Performance Level Vs Sil

Www Ifm Com Img Safety White Paper Pdf

Http Ifev Rz Tu Bs De Sit Safetyintransportation Sit11 Graefeling Pdf

Http Www Iceweb Com Au Manufacturing and auto safety Machautosafetykenrobertson Pdf

Safety For Machines Pl Pfannenberg

Relation Between Rrf And Sil In Low Demand Mode Download Table

Terminology Explained What Is Safety Integrity Level Sil Dnv Gl Software

The actual need for SIL 3 must be determined through an accurate and thorough SIL determination, and through a reassessment, also in consideration of the additional.

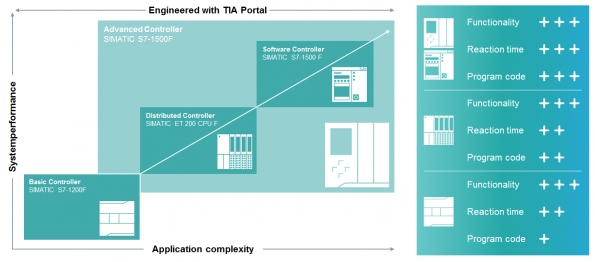

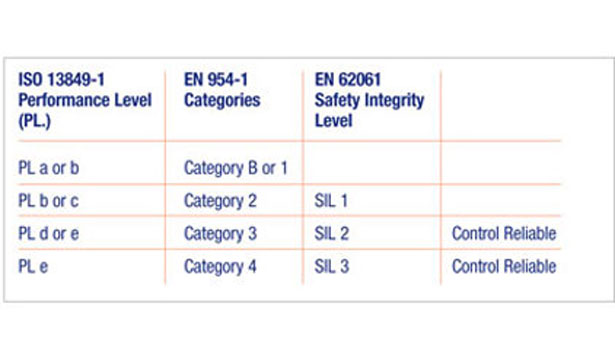

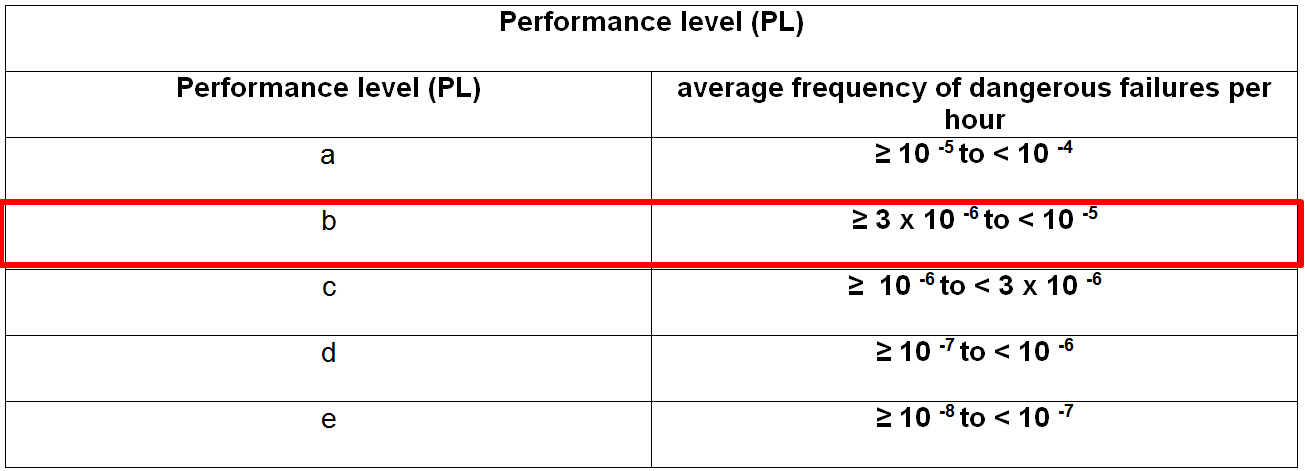

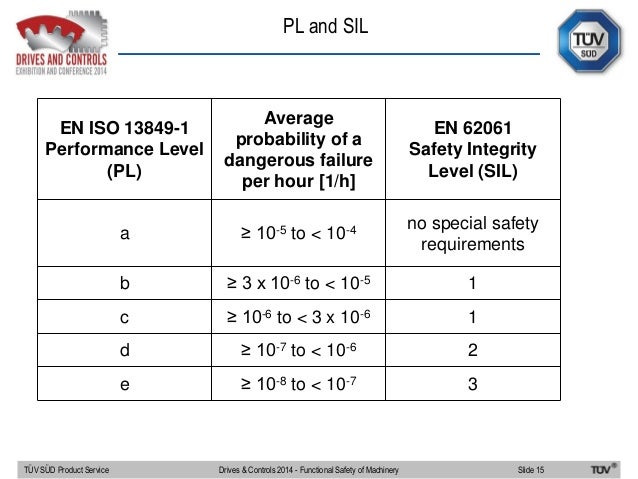

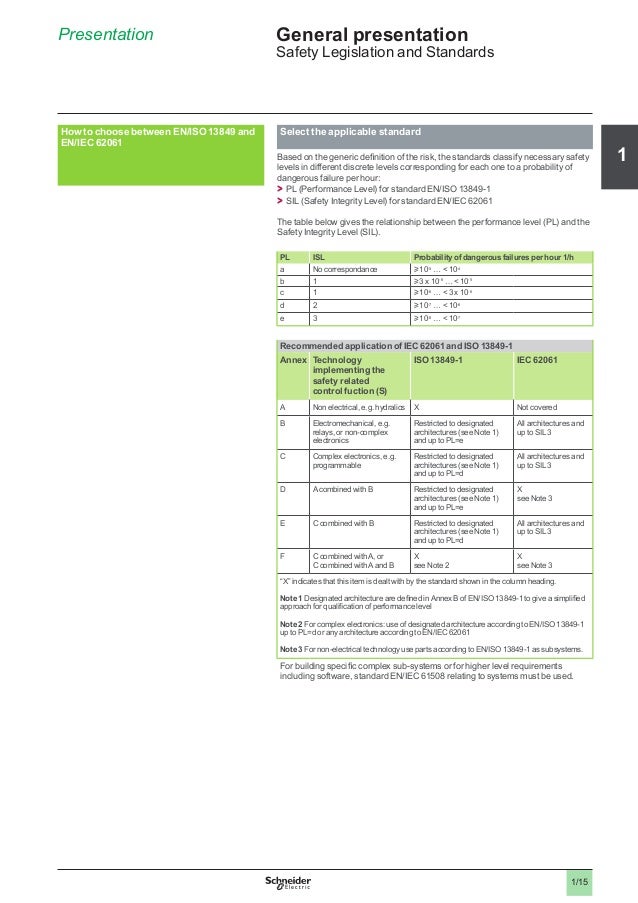

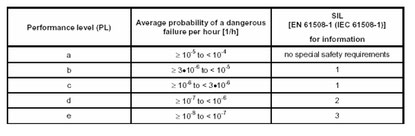

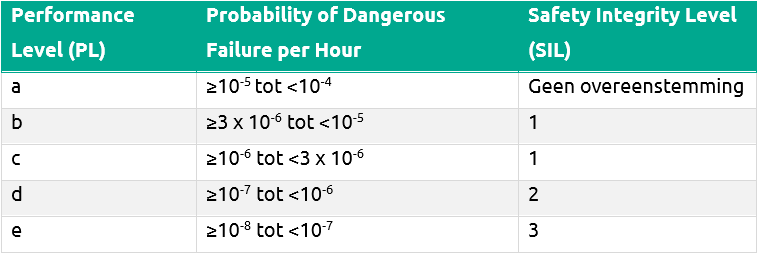

Performance level vs sil. Safety Integrity Level SIL stands for Safety Integrity Level A SIL is a measure of safety system performance, in terms of probability of failure on demand (PFD) This convention was chosen based on the numbers it is easier to express the probability of failure rather than that of proper performance (eg, 1 in 100,000 vs 99,999 in 100,000). QUESTION Is it possible to achieve Performance Level PL d with Category 3 according to ISO or SIL 2 according to IEC 661 with application of only one SIRIUS Position switch with or without solenoid interlocking (type 2) or only one SIRIUS Hinge switch?. SIL has gathered about $154 million in assets and trades in an average volume of more than 238,000 shares It charges 65 bps in fees from investors per year and offers a dividend yield of only 009%.

