensure you are bringing them value. 5S EXERCISES FOR TEACHING · 5S Factory Game Teaches the Basic Benefits in a Fun Exercise 5S is a prerequisite for most other Lean tools • Plan/Prepare 5S Kaizen Blitz Workshop Exercises • 5S Experiment #1 – Sort, Straighten, Shine • 5S Experiment #2 – · I heard about a quick classroom exercise. A 5S can be applied to any work environment It could be a supply/store in a hospital, a repair truck for a telecom company, a CSR desk/work area in a call center, the baggage claim area of an airline or a laptop computer.

Develop a continuous improvement culture that drives excellence and maintains the 5s methodology Ensuring the 5S principles are embedded in training activities;. 5S best practices Communicate goals of 5S Visible leadership interest Participation Reinforce with training Hold each other accountable Attention to detail Incorporate 5S into daily work Source Gary Larson, Far Side. 5S • This is a simple and easy to use demonstration of the power and simplicity of 5S • Provide each of the people in the room with a copy of the pages that follow • Ask them to strike out the phrase “Workplace organisation” one letter at a time in order on the page and put their hands up when complete.

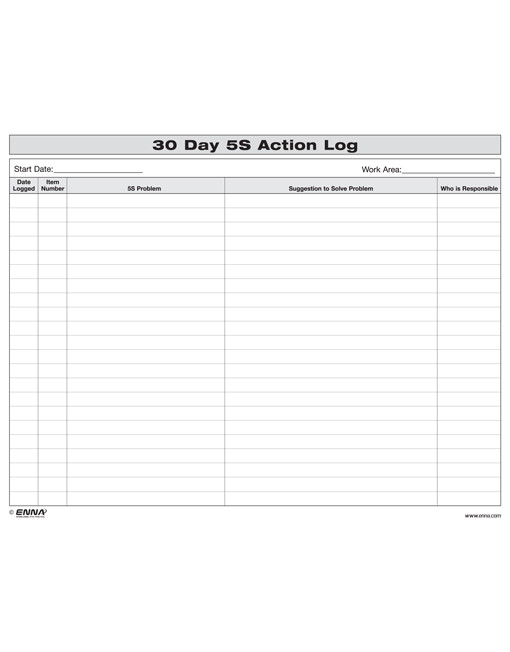

5S – Integration and Rollout Even though 5S is a tool, aim to integrate 5S thinking into your daytoday activities, rather than something you apply at set times So in a similar way to Health and Safety (H&S) or Good Manufacturing Practice (GMP), be aware of 5S and incorporate it into everyday tasks. Furthermore, the 5S Map form should be utilized to document the new current state at the end of the workshop It provides a bird’s eye perspective of the area to communicate to others outside the workshop the progress taken at just a glance Using this form assists in solidifying a strong 5S program Enna’s forms in this 5S program are designed for practical use and to accomplish two main roles in a 5S program involve and document. Steps of 5S hSeiri –Sort (Clearing)clearly separating necessary from unnecessary, and remove unnecessary hSeiton–Set in order (Configure)visually arrange and identify items for ease of use and retrieval hSeisoShine & Check (Clean & Check)keep the workplace clean (not pretty) to allow problems to be identified.

5S • This is a simple and easy to use demonstration of the power and simplicity of 5S • Provide each of the people in the room with a copy of the pages that follow • Ask them to strike out the phrase “Workplace organisation” one letter at a time in order on the page and put their hands up when complete. 1 5S Training & Awareness 2 Thirty years ago, researchers started studying the secret of success of Japanese manufacturing companies It was Hiroyuki Hirano who developed 5s within his overall approach to production systems 5s turned out to be the most impressive ‘secret’. The objectives of the 5S training is to disseminate 5S methodology and prepare the workforce for meaningful participation in 5S activities This training program, which is the starting point of StepbyStep Implementation of 5S, encourages workers to become actively involved in the application exercises.

Training participants are typically tasked to complete both individual and team activities covering each of the 5 principles 5S training is best conducted in the individual or team’s place of work as this maximizes efficiency by going through training while actually practicing 5S in your workspace.

5s Workshop 30 Day Action Log Problem Solving Enna Com

5s Singapore Operational Excellence Consulting

5s Basics Workplace Organization Webinar New Hampshire Manufacturing Extension Partnership Nh Mep

5s Examples In Action The Good The Bad Graphic Products

Tpm Improves Equipment Effectiveness Lean Production

3

1 8 5s Activity Japanese Gemba Kaizen Web

5s In Malaysia

4 Days Workshop On Training For Trainers Qcfi Delhi Chapter Headquarter Qcfi Quality Circle Lqc 5s Kaizen Total Quality Management Training Certifications

Pitfalls In 5ss And How To Avoid Them Daily Ft

Lkdf Rt Zamitazambia Zamita Students Implementing 5s Method In The Workshop During Kaizen Activities For Best Practices And Faster Turnaround Time In Their Workplace T Co Vnazkxgaqd

