Food Processing Hygienic Design

Food Safety By Design New Food Magazine

Hygienic Design A Food Industry Essential

The Hygienic Sanitary Design Of Food And Beverage Processing Equipment Springerlink

Sanitary Design An Introduction To Standards Of Design Excellence Nov

Ehedg Hygienic Design Of Pumps

Hygienic Design Of Food Processing Equipment Sciencedirect

Evaluating Equipment and Buildings for Hygienic Design The principles of hygienic design can be readily applied to any piece of equipment or building The accompanying checklist has been developed specifically for farmbased produce handling equipment and buildings It is based on other, more extensive guides from the processing industry.

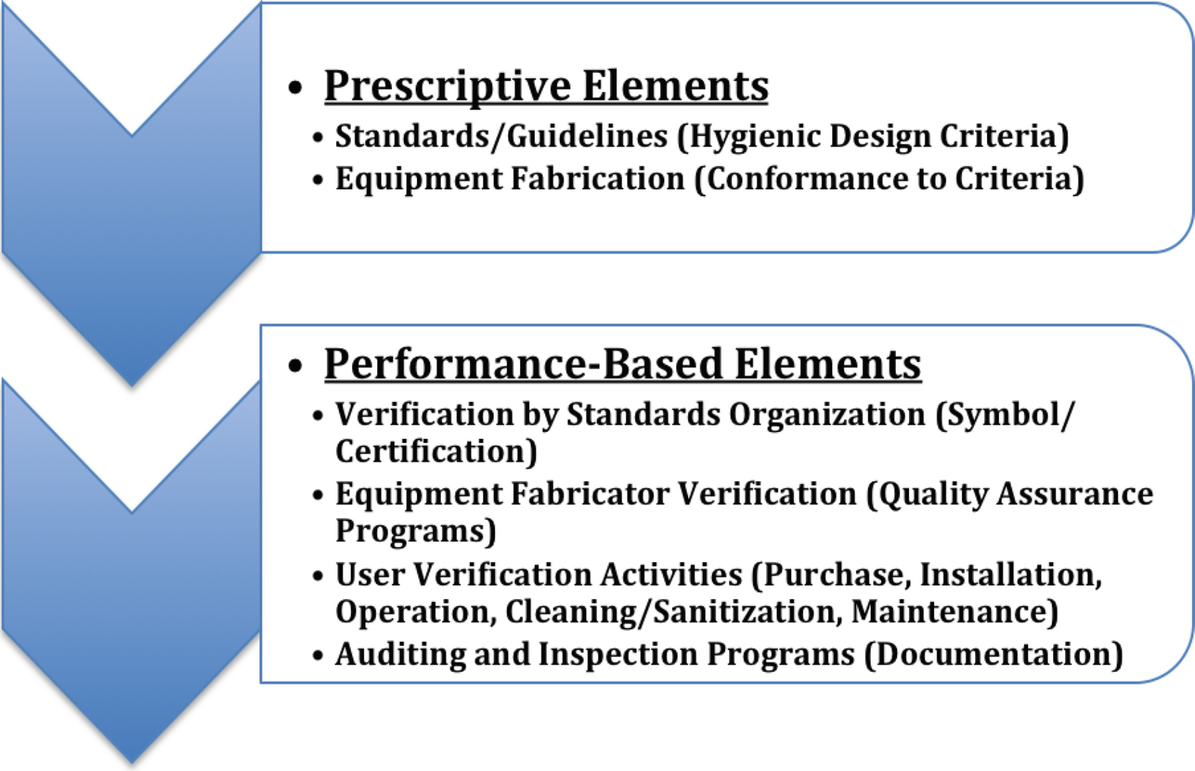

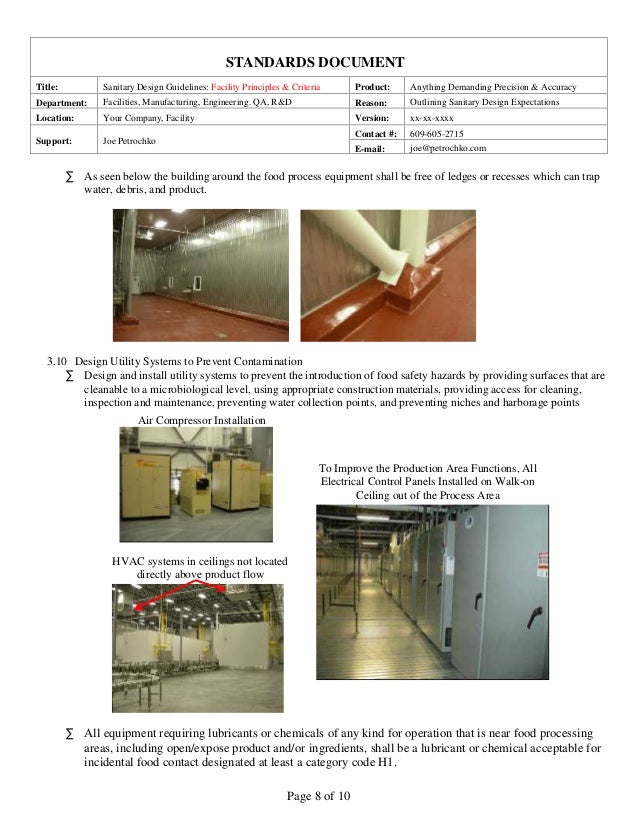

Food processing hygienic design. Optimizing the design and performance criteria for equipment and related systems as well as establishing industrywide specifications benefit the entire industry by promoting one standard design that will help reduce contamination and associated recalls These principles are applicable to equipment for all food uses Importance of Design Principles. Food processing, including dairy, meat & cheese processing and readytoeat (RTE) food preparation requires hygienic air handling as a critical element of the food processing environment Too often, the focus of engineering is concentrated on the hygienic air handler with insufficient consideration given to the air delivery system. Food safety is vital for consumer confidence, and the hygienic design of food processing facilities is central to the manufacture of safe products Hygienic design of food factories provides an.

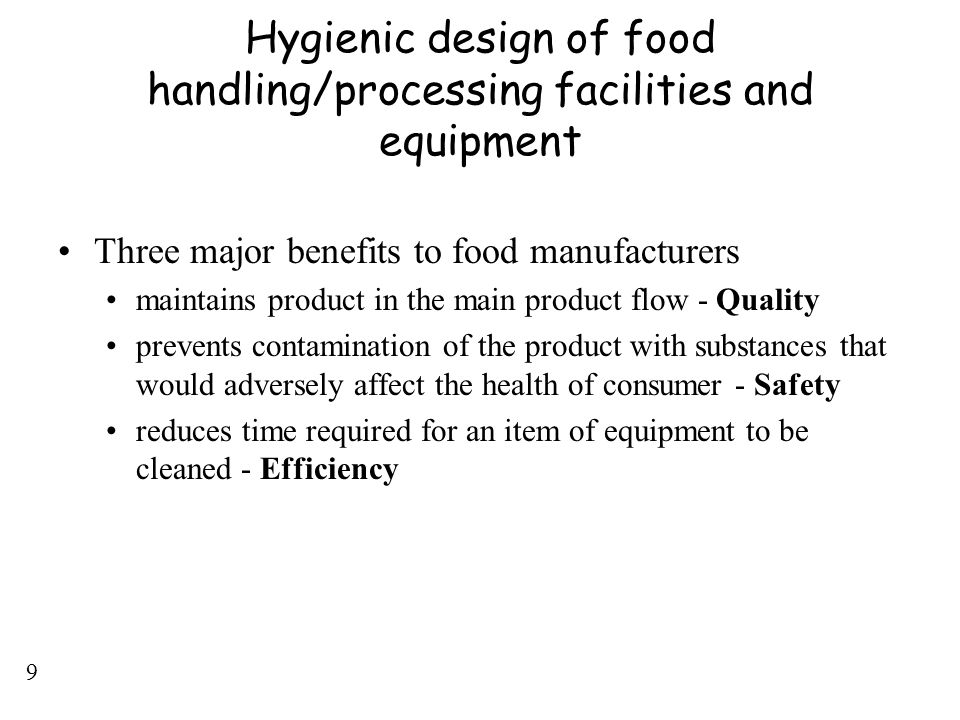

