5s Workshop Meaning

5s Methodology The Secret To Japanese Success

5s Good Housekeeping Techniques For Enhancing Productivity

Pdf An Application Of 5s Concept To Organize The Workplace At A Scientific Instruments Manufacturing Company

100 5s Ideas In 21 فعل ماض قراءة سريعة قلم حبر

5s Resource Center Qualitytrainingportal

Lean Thinking And Methods 5s Sustainability Us Epa

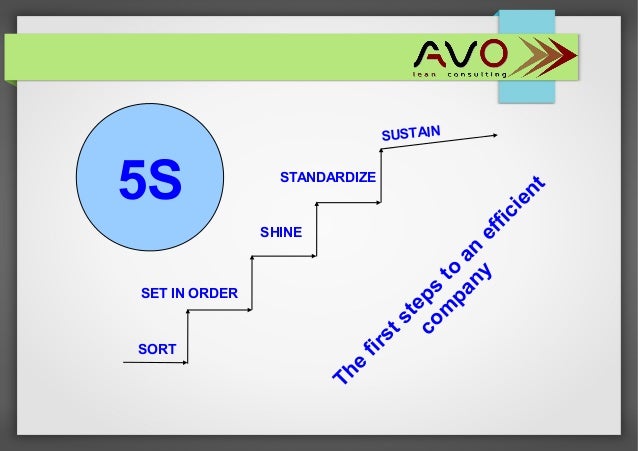

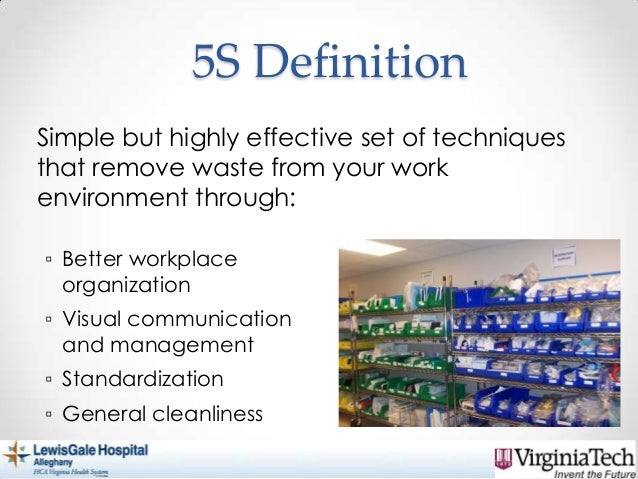

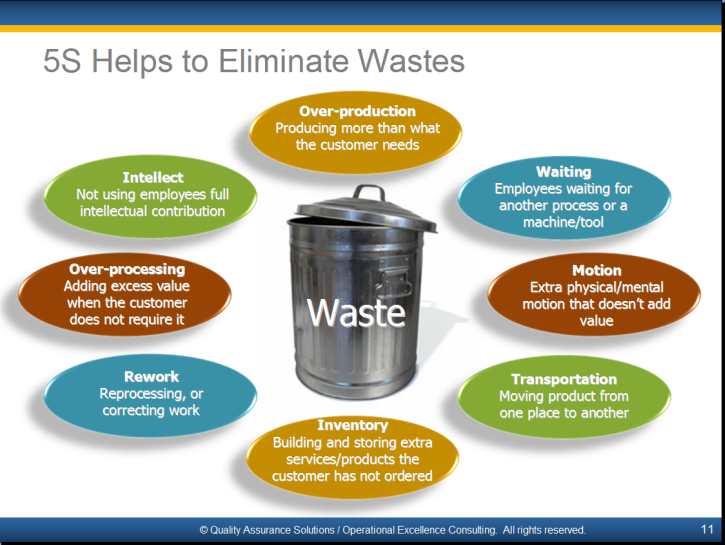

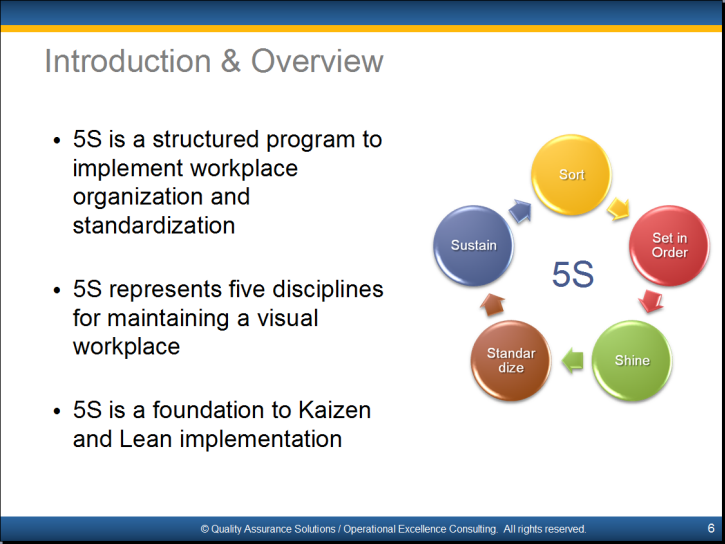

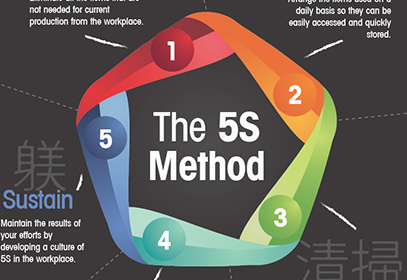

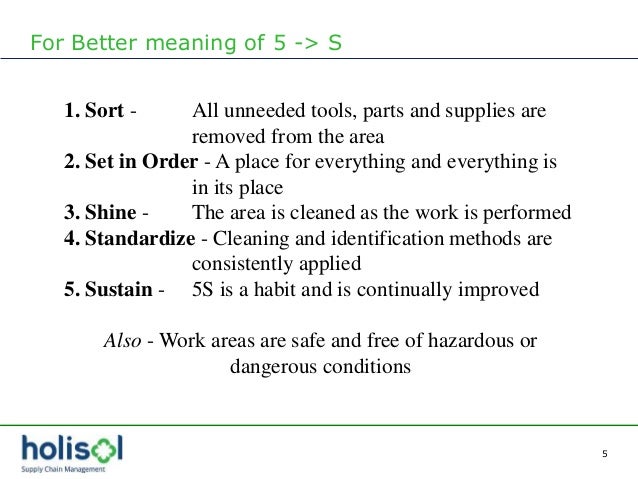

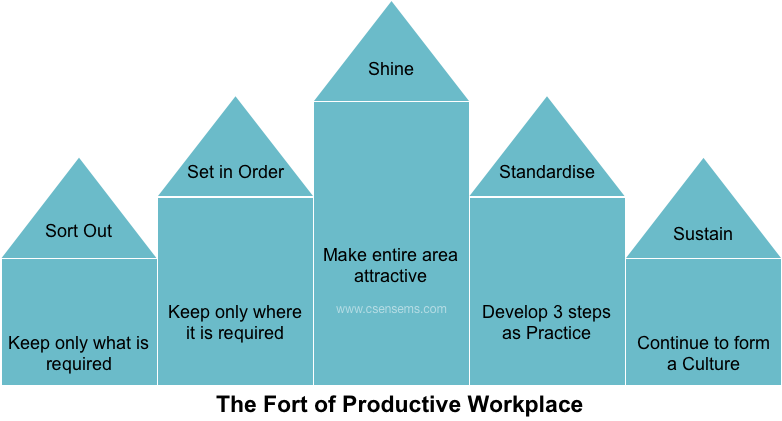

The 5S Method is a standardized process that when properly implemented creates and maintains an organized, safe, clean and efficient workplace Improved visual controls are implemented as part of 5S to make any process nonconformance’s obvious and easily detectable 5S is often one element of a larger Lean initiative and promotes continuous improvement.

5s workshop meaning. When it comes to comparing 5S vs 6S methodologies, is the necessary sixth S or safety element only required in the United States?. 