Pdf An Application Of 5s Concept To Organize The Workplace At A Scientific Instruments Manufacturing Company

5s Lean Manufacturing And Six Sigma Definitions

Japanese Terminology For 5s Is Seiri Seiton Seiso Seiketsu And Shitsuke Continuously Improving Manufacturing

What Is The 5s System Definitions Core Concepts Principles Graphic Products

What Is 5s 5s System Is Explained Including Tips On Getting A 5s Program Started

Pdf Applying The Kaizen Method And The 5s Technique In The Activity Of Post Sale Services In The Knowledge Based Organization Semantic Scholar

Lean Thinking And Methods 5s Sustainability Us Epa

Some Images Of 5s Houskeeping In Factories Total Quality Management

5s Training Program India 5s System Training Tqmi

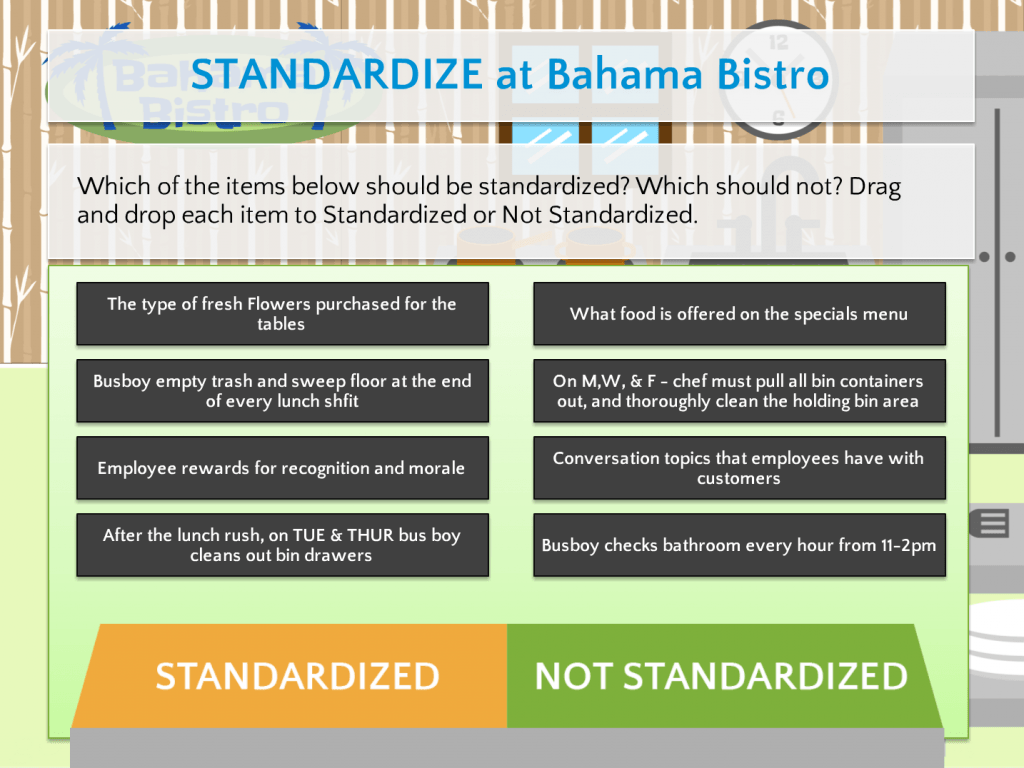

5s Online Learning Activity At Bahama Bistro Goleansixsigma Com

Learn And Implement Lean A Similar Lean 5s Tei Transformation Can Happen To Your Shop Floor Before Lean Implementation After Lean Implementation Click On The Photographs For A Big View More Photos Albs Undertakes Training

5s Online Learning Activity At Bahama Bistro Goleansixsigma Com

Pdf Applying The Kaizen Method And The 5s Technique In The Activity Of Post Sale Services In The Knowledge Based Organization

Http Www Intracen Org Uploadedfiles Intracenorg Content Exporters Exporting Better Quality Management Assetpdf Bulletin eqm 5s Pdf

Intro To 5s Emcc

Keys And Tips To Implement The 5s Methodology

A Practical Approach To The Successful Practice Of 5s

Some Images Of 5s Houskeeping In Factories Total Quality Management

5th S Of 5s Methodology Shitsuke Or Sustain Train Activities Knowledge Management Lean Sigma

The 3 Best Lean Games Every Company Should Learn To Play St Andrews Lean

Shitsuke Is The Fifth And Final Step Of The 5s Method

5s Training Package Enna Com

The 5s System Lean Manufacturing Methodology

5s Concept Is Applicable All Working Areas

5s Tpm Course Introduction Mu Sigma Group

5s Presentation For Beginners And Professionals For Implementation

5s Implementation Workshop

5s Map Form Used To Map Activities In A Workshop Enna Com

Tij 5s Housekeeping Training Brochure 10 By Tij Consultants Sdn Bhd Issuu

5s Methodology Wikipedia

Lkdf Rt Zamitazambia Zamita Students Implementing 5s Method In The Workshop During Kaizen Activities For Best Practices And Faster Turnaround Time In Their Workplace T Co Vnazkxgaqd