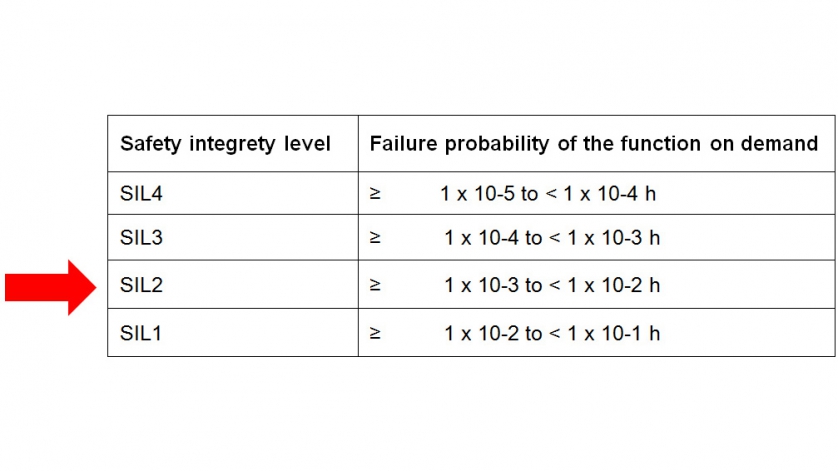

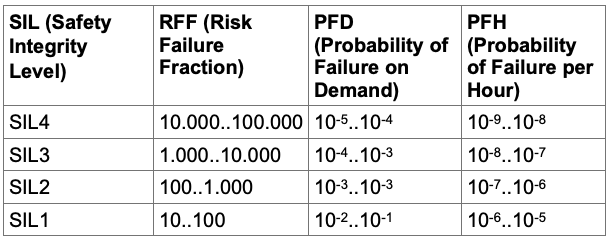

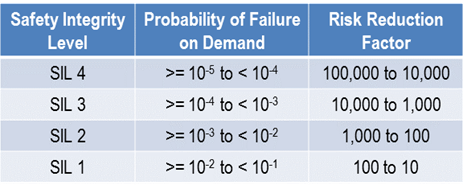

Safety Integrity Level 31 Safety Integrity Level SIL 4 SIL 3 SIL 2 SIL 1 Risk Reduction Factor to to 1000 1000 to 100 100 to 10 1 Each safety function has a requirement to reduce risk SIL level Order of magnitude level of risk reduction required. Four (4) Safety Integrity Levels (SIL 1 to SIL 4) define the level of security measure for each plant component Selecting one of the Safety Integrity Levels also determines limiting value of remaining risk Most common selection for circuit calculation is SIL 2, rarely is SIL 3 used. Safety Integrity Level (SIL) EN 661 defines how to determine the Safety Integrity Level (SIL) SIL represents the reliability of safety functions Four SIL levels are possible 1, 2, 3, and 4 ‘SIL 4’ is the highest level of safety integrity and ‘SIL 1’ the lowest Only levels 13 are used in machinery See the example on page 12.

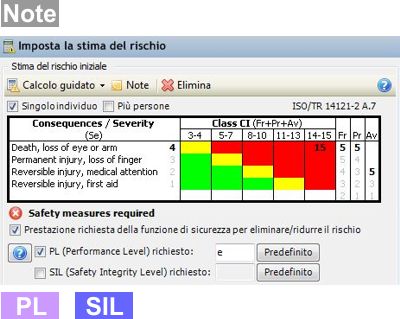

•Black boxes with assigned SIL levels are mandatory •Grey boxes with no SIL level assigned means recommended other measures •A specific hazard with Se=3, Fr=4 and Pr=5 and an Av=5 will be –CI = Fr Pr Av –CI=455 =14 for Se of 3 –Which leads to SIL=3. QUESTION Is it possible to achieve Performance Level PL d with Category 3 according to ISO or SIL 2 according to IEC 661 with application of only one SIRIUS Position switch with or without solenoid interlocking (type 2) or only one SIRIUS Hinge switch?. To determine SIL Levels of process hazards, it is helpful to understand the Safety Life Cycle The IEC standards define a concept known as the Safety Life Cycle, see Figure 2The Safety Life Cycle provides a repeatable framework whereby all process hazards are identified and analyzed to understand which hazards require the use of a SIS for mitigation.

Safety Integrity Level (SIL) The Required Safety Availability (RSA) value is synonymous with dependability the probability (Note 1) that a Safety Instrumented Function will perform its duty when faced with a dangerous process condition. Safety Integrity Level 31 Safety Integrity Level SIL 4 SIL 3 SIL 2 SIL 1 Risk Reduction Factor to to 1000 1000 to 100 100 to 10 1 Each safety function has a requirement to reduce risk SIL level Order of magnitude level of risk reduction required. SIL stands for Safety Integrity Level A SIL is a measure of safety system performance, in terms of probability of failure on demand (PFD) This convention was chosen based on the numbers it is easier to express the probability of failure rather than that of proper performance (eg, 1 in 100,000 vs 99,999 in 100,000).

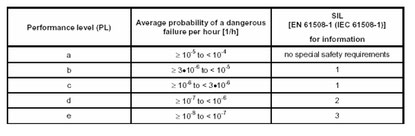

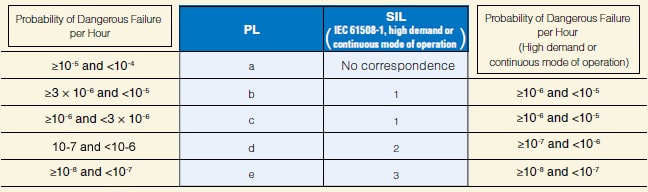

Safety Integrity Level (SIL) is a measure of safety system performance – not a measure of process risk The higher the level of risk, the greater the system performance required. Safety Integrity Level (SIL) is a measure of safety system performance – not a measure of process risk norme safety integrity level norsok safety integrity level o que é safety integrity level performance level vs safety integrity level PLC ppt on safety integrity level presentation on safety integrity level que es safety integrity. SIL (Security Integrity Level), like Performance level, is a measure of how likely it is that a dangerous failure will occur in a system SIL 2 roughly equivalent to PL d (performance level d) (See IEC 661 or EN 661 for more details).

HERVE BARON ©16–HervéBaron SIL Study Step 2 calculations and recommendation SIS Performance Verification Evaluate the performance of each SIF, based on device selection, architecture, voting, testing etc Compare to required SIL level and specify modifications to the SIF design (device selection, component redundancy) or testing. The term Safety Integrity Level (SIL) is now fairly familiar to most process plants with hazards that require independent protection layers, albeit SIL is often misunderstood to apply to individual equipment items When correctly applied, a SIL requirement from SIL 1 to SIL 4 can be assigned to an endtoend safety function to provide a marker of the level of integrity required for equipment. Functional Safety—Safety Integrity Level (SIL) and Performance Level (PL) 3 Safety Values for Standard Components;.

Safety Integrity Level, or as more usually referred to "SIL" or "SIL level", is a unit of measurement for quantifying risk reduction There are four integrity levels, ie SIL 1 represents the integrity required to avoid relatively minor incidents and is likely to be satisfied by a certain degree of fault tolerant design using guidelines that. SIL Max N* P* no_danger 1 105 /hr 072 2 106 /hr 3 107 /hr 4 108 /hr Table 1 Residual dangerous faults vs SIL failure targets (* assuming T=104 hours) So it can be seen that for SIL1, in this simplified example, there should be a better than 5050 chance. The type, Safety Integrity Level (SIL) and Performance Level (PL) are classifications of safety related components The IEC standard series for example sets out criteria for the design and testing of electro sensitive protective equipment (ESPE).