Hygienic design in food processing plays an important role in controlling the microbiological safety and quality of the products made This will prevent products from having undesirably high microbial counts, containing toxins or chemical residues, or from contamination from other nonfood substances. Hygienic design and practices are thus two of the key factors in producing safe and wholesome foods Food processing equipment that is designed hygienically has three key advantages• Food quality Good hygienic design maintains product in the main product flow This ensures that product is not 'heldup' within the equipment where it could. Please see below for the available presentations from the Hygienic Design in Food Processing Environments ConferencePlease note that not all presentations are available due to permissions or the format of the presentationEric Partington, Chair UK IE European Hygienic Engineering Design Group (EHEDG)What is hygienic design and why is it important?.

Hygienic System Design for Food Processing Facilities The demand for freshly made food is increasing on the rise This demand has led to the development of methods that use minimal preservatives and additives The use of lesser preservatives lead to decreased shelf life of food and makes them more susceptible to contaminants. Mark Morgan of the University of Tennessee discuses hygienic design in his presentation at PROCESS EXPO 15 Skip navigation Hygienic Design of Food Processing Equipment PROCESS EXPO. A high standard of hygiene is a prerequisite for safe food production, and the foundation on which HACCP and other safety management systems depend Edited and written by some of the world's leading experts in the field, and drawing on the work of the prestigious European Hygienic Engineering and Design Group (EHEDG), Hygiene in food processing provides an authoritative and comprehensive.