5S is believed to have started as early as the 16th century with the Venetian shipbuilders in Venice, Italy They used quality inspection techniques in an assembly line approach to manufacturing ships for the royal navy Fast forward to postWorld War II, the Japanese automotive manufacturing industry gave way to the formal birth of 5S. A 5S can be applied to any work environment It could be a supply/store in a hospital, a repair truck for a telecom company, a CSR desk/work area in a call center, the baggage claim area of an airline or a laptop computer.

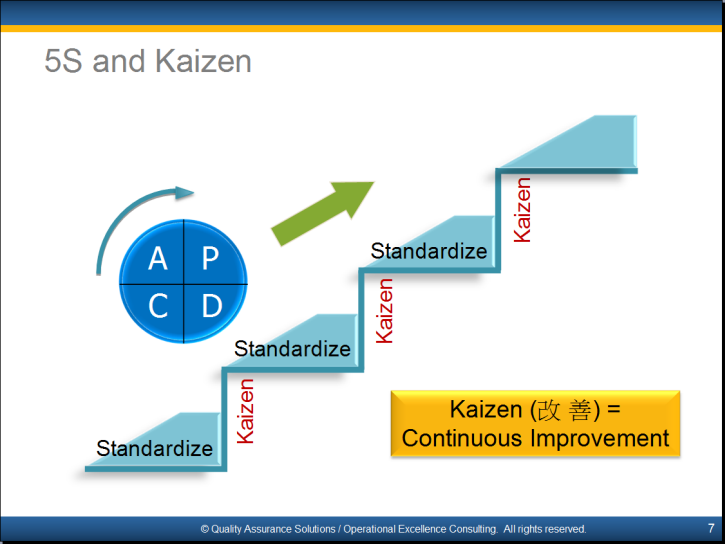

Kaizen is a concept referring to business activities that continuously improve all functions and involve all employees from the CEO to the assembly line workers Kaizen (改善) (かいぜん) is the SinoJapanese word for "improvement" Kaizen also applies to processes, such as purchasing and logistics, that cross organizational boundaries into the supply chain. 5S is a system for organizing spaces so work can be performed efficiently, effectively, and safely This system focuses on putting everything where it belongs and keeping the workplace clean, which makes it easier for people to do their jobs without wasting time or risking injury 5S Translation The term 5S comes from five Japanese words. Japan manufacturing plants seem to do well using the 5S Methodology as the sustain element does consider safety, but with America having so many workplace safety rules and organizations, that sixth S may be necessary prior to implement 5S in the US.