Safety Integrity Level (SIL) and Performance Level (PL)—History and Distinction Speaking of ways to rate systems for use in today’s safety applications, the acronyms SIL (safety integrity level), PL (performance level), and SILCL (SIL claim level) come to mind. Fixed gas detectors vs SIL Fixed gas detection systems have been used for many years to perform safety instrumented functions Like any instrumented system, a fixed gas detection system commonly comprises of a single or multiple gas detector input(s), a control unit and a single or multiple final element(s) or output(s). Safety Integrity Level (SIL) is a measure of safety system performance – not a measure of process risk The higher the level of risk, the greater the system performance required.

3 Safety Values for Standard Components Your Benefits PepperlFuchs products evaluated to ISO mostly show a performance level and category in the respective documentation In other cases (mainly sensors) there are. 06 introducing PL (performance level) Most everyone agrees that both SIL and PL are hazard ratings that are quantitatively derived and can be directly related. Safety Integrity Level (SIL) is a measure of safety system performance – not a measure of process risk The higher the level of risk, the greater the system performance required Based on a hazard.

The actual need for SIL 3 must be determined through an accurate and thorough SIL determination, and through a reassessment, also in consideration of the additional. QUESTION Is it possible to achieve Performance Level PL d with Category 3 according to ISO or SIL 2 according to IEC 661 with application of only one SIRIUS Position switch with or without solenoid interlocking (type 2) or only one SIRIUS Hinge switch?. Both ISO – 1 and IEC 661 8 base the initial requirements for reliability on the outcome of the risk assessment (PL r or SIL r) If the stopping condition is part of normal operation, then simple circuit requirements (ie PL a , Category 1) are all that may be required.

In this article you will learn the difference between different level measurement technologies and why level measurement technology is universal. This is below SIL 1 performance (a Risk Reduction Factor between 10 and 100, as shown in Table 1) Therefore, debating on the level of performance of the fire & gas system hardware alone may prove to be of little worth In this example – which is realistic – the overall system will never meet SIL 1 performance no matter what hardware is used. Safety Performance criteria for SIS should be defined by Safety Integrity Levels (SIL) The determination of Safety Integrity Level required for the SIS will help verification of configuration of.

Stipulated Performance Level PL d with Category 3 according to ISO or SIL due to IEC 661) Possible constructive measures (high protection against failure) can be like this • Protection against self loosening (eg welding, riveting). Conclusions The Main Concepts with SIL 3 are the following SIL 3 is a Safety Integrity Level that is appropriate for very specific and rare situations, in which a high level of riskreduction performance by a SIF is required;. Putting simple safety Integrity level is a measure of performance required from a safety instrumented system to.

Safety Integrity Level Safety Integrity Level it is a discrete level (one out of a possible four) for specifying the safety integrity requirements of the safety functions to be allocated to the E/E/PE safetyrelated systems;. In different industrial sectors risk assessment is fundamental step to determine required safety integrity level (SIL), eventually performance level (PL), which guarantees risk linked to some. We all know by now about safety rated devices according to SIL(safety integrity level) and Cat(category) Recently, a new term has emerged from Europe via ISO ;.

• The IEC specifies 4 levels of safety performance for a safety function • These are called safety integrity levels Safety integrity level 1 (SIL1) is the lowest level of safety integrity • safety integrity level 4 (SIL4) is the highest level • The standard details the requirements necessary to achieve each safety integrity level. Conclusions The Main Concepts with SIL 3 are the following SIL 3 is a Safety Integrity Level that is appropriate for very specific and rare situations, in which a high level of riskreduction performance by a SIF is required;. Safety Integrity Level (SIL) is defined as a relative level of riskreduction provided by a safety function, or to specify a target level of risk reduction In simple terms, SIL is a measurement of performance required for a Safety Instrumented Function (SIF) Fike Europe's range of Fike bursting discs (also known as rupture discs) has an.

