Sil 3 Performance Level

Wat Zijn De Verschillen Tussen Safety Integrity Level Sil En Performance Level Pl Istec International

Pl Parameter Sicherheits Wissen Keyence Deutschland

Functional Safety Part 2 Of 2 Machine Design

Q Tbn And9gcs2ys6bfmsuzpchdg3vn Boeqfjt3flu9b Ocwsrk2plddeujtp Usqp Cau

Safety Integrated Level And Performance Levels For Machine Safety

Iso 1 Analysis Part 3 Architectural Category Selection

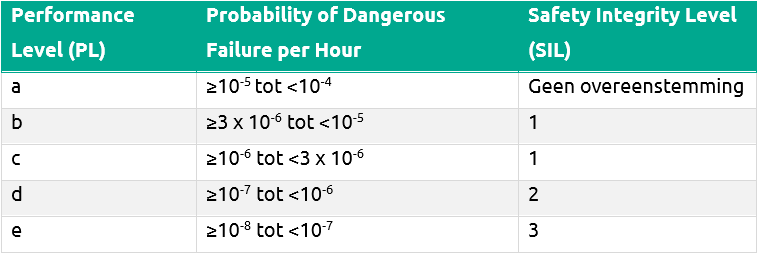

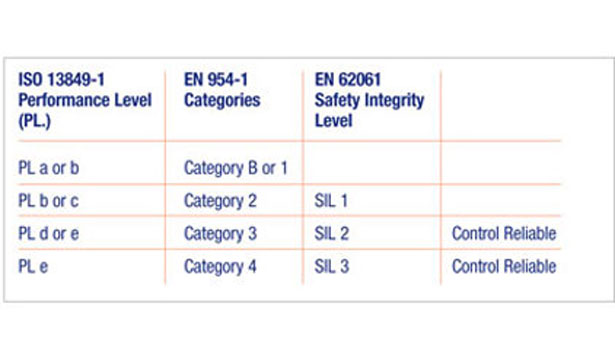

Performance Levels and Safety Integrity Levels A Closer Look Historically, SIL (Safety Integrity Level) is often used as a synonym for functional safety SIL refers to the functional safety rating of the predominant functional safety standard the IEC and its numerous derivate standards such as IEC 661 and IEC.