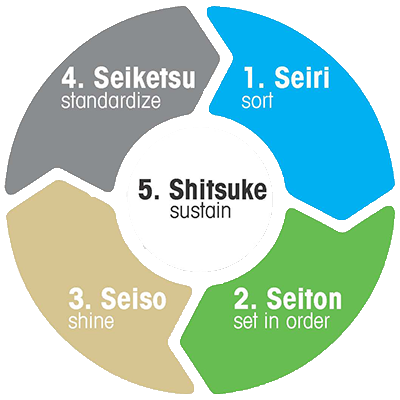

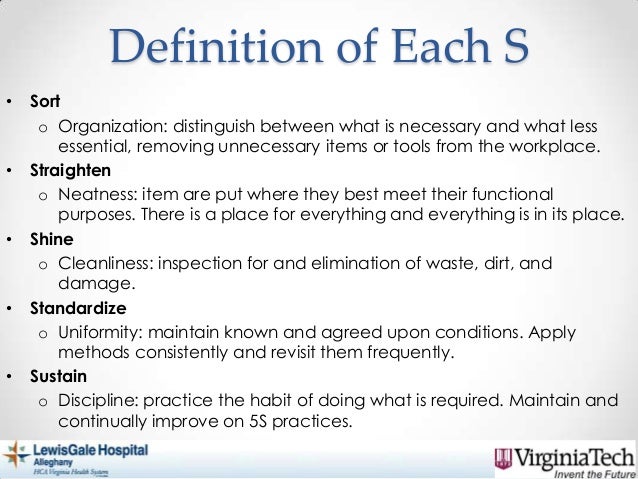

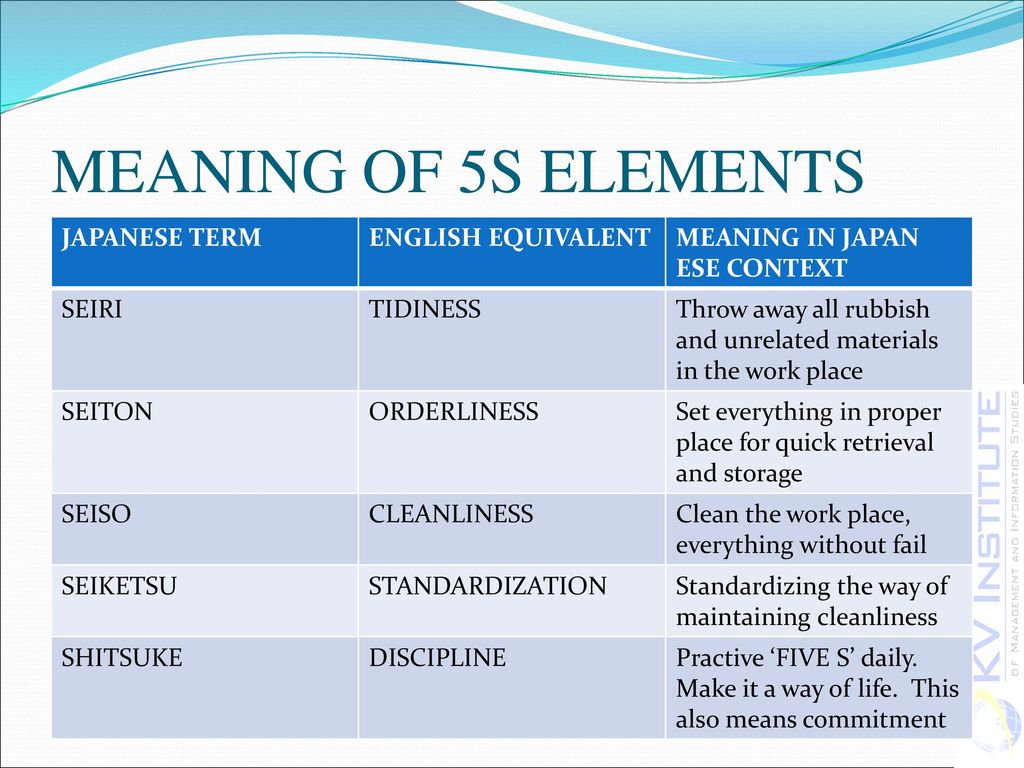

A 5S can be applied to any work environment It could be a supply/store in a hospital, a repair truck for a telecom company, a CSR desk/work area in a call center, the baggage claim area of an airline or a laptop computer. Sustain 5S is a habit and is continually improved 5S is a simple concept with powerful results You will get additional information on 5S so that you will be well equipped Our experience is that the more we do 5S the better the work environment becomes cleaner, safer, more organized, the work is easier, less confusion and less stress. The meaning of various 5S terms has been de scribed below The first S, Seiri, Zhang, S and Yaqing, T (11) ‘Defects and improvement of 5S implementation in the workshop.