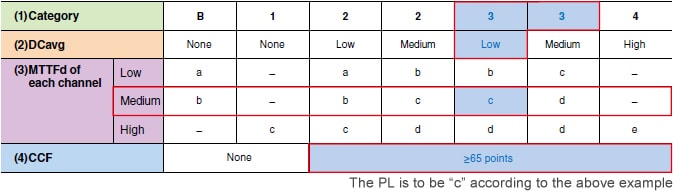

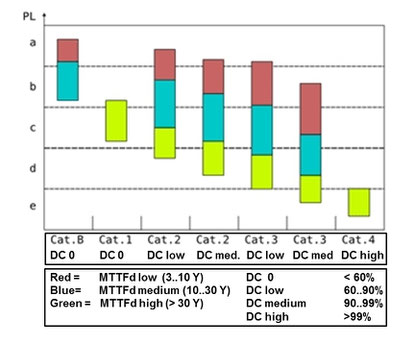

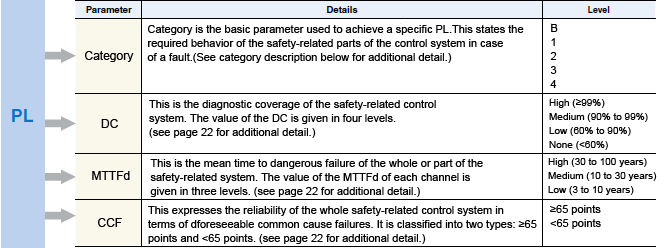

I SO Category and Performance Level (PL) versus IEC Safety Integrity Level (SIL) Functional Safety Introduction Safety vs Reliability IEC ISO. SIL basics and terminology SIL is a measure “Functional Safety” on a safety device, in terms of probability of failure on demand (PFD) It is in effect easier to express the probability of failure, rather than that of correct performance (eg, 1 in 100,000 vs 99,999 in 100,000) There are four discrete levels SIL 1, SIL 2, SIL 3, and SIL 4. The essential difference between PL and SIL is rooted in the parameters that express the degree of fault detection, the degree of redundancy, and the degree of reliability The PL not only has a PFH, but also a reliability value for each channel inside the safetyrelated system.