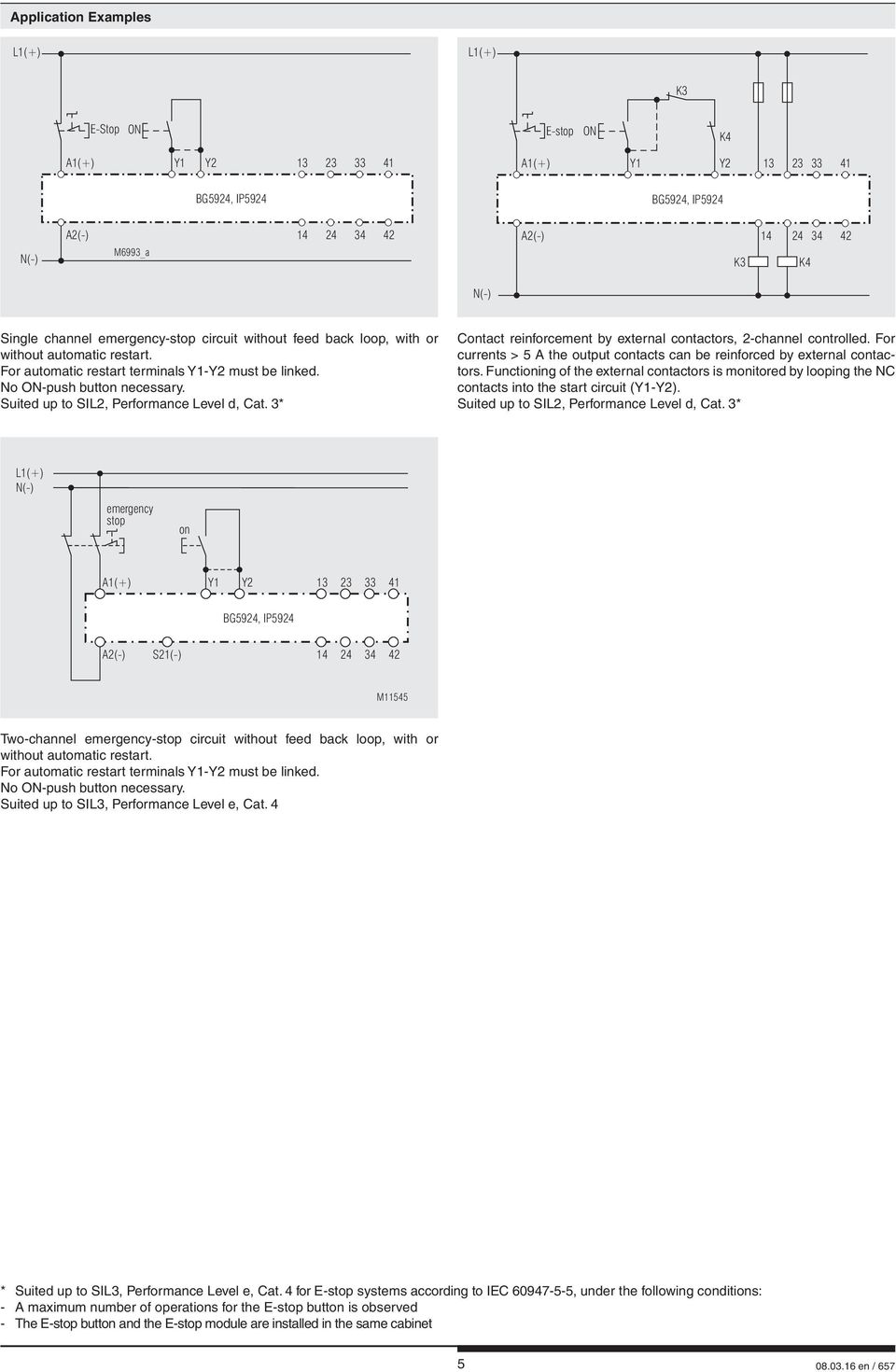

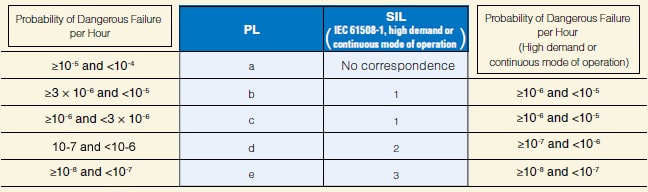

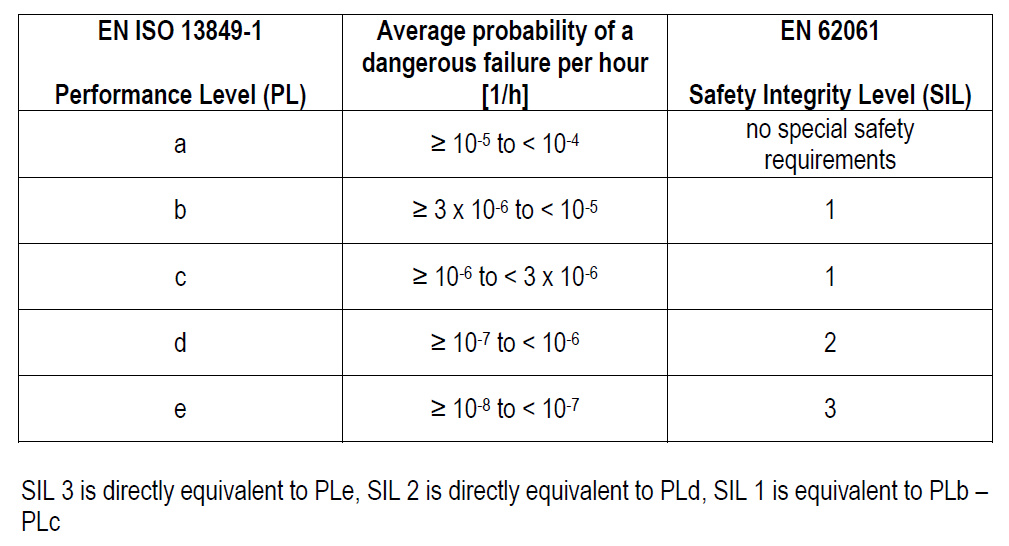

Sil 3 performance level. For that purpose, PepperlFuchs offers a large number of products with a SIL/PL assessment On this site, choose from various selection criteria like safety integrity level, performance level, device function, and signal type to quickly find the SIL/PL assessed device that you are looking for. SIL stands for Safety Integrity Level A SIL is a measure of safety system performance, in terms of probability of failure on demand (PFD) This convention was chosen based on the numbers it is easier to express the probability of failure rather than that of proper performance (eg, 1 in 100,000 vs 99,999 in 100,000). IEC 661 addresses SIL levels and ISO addresses Performance Levels While there are two different standards, the scope of each standard is very similar Note that either a SIL or Performance Level would be used, but not both The figure below shows an overview of the risk assessment process.

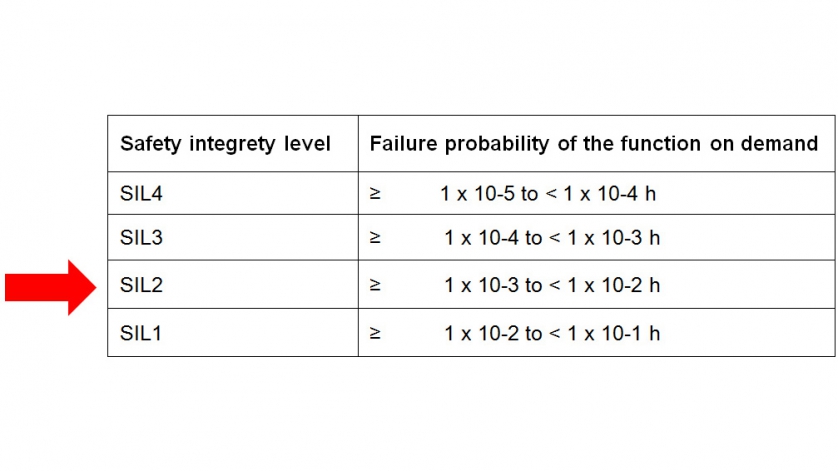

Three safety integrity levels (SIL) were described in the ANSI/ISA standard Revised standard ANSI/ISA (IEC mod) now includes the higher SIL 4 SILs are a measure of system performance the higher the number, the better the safety performance, such as lower probability of failure on demand. Performance metric constraint) that are implied by requirements per international safety standards IEC 1 and IEC 2 to determine the safety integrity level (SIL) of a safety instrumented function (SIF) are described and discussed Examples of their applications are presented For low demand mode. SIL stands for Safety Integrity Level A SIL is a measure of safety system performance, in terms of probability of failure on demand (PFD) This convention was chosen based on the numbers it is easier to express the probability of failure rather than that of proper performance (eg, 1 in 100,000 vs 99,999 in 100,000).

A Safety Integrity Level (SIL) is a measure of performance required for a Safety Instrumented Function (SIF) within a Safety Instrumented System (SIS), which is used to prevent or limit hazardous events against people, equipment and the environment. SIL stands for Safety Integrity Level A SIL is a measure of safety system performance, in terms of probability of failure on demand (PFD) This convention was chosen based on the numbers it is easier to express the probability of failure rather than that of proper performance (eg, 1 in 100,000 vs 99,999 in 100,000). – How to find a safety integrity level – How is SIL used?.

(no SIL, or SIL 0), SIL 1, SIL 2, SIL 3 and SIL 4 Sil0 reflects the lowest, and SIL4 the highest safety level The SIL classification of safety related systems depends on the following parameters. Performance metric constraint) that are implied by requirements per international safety standards IEC 1 and IEC 2 to determine the safety integrity level (SIL) of a safety instrumented function (SIF) are described and discussed Examples of their applications are presented For low demand mode. (no SIL, or SIL 0), SIL 1, SIL 2, SIL 3 and SIL 4 Sil0 reflects the lowest, and SIL4 the highest safety level The SIL classification of safety related systems depends on the following parameters.

– What is SIL Capability?. GlobalSafety Printed in USA 3/17 l MTS SOLUTIONS FOR PERFORMANCE LEVEL c, d AND e COMPLIANCE Performance Level c (PLc) Applicable for test systems in which the test specimen area is not accessed more frequently than once every 15 minutes Performance Level c (PLc) is the standard option on most MTS Landmark® Test Systems. As defined in the IEC standards, there are four SIL Levels (14) A higher SIL Level means a greater process hazard and a higher level of protection required from the SIS To generalize how SIL Level is determined, see Figure 1 SIL Level is a function of hazard frequency and hazard severity.