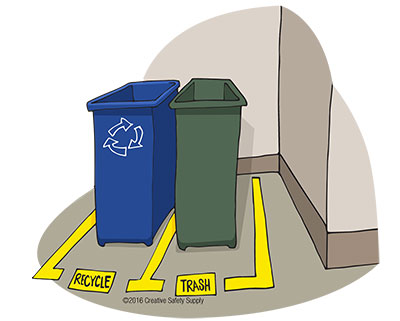

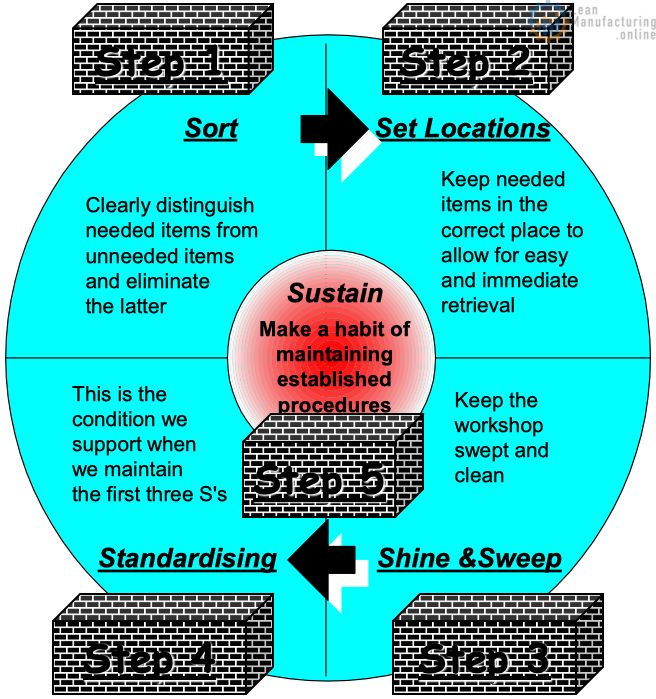

Lean/5S Tape Floor Marking Diecut Shapes Use as few colors as possible to make it easier for employees to remember the meaning of each color and reduce the number of floor marking products you need This color guide will help your floor marking be consistent in your workplace Yellow Aisle ways, traffic lanes and work cells. When it comes to comparing 5S vs 6S methodologies, is the necessary sixth S or safety element only required in the United States?. Definition Sort Target Outcome Eliminate nonessential items from the workplace An uncluttered workplace Action Steps 1 Identify a 5Sproject area and take "before" pictures 2 Review sorting criteria 3 Create a local red tag area 4, record, and move red tagged items 5Take "after" pictures 6After target time, move unclaimed items to the.

# 5S methodology management with circle arrow line roll diagram Vector Similar Images Add to Likebox # Project Management Success in Tablet Form Similar Images Add to Likebox # Six Sigma The popular business improvement concept Similar Images. Dave Visco and the team at the 5S store have been successfully servicing our organization for more than two years He has helped in a variety of areas, including new idea/best practice adoption, and implementation of key projects in both manufacturing and warehousing I highly recommend Dave and the 5S Store as a strategic addition to your team. 5S is a system and way of organizing and managing workspaces to improve efficiency by eliminating waste, improving flow and reducing the number of processes where possible 5S systems are common in manufacturing, warehouses, offices and hospitals but 5S principles can be applied to any workplace.

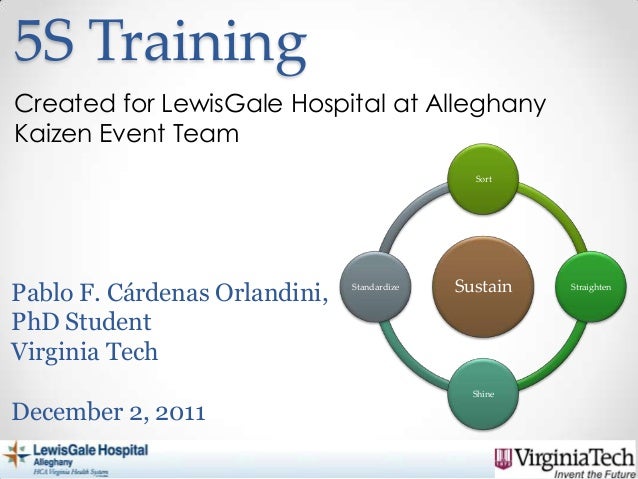

5S Workplaces When Safety and Lean Meet The five in a 5S workplace organizational and housekeeping methodology refers to five steps – sort, set in order, shine, standardize and sustain Safety should be the honorary sixth “S”. Purpose To show the 5th S, sustain or self discipline Main Points Begins with training so people understand the meaning and importance of 5 S Workers buyin and agree to support 5S activities Once 5S is implemented and people continue to do it, it becomes a habit like brushing your teeth every morning Management supports people who are. That is the purpose of concepts like standardized cleanup and visual control.

A two day 5S training workshop is a good way to begin the implementation Some managers or directors should participate in the workshop so that operators see that the company is really committed The 30 seconds test is an easy way to make sure you have done a good job you should find any item, tool, information, document, or person in less. The offsite 5S Training option is generally most popular with organizations having five or less associates that require a thorough working knowledge of 5S Our training centers provide the participants an environment free from the distractions and interruptions of daily work activities. Because 5S requires the involvement of everyone in the shop 5S is about creating the discipline, standard work, accountability and teamwork necessary to sustain It's the same discipline, standard work, accountability and teamwork it will take on everything else on the CI journey to transform the plant and then sustain worldclass performance.