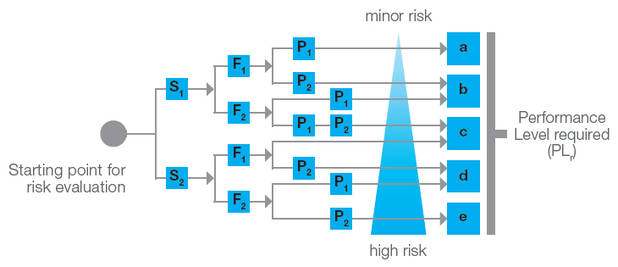

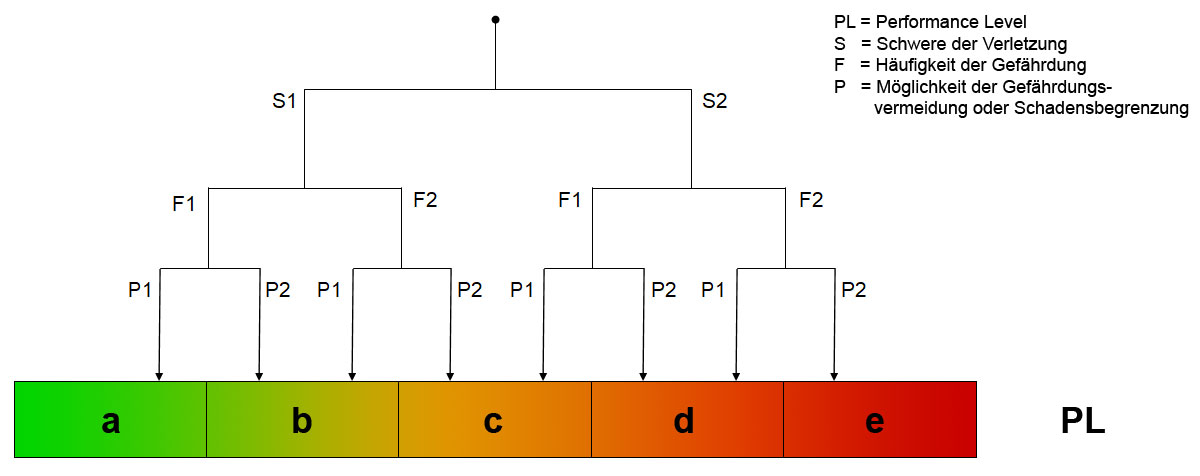

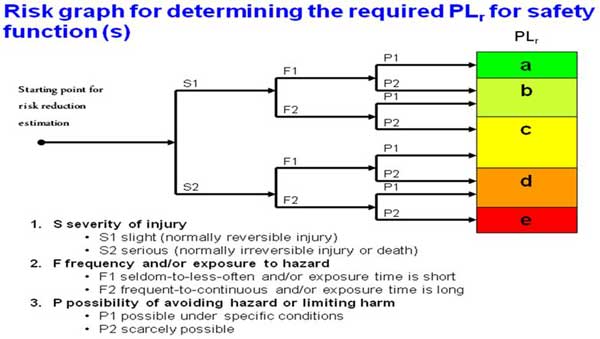

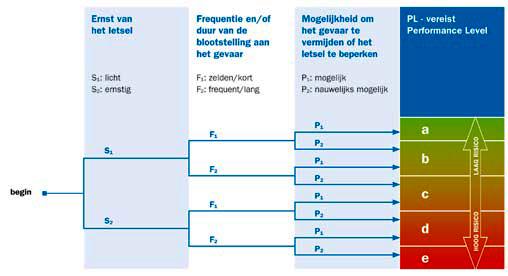

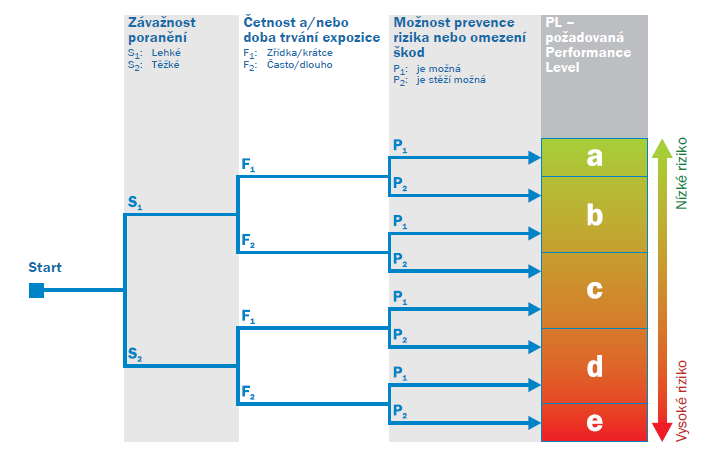

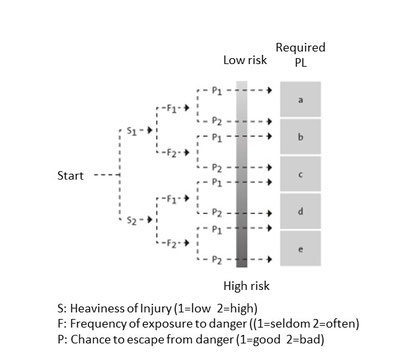

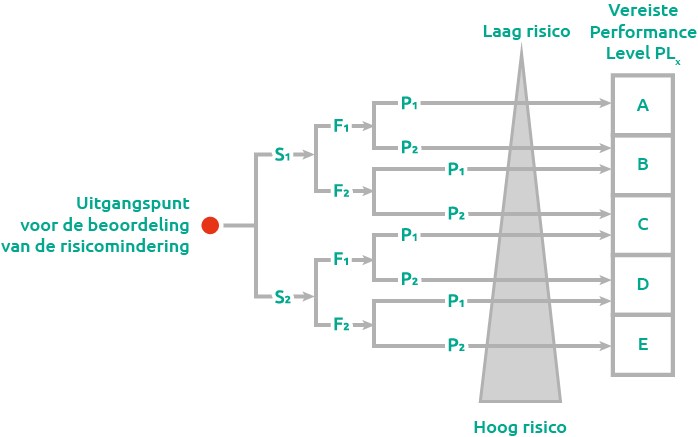

The reliability of a single component or assembly of components (ie the machine) is designated as either its Safety Integrity Level (SIL) or Performance Level (PL) In both cases, the corresponding SIL or PL value is determined based on the calculated ‘statistical probability of failure’. The P7000 combined with Kollmorgen's stepper motors provide unique level of system smoothness, functionality and performance 6410 Stepper Drive These modular, highperformance microstepping drives support a broad range of requirements. The greater the risk, the higher the requirements of the control systems The hazardous situation is classified into five levels, known as Performance Levels (PL), from PL "a" (low) to PL "e" (high)The required PL is determined and assigned as part of the risk assessment in accordance EN ISO.

I SO Category and Performance Level (PL) versus IEC Safety Integrity Level (SIL) Functional Safety Introduction Safety vs Reliability IEC ISO. Following either standard leads to a very similar outcome and their resulting safety integrity levels (SIL) and performance levels (PL) are comparable (see Table 7) This document includes safety performance/ integrity examples for both standards. An appropriate PLr (Performance Level required) for each identified safety function A central part of EN ISO is to choose an appropriate category for the identified safety functions Categories were used also in the earlier machinery safety standard EN The report describes in detail the meaning of each category and.