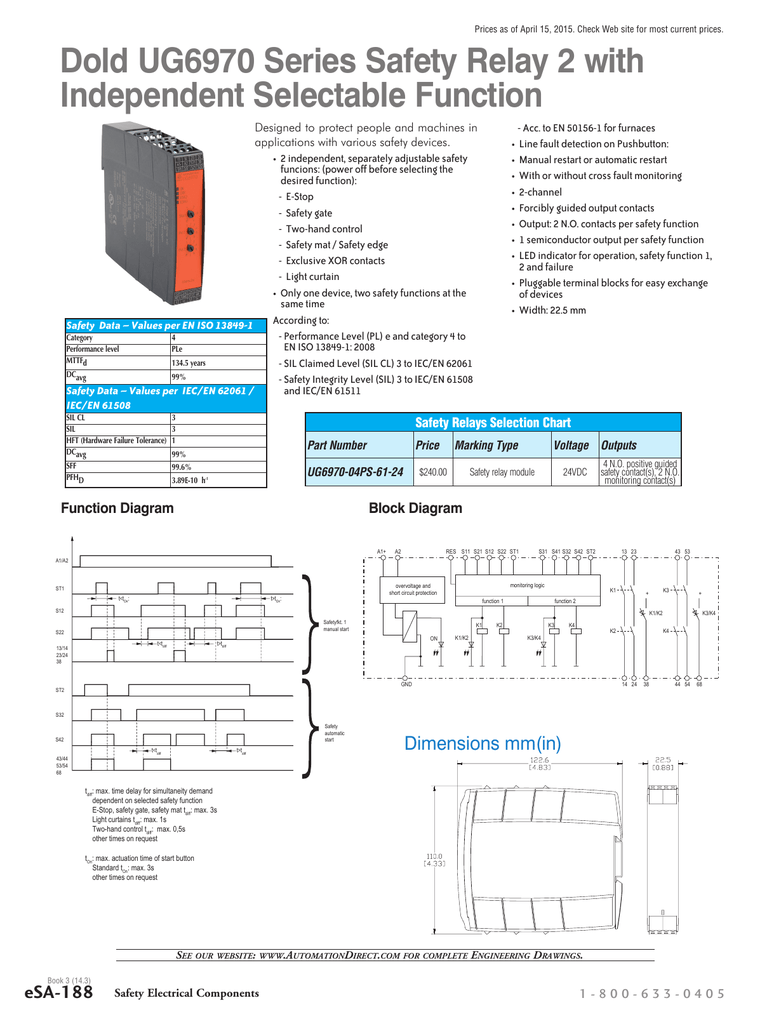

In simple terms, SIL is a measurement of performance required for a Safety Instrumented Function (SIF) Fike Europe's range of Fike bursting discs (also known as rupture discs) has an assigned equivalent SILlevel 3 The SIL 3 has been derived from comparison with published and generally accepted probability of failure on demand (PFD) values. Putting simple safety Integrity level is a measure of performance required from a safety instrumented system to. (SIL 3), Performance Level e (PL e) functionality SIL (Safety Integrity Level) is a measure of a products ability to lower the risk that a dangerous failure could occur As defined in IEC “Functional Safety of Electrical/Electronic/ Programmable Safety Related Systems” SIL defines a products ability to operate in safetyrated aspects.

SIL 3capable products as an option for all standard, nonrotational mounting styles of its H and MH series products See our Safety Manual for Series H & MH Hydraulic Cylinders for specific information SAFETY INTEGRITY LEVEL (SIL) A key factor defined and used in the IEC and IEC standards is Safety Integrity Level, also known as. FRAGE Ist es möglich, Performance Level PL d mit Kategorie 3 gemäß ISO oder SIL 2 gemäß IEC 661 unter Einsatz nur eines SIRIUS Positionsschalters mit oder ohne Zuhaltung. NOTE 2 For the definition of required performance level, see 3124 NOTE 3 The requirements provided in this part of ISO for programmable electronic systems are compatible with the methodology for the design and development of safetyrelated electrical, electronic and programmable electronic control systems for machinery given in IEC 661.