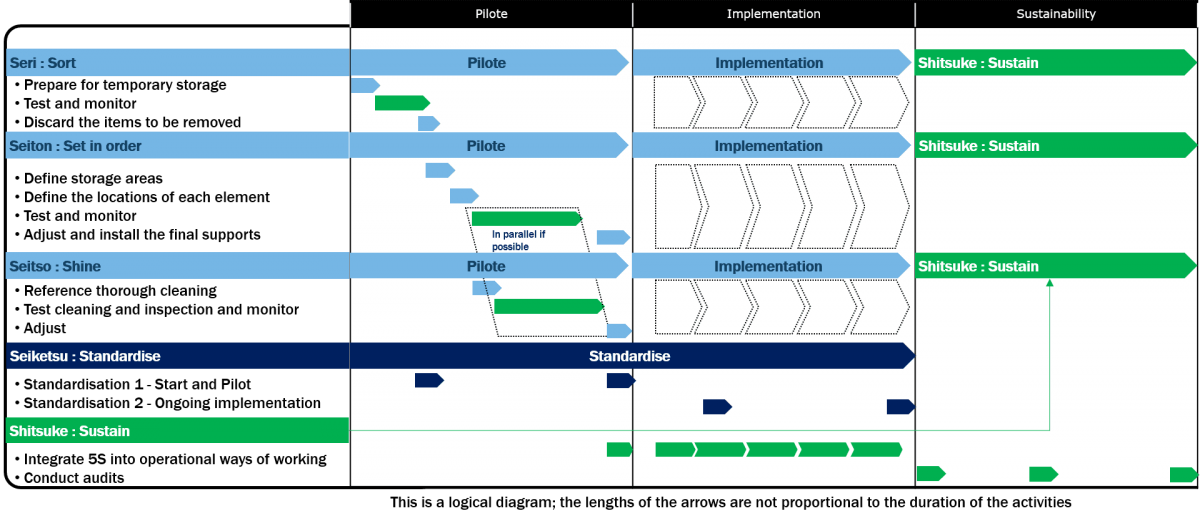

Purpose To show the 5th S, sustain or self discipline Main Points Begins with training so people understand the meaning and importance of 5 S Workers buyin and agree to support 5S activities Once 5S is implemented and people continue to do it, it becomes a habit like brushing your teeth every morning Management supports people who are. The next two articles discuss "how to" sustain 5S, and the benefits of sustaining 5S Later articles will deal with certification and audit, which are also part of sustaining 5S How to Sustain in Lean 5S The previous article introduced Shitsuke This article will discuss "how to" sustain the 5S efforts made so far. 5S methodology helps organizations achieve more consistent operational results through maintaining an orderly workplace This workshop will introduce you to the 5S methodology and help you learn basic implementation steps including evaluation and audit Read more » New!.

2 Stick to the „5S‟ rules for proper workplace management 3 Encourage the participation of all, for consistency in „5S‟ activities 4 Perform „5S‟ activities periodically 12 Organization Introduction Menon Piston Ltd, Maharashtra, India inaugurated in 1969 MPL is a total engineering solution. Why Implement 5S There are many benefits to implementing the 5S Methods into a work area on the production line or in the business office To not only survive but thrive in business today, cost must be controlled and waste must be avoided or eliminated. Previously our workshop was ‘pigsty’ We could not find tools, materials were scattered all over the place We adopted a 5S approach (part of Certificate 2 in Engineering VETiS) to what we do and have seen the improvements We are still improving but some of the comments by the students have been ‘it is much easier to work on our bikes’.

Find out what 5S is all about in this entertaining and simple video. 5S is called 5S because their are 5 steps and each step begins with the letter “S” (and/or the sound “s”) This is true in the original Japanese and it’s true in the English translation as well The five steps of 5S are Seiri, or Sort;. 5S is a popular and commonlyused tool in Lean manufacturing and is used for the optimization of workplace conditions Often, 5S is used as a key building block within many lean continuous improvement efforts.

Your 5S floor marking standard establishes the means by which most location and storage information will be communicated There is a fourlevel hierarchy of methods for communication The fastest, easiest to understand is color, but using color communicates a limited amount of information Text communicates the most information, but. 5S Explained Lean Manufacturing Tools and Techniques 5S is a practical method of dramatically improving the work environment It is based on good housekeeping, establishing an orderly workplace and continuing to improve in the long term 5S is a particularly effective lean manufacturing tool, as it can engage and involve all employees who visually see the improvements to where they work 5S. 5S is a system and way of organizing and managing workspaces to improve efficiency by eliminating waste, improving flow and reducing the number of processes where possible 5S systems are common in manufacturing, warehouses, offices and hospitals but 5S principles can be applied to any workplace.