Abstract Hygienic Design Considerations for Food Processing Equipment EHEDG recognises the need to regularly review and update existing guidelines as well as create new ones based on the needs of equipment manufacturers and food producers to provide safe food in increasing quantities cost effectively. With Rittal's hygienic design wall mounted enclosures there is no need to stress about contamination Keep your food processing safe with Rittal. Hygienic design in food processing plays an important role in controlling the microbiological safety and quality of the products made This will prevent products from having undesirably high microbial counts, containing toxins or chemical residues, or from contamination from other nonfood substances.

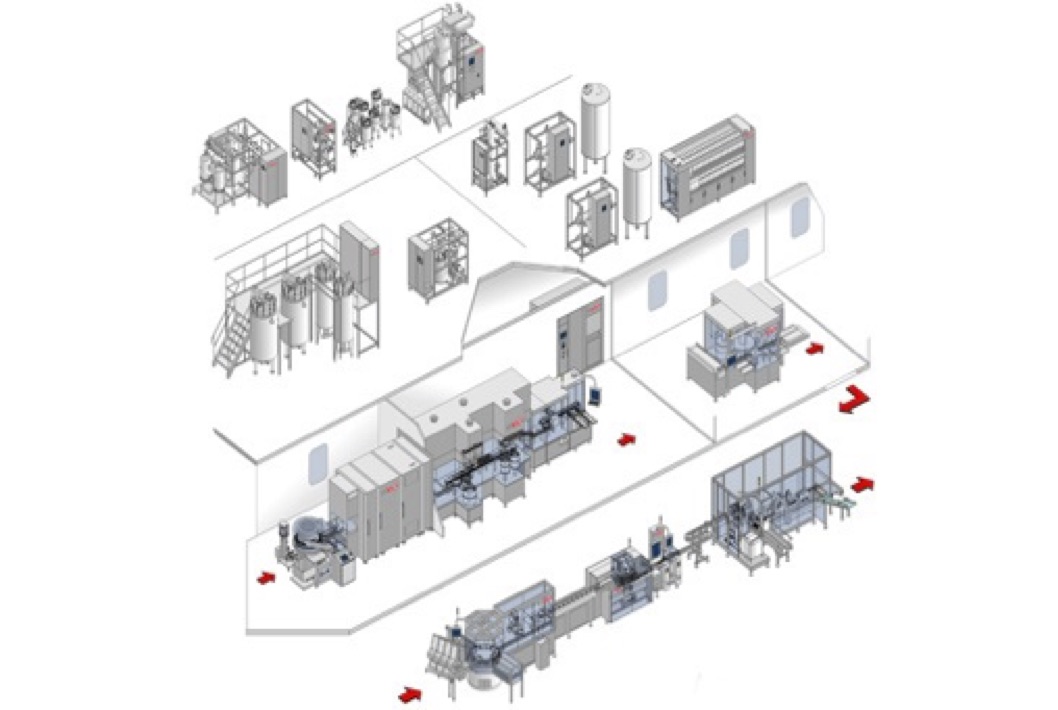

The hygienic processing of food concerns both potential hazards in food products and the regulation, design, and management of food processing facilities. Our experience in food processing plant design spans more than 15 years of factory builds, equipment installs and production line extensions From conveyors to packing machines to coolers and chillers, we work with both large and small clients in hygienic design, highcare and lowcare environments. Our experience in food processing plant design spans more than 15 years of factory builds, equipment installs and production line extensions From conveyors to packing machines to coolers and chillers, we work with both large and small clients in hygienic design, highcare and lowcare environments.