Safety Performance criteria for SIS should be defined by Safety Integrity Levels (SIL) The determination of Safety Integrity Level required for the SIS will help verification of configuration of. Both SIL (Safety Integrity Level) and PL (Performance Level) are measures of the reduction in risk provided by a safety function of a control system For systems that are operating continuously, SIL and PL are both defined as ranges of the probability of dangerous failure per hour and they overlap. • The IEC specifies 4 levels of safety performance for a safety function • These are called safety integrity levels Safety integrity level 1 (SIL1) is the lowest level of safety integrity • safety integrity level 4 (SIL4) is the highest level • The standard details the requirements necessary to achieve each safety integrity level.

The safety lifecycle of any ISO compliant automotive application development begins with determination of ASIL (Automotive Safety Integrity Level) Determined through hazard analysis and risk assessment of automotive component, the ISO ASIL rating helps in identifying safety measures required to reduce the potential hazards.

Pl Parameters Safety Knowledge Keyence

Cdn Sick Com Media Content Hb0 H53 Pdf

Machinery Sensor Safetty Systems Ltd

Control Engineering Machine Safety 13 Terms To Know For Compliance With Functional Safety Iso 1

What S The Difference Between Pl And Sil Machine Safety Standards

Is Mandating A Category Or Hft Best Practice Engineerzone Spotlight Engineerzone Engineerzone

Performance Level Pl

Umrechnung Von Performance Level Pl Auf Sicherheits Integritatslevel Sil

Cdn Sick Com Media Content Hb0 H53 Pdf

Artikel Machinebouwers Pas Op Met Sil Componenten Uit De Procesindustrie D F

What S The Difference Between Pl And Sil Machine Safety Standards

What S The Difference Between Pl And Sil Machine Safety Standards

Safety Functions Of Safety Components Technical Guide Australia Omron Ia

Safety Integrity Level Sil Risk Analysis

Simatic S7 F P Press Safety Blocks Id Industry Support Siemens

Difference Between Sis Plc And Bpcs Systems Instrumentation Tools

Difference Between Sis Plc And Bpcs Systems Instrumentation Tools

Http Www Diva Portal Org Smash Get Diva2 Fulltext01 Pdf

Protect Your Machine Operators 13 04 02 Ishn

Control Engineering En Iso 1 The Quantitative Approach To Machine Safety Begins With A Qualitative Process