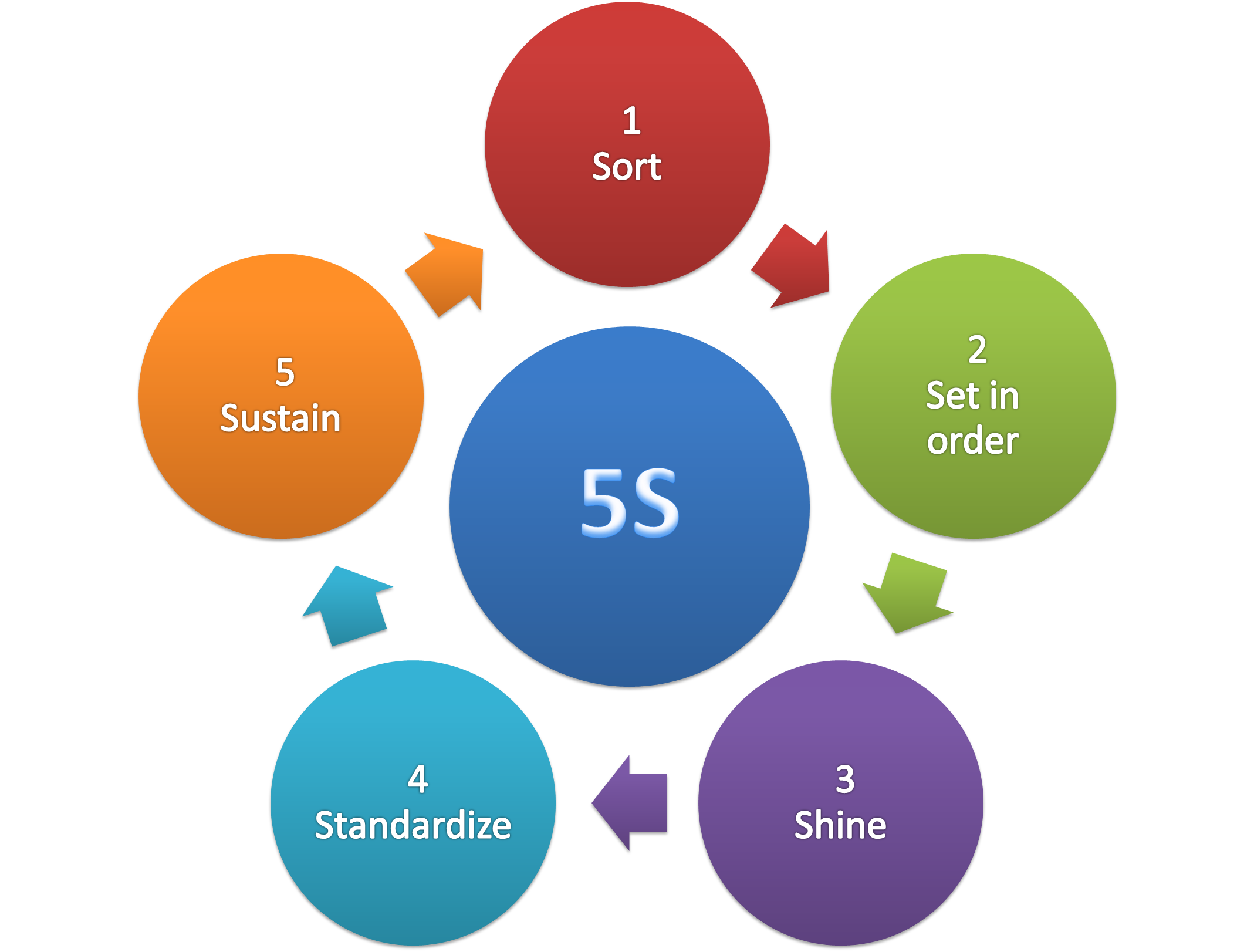

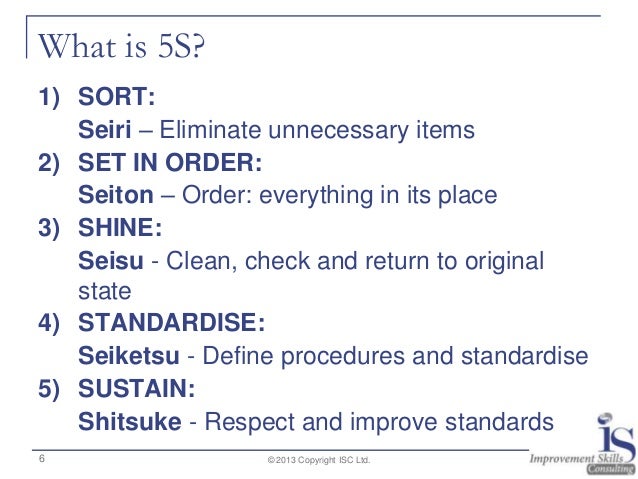

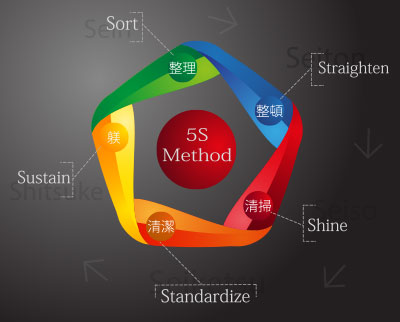

5S is also derived from Japanese concepts, but this time it is used to help improve workplace organization The 5S gets its name from the five words that are used to remind people of the different ways that a facility can become more organized These words are Sort, Straighten, Shine, Standardize and Sustain. Other 5S floor marking color guidelines and best practices Use as few colors as possible This will make it easier for employees to remember the intended meaning of each color and reduce the number of vinyl tape products kept in inventory Identify specific colors with specific purposes Some companies opt to mark equipment locations using the same color for aisleways and work cell boundaries. 5S is a workplace organization method that uses a list of five Japanese words seiri, seiton, seisō, seiketsu, and shitsuke These have been translated as "sort", "set in order", "shine", "standardize" and "sustain" The list describes how to organize a work space for efficiency and effectiveness by identifying and storing the items used, maintaining the area and items, and sustaining the new order The decisionmaking process usually comes from a dialogue about standardization, which.

Preview our hilarious Introduction to 5S video from our 5S Productivity training series!. 5S, sometimes referred to as 5s or Five S, refers to five Japanese terms used to describe the steps of the 5S system of visual management Each term starts with an S In Japanese, the five S's are Seiri, Seiton, Seiso, Seiketsu, and Shitsuke In English, the five S's are translated as Sort, Set in Order, Shine, Standardize, and Sustain. 5S visual cues (eg, signs, placards, scoreboards, laminated procedures in workstations) can be used to raise employee understanding of proper waste handling and management procedures, as well as workplace hazards and appropriate emergency response procedures 5S techniques can be used to improve labeling of hazardous materials and wastes.

5S is simple to start and shows the value of Lean 5S is easily recognizable by both employees and members of higher management 5S is a component of visual control, which can recognize operational efficiency, create opportunities for abnormality detection, build specific behaviors and discipline, and promote new culture. If you want to understand why 5s is one of the basic lean building blocks then Many Caps Consulting have the answers for you, why not give us a call to find out more 5s Workshop Lean 021 164 9739. Japan manufacturing plants seem to do well using the 5S Methodology as the sustain element does consider safety, but with America having so many workplace safety rules and organizations, that sixth S may be necessary prior to implement 5S in the US.

What are the Five S's (5S) of Lean Quality Glossary Definition Five S’s (5S) 5S is defined as a methodology that results in a workplace that is clean, uncluttered, safe, and well organized to help reduce waste and optimize productivity It's designed to help build a quality work environment, both physically and mentally. 5S is based on the CANDO system developed by Henry Ford in the early th century Watch this video, which explains the steps, and provides video time lapse of how a healthcare organization performed their 5S event Here is a breakdown of each ‘S’. The 5S Housekeeping Standards First Step towards Continuos Improvement The aim of 5S is to create an atmosphere to keep a clean, organized, safe and efficient workplace for everyone The foundation for the practice of 5S, comes from a Japanese program derived from these words, seiri, seiton, seiso, seiketsu and shitsuke The.