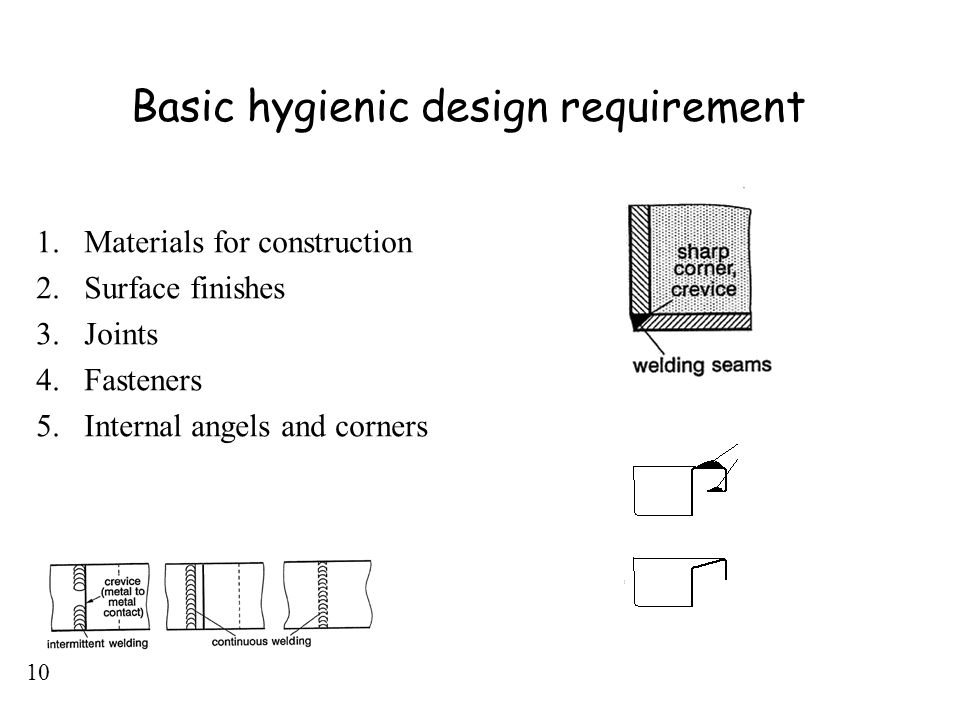

As indicated above, food processing equipment must be constructed with consideration to hygienic design Beyond this requirement, equipment must also be designed and built to withstand the stress from the various mechanical, chemical, thermal, and physical processes and unit operations of the food processing cycle. The first step to creating a hygienic facility is to look at the construction of the facility itself Examine your layout — does the design allow the processing and packaging of the food product to flow in the same direction, or do you have to move back and forth to complete everything?. Hygienic Design Hygienic design impacts all elements of the food manufacturing infrastructure, including equipment, the facility, buildings and grounds This section outlines key principles of hygienic equipment and facility design with illustrative examples frozen food companies can implement to best address Listeria monocytogenes (Lm) risks.

Hygienic spray dryer design for processing food ingredients Hygienic spray dryer designs which exceed 3A Sanitary Standards are increasingly being specified for the processing of food ingredients used in sensitive applications such as infant formula. Sanitation challenges food processors are facing and an overview of the most uptodate standards and regulations How hygienic design principles are helping food processors meet and exceed these standards while increasing efficiency. Many food safety and sanitation training programs cover diverse topics to deliver the expertise required to ensure that food processing is entirely safe and hygienic, including equipment design, purchasing, receiving, and raw material storage, as well as operation and finished goods distribution Roles and responsible persons also need to be.

Food safety is vital for consumer confidence, and the hygienic design of food processing facilities is central to the manufacture of safe products Hygienic design of food factories provides an. April 29, Established in 18, the Food Safety Modernization Act (FSMA) demands that food processors comply with advanced hygienic design standards FSMA represented a major shift in the industry, transferring priority from treating foodborne illness to preventing it entirely When plant operators are upgrading their food processing equipment, it’s easy to forget smaller components like control panels. Hygienic Ecodesign for Food Processing Equipment Manufacturers of machinery for processing of fish and milk that also (requirement) possess hygienic design certification may be involved in the project by putting their equipment to the disposal of the test phase, serving directly as a basis for the proposed improvements.

The first step to creating a hygienic facility is to look at the construction of the facility itself Examine your layout — does the design allow the processing and packaging of the food product to flow in the same direction, or do you have to move back and forth to complete everything?. When it comes to designing hygienic equipment for the food industry, the American Meat Institute implemented the Principles of Sanitary Design in 11, and the Foundation for Meat and Poultry Research and Education published the Checklist and Glossary of Sanitary Equipment & Design Principles in 14. Progress in the Hygienic Design of Food Processing Equipment By Huub Lelieveld Food Safety Magazine eBook Principles of Sanitary Design In the age FSMA, processing equipment and facilities must be designed with sanitation in mind This ensures that equipment can be adequately cleaned and sanitized and that there are no harborage points for.

The fundamental reason for applying hygienic design principles is to prevent contamination of food products Equipment and factories of poor hygienic design are difficult to clean The document details the hygienic design principles that shall be followed when designing and constructing equipment and factories for manufacturing of foods. Food processing, including dairy, meat & cheese processing and readytoeat (RTE) food preparation requires hygienic air handling as a critical element of the food processing environment Too often, the focus of engineering is concentrated on the hygienic air handler with insufficient consideration given to the air delivery system. Considering the importance of hygienic design of equipment used in food processing industry, it is important to use the right materials and design techniques The designer, firstly, should determine the requirements, that can keep the equipment from causing contamination.

Cleaning, Sanitation, Hygiene / Food Safety / Regulatory Compliance / Inspection and Sorting Equipment Designed With Sanitation In Mind Can Ease Processors' FSMA Concerns Thorough cleaning and sanitizing of foodhandling machines and equipment is a requirement, but the task becomes easier and faster when upfront consideration is given to sanitary design. Bacterial adhesion and biofilm formation are of major concern in food production and processing industry In 1998 a Danish cooperation programme under the title Centre for Hygienic Design was funded to combine the skills of universities, research institutes and industry to focus on the following goals • Development of materials with low bioadhesion (defined as resistance towards biofilm. Hygienic Zoning in a food processing facility is important to avoid cross contamination from raw areas to high care/high hygiene or Ready to Eat (RTE) areas A solid Hygienic Zoning design ensures traffic movements of personnel, material, product and waste are controlled and mapped, and active barriers are in place and properly maintained.