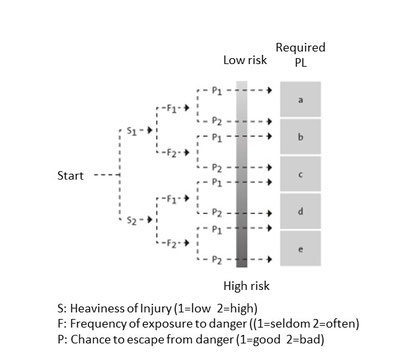

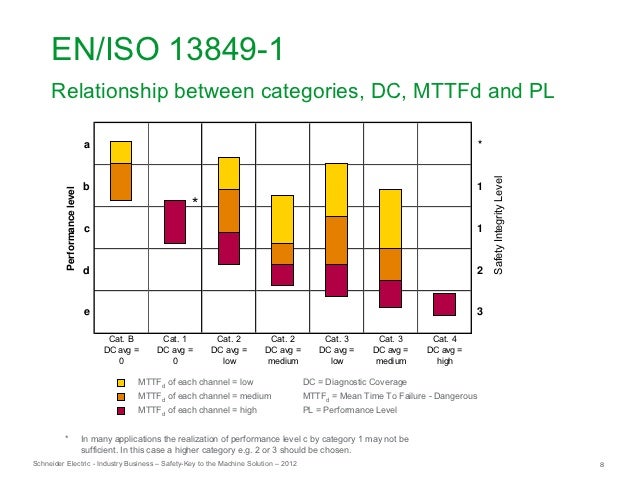

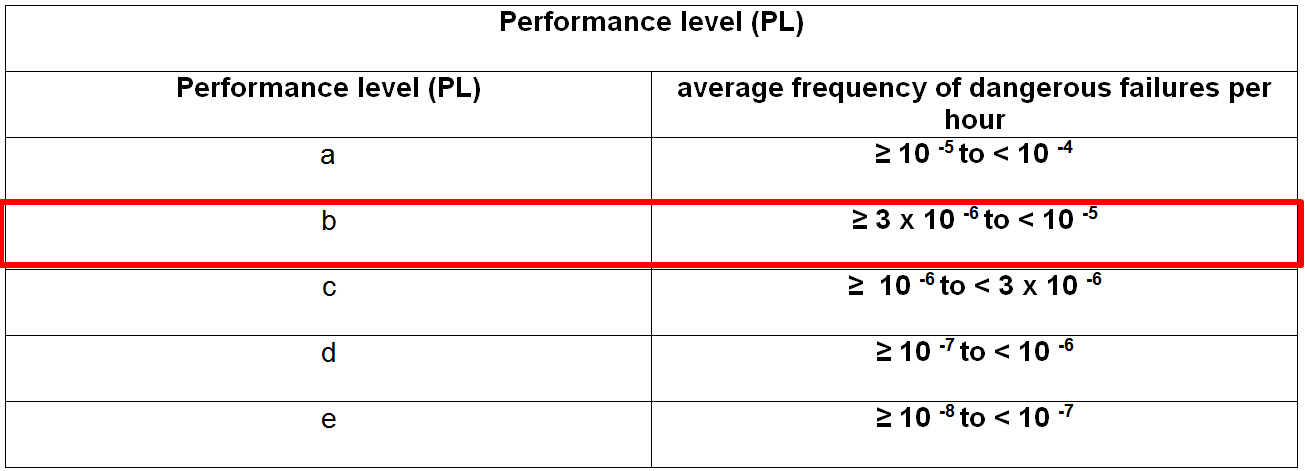

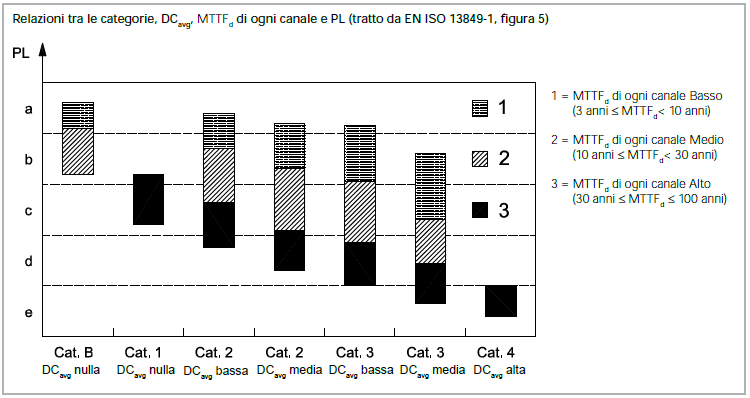

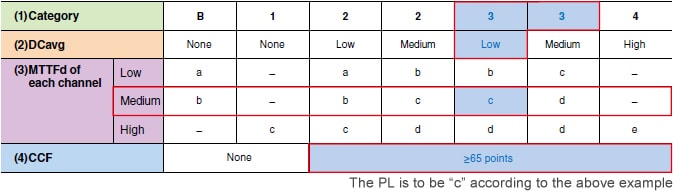

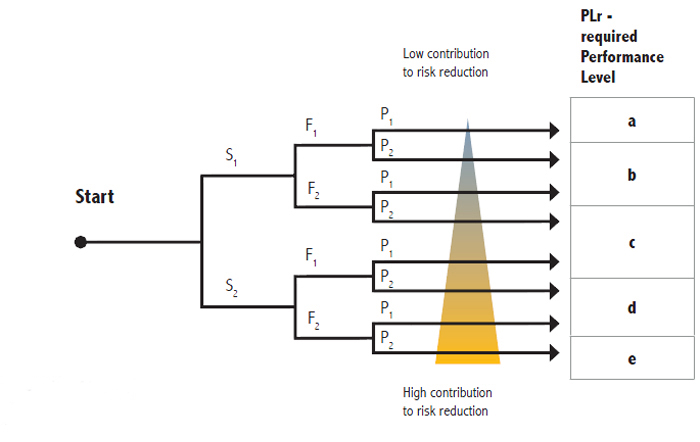

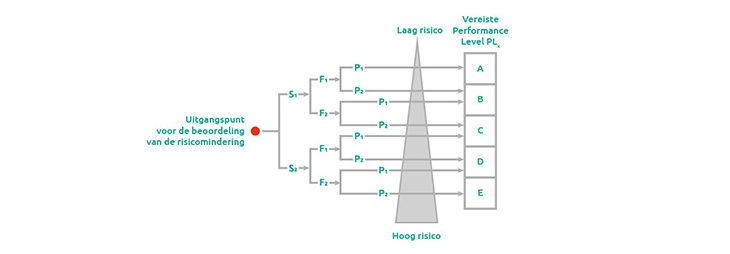

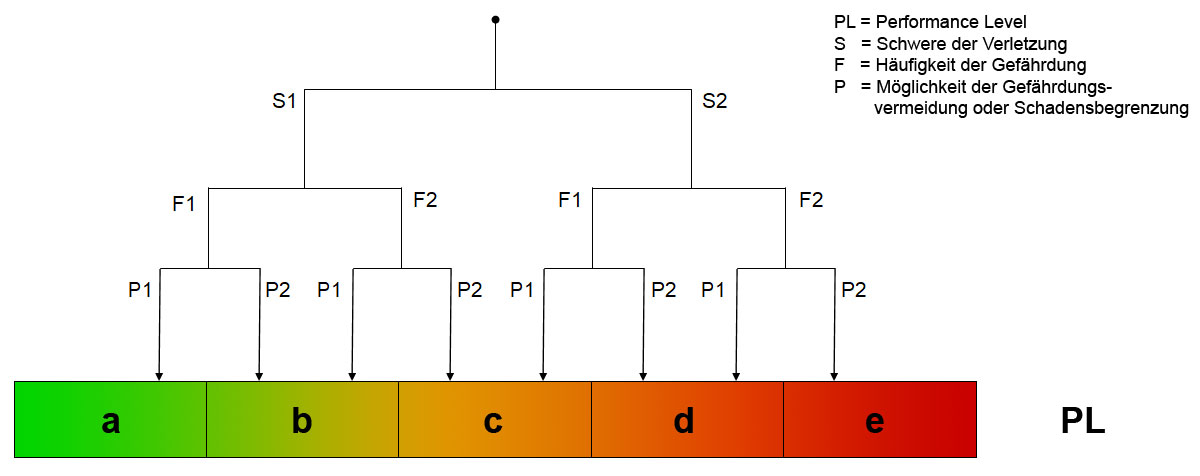

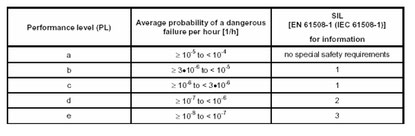

The Performance Level is divided into five categories designated a to e, where a represents the lowest reliability, and e the highest reliability In other words the worse the risk, the higher the necessary PL category SIL At most companies, SIL is generally seen as solely for the process industry, but this is far from the truth. Safety Integrity Level (SIL) / Background SIL Determination Safety Integrity Level (SIL) is defined as a relative level of riskreduction provided by a safety function, or to specify a target level of risk reduction In (somewhat) simple terms, SIL is a measurement of performance or probability of failure on demand (PFD) required. Safety Integrity Level (SIL) / Background SIL Determination Safety Integrity Level (SIL) is defined as a relative level of riskreduction provided by a safety function, or to specify a target level of risk reduction In (somewhat) simple terms, SIL is a measurement of performance or probability of failure on demand (PFD) required.

Safety integrity level (SIL) is defined as a relative levels of riskreduction provided by a safety function, or to specify a target level of risk reduction In simple terms, SIL is a measurement of performance required for a safety instrumented function (SIF) The requirements for a given SIL are not consistent among all of the functional safety standards. − Performance level “e” (PLe) in compliance with ISO − Safety Integrity Level (SIL) 3 in compliance to IEC 2 emergency stop application breaking forward, reverse and logic return Figure 1 shows a dual channel emergency stop application for safety category 3, PLe and SIL 3 degrees of safety This. (SIL 3), Performance Level e (PL e) functionality SIL (Safety Integrity Level) is a measure of a products ability to lower the risk that a dangerous failure could occur As defined in IEC “Functional Safety of Electrical/Electronic/ Programmable Safety Related Systems” SIL defines a products ability to operate in safetyrated aspects.