5s Safetyculture

5s And Visual Management Six Sigma Daily

5s Course Business Performance Improvement Bpi

5s Red Training Uk Visual Training Guide Fabufacture Fabufacture Uk

Q Tbn And9gcqctnit5bvhcj0q9ywuzvdbba2ix Aljurcuusd Sizknzacben Usqp Cau

The Importance Of 5s Manufacturing Net

5s For The Office By Operational Excellence Consulting Operational Excellence Visual Management Lean Manufacturing

What Is 5s 5s System Is Explained Including Tips On Getting A 5s Program Started

5s Online Learning Activity At Bahama Bistro Goleansixsigma Com

5s Methodology Wikipedia

100 5s Ideas In 21 فعل ماض قراءة سريعة قلم حبر

5s Principles And Awareness Quality Management Selangor Malaysia Kuala Lumpur Kl Shah Alam Training Workshop

Implementation Of 5s In Apparel Industry Ordnur

5s Lean Manufacturing And Six Sigma Definitions

3

5s Methodology And Tips Youtube

Http Www Quickbizgroup Com Images Events Pdf Productivity Improvements Pdf

What Is 5s 5s System Is Explained Including Tips On Getting A 5s Program Started

Practical Implementation Of 5s Method

100 5s Ideas In 21 فعل ماض قراءة سريعة قلم حبر

The 5 S System A How To Guide Reliable Plant

Workshop On 5s Breval Consulting Services

How To Explain 5s Lean With This Simple Game In 10 Minutes Leanvlog

How To Do A 5s Audit With Your Iphone Flexpipe

Plant Engineering Safety Is It The Sixth S In A 5s System

How To Run An In House 5s Training Course

Practical Implementation Of 5s Method

How To Implement 5s In The Workplace Kanban Zone

5s Workplace Organization Ut Center For Industrial Services

Tij 5s Housekeeping Training Brochure 10 By Tij Consultants Sdn Bhd Issuu

5s Lean Simulation Simply Improvement

5s Training Cycle Time Management

5s Singapore Operational Excellence Consulting

The Lean Training Game Exchange

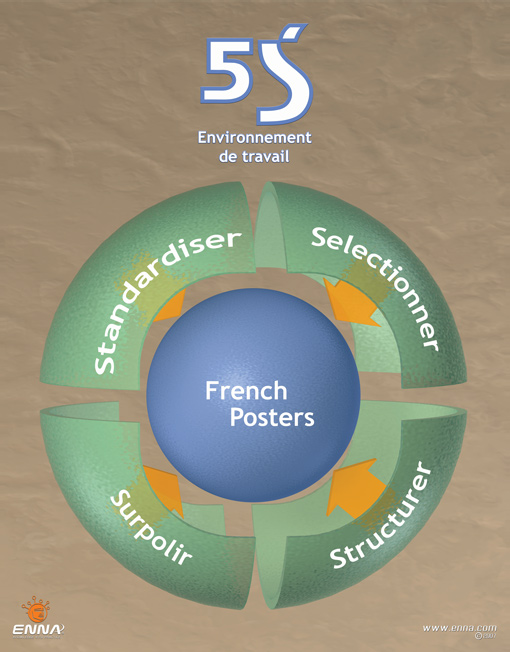

5s Summary Poster French Enna Com

Free 5s Training Presentations Ppt And Pdf To Download

Pdf Workshop Store Room Improvement With 5s A Case Study Semantic Scholar

5s Implementation Workshop

Office 5s Implementation Workshop

5s 5s Methodology Quality One

Q Tbn And9gcthqjqe3zi0vwlutrvmoxa2gnanjejskz 13xrxsbcrgvrkas1d Usqp Cau

How To Implementing 5s Activities Uttana Com

Implementation Of The 5s Methodology In Maintenance Activities Download Table

5s Audit Checklist Requirements To Sustain A Lean Laboratory

Http Www Intracen Org Uploadedfiles Intracenorg Content Exporters Exporting Better Quality Management Assetpdf Bulletin eqm 5s Pdf

Method 5s Explanations And Example Of The 5s Lean Sesa Systems

Www Jica Go Jp Activities Issues Health 5s Kaizen Tqm 02 Ku57pqpi3y4 Att Malaw 03 Pdf

5s Safetyculture

5s Continuous Improvement Toolkit

5s In Malaysia

5s Tpm Implementation At Leading Manufacturer Of Plastics Injection Moulding Machines Blow Moulding Machines In India Business Consultant Management Consulting Cbepl

Advanced 5s Workshop Taking 5s To The Next Level Strategos

Keys And Tips To Implement The 5s Methodology

2

Www Jica Go Jp Activities Issues Health 5s Kaizen Tqm 02 Ku57pqpi3y4 Att Malaw 03 Pdf

Training 5s Workplace Management Training Consultants From Ahmedabad