Life Cycle for Equipment in a Plant Sanitary Design Opportunities •Produce 2 billion meals •Train 250 employees on how to clean •Introduce and train 80 production supervisors •Spend up to 33,000 hours cleaning it •Spend 2500 hours doing preop inspections •Not produce up to 295 Million lbs of food •Generate 15 million gallons of effluent BOD. And AIB Food Safety and Sanitation. Life Cycle for Equipment in a Plant Sanitary Design Opportunities •Produce 2 billion meals •Train 250 employees on how to clean •Introduce and train 80 production supervisors •Spend up to 33,000 hours cleaning it •Spend 2500 hours doing preop inspections •Not produce up to 295 Million lbs of food •Generate 15 million gallons of effluent BOD.

The hygienic processing of food concerns both potential hazards in food products and the regulation, design, and management of food processing facilities This second edition of Hygiene in Food Processing gives a revised overview of the practices for safe processing and incorporates additional chapters concerning pest control, microbiological. There is no doubt how important it is for meat and poultry food processing equipment to satisfy strict hygienic design standards As with foodcontact surfaces, nonfoodcontact surfaces have the potential to spread pathogens (especially Listeria monocytogenes), provide harborage areas for insects and rodents, and develop dangerous levels of rust and corrosion. Using machinery designed with hygienic design principles in mind helps food manufacturers limit the risk of toxins or other microbiological organisms coming into contact with food supplies The good news is that sanitary and hygienic design doesn’t necessarily cost more than the same equipment would cost without these principles in mind That said, there is sometimes a higher upfront cost due to certain material choices, but the benefits of these choices reduce operating costs in the long.

Equipment and Utensils Incorporating hygienic design is thus a requirement of GMP’s in food production While the food regulatory agencies in the United States do not regulate food processing equipment, they do regulate its sanitary use As a key element of the Food Safety. FoodInfonet> Topics > Food Engineering > Hygienic Engineering > EHEDG Documents Hygienic Design Guidelines (As published by EHEDG) The EHEDG (European Hygienic Engineering and Design Group) is a consortium of equipment manufacturers, food industries, research institutes, universities and public health authorities, founded in 19 with the aim to promote hygiene during the processing and. Food processing equipment is designed and built to be suitable for a purpose In practice, this means different levels of hygienic design for differing pieces of equipment (Holah, 00) As an example, a mixer for raw meat need not be designed to the same hygienic level as a slicer of cooked meats (Timperley and Timperley, 1993).

Cleaning, Sanitation, Hygiene / Food Safety / Regulatory Compliance / Inspection and Sorting Equipment Designed With Sanitation In Mind Can Ease Processors' FSMA Concerns Thorough cleaning and sanitizing of foodhandling machines and equipment is a requirement, but the task becomes easier and faster when upfront consideration is given to sanitary design. The layout and design of the food factory must be adapted to the hygienic requirements of a given process, packaging or storage area The interior of the factory must be designed so that the flow of material, personnel, air and waste can proceed in the right direction. The hygienic standards writing organization for dairy and food processing equipment is 3A Sanitary Standards Inc Its Standards and Accepted Practices are recognized internationally During the 19s, the need for more stringent and uniform standards for dairy processing equipment became evident as the US economy and consumers entered the modern era.

There is no doubt how important it is for meat and poultry food processing equipment to satisfy strict hygienic design standards As with foodcontact surfaces, nonfoodcontact surfaces have the potential to spread pathogens (especially Listeria monocytogenes), provide harborage areas for insects and rodents, and develop dangerous levels of rust and corrosion. The fundamental reason for applying hygienic design principles is to prevent contamination of food products Equipment and factories of poor hygienic design are difficult to clean The document details the hygienic design principles that shall be followed when designing and constructing equipment and factories for manufacturing of foods. Hygienic Design Hygienic design impacts all elements of the food manufacturing infrastructure, including equipment, the facility, buildings and grounds This section outlines key principles of hygienic equipment and facility design with illustrative examples frozen food companies can implement to best address Listeria monocytogenes (Lm) risks.