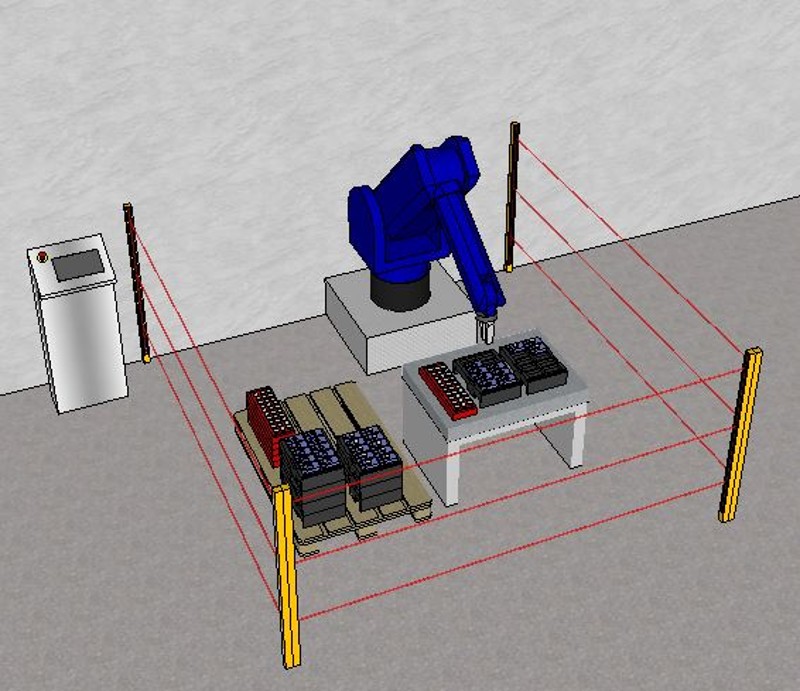

GlobalSafety Printed in USA 3/17 l MTS SOLUTIONS FOR PERFORMANCE LEVEL c, d AND e COMPLIANCE Performance Level c (PLc) Applicable for test systems in which the test specimen area is not accessed more frequently than once every 15 minutes Performance Level c (PLc) is the standard option on most MTS Landmark® Test Systems. Performance Requirement For robots (type –C Standard), safetyrelated parts of control systems shall specifically be designed so that they comply with –PL=d with structure category 3 as described in ISO , OR –SIL 2 with a hardware fault tolerance of 1 with a proof test interval of not less than years, as described in. – What this means for the manufacturer?.

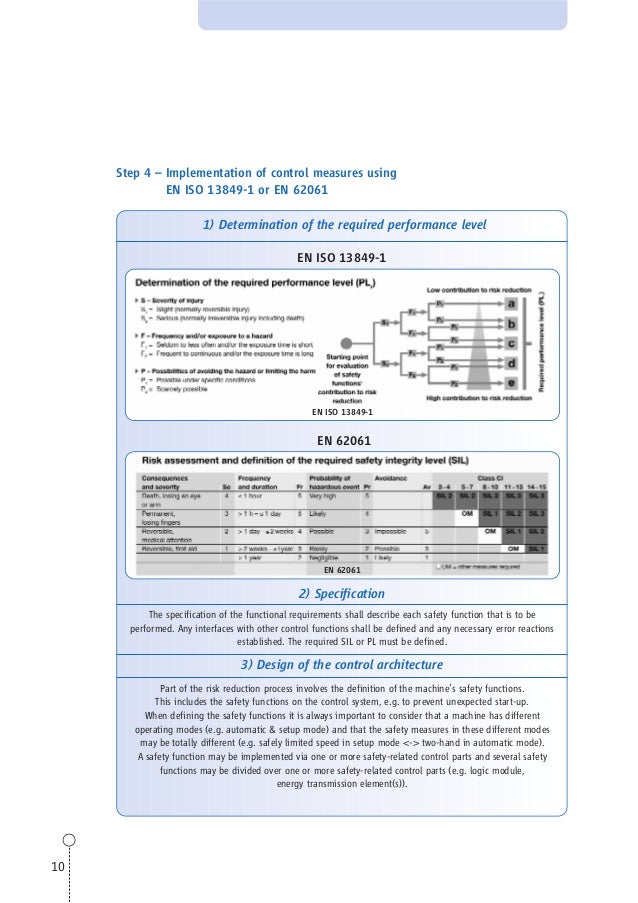

Performance metric constraint) that are implied by requirements per international safety standards IEC 1 and IEC 2 to determine the safety integrity level (SIL) of a safety instrumented function (SIF) are described and discussed Examples of their applications are presented For low demand mode. – – d 3 100 71 – It has a structure that conforms to IEC6041 Stop Category 0 As a subsystem, it conforms to ISO PLd Noncontact Door Switch D40A Safety Output SIL2 24E8 d 3 – – – It can be applicable as Type 4 interlocking switch according to ISO A noncontact door switch alone conforms as a subsystem to. In the Safety Integrity Level (SIL 13 in EN 661) or in the Performance Level (PL ae in EN ISO ) Safety, risk Analysing risk Assessing availability and reliability Step by step to safety – Step 1 Risk assessment to EN 1050 / EN ISO Without any protective measures a risk will lead to harm Therefore the designer has to.

Safety Integrity Level (SIL) The Required Safety Availability (RSA) value is synonymous with dependability the probability (Note 1) that a Safety Instrumented Function will perform its duty when faced with a dangerous process condition. Safety Integrity Level (SIL) rating This webinar will cover – What happens in an exida certification?. The Performance Level is divided into five categories designated a to e, where a represents the lowest reliability, and e the highest reliability In other words the worse the risk, the higher the necessary PL category SIL At most companies, SIL is generally seen as solely for the process industry, but this is far from the truth.

– – d 3 100 71 – It has a structure that conforms to IEC6041 Stop Category 0 As a subsystem, it conforms to ISO PLd Noncontact Door Switch D40A Safety Output SIL2 24E8 d 3 – – – It can be applicable as Type 4 interlocking switch according to ISO A noncontact door switch alone conforms as a subsystem to. QUESTION Is it possible to achieve Performance Level PL d with Category 3 according to ISO or SIL 2 according to IEC 661 with application of only one SIRIUS Position switch with or without solenoid interlocking (type 2) or only one SIRIUS Hinge switch?. When designing a SIF, the appropriate SIL is crucial for achieving the required level of safety IEC defines four SIL levels, with SIL 4 providing the highest level of safety performance For example, SIL 1 corresponds to a Risk Reduction Factor (RRF) of at least 10, and SIL 4 to a Risk Reduction.