Training is the act of providing information and instruction to someone It is the act of teaching and or developing skills, knowledge, etc in a student Workshops, on the other hand, are like training events, in which the basic information is provided Workshops can be used to create or generate plans, analysis, or design that supports the employees and/or the organization. 5S is sometimes called the five pillars because just like the physical pillars that hold up a structure, 5S has five elements that support the effectiveness of the system And just like the pillars of a building, if one was to weaken or fail, the entire structure would fall The five steps/pillars of 5S are 1 Sort 2 Set in Order 3 Shine. Dave Visco and the team at the 5S store have been successfully servicing our organization for more than two years He has helped in a variety of areas, including new idea/best practice adoption, and implementation of key projects in both manufacturing and warehousing I highly recommend Dave and the 5S Store as a strategic addition to your team.

The offsite 5S Training option is generally most popular with organizations having five or less associates that require a thorough working knowledge of 5S Our training centers provide the participants an environment free from the distractions and interruptions of daily work activities. The workshop It is through these strategies that the workshop and the 5S culture will have new perspectives The newly cultured workshop shows more discipline and standardized workplace Orderliness and suave operations are the greatest results by far In a developed checklist which is a data collection technique to check and collect. The 5S system is a way of focusing and thinking in order to better organize and manage a workspace, with the goal of increasing productivity and profits It is one of the elements within the Lean Methodology , a process that encompasses several elements to take the traditional operation and streamlining the environment in a way that maximizes.

5S methodology helps organizations achieve more consistent operational results through maintaining an orderly workplace This workshop will introduce you to the 5S methodology and help you learn basic implementation steps including evaluation and audit Read more » New!. ABSTARCT 5S is an important tool within Lean Manufacturing, developed as part of the Toyota Production System (TPS) and Total Productive Maintenance (TPM), it is a highly effective and simple tool. 5S BASIC MANUAL Table of contents Since the establishment of a healthcare services quality improvement workshop in 04, the Ministry of Health (MOH) has been striving for the improvement under the initiative of chiefs of relevant agencies Several Quality Assurance Programs (QAPs) are introduced to.

Find out what 5S is all about in this entertaining and simple video. Introduction to 5S Training Workshop Welcome to the oneday 5S training course by Lifetime Reliability Solutions Introduction to 5S 5S is workplace management where the work area and workplace are organised and ritualised to minimise the loss of time and the use of movement. Preview our hilarious Introduction to 5S video from our 5S Productivity training series!.

Commonly, 5S events run for three to five days Reserve a facilitator for an upcoming event Preparation for Your 5S Event Running this event is fairly simple and, with a bit of preparation, a 5S event can offer some pretty impressive results What’s more, it is also great for team building and morale. Previously, we have discussed 5S in general, the phases Sort and Straighen, and the phases Sweep and Standardizing in previous articles This article will discuss the final phase of 5S the sustain phase All these articles are coverd in the book Sustainable 5S The fifth and final S in the 5S model stands for SUSTAIN, and this is the most difficult of the stages to implement in practice. If 5S is seen as something else that has to be done besides the regular work, then it has not been wellimplemented 5S practices must become routine and part of the work;.

Because the 5S Methodology relies on organized, standard practices and processes to improve and sustain quality in production, the 5S checklist for manufacturing divides each of the housekeeping stages that are graded from zero to four, with zero being unacceptable and four meaning outstanding or perfect. The 5S system is an important part of the Toyota Production System, which provides us with a way to organize and maintain a workplace in order to achieve maximum efficiency and effectiveness 5S stands for five Japanese words seiri, seiton, seiso, seiketsu, and shitsuke. Let’s begin by getting those who haven’t heard of 5S up to speed Here are a few definitions of 5S to get you in the ballpark US EPA “ 5S is a system to reduce waste and optimize productivity through maintaining an orderly workplace and using visual cues to achieve more consistent operational results Implementation of this method “cleans up” and organizes the workplace.

The true goal of 5S activities is to realize expose the problems that prevent us from being successful Make everyone happy 1) Form a comfortable workshop 2) Be aware that 5S benefits the worker, and that is its purpose 3) Involve all members Do not rush when performing 5S Take the initiative, do not wait for the next person to start Provide. A two day 5S training workshop is a good way to begin the implementation Some managers or directors should participate in the workshop so that operators see that the company is really committed The 30 seconds test is an easy way to make sure you have done a good job you should find any item, tool, information, document, or person in less. Started 5S’ing and colorcoding your facility Each kit contains an assortment of our most popular floor and workbench marking supplies Kits that include a Brady portable label printer are also available.

5S is a system and way of organizing and managing workspaces to improve efficiency by eliminating waste, improving flow and reducing the number of processes where possible 5S systems are common in manufacturing, warehouses, offices and hospitals but 5S principles can be applied to any workplace.