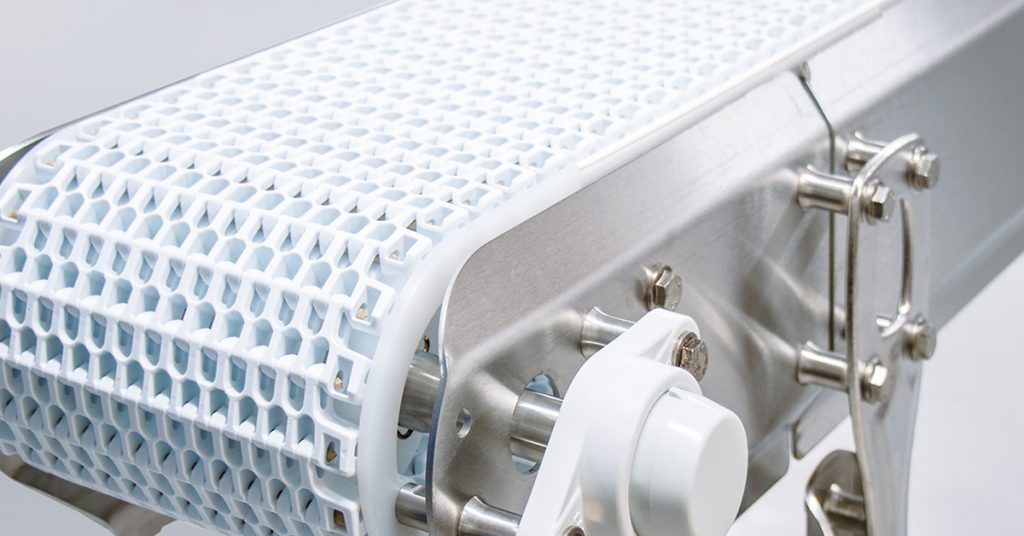

FoodInfonet> Topics > Food Engineering > Hygienic Engineering > EHEDG Documents Hygienic Design Guidelines (As published by EHEDG) The EHEDG (European Hygienic Engineering and Design Group) is a consortium of equipment manufacturers, food industries, research institutes, universities and public health authorities, founded in 19 with the aim to promote hygiene during the processing and. Hygienic Design of Food Processing Equipment Perry Johnson Registrars Food Safety, Inc Hygienic conveyor design in the food factory Duration 224 FlexLink 7,860 views 224. Tim Freier, Mérieux NutriSciences 3 Considerations for Your Hygienic Zoning Practices;.

Hygienic Ecodesign for Food Processing Equipment Manufacturers of machinery for processing of fish and milk that also (requirement) possess hygienic design certification may be involved in the project by putting their equipment to the disposal of the test phase, serving directly as a basis for the proposed improvements. Hygienic System Design for Food Processing Facilities The demand for freshly made food is increasing on the rise This demand has led to the development of methods that use minimal preservatives and additives The use of lesser preservatives lead to decreased shelf life of food and makes them more susceptible to contaminants. Edited and written by some of the world's leading experts in the field, and drawing on the work of the prestigious European Hygienic Engineering and Design Group (EHEDG), Hygiene in food processing provides an authoritative and comprehensive review of good hygiene practice for the food industry.

The European Hygienic Engineering & Design Group (EHEDG) was founded in 19 as a nonprofit consortium of equipment manufacturers, food producers, suppliers to the food industry, research institutes and universities, public health authorities and governmental organisations More Downloads EHEDG Constitutions and Internal Rules (PDF). HYGIENIC DESIGN October/November 10 Hygienic Design of Food Processing Facilities By Frank Moerman, MSc Increasing consumer demand for fresh foods has led to the development of processing and preservation methods that have minimal impact on either the nutritional or sensory properties of foods. Principles of Hygienic Design for Food Processing Facilities 08 July, 19 The American Meat Institute has come up with the following principles of hygienic design for food processing facilities These design principles have been created to reduce food safety hazards, keeping food safe Whether you're building a new facility, updating your existing one or onboarding new employees, take these principles of hygienic design into consideration to prevent food borne illness and product recalls.

The principles of hygienic design are set by the European Hygienic Engineering and Design Group (EHEDG), with clear guidelines for food manufacturing machinery and factories Some of the key principles include cleanability, preventing ingress and growth of bacteria, avoiding contamination and choosing suitable materials of construction. Hygienic Design of Food Processing Equipment Perry Johnson Registrars Food Safety, Inc Hygienic conveyor design in the food factory Duration 224 FlexLink 7,860 views 224. Cleaning and hygienic versions can readily withstand cleaning in place (CIP) procedures Their design ensures cleaning fluids reach all areas of the pump during this process and have passed the latest 0210 standards of the 3A Sanitary Standards Administrative Council in the USA For many in the food industry, pumping delicate, viscous fluids.

To that end, the following compiles information and recommendations from Ron Schmidt and Daniel Erickson, University of Florida/IFAS Extension Sanitary Design and Construction of Food Processing and Handling Facilities;. Hygienic Design of Food Processing Equipment November 2, 16 FPSA Webmaster Food Safety, PROCESS EXPO University, Technology PROCESS EXPO University. The hygienic design of food processing sites and the equipment in them as well as the behaviour of teams working in them is recognised as crucial to food safety It’s also one of the most important elements of the work we carry out with our customers.

The hygienic design of food processing sites and the equipment in them as well as the behaviour of teams working in them is recognised as crucial to food safety It’s also one of the most important elements of the work we carry out with our customers.