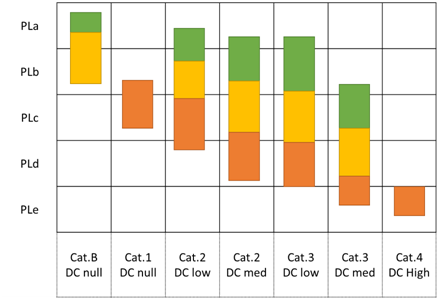

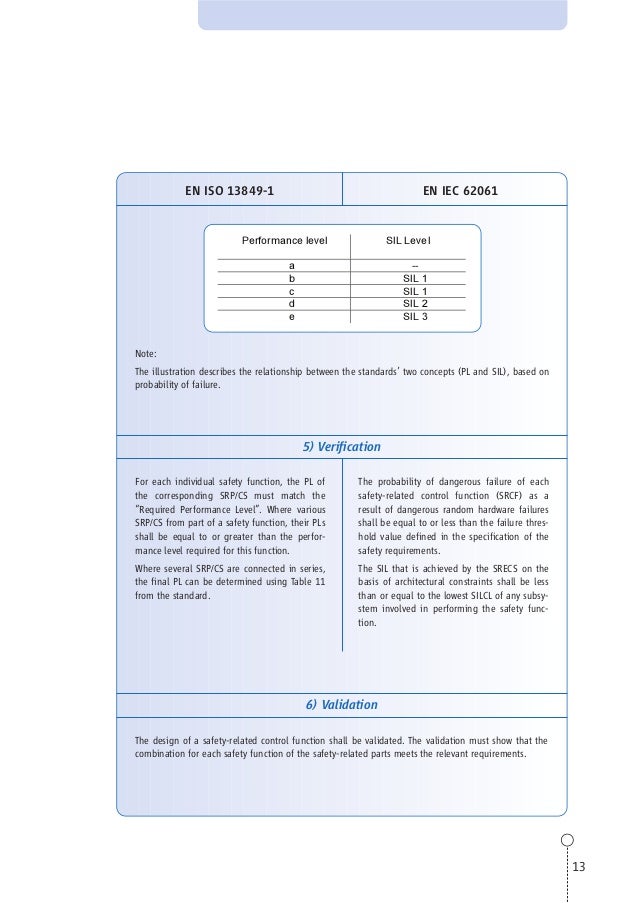

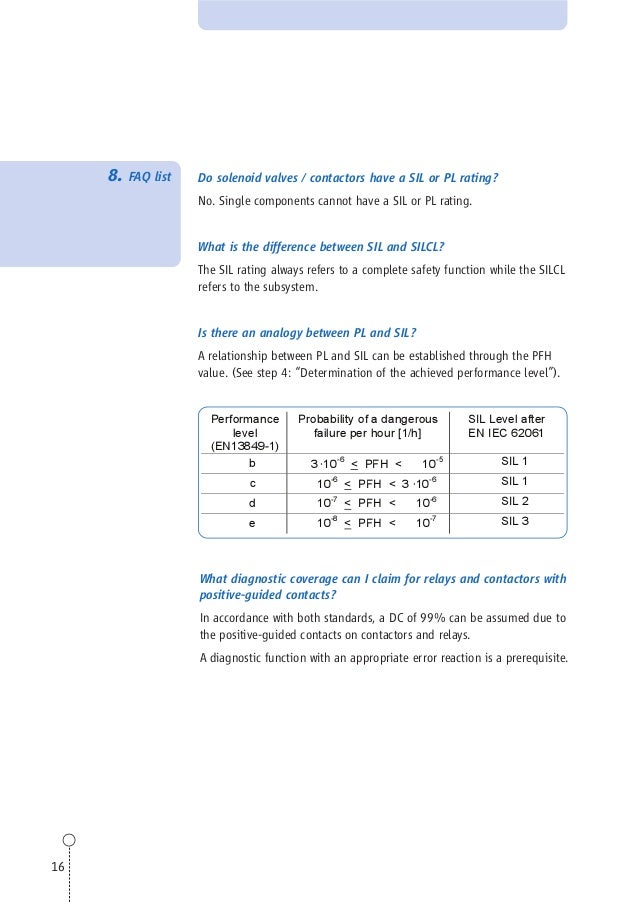

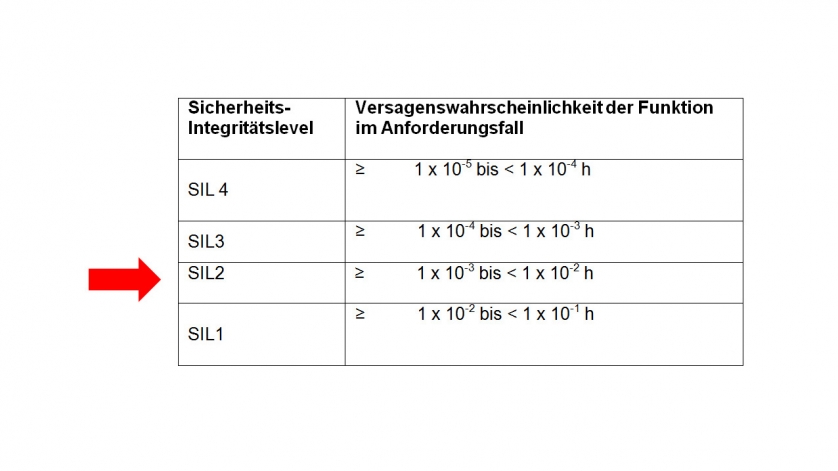

Safety Integrity Level (SIL) EN 661 defines how to determine the Safety Integrity Level (SIL) SIL represents the reliability of safety functions Four SIL levels are possible 1, 2, 3, and 4 ‘SIL 4’ is the highest level of safety integrity and ‘SIL 1’ the lowest Only levels 13 are used in machinery See the example on page 12. This is below SIL 1 performance (a Risk Reduction Factor between 10 and 100, as shown in Table 1) Therefore, debating on the level of performance of the fire & gas system hardware alone may prove to be of little worth In this example – which is realistic – the overall system will never meet SIL 1 performance no matter what hardware is used. − Performance level “e” (PLe) in compliance with ISO − Safety Integrity Level (SIL) 3 in compliance to IEC 2 emergency stop application breaking forward, reverse and logic return Figure 1 shows a dual channel emergency stop application for safety category 3, PLe and SIL 3 degrees of safety This.

SIL 3capable products as an option for all standard, nonrotational mounting styles of its H and MH series products See our Safety Manual for Series H & MH Hydraulic Cylinders for specific information SAFETY INTEGRITY LEVEL (SIL) A key factor defined and used in the IEC and IEC standards is Safety Integrity Level, also known as. QUESTION Is it possible to achieve Performance Level PL d with Category 3 according to ISO or SIL 2 according to IEC 661 with application of only one SIRIUS Position switch with or without solenoid interlocking (type 2) or only one SIRIUS Hinge switch?. While emergency stop is not a safeguard, it is considered to be a ‘complementary protective measure’ 6, , 7, 319, 63 Understanding the hazards that need to be controlled and the degree of risk related to the hazards is basic design information that will provide specific direction on.

FRAGE Ist es möglich, Performance Level PL d mit Kategorie 3 gemäß ISO oder SIL 2 gemäß IEC 661 unter Einsatz nur eines SIRIUS Positionsschalters mit oder ohne Zuhaltung. SIL stands for Safety Integrity Level A SIL is a measure of safety system performance, in terms of probability of failure on demand (PFD) This convention was chosen based on the numbers it is easier to express the probability of failure rather than that of proper performance (eg, 1 in 100,000 vs 99,999 in 100,000). Stipulated Performance Level PL d with Category 3 according to ISO or SIL due to IEC 661) Possible constructive measures (high protection against failure) can be like this • Protection against self loosening (eg welding, riveting).

Safety Integrity Level (SIL) EN 661 defines how to determine the Safety Integrity Level (SIL) SIL represents the reliability of safety functions Four SIL levels are possible 1, 2, 3, and 4 ‘SIL 4’ is the highest level of safety integrity and ‘SIL 1’ the lowest Only levels 13 are used in machinery See the example on page 12. Safety requirements – SIL 2 and SIL 3 These proven and reliable systems perform mission critical applications worldwide, utilizing flexible Safety Integrity Level (SIL) configuration and qualified manufacturing and solution delivery processes. The safety function in this application technique meets or exceeds the requirements for Category 3, Performance Level d (CAT 3, PLd), per ISO and control reliable operation per ANSI B1119 Functional Safety Description Hazardous motion is interrupted or prevented by actuation of the emergency stop button Each Estop is considered a.