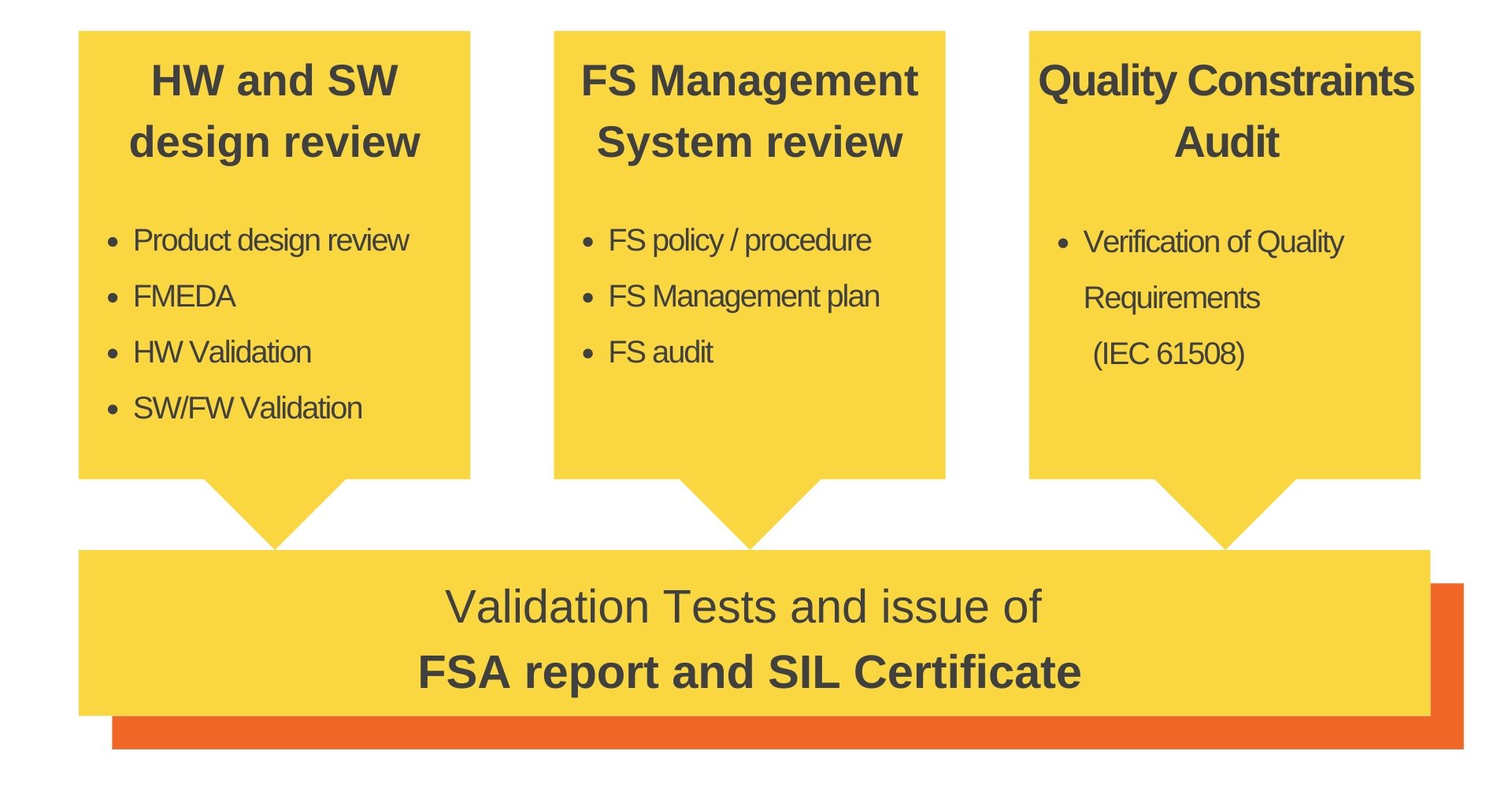

Safety Integrity Level Sil Certification

Noser Blog Was Ist Funktionale Sicherheit Noser Blog

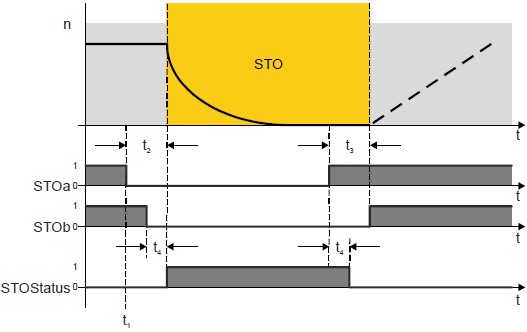

What Are Functional Safety Standards For Servo Drives

Q Tbn And9gcqij6vxv44x6dwusi Iukgiu1ibkmsuvdomuoddrfhd014fdmgz Usqp Cau

Cdn Sick Com Media Content H97 Hfe Pdf

Safety Integrated Level And Performance Levels For Machine Safety

Sil Why Is That Important To Me An Overall Introduction To Standards And Concepts Cenosco

Safety Functions Of Safety Components Technical Guide Australia Omron Ia

Zijn Standaardcomponenten Inzetbaar Voor Veiligheidsfuncties Safety Kennis Engineersonline Nl