Plant Engineering 5 Key Questions To Answer During Hygienic Food Plant Design

Food Processors Must Be Proactive In Sanitary And Hygienic Design 19 10 14 Food Engineering

Hygienic Equipment Design For Low Moisture Food Manufacturing May 29th 14 At 12 00 Edt Kollmorgen

Hygienic Design For Food And Beverage Applications Psi Technologies

Sanitary Process Installation What To Ask When Selecting A Subcontractor Stellar Food For Thought

Sanitary Facility Design Guidelines Part 2 Of 2

Hygienic Design Of Food Processing Equipment Sciencedirect

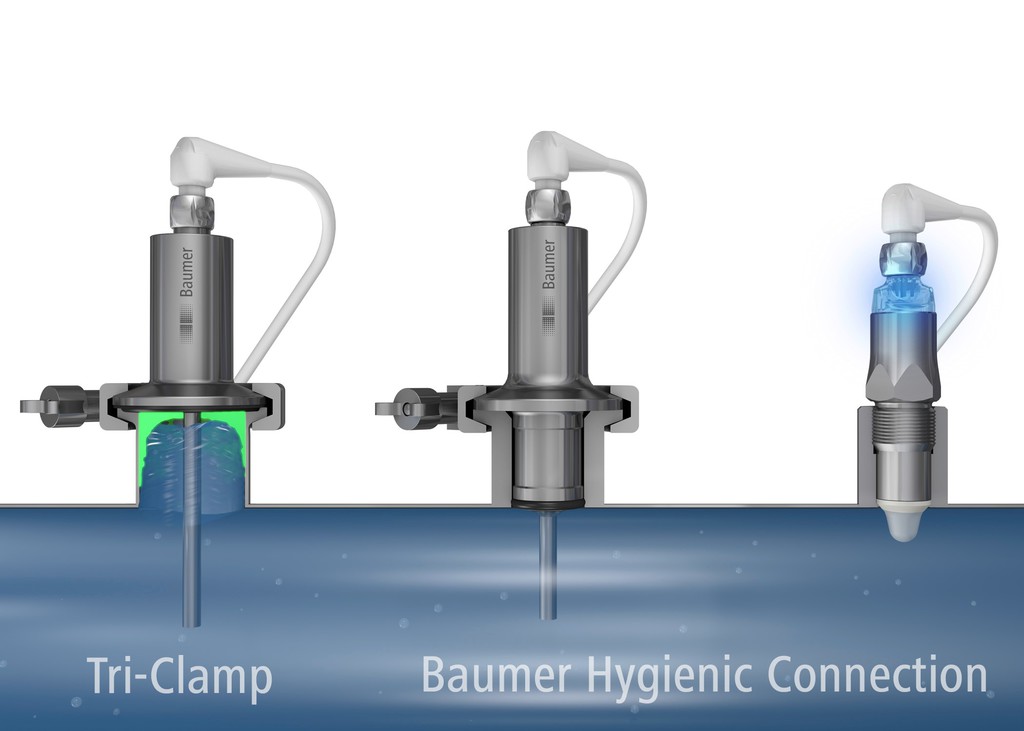

Hygienic Design Of Process And Utility Piping Drainable Process And Utility Lines Without Dead Ends Food Protection And Security Preventing And Mitigating Contamination During Food Processing And Pro

Food Industry

Design And Facilities

Hygienic Design For Process Systems Ruland

Food Processing 10 Ways To Ensure Food Safety Rentokil

Hygienic Design Affi Food Safety Zone

Hygiene In Food Processing Principles And Practice Woodhead Publishing Series In Food Science Technology And Nutrition Lelieveld H L M Holah John Napper David Amazon Com Books

Eliminating Hygienic Hazards 15 11 25 Food Engineering

Factors To Consider In Designing Food Processing Equipment

Designing Your Hygienic Zoning Quality Assurance Food Safety

Hygienic Machine Cabling Flexible Conduits Safe Food Factory

Sanitary Design A Competitive Advantage Food Safety Magazine

Www Ehedg Org Guidelines Tx Ehedgguidelines Guidelines 5bfiletodownload 5d File 3a6700 Tx Ehedgguidelines Guidelines 5bguideline 5d 8 Tx Ehedgguidelines Guidelines 5btitel 5d Hygienic design principles Tx Ehedgguidelines Guidelines 5blanguage 5d 1 Tx Ehedgguidelines Guidelines 5baction 5d Ajaxdownloadcounter Tx Ehedgguidelines Guidelines 5bcontroller 5d Guidelines Chash A50e63faaad23c6a08cc8578c2f4

Sanitary Design

Cables And Connectors For Food And Beverage Industry

Whitepaper The Hygienic Design Of Food Industry Brushware Microscope Hygiene

Sanitary Facility And Equipment Design 01 31 Food Safety Strategies

Q Tbn And9gcruaxtw2cx6adt38j9pbrwkuyvle0begu0r4 28ttum5p1tpe0s Usqp Cau

Robotics In The Food Industry And Hygienic Design 3 A Sanitary

Guidelines For The Hygienic Design Construction And Layout Of Food Processing Factories Ebook By Dr John Holah Rakuten Kobo Greece