– How to calculate SIL – How to reach a certain rating. In simple terms, SIL is a measurement of performance required for a Safety Instrumented Function (SIF) Fike Europe's range of Fike bursting discs (also known as rupture discs) has an assigned equivalent SILlevel 3 The SIL 3 has been derived from comparison with published and generally accepted probability of failure on demand (PFD) values. There are four discrete integrity levels associated with SIL SIL 1, SIL 2, SIL 3, and SIL 4 The higher the SIL level, the higher the associated safety level, and the lower probability that a.

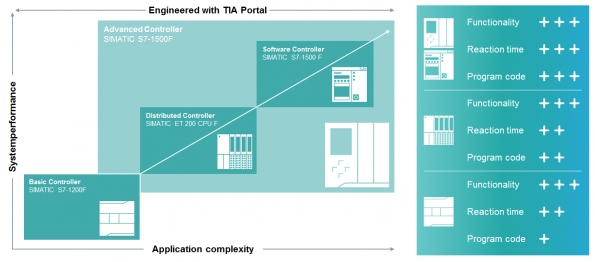

1 Introduction Emergency Stop up to PL e / SIL 3 with a FailSafe S Controller Entry ID , V50, 01/17 7 G 7 d 122 Safety program. SIL stands for Safety Integrity Level A SIL is a measure of safety system performance, in terms of probability of failure on demand (PFD) This convention was chosen based on the numbers it is easier to express the probability of failure rather than that of proper performance (eg, 1 in 100,000 vs 99,999 in 100,000). This is below SIL 1 performance (a Risk Reduction Factor between 10 and 100, as shown in Table 1) Therefore, debating on the level of performance of the fire & gas system hardware alone may prove to be of little worth In this example – which is realistic – the overall system will never meet SIL 1 performance no matter what hardware is used.

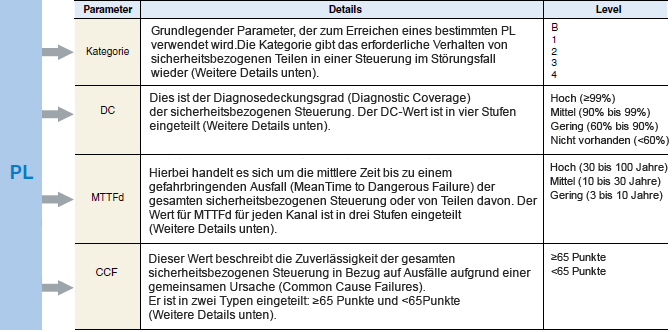

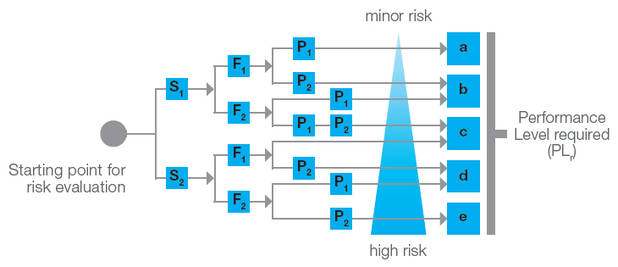

SIL – Safety integrity level The intrinsically safe pressure sensor IS meets the requirements of the safety integration level SIL 2 This level has a mean time to failure of ≥ 1 x 10 3 to < 1 x 10 2 h according to the following established reference table (excerpt from IEC/EN ). IEC 661 addresses SIL levels and ISO addresses Performance Levels While there are two different standards, the scope of each standard is very similar Note that either a SIL or Performance Level would be used, but not both The figure below shows an overview of the risk assessment process. The performance level (PL) is a value used to define the ability of safetyrelated parts of control systems to perform a safety function under foreseeable conditions On the other hand, the required performance level (PLr) is used in order to achieve the required risk reduction for each safety function.

EN/IEC 661 represents a sectorspecific standard under IEC It describes the implementation of safetyrelated electrical control systems on machinery and examines the overall lifecycle from the concept phase through to decommissioning In contrast to EN , EN IEC is published in the Official Journal of the EU as a harmonised standard under the Machinery Directive. 1 Introduction Emergency Stop up to PL e / SIL 3 with a FailSafe S Controller Entry ID , V50, 01/17 7 G 7 d 122 Safety program. SIL (Safety Integrity Level) La norma EN 661 specifica il modo in cui viene definito il livello SIL (Safety Integrity Level) Il livello SIL è una rappresentazione del livello di integrità delle funzioni di sicurezza Sono disponibili quattro livelli di integrità della sicurezza 1, 2, 3 e 4.

– What this means for the manufacturer?. SIL is a relative level of risk reduction provided by a safety function SIL ratings correlate to frequency and severity of hazards They determine the performance required to maintain and achieve safety — and the probability of failure There are four SILs — SIL 1, SIL 2, SIL 3, and SIL 4. Safety Integrity Level (SIL) / Background SIL Determination Safety Integrity Level (SIL) is defined as a relative level of riskreduction provided by a safety function, or to specify a target level of risk reduction In (somewhat) simple terms, SIL is a measurement of performance or probability of failure on demand (PFD) required.

Safety Integrity Level Safety Integrity Level it is a discrete level (one out of a possible four) for specifying the safety integrity requirements of the safety functions to be allocated to the E/E/PE safetyrelated systems;. SIL 3 is a Safety Integrity Level that is appropriate for very specific and rare situations, in which a high level of riskreduction performance by a SIF is required. – How to find a safety integrity level – How is SIL used?.

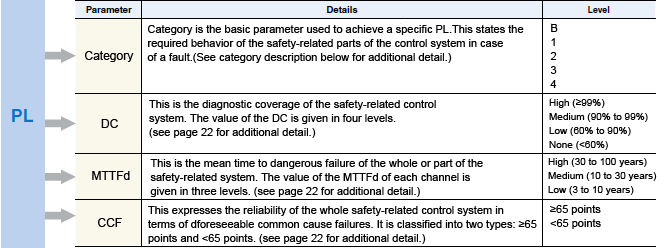

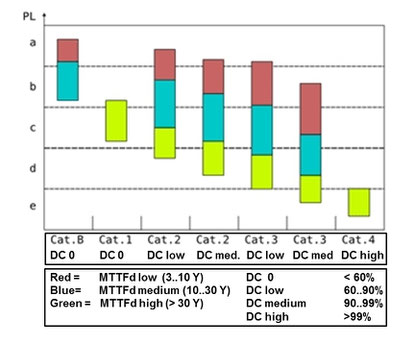

Relevant parameters such as the risk parameters for determining the required performance level (PL r), the category of the SRP/CS, measures against commoncause failures (CCF) on multichannel systems, the average component quality (MTTF d) and the average test quality (DC avg) of components and blocks, are entered step by step in input dialogs. – What is SIL Capability?.