Iso 1 Analysis Part 3 Architectural Category Selection

Inhouse Schulung Beratung Din En Iso Mttfd Pl Sil Bestimmung Mittels Risikobeurteilung Und Sistema Abschatzung Maschinensicherheit Berechnung Des Performance Level Sicherheit Von Maschinen Risikominderung Qmti Luciano Bianchin

Terminology Explained What Is Safety Integrity Level Sil Dnv Gl Software

Safety Integrity Level Sil And Performance Level Pl Logic Srl

Q Tbn And9gcsexbkvv5xvvcpjtd9fwiwi0euqkk7huozuhijqhnujikq6ntfa Usqp Cau

2 4 2 Iec En 661 Functional Safety Control Systems Leuze The Sensor People

Http Www Iceweb Com Au Manufacturing and auto safety Machautosafetykenrobertson Pdf

Cdn Sick Com Media Content Hb0 H53 Pdf

Iso 1 Analysis Part 3 Architectural Category Selection

Functional Safety Sil Pl

Sil Pl What Is The Probability Of Failure Of A Safety Function Wika Blog

Calculation Tool To Verify Functional Safety Pilz Int

Bezpecnost Stroju 2 Dil Pl Vs Sil Automatizace Hw Cz

Compliance With Iec In The Process Industry

Determine Safety Integrity Levels Sil For Process Applications

En 1 Sil 2 Pl D Mttfd Etc And What Does It Mean For Crane Safety Systems Kst Systemss Webseite

Method For Assigning Safety Integrity Level Sil During Design Of Safety Instrumented Systems Sis From Database Sciencedirect

Q Tbn And9gcsfvufyvipqdvfxmdv1c2lxhm61t4ynfsisdvsgsl0 Usqp Cau

Functional Safety Standards For Machinery

Reer Iec 661 Sil Conclusions

Performance Level En Sil Bij Atex Machines

Sil Pl What Is The Probability Of Failure Of A Safety Function Wika Blog

Functional Safety For Integrated Circuits Analog Devices

Probability Of Failure In Functional Safety Systems

Valg Av Sil Eller Pl Kategori Forum Www Trainor No

Functional Safety Part 2 Of 2 Machine Design

Www Insafetyconf Com Wp Content Uploads 19 02 4h Pdf

Functional Safety And Industry 4 0 Analog Devices

Iso 1 Analysis Part 3 Architectural Category Selection

Table 3 From Safety Integrity Level Sil Versus Full Quantitative Risk Value Nienaruszalnosc Bezpieczenstwa A Wartosc Ryzyka Semantic Scholar

Sil And Pl Certified Digital Proportional Valves Offer New Design Opportunities Hydraulics Pneumatics

What S A Safety Plc Fundamentals And Differences

Sil Why Is That Important To Me An Overall Introduction To Standards And Concepts Cenosco

What S The Difference Between Pl And Sil Machine Safety Standards

Functional Safety Sil In The Subsea And Drilling Industry

Functional Safety And Industry 4 0 Analog Devices

Cdn Sick Com Media Content Hb0 H53 Pdf

Www Robotics Org Filesdownload Cfm Dl4 3 Iso pl calculations simplified 1 Pdf

Berechnung Des Performance Level Nach En Iso 1

Functional Safety Plays An Increasingly Important Role On The Construction Site

Importance Of Safety Integrity Level Sil Instrumentation Tools

What Does Sil Stand For In Safety Indelac Controls Inc

Safety Functions Of Safety Components Technical Guide Australia Omron Ia

Il Report Di Cem4 Relativo Al Calcolo Del Pl Sil Delle Funzioni Di Sicurezza Certifico Srl

Pl Parameters Safety Knowledge Keyence

Functional Safety Assessment Of Hw And Sw H On Blog

Functional Safety In Manufacturing Plant Operations

Difference Between En Iso And En Iec 661

Wat Zijn De Verschillen Tussen Safety Integrity Level Sil En Performance Level Pl Istec International

2 4 Safety Related Parts Of Control Systems Leuze The Sensor People

Sr6 Atb Automation

1

En 1 Sil 2 Pl D Mttfd Etc And What Does It Mean For Crane Safety Systems Kst Systemss Webseite

Safety Integrity Level Explained Malefasr

En 1 Sil 2 Pl D Mttfd Etc And What Does It Mean For Crane Safety Systems Kst Systemss Webseite

Understanding Safety Integrity Level Iec Instrumentation Tools

Http Www Ein Org Pl Sites Default Files 13 02 02 Pdf

Phoenix Contact Standards And Directives

Functional Safety And Industry 4 0 Analog Devices

What S The Difference Between Pl And Sil Machine Safety Standards

Safety For Machines Pl Pfannenberg

Wat Zijn De Verschillen Tussen Safety Integrity Level Sil En Performance Level Pl Istec International

Reer Iso 1 Pl

Safety Integrated Level And Performance Levels For Machine Safety

Www Vttresearch Com Sites Default Files Julkaisut Muut 17 Vtt R 17 Pdf

Safety Update This Presentation Covers Machinery Directive 06 42 Ec Ppt Download

Pl Parameters Safety Knowledge Keyence

Umrechnung Von Performance Level Pl Auf Sicherheits Integritatslevel Sil

Http Www Ein Org Pl Sites Default Files 13 02 02 Pdf