Hygienic Design Of Food Processing Equipment Sciencedirect

Hygienic Design Reduces Cleaning Effort

Importance Of Hygienic Design Of Food Processing Industry Equipment By Reitz India Limited Issuu

Food Processors Must Be Proactive In Sanitary And Hygienic Design 19 10 14 Food Engineering

Improving Food Safety And Sanitation Through Facility Layout And Design 02 18 Snack Food Wholesale Bakery

Province Of Manitoba Agriculture Sanitary Design Of Equipment

Pdf Food Safety And Hygiene Systematic Layout Planning Of Food Processes

Http Www Cocker Ie Evalves Pdf

Hygiene In Food Processing 1st Edition

Hygiene Standards For Equipment Food Safety Aventics

Hygienic Design Of Food Processing Equipment Youtube

Hygienic Design Of Food Processing Equipment Sciencedirect

Hygienic Design Of Food Processing Equipment Youtube

Food Factory Design Factoring In Hygiene And Efficiency

Hygienic Design Is Mandatory Hbm

Hygienic Design Affi Food Safety Zone

Progress In The Hygienic Design Of Food Processing Equipment Food Safety Magazine

Edepot Wur Nl 4570

Hygienic Design How Our Thinking Has Evolved Food Safety Magazine

Standard Parts In Hygienic Design Ganter Norm

Ten Principles Of Hygienic And Sanitary Design Diversey

Many Food Manufacturers Do Not Fully Integrate Hygienic Design Into The Processing Environment

Hygienic Equipment Design Is Essential To Food Safety

Principles For Hygienic Design And Zoning Ppt Video Online Download

Hygienic Design Archives Your Partners In Hygiene

Ehedg Connects By Ehedg Issuu

Hygienic Design For Processing Equipment Food Quality Safety

Hygienic Design Of Food Processing Equipment Sciencedirect

Sanitary And Hygienic Design Guide For Food Equipment Mpc

Boosting Food Safety Through Hygienic Design And Employee Training Process Expo 21

5 Factors That Matter The Most In Hygienic Equipment Design Profood World

Handbook Of Hygienic Design In Dairy Industry Guide For Food Processing Plants Zeytinci Ceren Amazon Com Books

Hygienic Design Of Closed Equipment For The Processing Of Liquid Food

China The Stainless Steel Gearboxes Are Intended For The Use In The Food Industry Hygienic Design Bevel Gearboxes Are Our Response To The Food Processing Industries Photos Pictures Made In China Com

Hygienic Design And Maintenance Of Equipment Sciencedirect

Hygienic Design Of Food Factories 1st Edition

Hygienic Design Food Safety Buhler Group

How To Design A Hygienic Food Processing Facility

Hygienic Design Of Food Processing Equipment Sciencedirect

Aquatiq Guidelines For The Food Industry Hygienic Design Of Food Processing Equipment

Ezma Hygienic Design Present And Future In The Food Industry Food Processing Technology Ezma S A

Www Ifst Org Sites Default Files J holah ifst hygiene 25th february Pdf

Sanitary And Hygienic Design Guide For Food Equipment Mpc

Orbit Dtu Dk Files Hygienicdesign Veterinarycongress15 Handout Pdf

Sanitary Design An Introduction To Standards Of Design Excellence Nov

Hygienic Design Phibo Be

Ipe Hygienic Sensors For Food Processing Industry

A Systems Approach To Hygiene In Food Processing Environments

Sanitary And Hygienic Design Guide For Food Equipment Mpc

Edepot Wur Nl 4570

Handbook Of Hygiene Control In The Food Industry 2nd Edition

Hygienic Design Of Food Processing Equipment Sciencedirect

Http Www Ifst Org Sites Default Files E partington ifst hygiene 25th february Pdf

Hygienic Floor Design Food Safety Bakerpedia

Hygienic Design Forward Commercial Food Sanitation Llc

Hygienic Drainage Design Promotes Food Safety Aco Food

Www Dairysafe Vic Gov Au Publications Media Regulations And Resources Guidelines 474 Hygienic Design Guideline File

The New Generation Of Laska Grinders

Pdf Hygienic Design And Microbial Control Of Refrigeration And Air Conditioning Systems For Food Processing And Packaging Plants

Hygienic Spray Dryer Design For Processing Food Ingredients Processing Magazine

Food Drink Manufacturing

Hygienic Design How Our Thinking Has Evolved Food Safety Magazine

Why Hygienic Design Protects Food Production Flexlink Blog

Food And Beverage Webinar When Hygienic Design Matters Youtube

Hygienic Design Enhances Food Safety Brand Protection Regulatory Compliance And The Bottom Line 16 10 25 Food Engineering

Hygienic System Design For Food Processing Facilities Panorama Consulting Engineers India

Principles For Hygienic Design And Zoning Ppt Video Online Download

Sanitary And Hygienic Design Guide For Food Equipment Mpc