Http Www Ein Org Pl Sites Default Files 13 02 02 Pdf

Eaton Xtse Safety Contactor Airline Hydraulics

Ifa Practical Aids Relationship Between Espe And Sil Pl

What S The Difference Between Pl And Sil Machine Safety Standards

Lc Automation Sigma Safety Relay 24vto 240v

All Around Safety Package Sil3 For Industrial Automation Marktechnical

Iso 1 Analysis Part 3 Architectural Category Selection

Cdn Sick Com Media Content Hb0 H53 Pdf

Functional Safety For Integrated Circuits Analog Devices

En 1 Sil 2 Pl D Mttfd Etc And What Does It Mean For Crane Safety Systems Kst Systemss Webseite

Safety Key To The Machine Solution

Functional Safety In Manufacturing Plant Operations

Sil Pl What Is The Probability Of Failure Of A Safety Function Wika Blog

What Is Iec And Safety Integrity Level Sil Basics Perforce

Safety Integrity Level Or Performance Level Beemster Electrical Solutions

En 1 Sil 2 Pl D Mttfd Etc And What Does It Mean For Crane Safety Systems Kst Systemss Webseite

Your Advantages For Safety Application Up To Pl E Cat 4 E G Sil 3 Manual Or Automatic Start See Variants Applications Pdf Free Download

Modular Universal Load Cell Sil3 Marktechnical

2

Pl Ok Esempi Di Calcolo Del Performance Level Pl En Iso 1 Certifico Srl

Reer Iec 661 Sil Conclusions

Safety Integrated Level And Performance Levels For Machine Safety

Pl Parameters Safety Knowledge Keyence

Difference Between En Iso And En Iec 661

Dold Ug6970 Series Safety Relay 2 With Manualzz

Iso Safety Of Machinery Sensy

Strain Gauge Bridge Amplifier Sil3 Ple Type Smm Hd Muller

Sil Why Is That Important To Me An Overall Introduction To Standards And Concepts Cenosco

Safety Of Machinery Application Of Standard En Iso 1

Sil3 Ready Load Pins Sensy

What Are Functional Safety Standards For Servo Drives

What S The Difference Between Pl And Sil Machine Safety Standards

Www Vttresearch Com Sites Default Files Pdf Technology 15 T241 Pdf

What S A Safety Plc Fundamentals And Differences

Safety Functions Of Safety Components Technical Guide Australia Omron Ia

Motrona Gmbh Speed Monitors With Sil3 Ple Sil2 Pld Certificate

Figure 3 From Sil 3 Sil 2 And Unicorns There Is A High Probability Your Sil 2 And Sil 3 Sifs Have No Better Performance Than Sil 1 Semantic Scholar

Cdn Sick Com Media Content Hb0 H53 Pdf

Phoenix Contact Standards And Directives

Www Vttresearch Com Sites Default Files Julkaisut Muut 17 Vtt R 17 Pdf

Http Ifev Rz Tu Bs De Sit Safetyintransportation Sit11 Graefeling Pdf

Functional Safety And Industry 4 0 Analog Devices

Functional Safety And Industry 4 0 Analog Devices

Sil Why Is That Important To Me An Overall Introduction To Standards And Concepts Cenosco

Noser Blog Was Ist Funktionale Sicherheit Noser Blog

Standstill Speed Monitoring Dold

What S The Difference Between Pl And Sil Machine Safety Standards

Pl Parameters Safety Knowledge Keyence

Q Tbn And9gcs Ionhffqlwkfhs4s8ffckuhtvojo2d Psgbrwkkydbegkqmr Usqp Cau

Importance Of Safety Integrity Level Sil Instrumentation Tools

Sps Magazin Safety Mess Modul Bietet Funktionale Sicherheit Gemass Sil 3

Www Robotics Org Filesdownload Cfm Dl4 3 Iso pl calculations simplified 1 Pdf

Safety For Machines Pl Pfannenberg

Bezpieczenstwo W Systemach Sterowania

En 1 Sil 2 Pl D Mttfd Etc And What Does It Mean For Crane Safety Systems Kst Systemss Webseite

Umrechnung Von Performance Level Pl Auf Sicherheits Integritatslevel Sil

Berechnung Des Performance Level Nach En Iso 1

2 4 2 Iec En 661 Functional Safety Control Systems Leuze The Sensor People

Safety Circuit Examples Of Safety Components Technical Guide Australia Omron Ia

Safety Sbw Technology

Functional Safety And Industry 4 0 Analog Devices

Safety Of Machinery Application Of Standard En Iso 1

Steute Funk Sicherheits Fussschalter Fur Performance Level E Und Sil 3 All Electronics

Cdn Sick Com Media Content Hb0 H53 Pdf

Q Tbn And9gcrdculxhxrig X9b9uarwjhmxjw6qk8x Jkworcvb1ys7lxqdya Usqp Cau

Protect Your Machine Operators 13 04 02 Ishn

Safety Integrity Level Sil Certification

Silo Tips Download Presentation Safety Legislation And Standards

Safety Integrity Level An Overview Sciencedirect Topics

What S The Difference Between Pl And Sil Machine Safety Standards

What S The Difference Between Pl And Sil Machine Safety Standards

Pl Parameters Safety Knowledge Keyence

Sil 3 Sil 2 And Unicorns There Is A High Probability Your Sil 2 And Sil 3 Sifs Have No Better Performance Than Sil 1 Semantic Scholar

2

Wat Zijn De Verschillen Tussen Safety Integrity Level Sil En Performance Level Pl Istec International

Contaval

Contrinex High Speed Safety Relays Manualzz

Www Ifm Com Img Safety White Paper Pdf

What Are Functional Safety Standards For Servo Drives

2

Sil Pl What Is The Probability Of Failure Of A Safety Function Wika Blog

Safety Relay Versisafe Peter Electronic 3 No 1 Nc Time Delay

Safety Integrity Level Sil Risk Analysis

Safety Of Machinery Application Of Standard En Iso 1

Performance Level Pl

Achieving Required Safety Levels With Pneumatic Exhaust Valves

Ausfallwahrscheinlichkeit Einer Sicherheitsfunktion Blog Wika

Determine Safety Integrity Levels Sil For Process Applications

Workplace Safety Do You Really Need Sil 3 Chemical Processing

Safety Integrity Level

Sil 3 The Definitive Guide To Sil 3 Safety Integrity Level

簡單聊聊歐規的功能安全 Functional Safety 的sil與pl 運動控制 傳動與控制科技論壇

Simatic S7 F P Press Safety Blocks Id Industry Support Siemens

Http Www Ein Org Pl Sites Default Files 13 02 02 Pdf

En 1 Sil 2 Pl D Mttfd Etc And What Does It Mean For Crane Safety Systems Kst Systemss Webseite

Cdn Sick Com Media Content Hb0 H53 Pdf

Control Engineering Machine Safety Can One Channel Mitigate A Cat 3 Pld Functional Requirement