Q Tbn And9gcrpg63gc9u7kaasglyxauoox Bn0 T4fqmfga Fatpyjohotgcy Usqp Cau

5s Methodology Wikipedia

The Ultimate Guide To 5s Improving Workplace Efficiency Tulip

5s Audit Checklist Requirements To Sustain A Lean Laboratory

Www Jica Go Jp Activities Issues Health 5s Kaizen Tqm 02 Ku57pqpi3y4 Att Text E 04 Pdf

5s S Of The 5s Methodology Uttana Com

5s In Hospitals Workshop

Q Tbn And9gcr00pubj9b L0 04nl0ynqx0wzf5sczhzqmwgghvqq Usqp Cau

What Is 5s In The Japanese Workplace 2 Seiton Manabink

Office 5s Implementation Workshop

Funny Forward Message 5s In Toyota Plant In Japan Toyota Motors Toyota Lean Manufacturing

A Practical Approach To The Successful Practice Of 5s

2

5s Poster 3 Page Pdf Document

What Is 5s Seiri Seiton Seiso Seiketsu Shitsuke

The 5s System Lean Manufacturing Methodology

5s Method Housekeeping Factory Systems

Total Quality Management Ppt Download

5s Implementation The First Step To Continuous Improvement

5s Safety Lean 6s Safety Convergence Training

Opep 5s In Manufacturing

The 5s System Lean Manufacturing Methodology

Teach This 5s Process With This 5s Ppt

How To Apply 5s Method To Improve Shop Efficiency 18 12 06 Snips

5s In Hospitals Workshop

Development Of 5s Implementation Aids

The 5s System Lean Manufacturing Methodology

The 5s Monografias Com

Q Tbn And9gcsgkyuctoovyu8 Dv3rfc7cm Qd1ic281fteiisxua Usqp Cau

Practical Implementation Of 5s Method

Keys And Tips To Implement The 5s Methodology

5s Implementation Meaning In English And Japanese Finance Positive Results Positivity

What Is 5s 5s System Is Explained Including Tips On Getting A 5s Program Started

5s 5s Methodology Quality One

5s Safety Lean 6s Safety Convergence Training

5s Lean Manufacturing And Six Sigma Definitions

Pdf 5s Implementation In Welding Workshop A Lean Tool In Waste Minimization

Using The Steps For 5s Red ging Enna Com

The 5s Approach To Waste Elimination For Lean Businesses Video Lesson Transcript Study Com

Office 5s Poster 3 Page Pdf Document

5s Examples In Action The Good The Bad Graphic Products

What Is 5s 5s System Is Explained Including Tips On Getting A 5s Program Started

2

Www Theseus Fi Bitstream Handle Olli Nissinen Thesis Metropoliameng Pdf Sequence 1 Isallowed Y

Applying 5s Series Part I Introduction Reliable And Efficient

5s Methodology Wikipedia

5s Or 6s Lean Management Technique Possible Uses In Project Management Ipma International Project Management Association

The 5s System Lean Manufacturing Methodology

Teach This 5s Process With This 5s Ppt

Sunrise Shine 5s Optima

5s Lean Manufacturing And Six Sigma Definitions

5 S Workshop Summary

The 5s System Lean Manufacturing Methodology

5s Methodology And Tips Youtube

5s Lean Manufacturing And Six Sigma Definitions

5s A Quality Improvement Tool For Sustainable Performance Literature Review And Directions Emerald Insight

Teach This 5s Process With This 5s Ppt

Using The Steps For 5s Red ging Enna Com

Pdf The 5s Lean Method As A Tool Of Industrial Management Performances

Shitsuke Is The Fifth And Final Step Of The 5s Method

Pdf 5 S Implementation Methodologies Literature Review And Directions 49 Semantic Scholar

5s In Hospitals Workshop

What Is The 5s System Definitions Core Concepts Principles Graphic Products

5 The 5s Wikilean

5s A Quality Improvement Tool For Sustainable Performance Literature Review And Directions Emerald Insight

5s Safetyculture

What Is The 5s System Definitions Core Concepts Principles Graphic Products

Http Www Intracen Org Uploadedfiles Intracenorg Content Exporters Exporting Better Quality Management Assetpdf Bulletin eqm 5s Pdf

5s Method Housekeeping Factory Systems

Method 5s Explanations And Example Of The 5s Lean Sesa Systems

The 5s System Lean Manufacturing Methodology

Http Www Intracen Org Uploadedfiles Intracenorg Content Exporters Exporting Better Quality Management Assetpdf Bulletin eqm 5s Pdf

5s In Malaysia

Hidden Meanings Quot If You Can 39 T Do 5s You Can 39 T Do Lean Quot

5s Methodology Wikipedia

5s Implementation Workshop

Shitsuke Is The Fifth And Final Step Of The 5s Method

Learn What 5s Is And How It Applies To Any Industry Youtube

The 5 S System A How To Guide Reliable Plant

Http Www Intracen Org Uploadedfiles Intracenorg Content Exporters Exporting Better Quality Management Assetpdf Bulletin eqm 5s Pdf

5s Trainers Archives Csense Management Solutions

What Is 5s

5s 5s Methodology Quality One

What Is 5s 5s System Is Explained Including Tips On Getting A 5s Program Started

Point Of Use Fleet Maintenance

Implementing 5s Methodology The First Step Toward Workplace Efficiency Updated

Japanese 5s Kaizen Qc Training Hr Training

What Is 5s 5s System Is Explained Including Tips On Getting A 5s Program Started

Lean 5s Seiton Straighten Simplify Set In Order Configure

Implementing 5s Methodology The First Step Toward Workplace Efficiency Updated

3

Japanese Terminology For 5s Is Seiri Seiton Seiso Seiketsu And Shitsuke Continuously Improving Manufacturing

5s Methodology Wikipedia

Lean 5s Seiso Sweep Shine Clean And Check

Practical Implementation Of 5s Method

100 5s Ideas In 21 فعل ماض قراءة سريعة قلم حبر

5s Definition What Is 5s Six Sigma Free Training

The Ultimate Guide To 5s Improving Workplace Efficiency Tulip